Mechanical electric liquid composite soft starting/stepless speed regulating transmission device for large power overloading equipment

A technology of stepless speed regulation and transmission device, which is applied in the direction of transmission device, gear transmission device, transmission device control, etc., and can solve the problems of large investment, high price and high maintenance cost of substations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

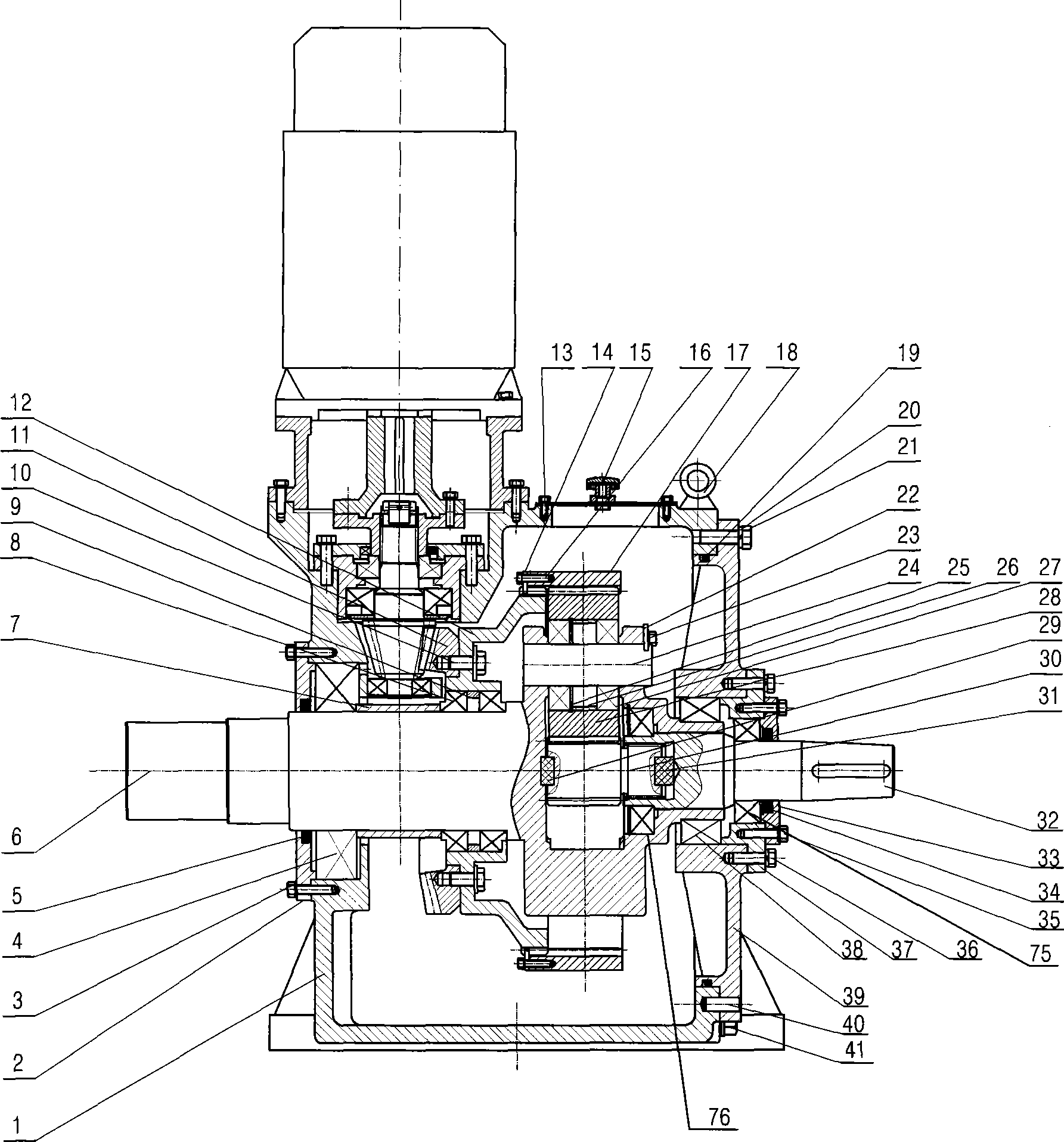

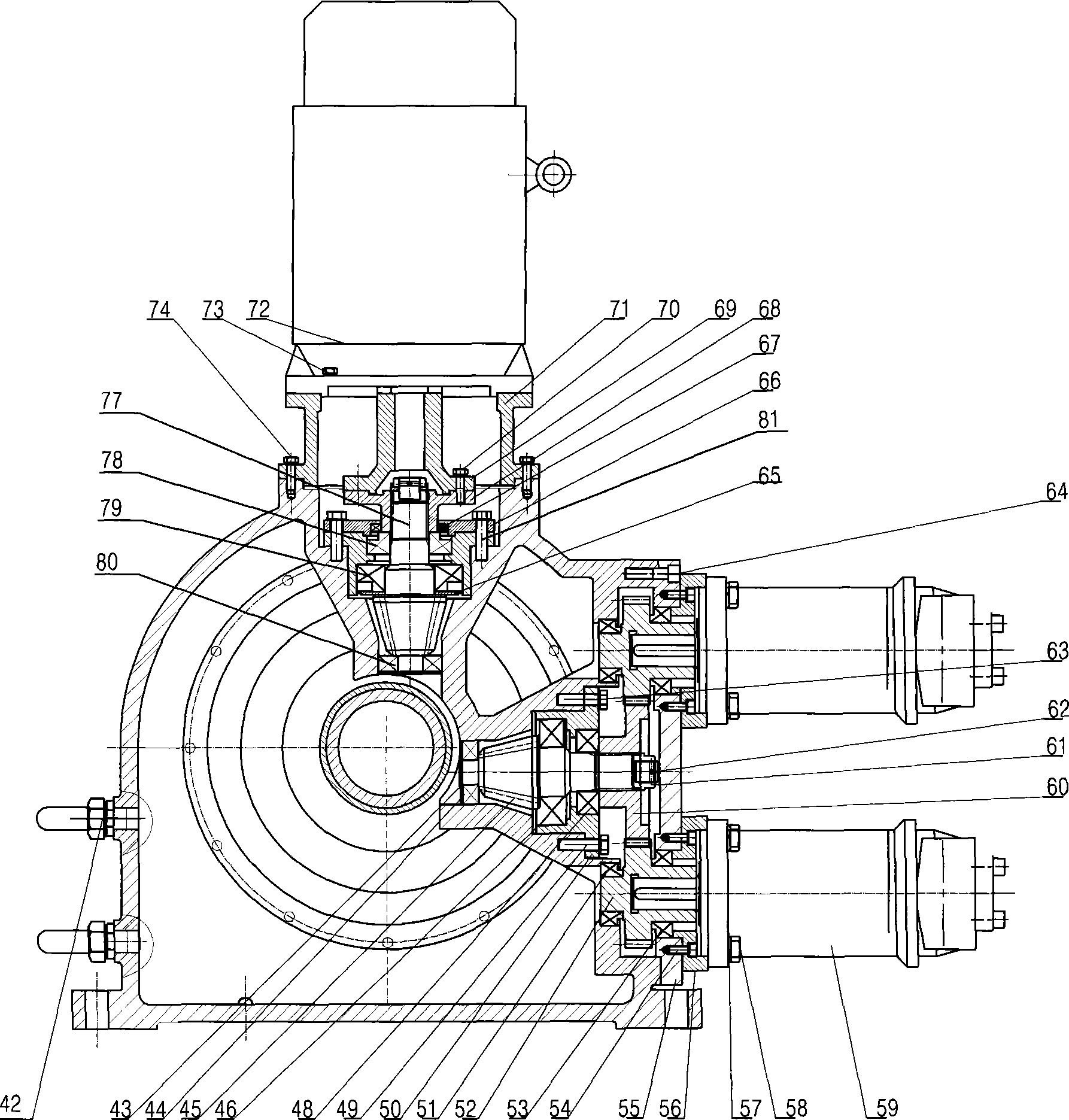

[0022] see figure 1 and figure 2 , the present invention includes a body 1 and a planetary carrier output shaft 6 fixed on the inner wall of the body 1 and the inner wall of the large end cover 39 by using rolling bearings 4 and 38. The inner sliding sleeve of the planetary carrier output shaft 6 has a power input shaft 32, and the power input shaft One end of 32 is fixed in the body 1 by a rolling bearing 75 and stretches out of the body 1 to be connected with the rotating shaft of the main motor, and the other end is fixed on the inner hole of the planet carrier output shaft 6 by a rolling bearing 76 . One end of the power input shaft 32 fixed to the inner hole of the planet carrier output shaft 6 is provided with an involute spline inner tooth, and the involute spline inner tooth is connected to one end of the sun gear shaft 30 located in the inner hole of the planet carrier output shaft 6 . The teeth are connected to form a backlash float. A block 31 for axially positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com