Discrete Suspended Cathode Electrochemical Machining Device

An electrochemical processing and cathode technology, which is applied in the direction of electrochemical processing equipment, electric processing equipment, processing electrodes, etc., can solve the problems of insufficient ability of electrochemical surface finishing processing technology to improve processing accuracy, and achieve improved stability and consistency. The robustness of the process system and the effect of constant re-mapping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

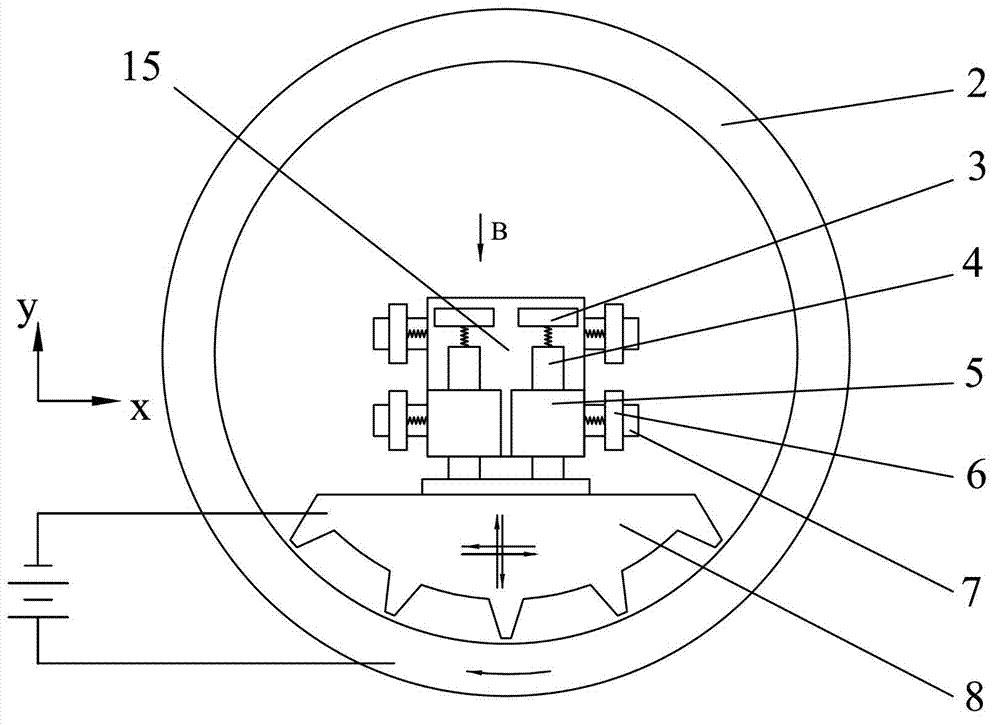

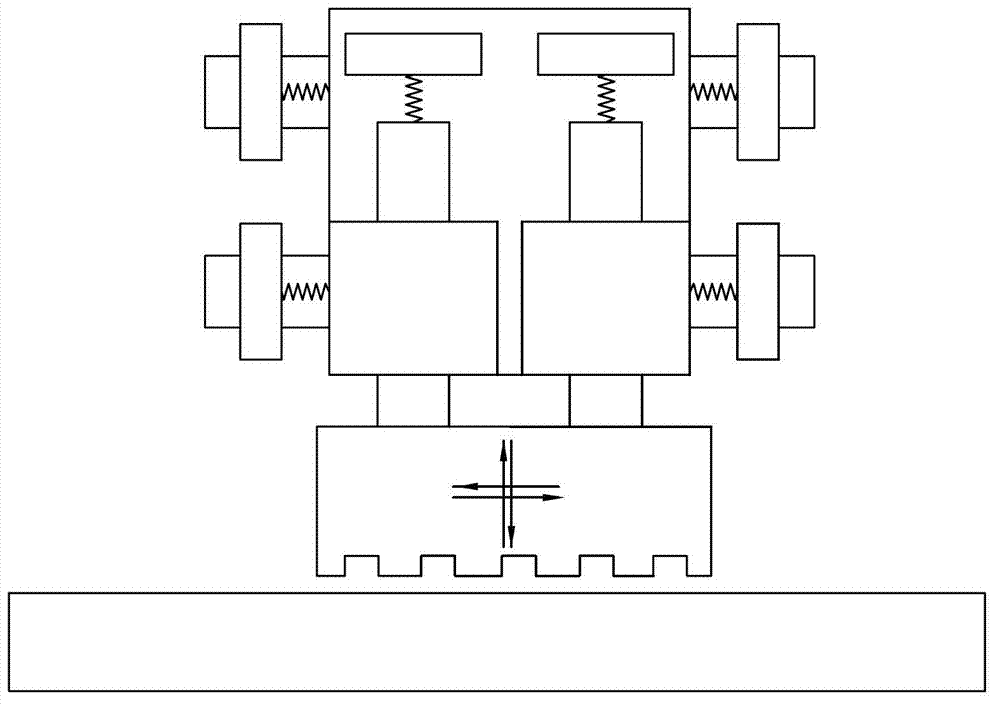

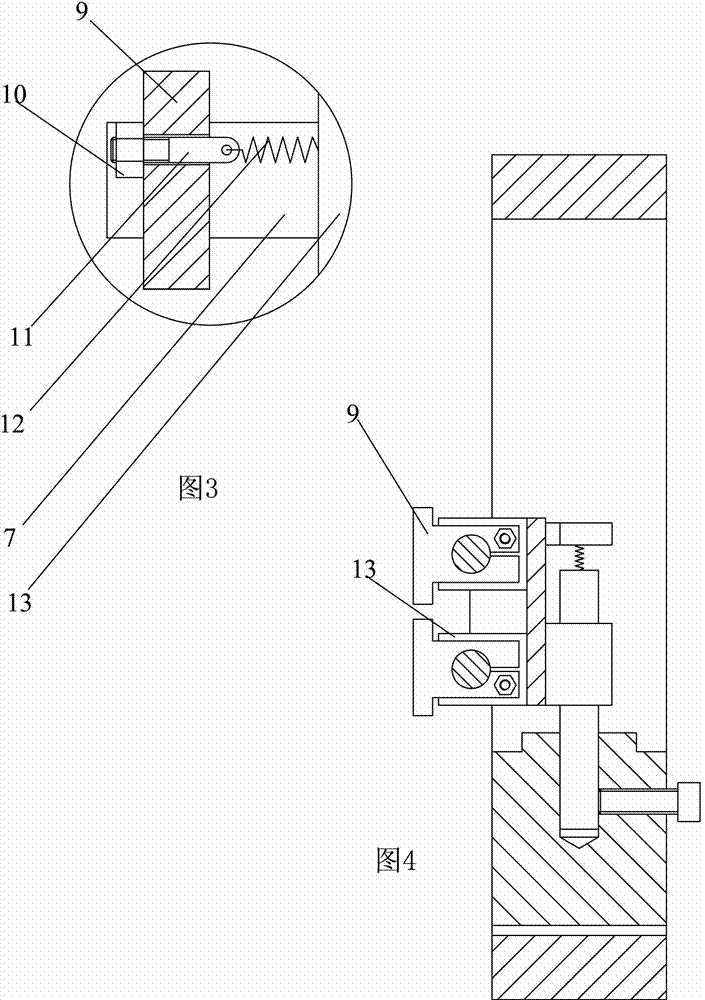

[0032] Such as figure 1 The electrochemical machining method of the discrete suspension cathode shown. In this embodiment, the cathode suspension is required to be able to move in translation in the axial section of the workpiece, but not to move along the axial direction of the workpiece, and not to rotate in any direction. It is proposed to use as Figure 3-4 The structure shown fulfills this requirement.

[0033] Such as Figure 4 Shown, combined figure 1 It is explained that the cathode 8 is fixedly connected to the slide rail 4 in the y direction. The slide rail 4 in the y direction can move linearly along the y direction in the figure. The y-direction linear bearing 5 is mounted on the support plate 15. The x-direction linear bearing 13 is installed at the back of the support plate, so that the cathode moves linearly along the x-direction along with the support plate by the x-direction linear bearing 13; Picture 11 As shown, the x-direction linear bearing 13 is matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com