Gas shock wave ash removing system equipped with Archimedes spiral accelerator

A technology of Archimedes spiral and acceleration device, which is applied in the field of ash removal device and boiler heating surface ash removal device, which can solve the problems of increased blockage, increased flue gas humidity, and insufficient removal of metal oxide dust to ensure Safe operation of equipment, efficient ash removal, and the effect of ensuring boiler heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

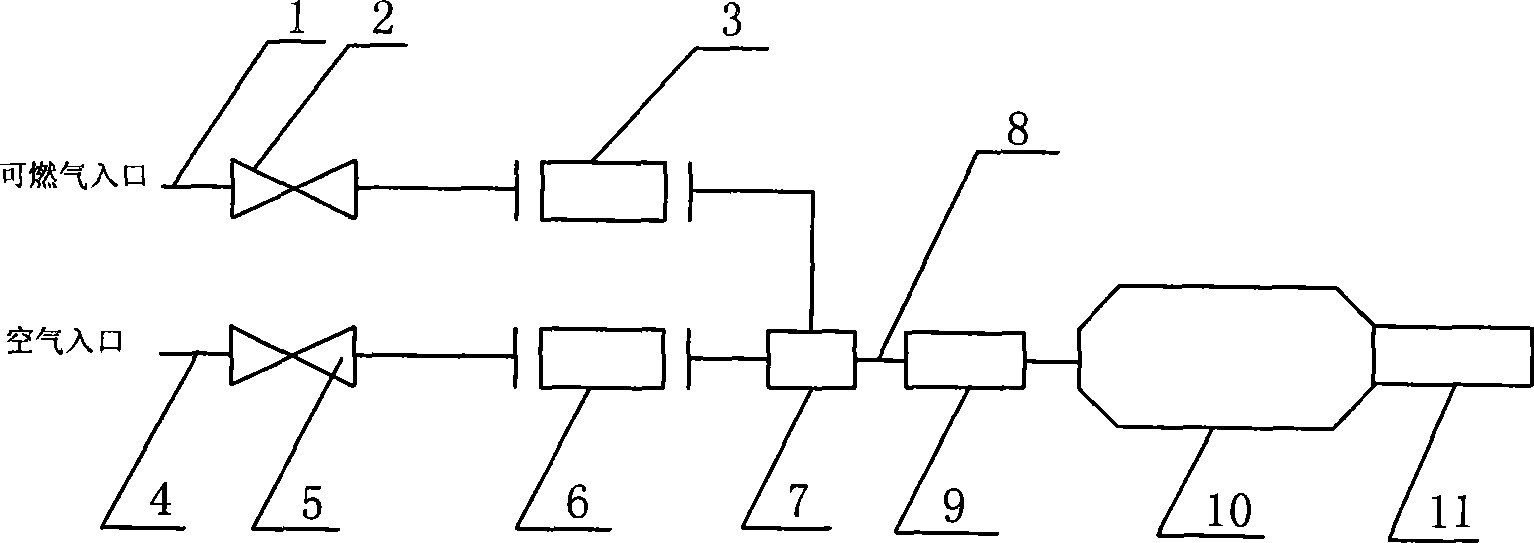

[0029] Embodiment 1: as figure 1 As shown, the combustible gas and air enter the premixer 7 through the combustible gas pipeline 1, the combustible gas valve 2, the combustible gas flowmeter 3 and the air pipeline 4, the air valve 5, and the air flowmeter 6 respectively, and the premixed gas passes through the premixed pipeline 8 enters the deflagration chamber 10, the igniter 9 ignites the premixed gas to form a premixed flame and enters the deflagration chamber 10, and the Archimedes spiral disturbance device composed of obstacle pins 102 is arranged in the deflagration chamber 10, and the number of the pins 102 is in accordance with the deflagration 4-20 tubes are installed in the circumferential direction of the tube 101. Since the flame front and the Archimedes spiral disturbance device form a positive feedback mechanism, the flame is continuously accelerated and the pressure is continuously increased. Finally, the shock wave is ejected from the output tube and directly ac...

Embodiment 2

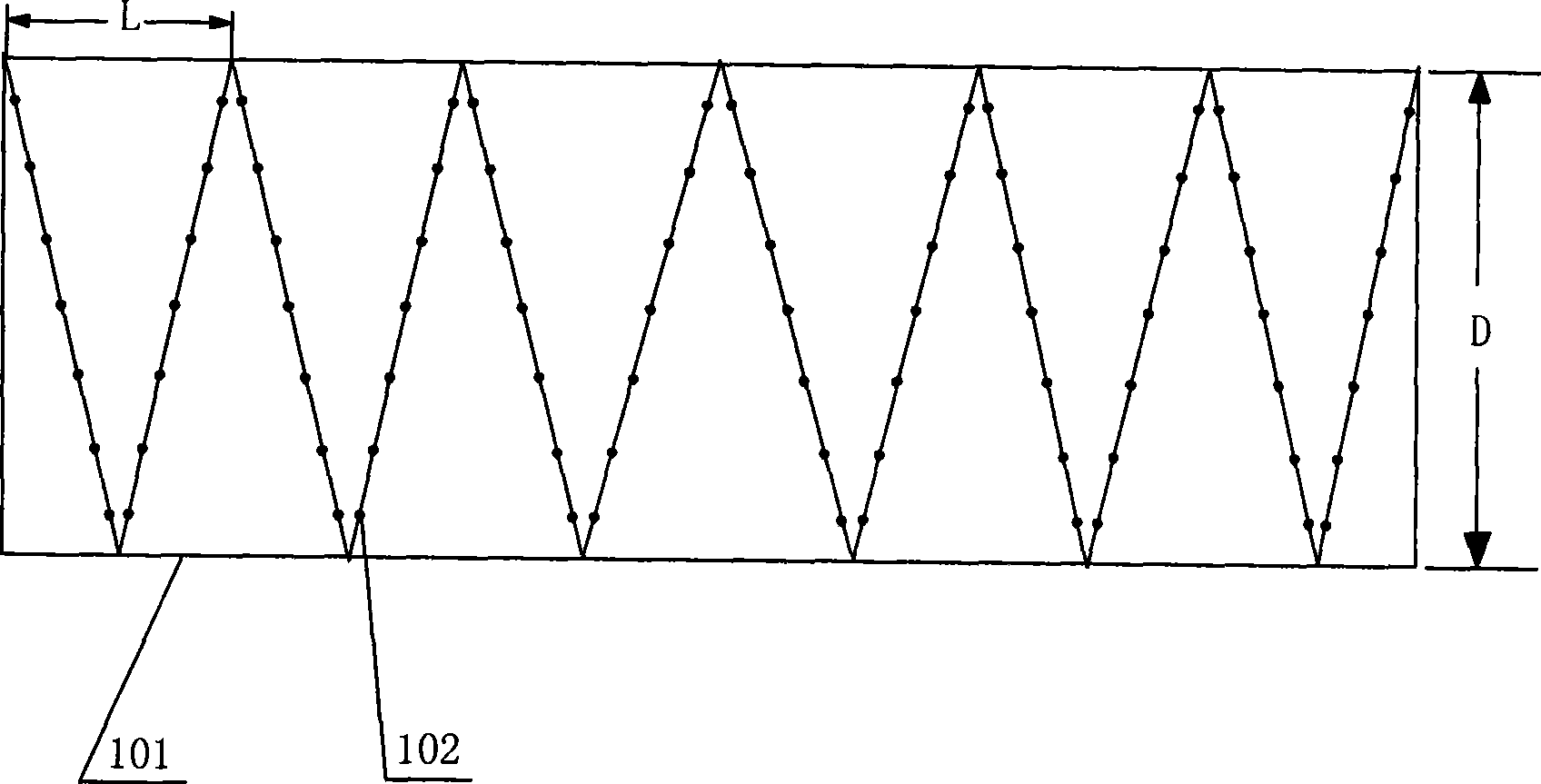

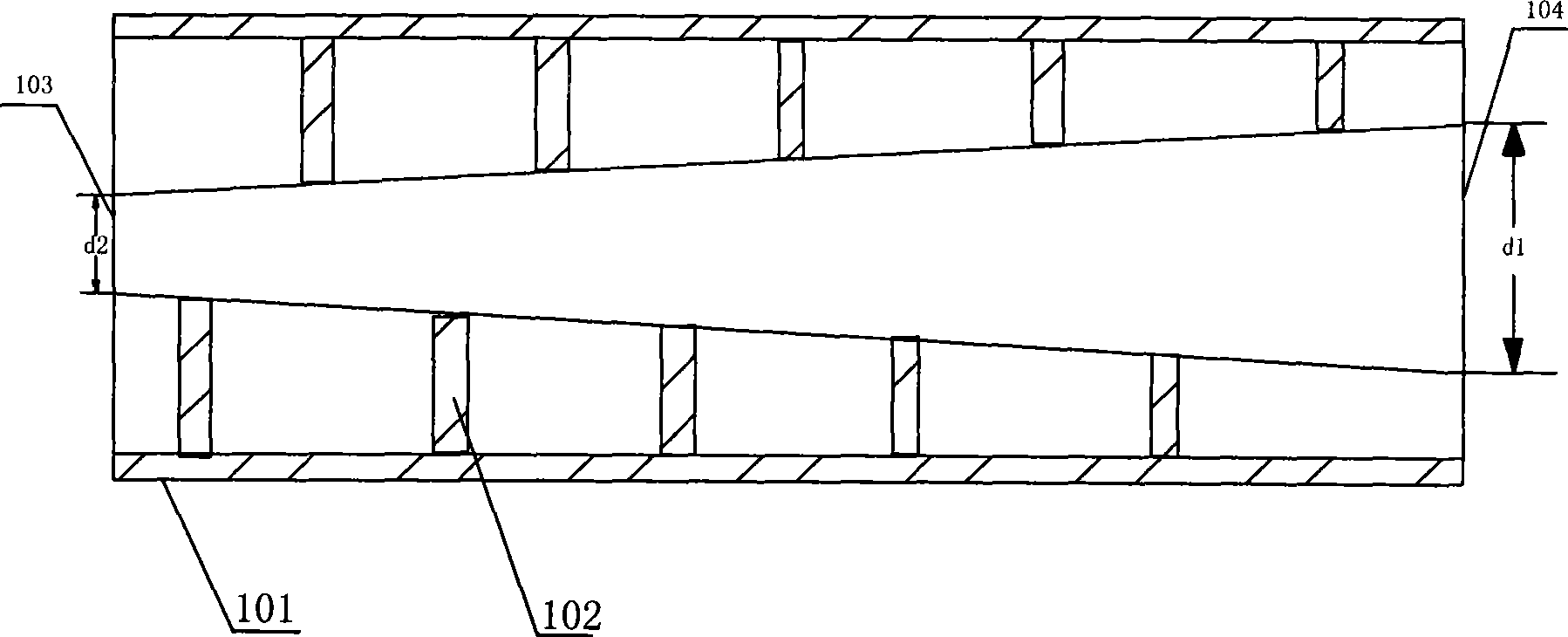

[0030] Embodiment 2: as figure 2 and if image 3 As shown, the deflagration tube 101 is generally cylindrical, and the pins 102 are evenly arranged on the inner wall of the deflagration tube 101 in the circumferential direction according to the Archimedes spiral, and the distance L between the Archimedes spirals on the inner wall of the deflagration tube 101 is 0.5- 2 times the diameter D of the deflagration tube 101 . The Archimedes spiral on the inner wall of the deflagration tube 101 disturbs the cone-shaped upper vertebral surface 104 with diameter d 1 It is 0.6-0.9 times the diameter D of the deflagration tube 101 . The Archimedes spiral on the inner wall of the deflagration tube 101 disturbs the cone-shaped lower vertebral surface 103 with diameter d 2 It is 0.1-0.3 times the diameter D of the deflagration tube 101 . 4-20 pins 102 are arranged in the circumferential direction of the deflagration tube 101 inner wall, and the pins 102 are perpendicular to the deflagra...

Embodiment 3

[0031] Embodiment 3: as Figure 4 As shown, different combustible gases produce different pressures after burning in the deflagration tube 101, such as methane, water gas, acetylene, hydrogen, etc., and the maximum pressure produced by the above-mentioned combustible gases in the deflagration tube 101 varies with the disturbance intensity. . Therefore, different combustible gases can be selected according to the firmness of the dust to achieve the best removal effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com