Liquid-gas control system for controlled-pressure drilling equipment

A pressure-controlled drilling and control system technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve problems such as flammable gas escape, pressure control drilling equipment in harsh environment, and pressure control difficulties. To achieve the effect of increasing the outlet pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

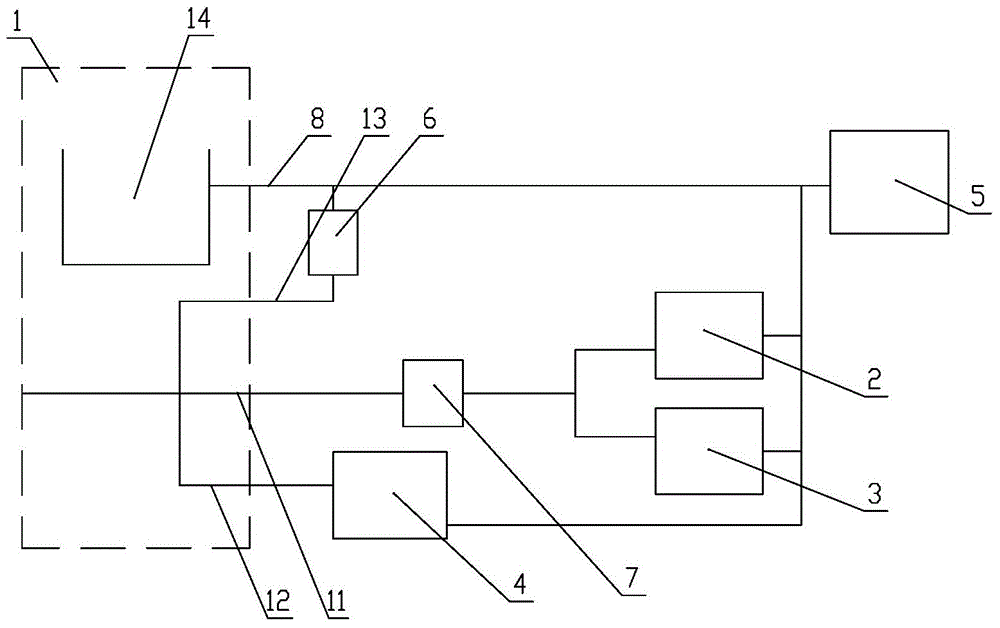

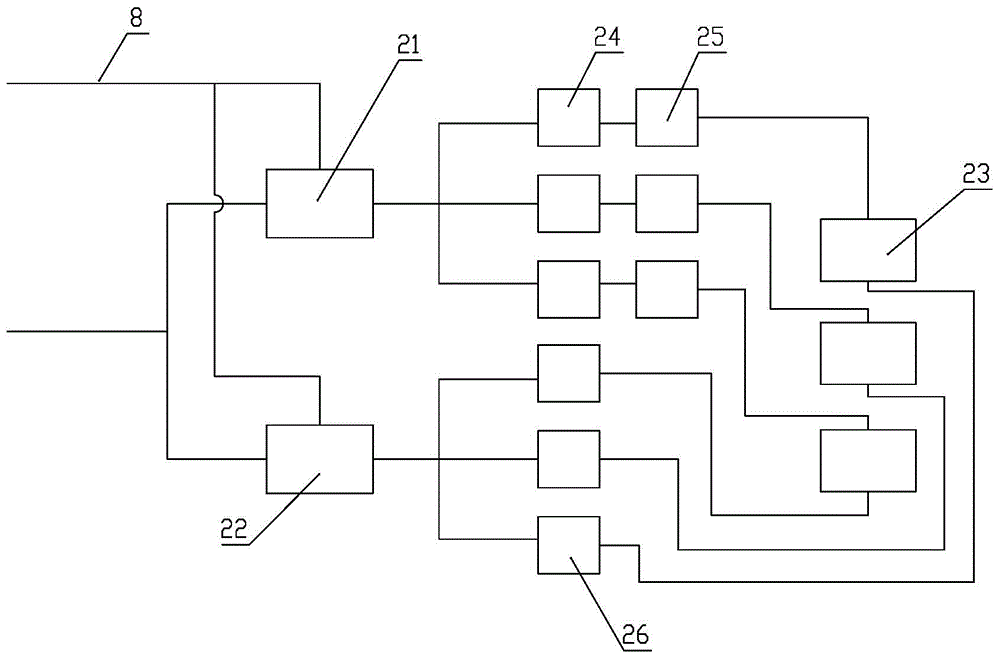

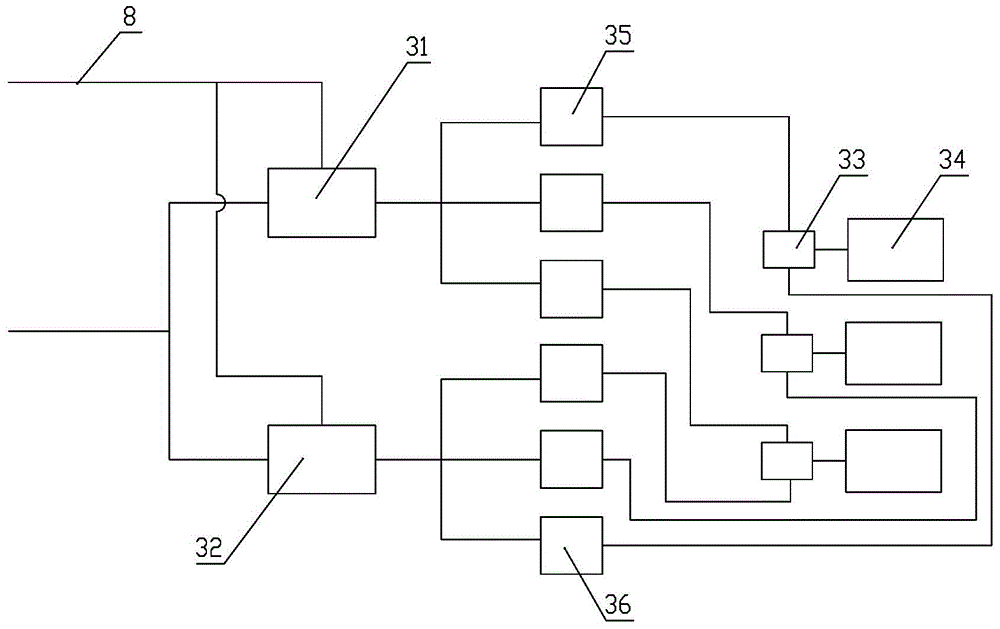

[0034] This embodiment provides a liquid gas control system for managed pressure drilling equipment, such as figure 1 As shown, the liquid and gas control system includes a central controller, a power source 1, a throttle valve control part 2 connected to the power source 1, a hydraulic control flat gate valve control part 5, an air control flat gate valve control part 3 and an oil return pump system Air-operated flat gate valve control part 4. The central controller is connected with the throttle valve control part 2, the air-controlled flat gate valve control part 3 and the air-controlled flat gate valve control part 4 of the oil return pump system.

[0035] Wherein, the power source 1 includes a compressed air processing device and an oil storage device. The compressed air processing device includes three branches separated by the compressed air source through the stop valve and the gas safety valve, the first branch 11 of which is connected to the throttle valve control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com