Device for preparing supported automotive catalyst with pulsating hydrogenation reduction method and application of device

A technology of catalyst and reduction method is applied in the field of devices for preparing CeO2 carrier vehicle catalyst by pulsating hydrogenation reduction method, which can solve the problems of high energy consumption and high cost carrier sintering and agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

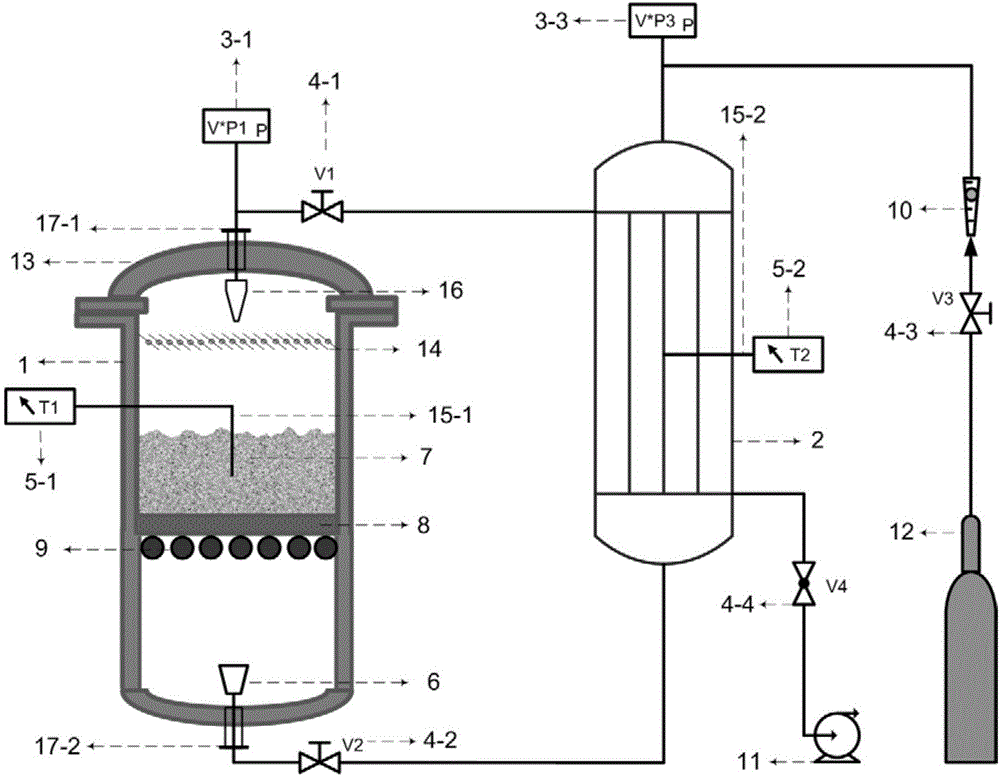

[0064] A device for preparing carrier vehicle catalysts by pulsating hydrogenation reduction method, its structure is as follows figure 1 As shown, the device consists of a heat-exchange hydrogen measuring cylinder assembly 2 connected to the feedback gas path control system assembly and a fluidized bed reactor assembly 1.

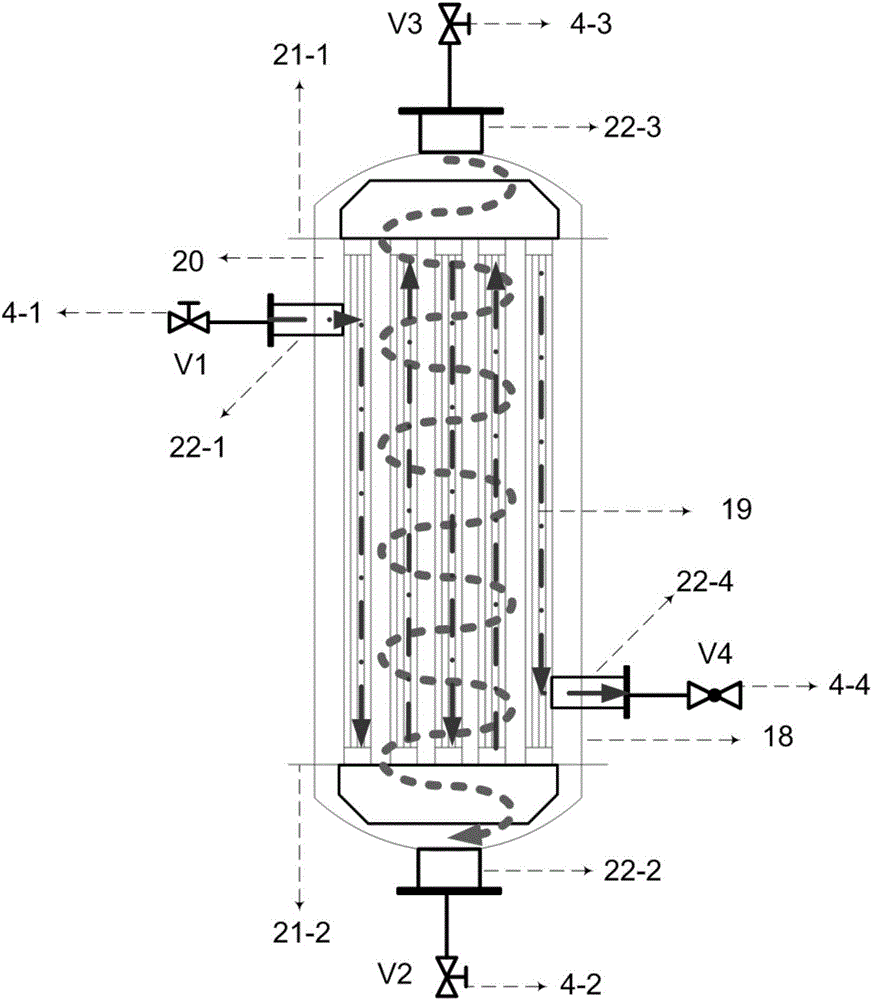

[0065] The reactor gas inlet 17-1 and the reactor gas outlet 17-2 of the fluidized bed reactor assembly 1 respectively pass through the gas path equipped with a vacuum pressure gauge and a shut-off valve and the heat exchange type hydrogen quantitative cylinder assembly 2 (its structure Such as figure 2 Shown) on the outer sleeve hydrogen outlet flange 22-4 and the inner tube reaction waste gas inlet flange 22-1 are connected.

[0066] The ebullating fluidized bed reactor assembly 1 includes: a temperature-resistant and pressure-resistant reactor shell of a closed structure made of high-strength temperature-resistant and pressure-resistant materials, the...

Embodiment 2

[0103] The device for preparing the carrier vehicle catalyst by the pulsating hydrogenation reduction method is composed of a heat-exchanging hydrogen metering cylinder assembly connected to the feedback gas path control system assembly and a bubbling fluidized bed reactor assembly, and the bubbling fluidized bed reactor assembly The gas inlet and gas outlet are respectively connected to the hydrogen outlet flange of the outer sleeve and the inlet flange of the inner tube reaction exhaust gas on the heat exchange type hydrogen measuring cylinder assembly through the gas circuit equipped with a vacuum pressure gauge and a stop valve.

[0104] The bubbling fluidized bed reactor assembly consists of the following components:

[0105] Temperature-resistant and pressure-resistant reactor shell: a closed structure made of high-strength temperature-resistant and pressure-resistant materials. The outer wall is covered with an insulating layer. The top cover of the reactor can be opened...

Embodiment 3

[0142] Utilize the device disclosed in embodiment 2 to carry out pulse type hydrogenation reduction method to prepare CeO 2 Carrier vehicle catalyst, including two steps of pretreatment and hydrogenation reduction reaction:

[0143] (1) Preprocessing steps:

[0144] (1-1) Extrude or extrude the reactant raw materials that meet the requirements of the process conditions in advance to make raw material particles of the required size and shape. The raw material particles used in this embodiment are made of CeO 2 Granules, activated carbon particles, and additives are mixed at a molar ratio of 100:8:5, and CeO 2 The particles are CeO prepared by gas phase combustion method 2 Submicron particles; additive is La 2 o 3 , BaO, Al 2 o 3 Micron-sized mixed powder, and also contains powder binder in the auxiliary agent;

[0145] (1-2) Calcining the raw material particles at a temperature of 850 degrees Celsius for 2 hours in a vacuum heating device under the protection of an inert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com