Ash removing agent and surface treatment method for zinc alloy die casting

A surface treatment, zinc alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of high toxicity, poor ash removal effect, endangering the health of operators, etc., to achieve good safety, good ash removal effect, Conducive to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

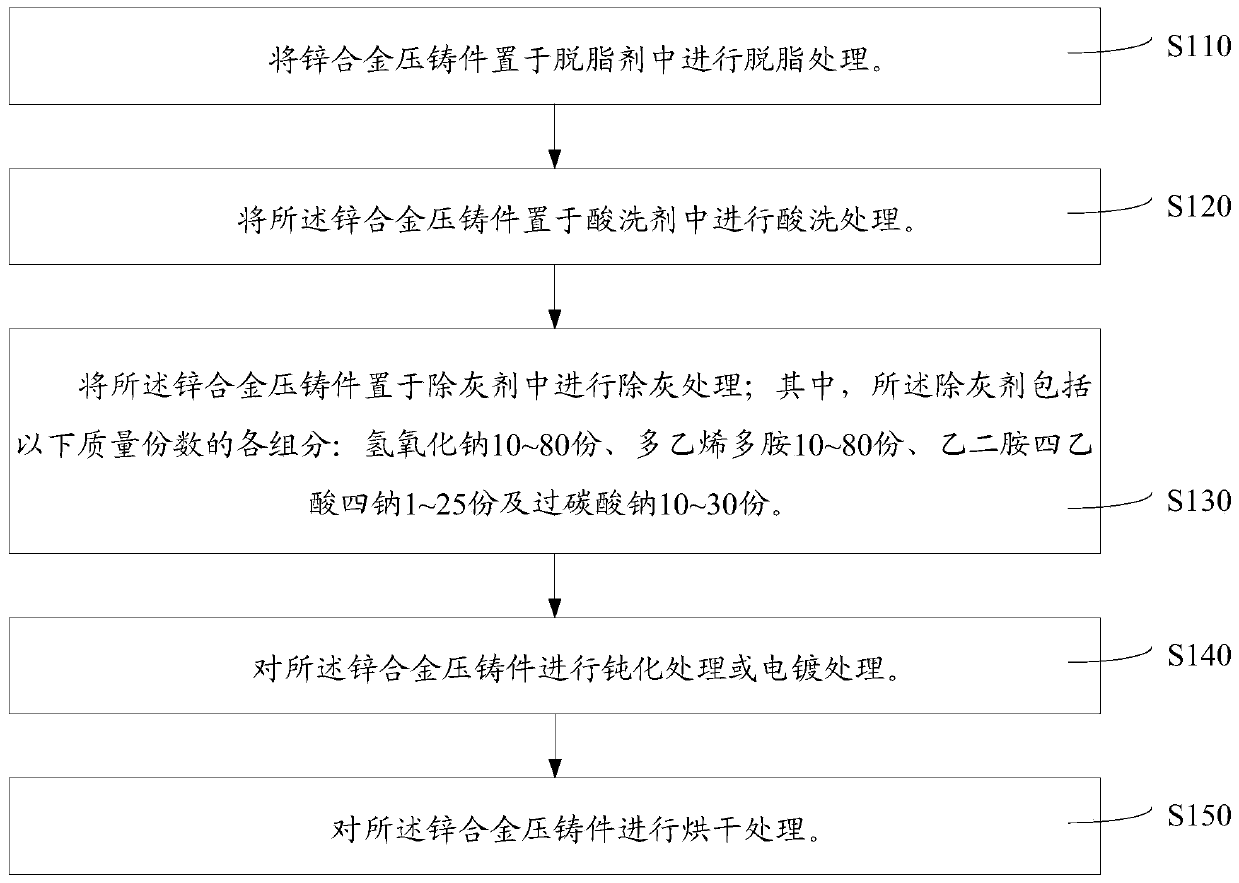

Method used

Image

Examples

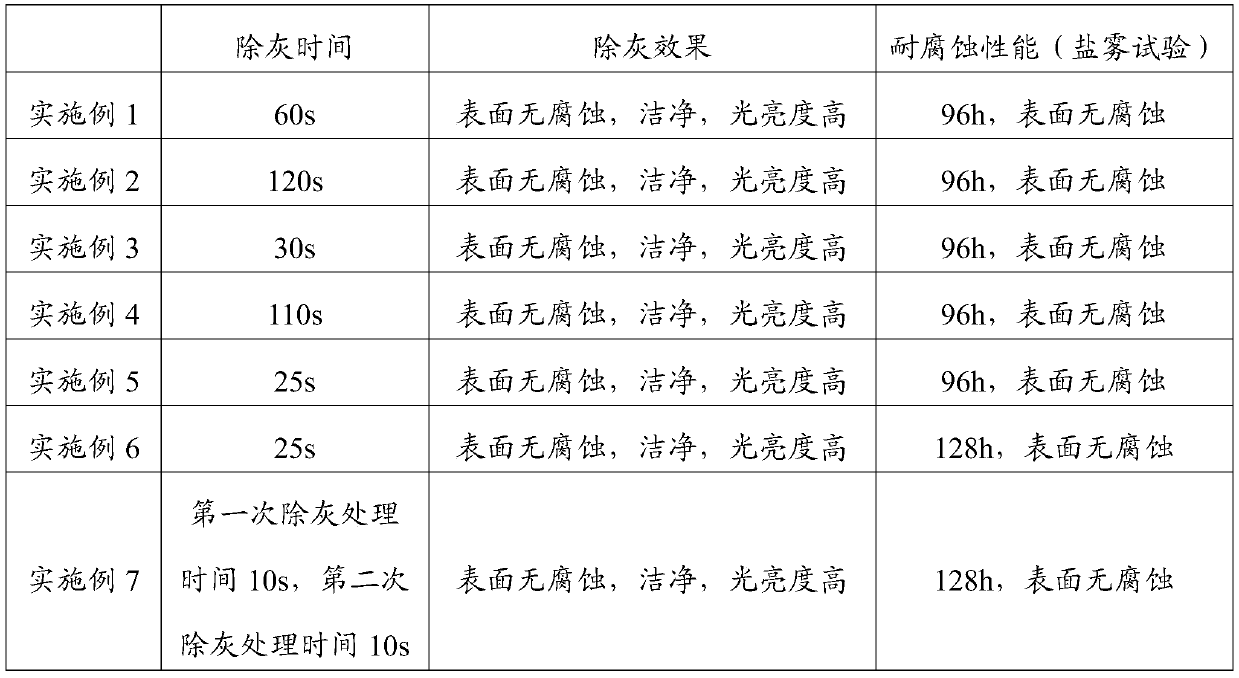

Embodiment 1

[0091] After the water washing operation, the zinc alloy die casting is placed in a degreasing agent for degreasing treatment; the degreasing agent includes each component of the following concentration: sodium carbonate 10g / L, sodium tripolyphosphate 20g / L, sodium tetraborate 5g / L L, sodium gluconate 2g / L, OP-10 emulsifier 1.5g / L and water balance; the temperature of the degreasing treatment is 60°C, and the time of the degreasing treatment is 6min.

[0092] After the water washing operation, the zinc alloy die casting is placed in a pickling agent for pickling treatment; the pickling agent includes the following concentrations of components: sulfuric acid 10g / L, hydrofluoric acid 10g / L, surface active Agent 0.2g / L and water balance; The temperature of the pickling treatment is normal temperature, and the time of the pickling treatment is 8s.

[0093] After the washing operation, the zinc alloy die casting is placed in a deashing agent for deashing treatment; the deashing age...

Embodiment 2

[0098] The difference between Example 2 and Example 1 is that the deashing agent includes the components of the following concentrations: sodium hydroxide 25g / L, polyethylene polyamine 20g / L, tetrasodium edetate 5g / L, Sodium percarbonate 15g / L and water surplus; Other contents are identical with embodiment 1.

Embodiment 3

[0100] The difference between Example 3 and Example 1 is that the deashing agent includes the components of the following concentrations: sodium hydroxide 40g / L, polyethylene polyamine 20g / L, tetrasodium edetate 20g / L, Sodium percarbonate 25g / L and water surplus; Other contents are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com