Cleaning agent for removing oil and dust and preparation method thereof

A cleaning agent and sedimentation agent technology, applied in the field of metal surface treatment, can solve the problems of corrosion, poor cleaning effect of metal surface dust, and inability to achieve simultaneous degreasing and ash removal, etc. Good oil removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

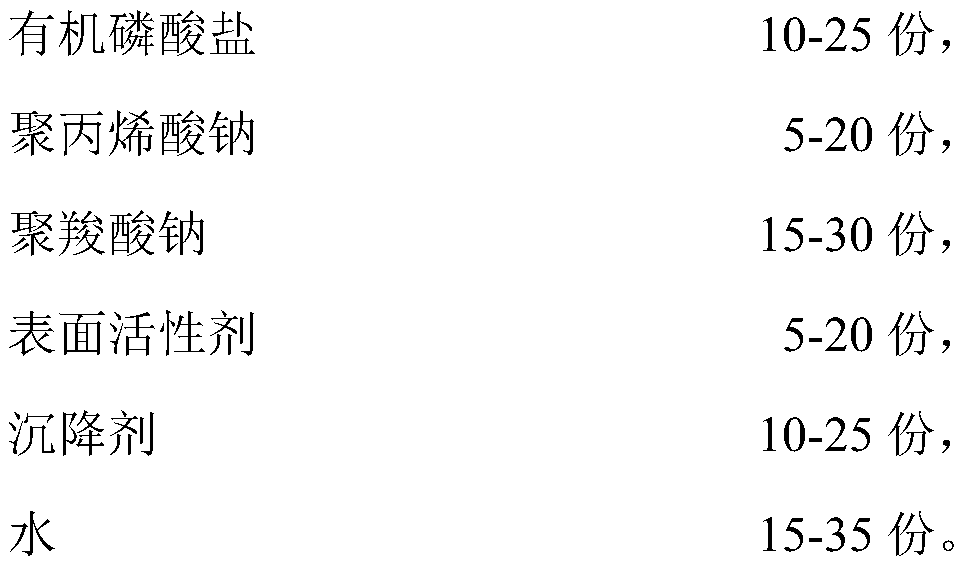

[0041] The cleaning agent for degreasing and ash removal of the present embodiment is made up of the components of following weight:

[0042]

[0043] The preparation method of the present embodiment degreasing and ash removal cleaning agent, comprises the following steps:

[0044] (1) Add HEDP Na2, sodium polyacrylate and water to the reaction kettle in sequence according to weight and mix, stir at 25°C for 20 minutes at a stirring speed of 65 rpm, then add sodium polycarboxylate and stir for 20 minutes to obtain a mixed solution 1.

[0045] (2) Add isomeric tridecyl alcohol polyoxyethylene ether and polyacrylic acid amide into another reaction kettle in sequence according to parts by weight and mix them, and stir for 15 minutes at a stirring speed of 65 rpm to obtain a mixed solution 2;

[0046] (3) Pour the obtained mixed solution 2 into the reaction kettle equipped with the obtained mixed solution 1 and stir for 20 minutes at a stirring speed of 65 rpm to obtain a clean...

Embodiment 2

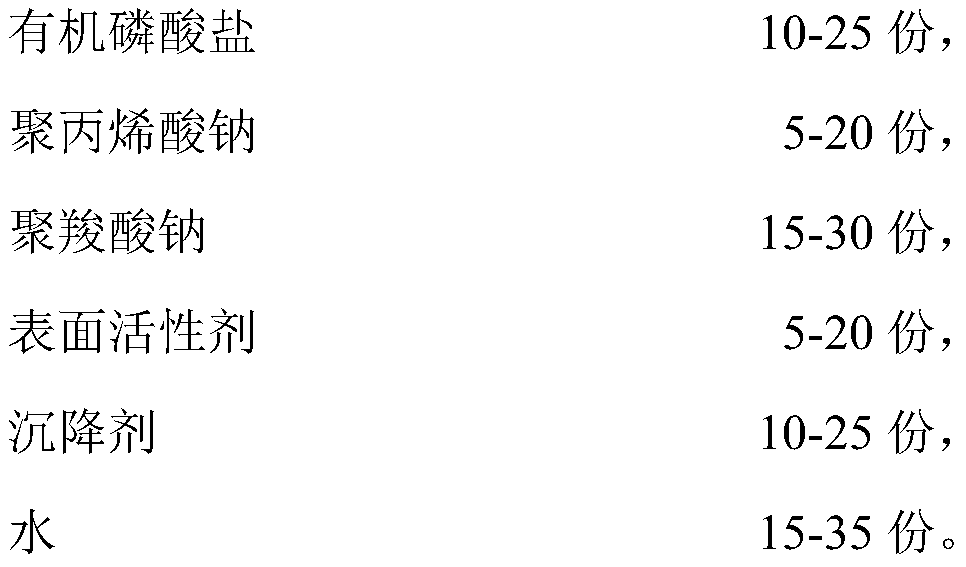

[0050] The cleaning agent for degreasing and ash removal of the present embodiment is made up of the components of following weight:

[0051]

[0052] The preparation method of the oil-removing and ash-removing cleaning agent of this embodiment is the same as that of Embodiment 1.

[0053] The cleaning effect test method of this embodiment is the same as that of Example 1, and its test results are as shown in Table 1.

Embodiment 3

[0055] The cleaning agent for degreasing and ash removal of the present embodiment is made up of the components of following weight:

[0056]

[0057] The preparation method of the oil-removing and ash-removing cleaning agent of this embodiment is the same as that of Embodiment 1.

[0058] The cleaning effect test method of this embodiment is the same as that of Example 1, and its test results are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com