Ash water treatment pump

A gray water and pump body technology, applied to pumps, jet pumps, non-displacement pumps, etc., can solve the problems of adjustment, inconvenient use, difficult gap adjustment, poor ash discharge effect, etc., and achieve good ash discharge effect and good clearance The effect of simple adjustment and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

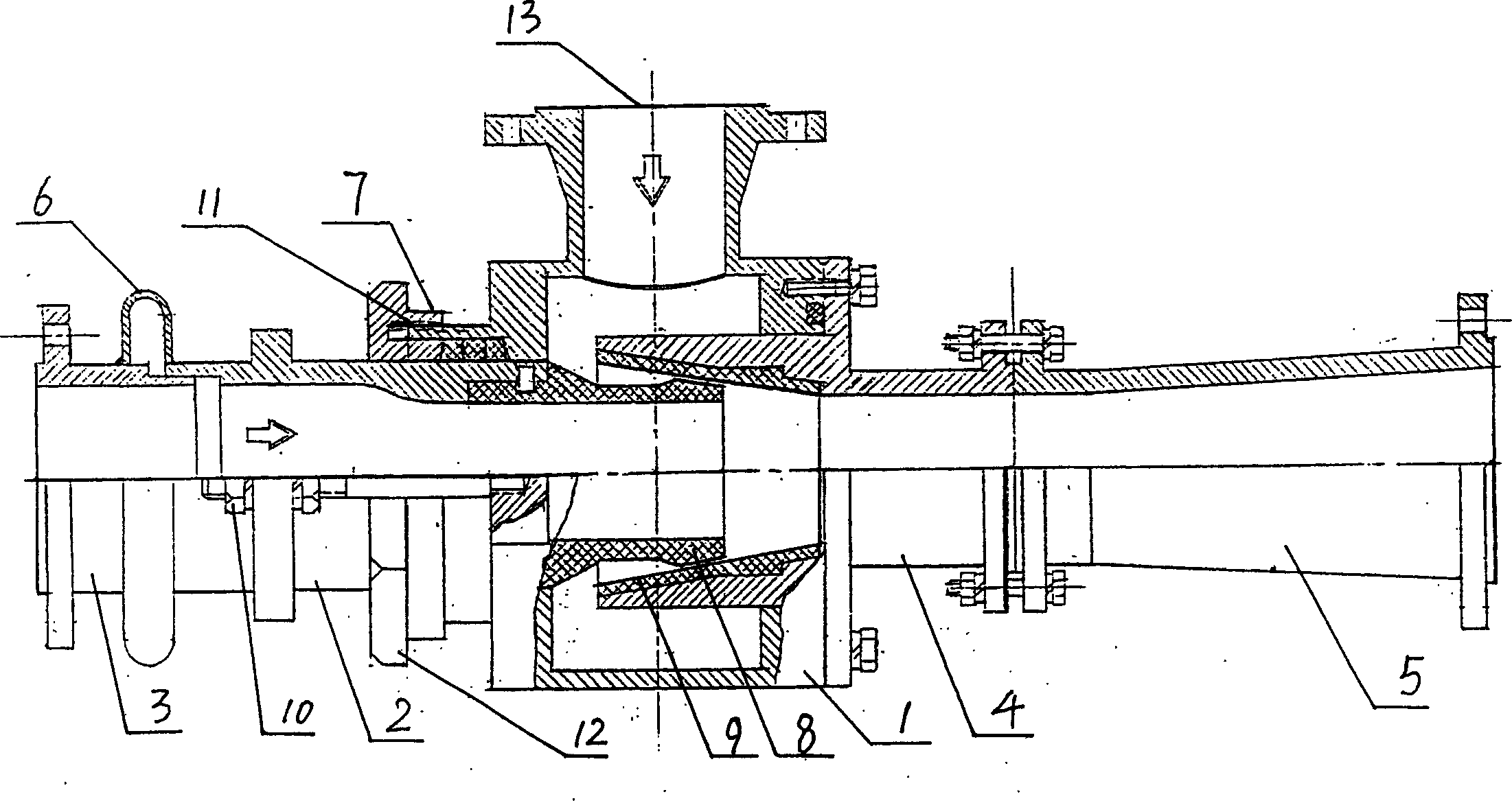

[0012] A gray water treatment pump according to the present invention includes a pump body 1 , a suction nozzle 2 , a suction joint 3 , a mixing chamber 4 and a diffusion chamber 5 . One end of the suction nozzle 1 is sealed and connected with the suction joint 3 through the telescopic joint 7, and the other end of the suction nozzle 2 extends into the pump body 1 and connects with the pump body 1 through the sealing ring 11 and the compression nut 12. Movably connected, the pump body 1 is provided with threads, and the compression nut 12 is sleeved on the threads, and the sealing ring 11 is arranged at the junction of the suction nozzle 2 and the pump body 1 and is fixed by the compression nut 12 . One end of the mixing chamber 4 is connected to the diffuser chamber 5, and the other end extends into the pump body and is fixed on the pump body 1 by screws; in the pump body 1, a water-cement mixing nozzle 8 is provided on the outer wall of the suction nozzle 2 , the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com