Patents

Literature

105results about How to "Reliable service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

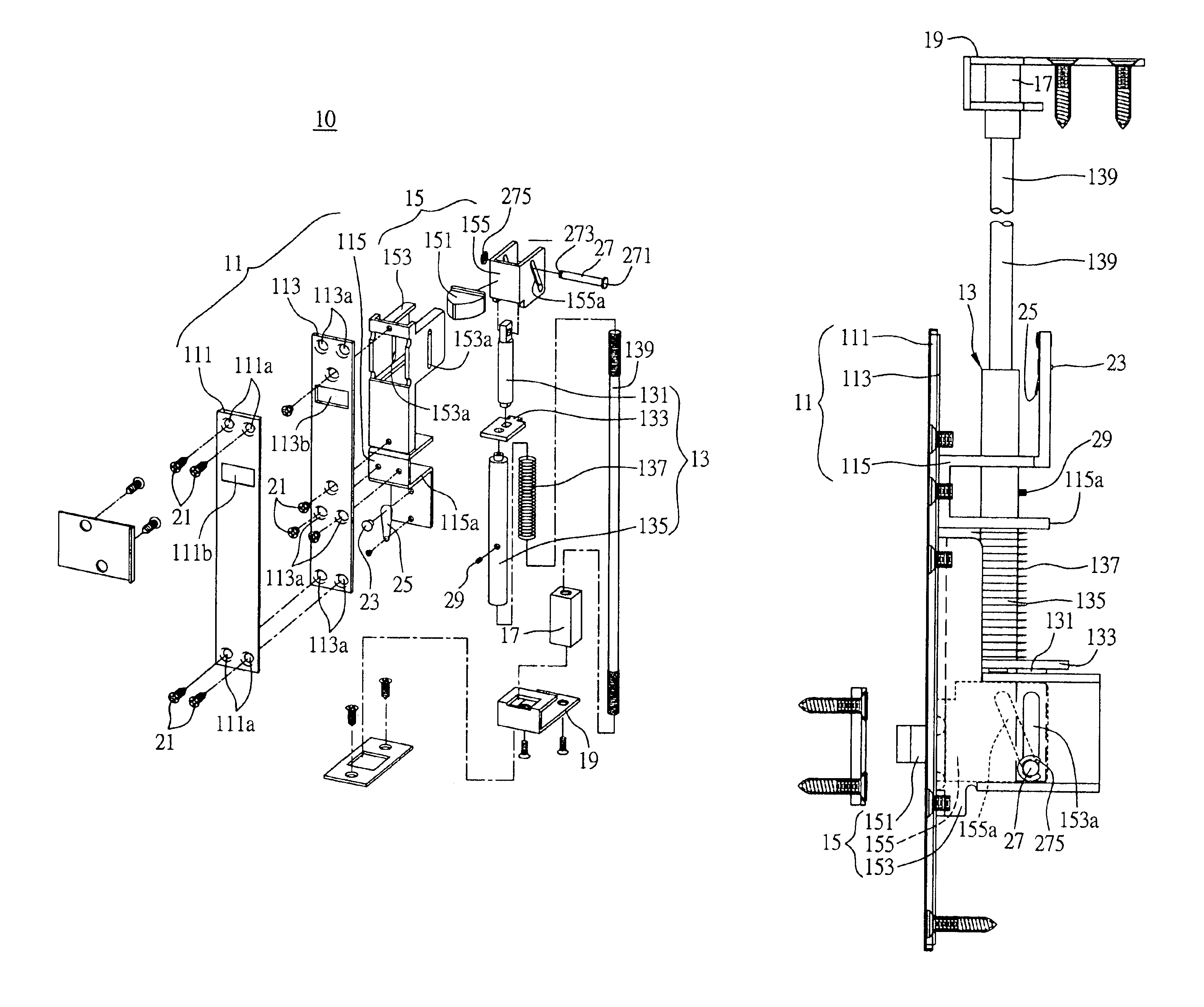

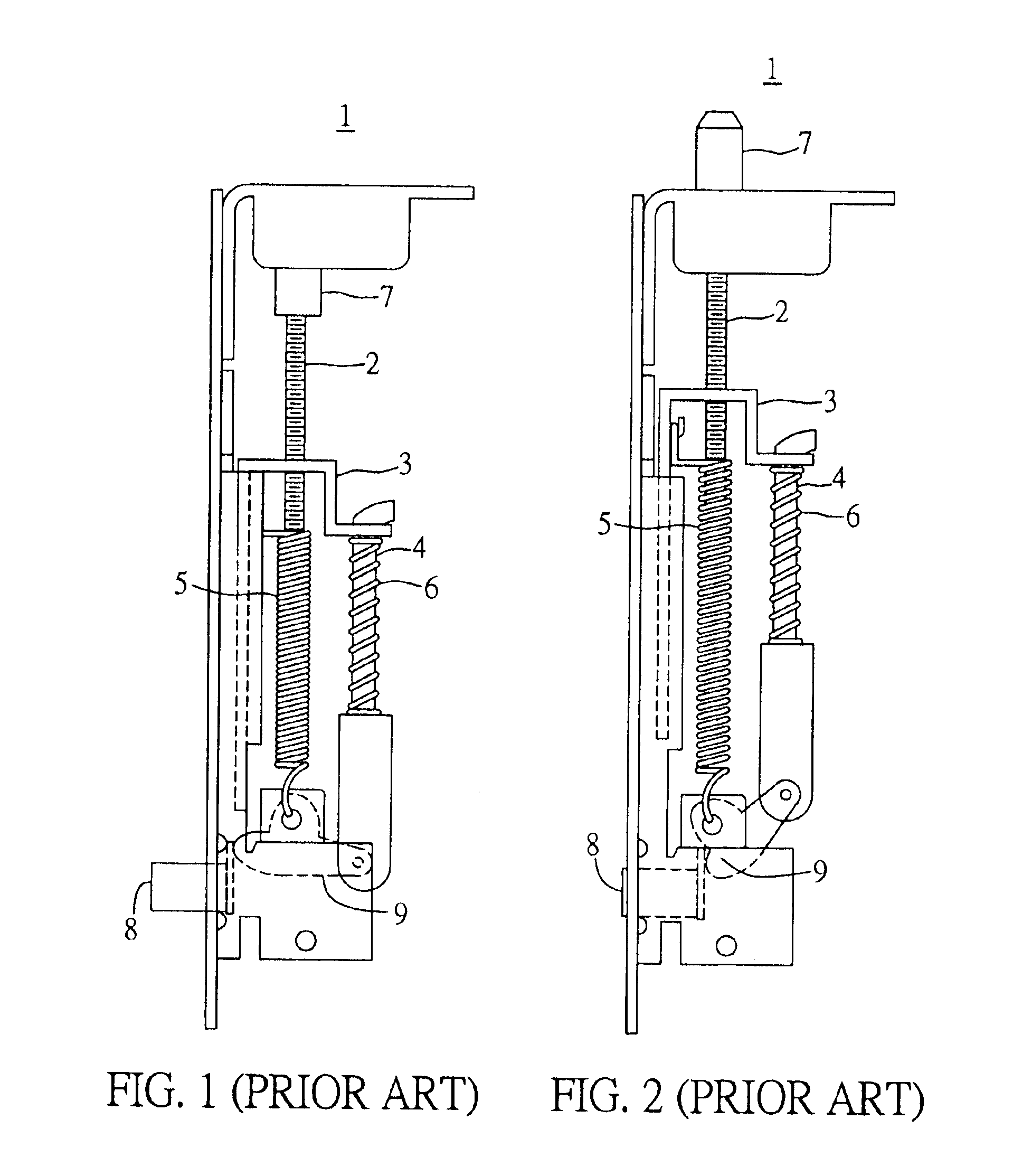

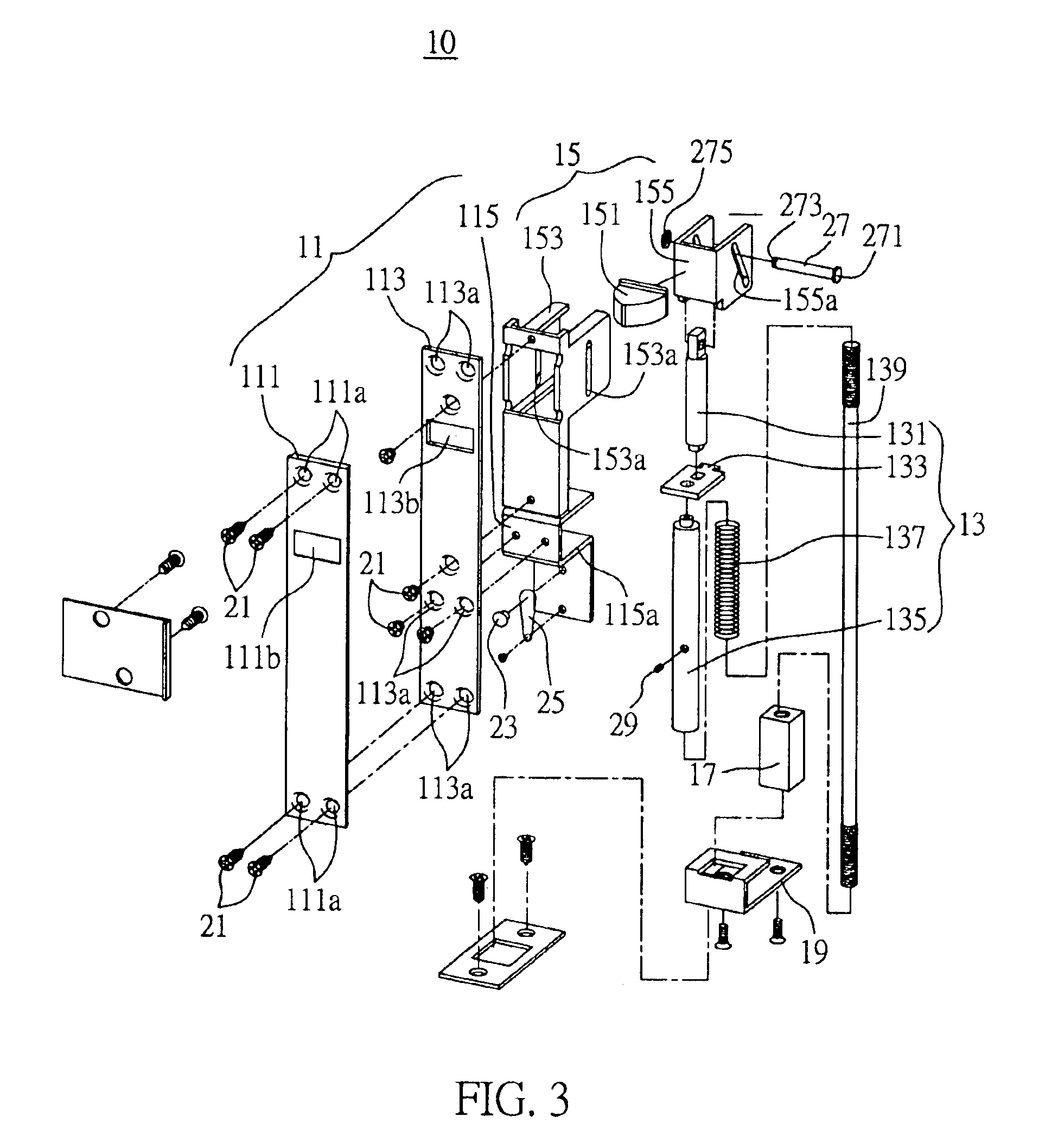

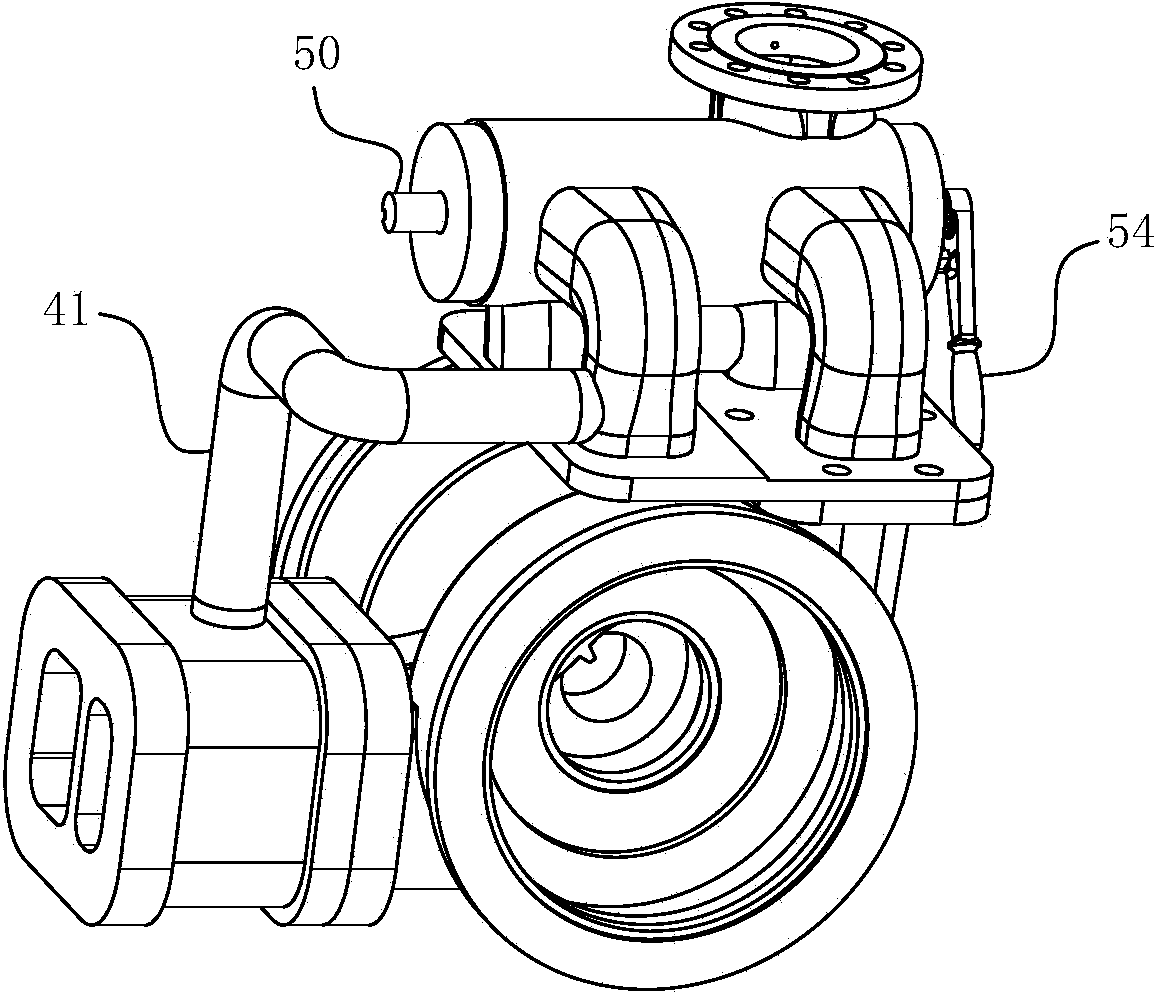

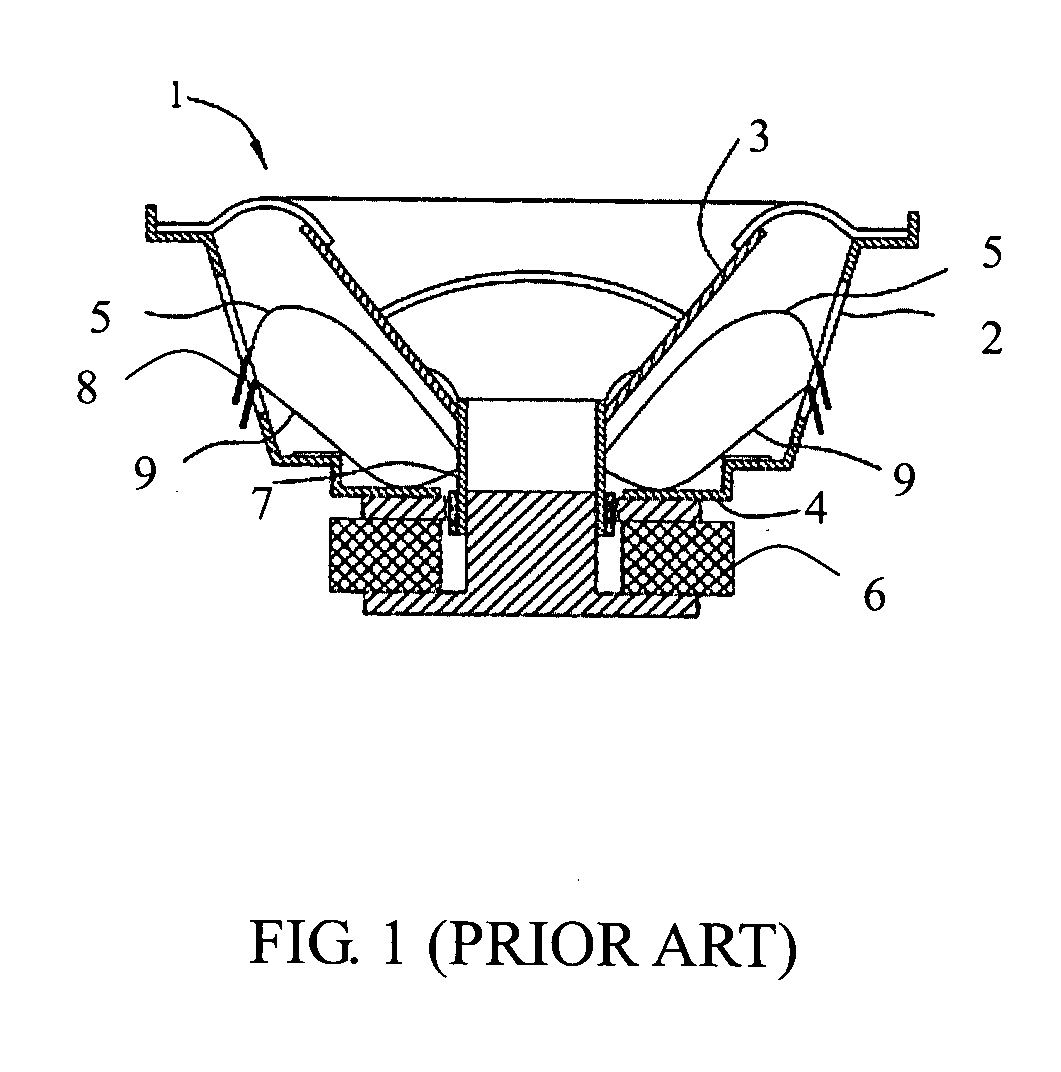

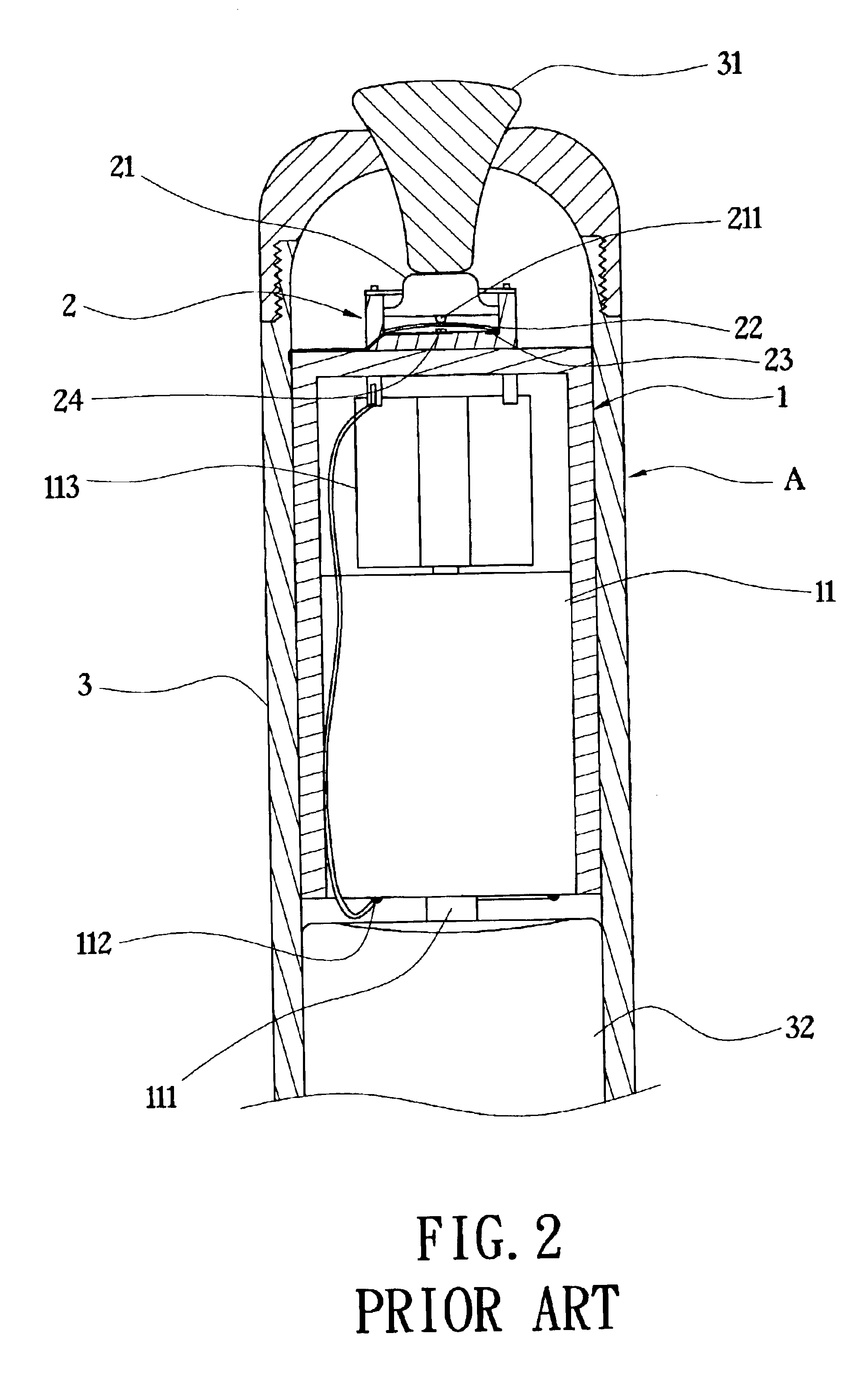

Flush bolt mechanism

A flush bolt mechanism includes a frame, a slide guide bracket, a plunger reciprocally retained in the slide guide bracket having two first slots, a trigger member mounted to the plunger and reciprocally movable between a retracted position and an extended position, an elongated linkage assembly extending through the frame, and a resilient member biasing the linkage assembly toward a downward direction. The linkage assembly having a first end coupled to the shaft. The plunger includes two second slots and a shaft movable in the slots. The first and second slots are offset at an angle such that when the trigger member is activated to the retracted position, a second end of the linkage assembly is carried upwardly for latching engagement in the associated strike; when the trigger member is released from the retracted position, the second end of the linkage assembly is carried downwardly for disengagement with the strike.

Owner:LIN CHING TIEN

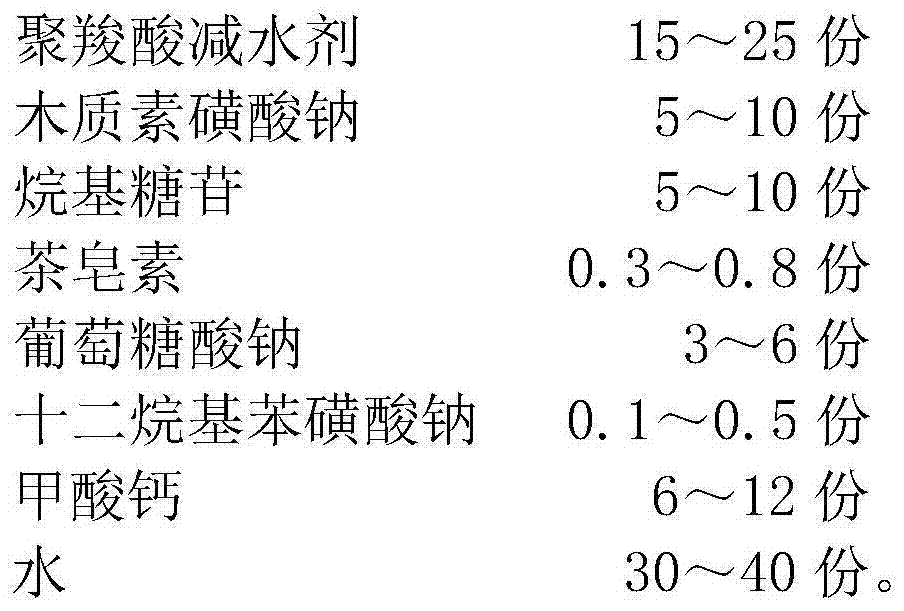

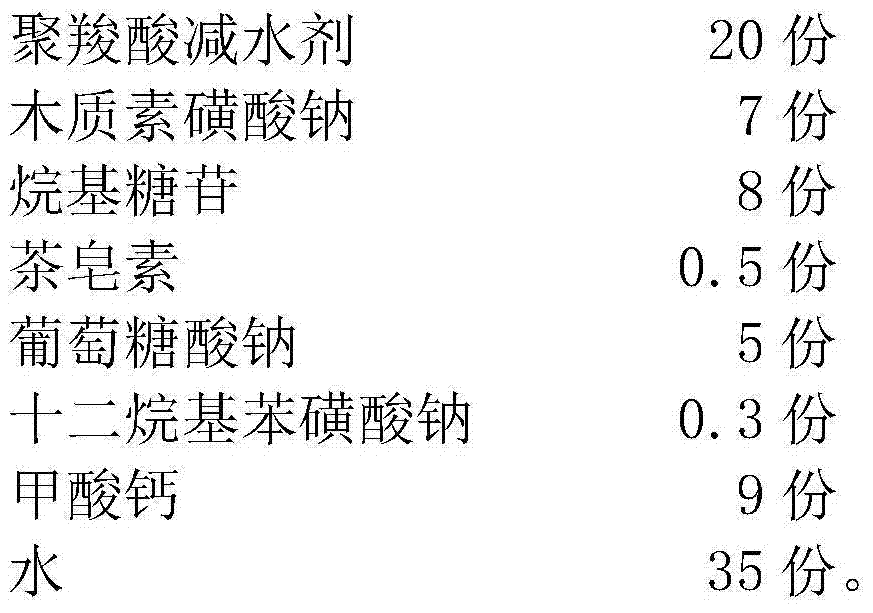

Concrete anti-freezing agent

The invention relates to the technical field of anti-freezing agents, particularly to a concrete anti-freezing agent. The concrete anti-freezing agent is formed by the following raw materials of, by weight, 15 to 25 parts of poly carboxylic acid water reducing agents, 5 to 10 parts of sodium lignin sulfonate, 5 to 10 parts of alkyl glycoside, 0.3 to 0.8 part of tea saponin, 3 to 6 parts of sodium gluconate, 0.1 to 0.5 parts of sodium dodecyl benzene sulfonate, 6 to 12 parts of calcium formate and 30 to 40 parts of water through preparation. According to the concrete anti-freezing agent, the adaptability to concrete is good, the quality is stable, the product is environmentally-friendly, various engineering requirements can be met, and the concrete can be maintained not to freeze at minus 30 DEG C to minus 20 DEG C.

Owner:唐山嘉业建材有限公司

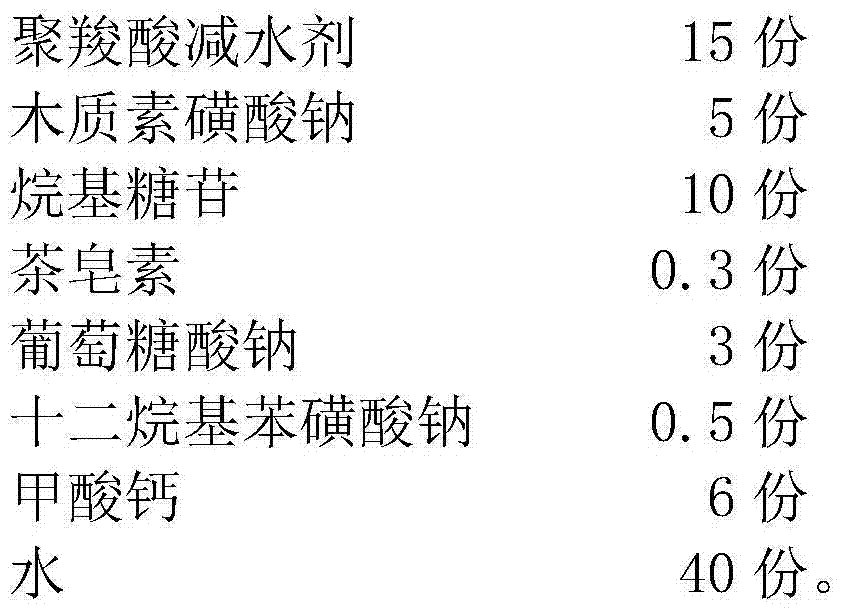

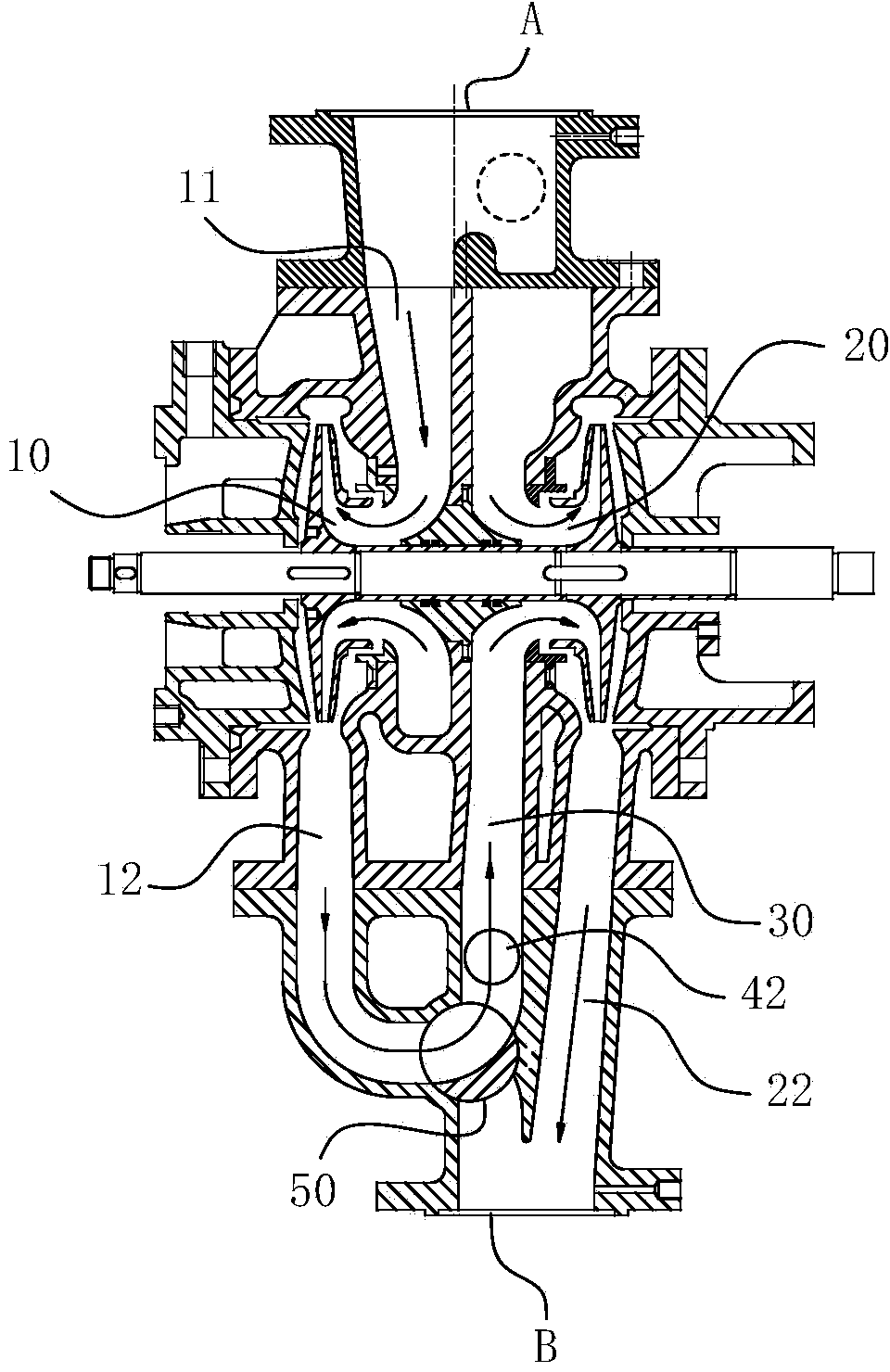

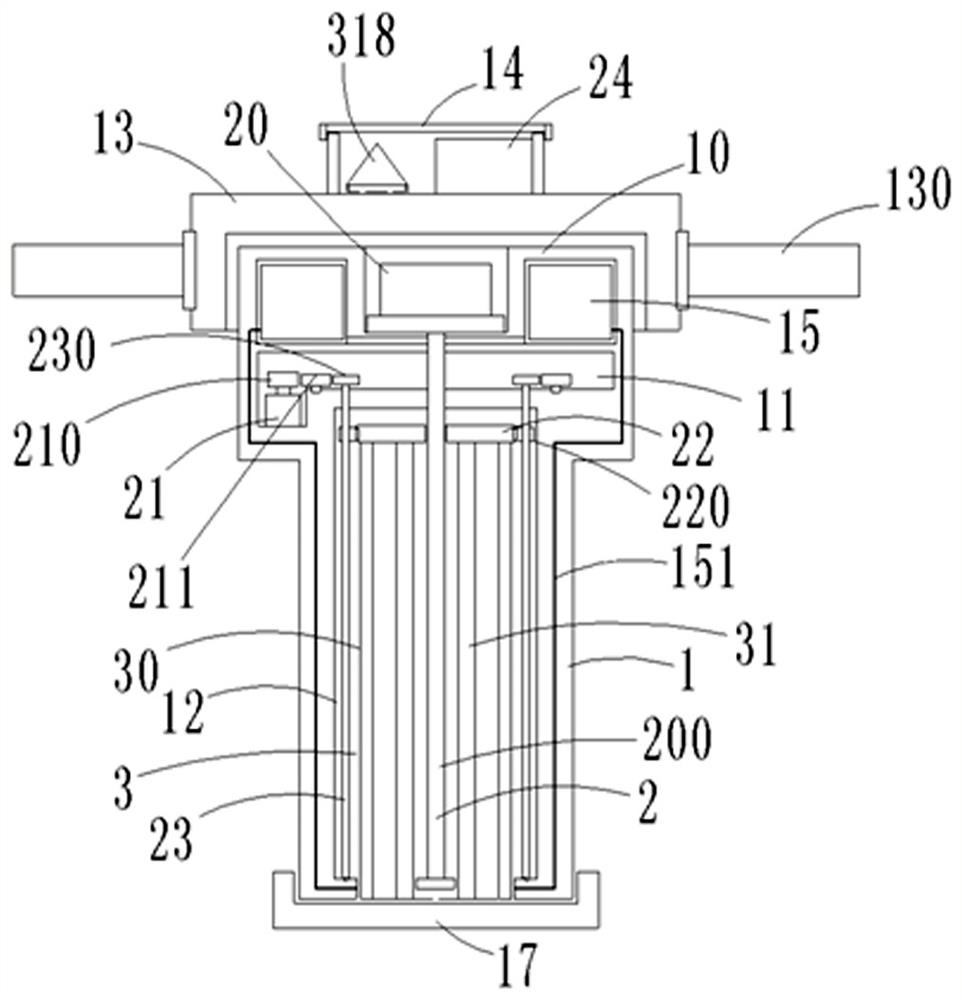

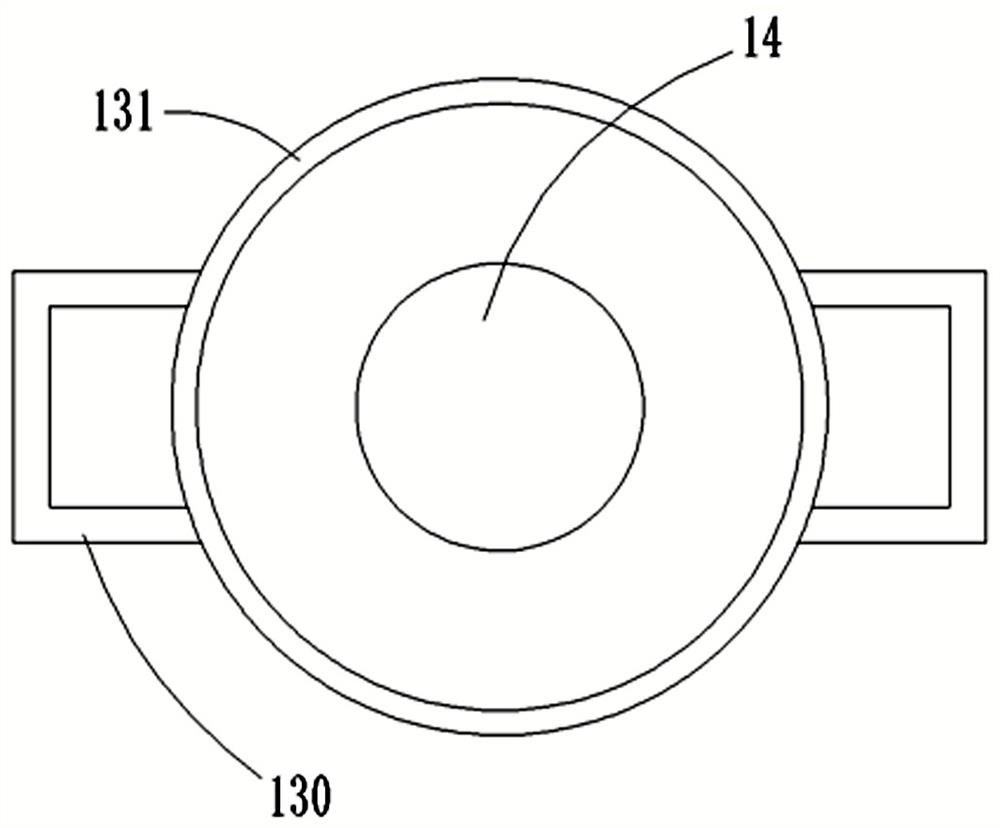

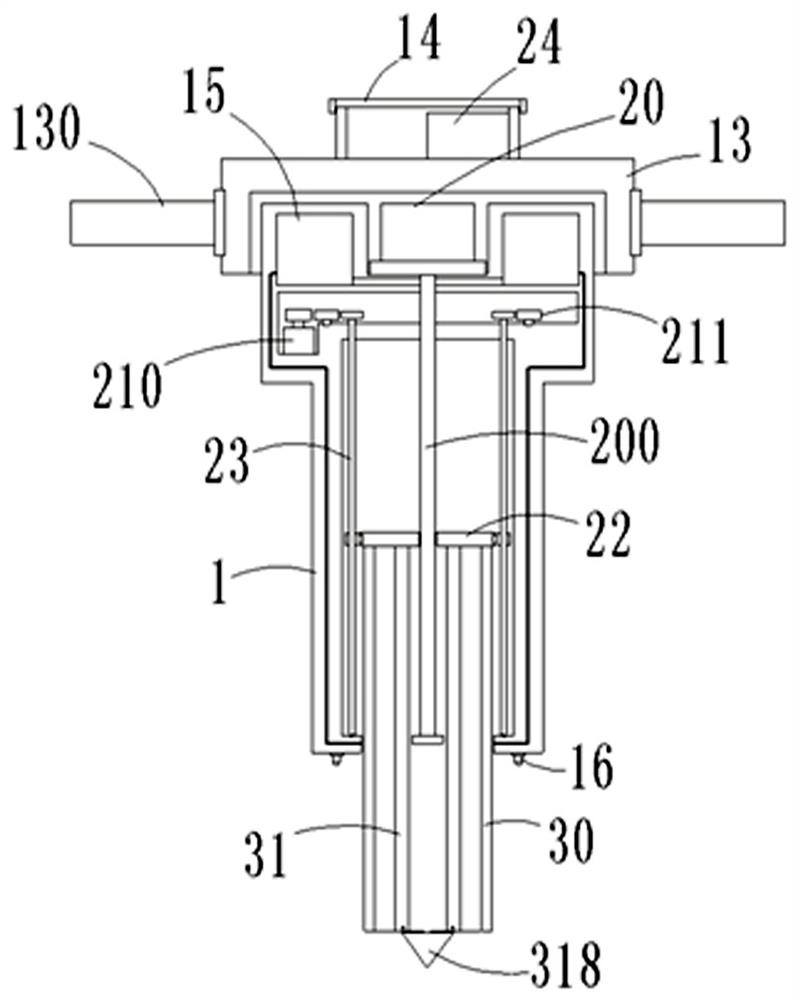

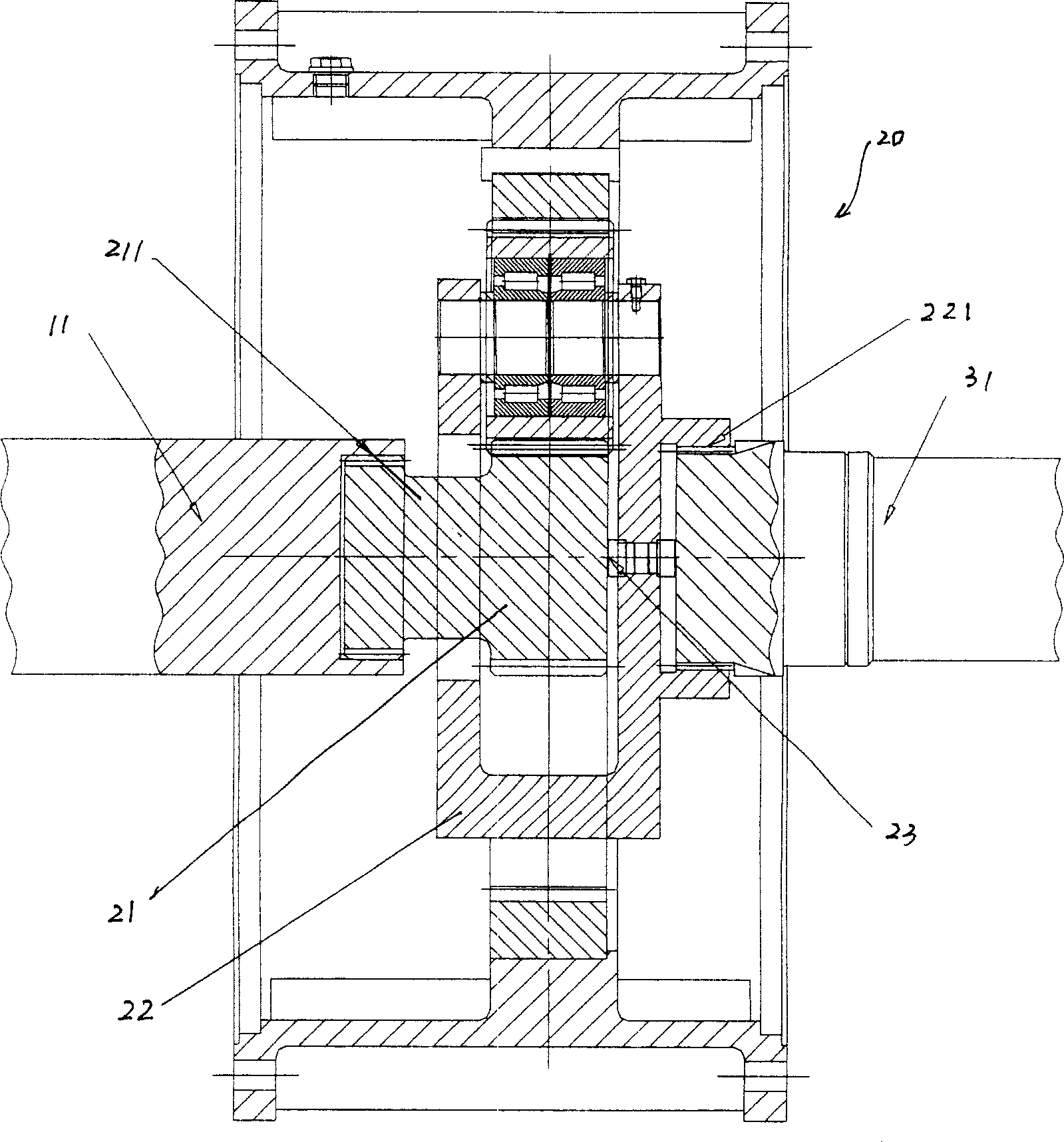

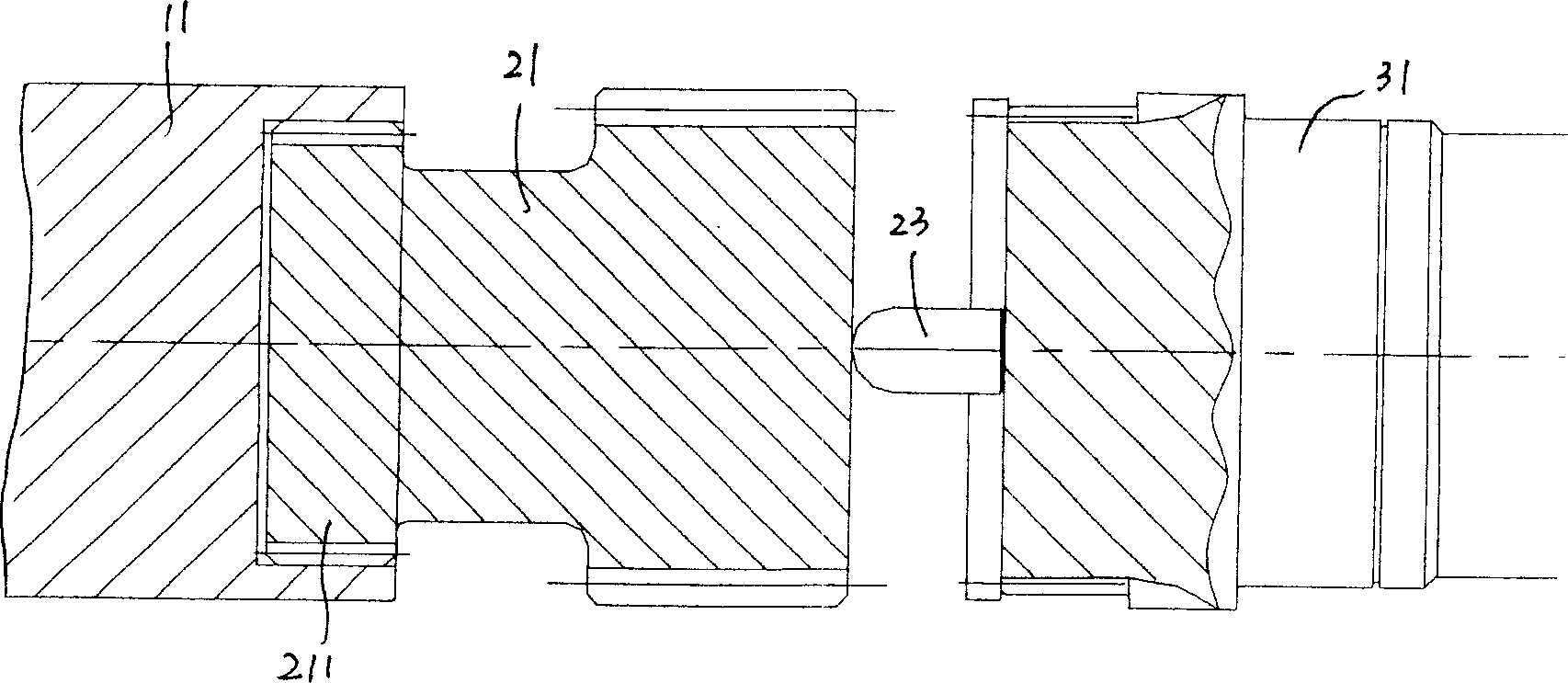

Series-parallel connection centrifugal pump

ActiveCN103899542AImproved physical sealing performance and controllabilityImproved service lifePump componentsPump controlCentrifugal pumpElectricity

The invention belongs to the field of centrifugal pumps and particularly relates to a series-parallel connection centrifugal pump which has the flow channel series-parallel connection switching capacity. The series-parallel connection centrifugal pump comprises a pump body and a pump shaft. The pump shaft is provided with two impeller parts, and a first cavity channel and a second cavity channel are formed in a pump cavity corresponding to the two impeller parts. A first bypass flow channel, a second bypass flow channel, a first liquid outlet flow channel and a second liquid outlet flow channel are formed in the pump body, wherein the first bypass flow channel and the second bypass flow channel are used for communicating an outlet of an external liquid inlet pipeline and an inlet of the first cavity channel as well as the outlet of the external liquid inlet pipeline and an inlet of the second cavity channel respectively, and the first liquid outlet flow channel and the second liquid outlet flow channel are used for communicating an inlet of the external liquid outlet pipeline and an outlet of the first cavity channel as well as the inlet of the external liquid outlet pipeline and an outlet of the second cavity channel. A branch flow channel is further arranged in the pump cavity, one end of the branch flow channel is communicated with a liquid inlet of the second cavity channel, and the other end of the branch flow channel is communicated with the first liquid outlet flow channel to form a three-way joint. The series-parallel connection centrifugal pump further comprises a switching part, a switching assembly is arranged at the second liquid outlet flow channel, and the switching assembly and the switching part are in electric linkage or mechanical linkage. Due to the linkage structure, the series-parallel connection centrifugal pump is reasonable and practical in structure, long in service life and reliable and stable in work.

Owner:合肥华升泵阀股份有限公司

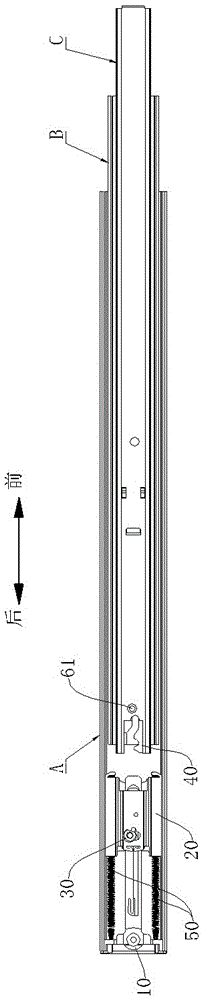

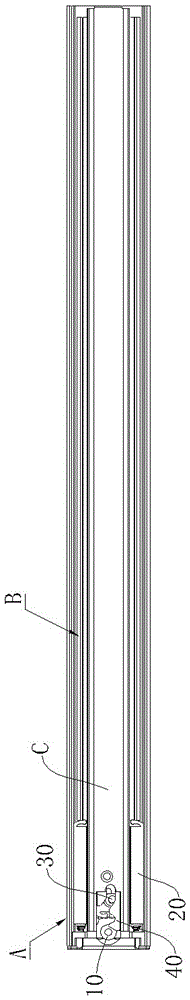

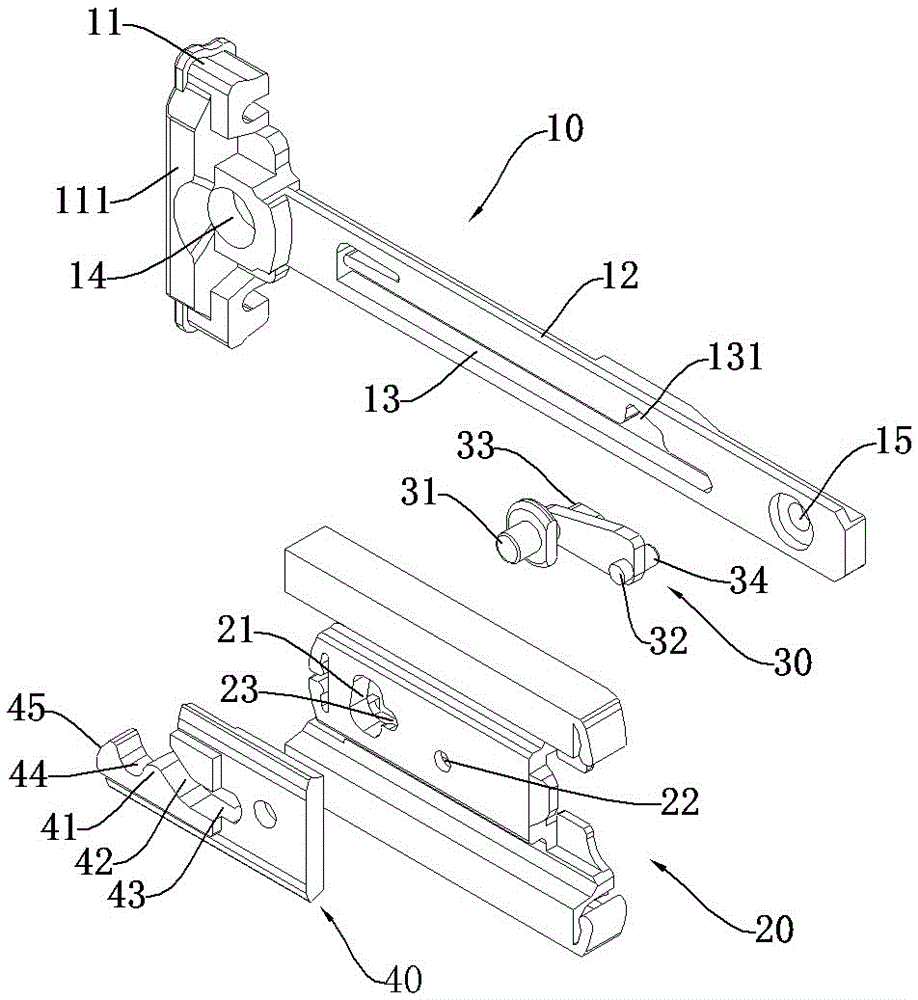

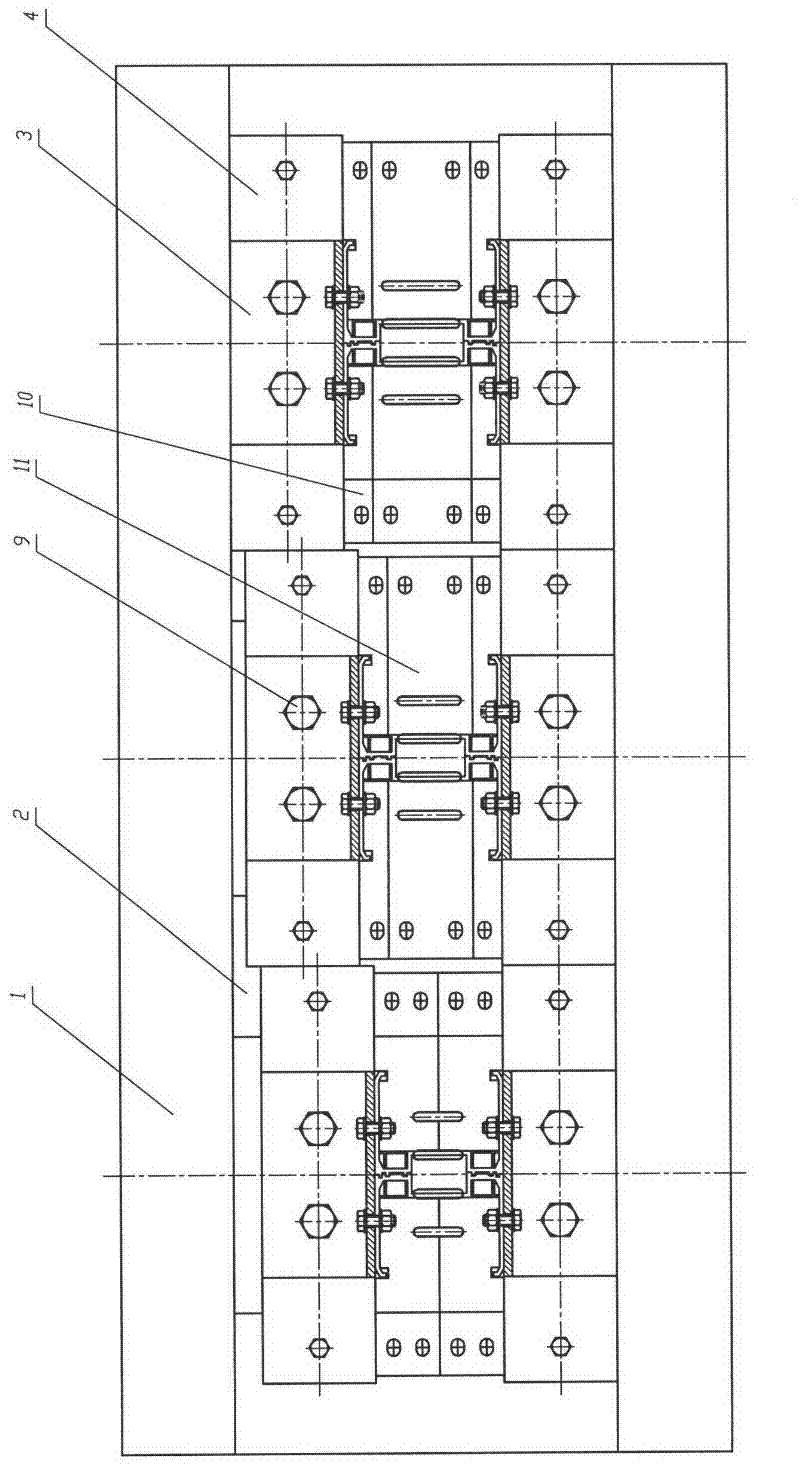

Automatic retracting device for small drawer slide rail

Owner:WUXI HAIDAER PRECISION SLIDES CO LTD

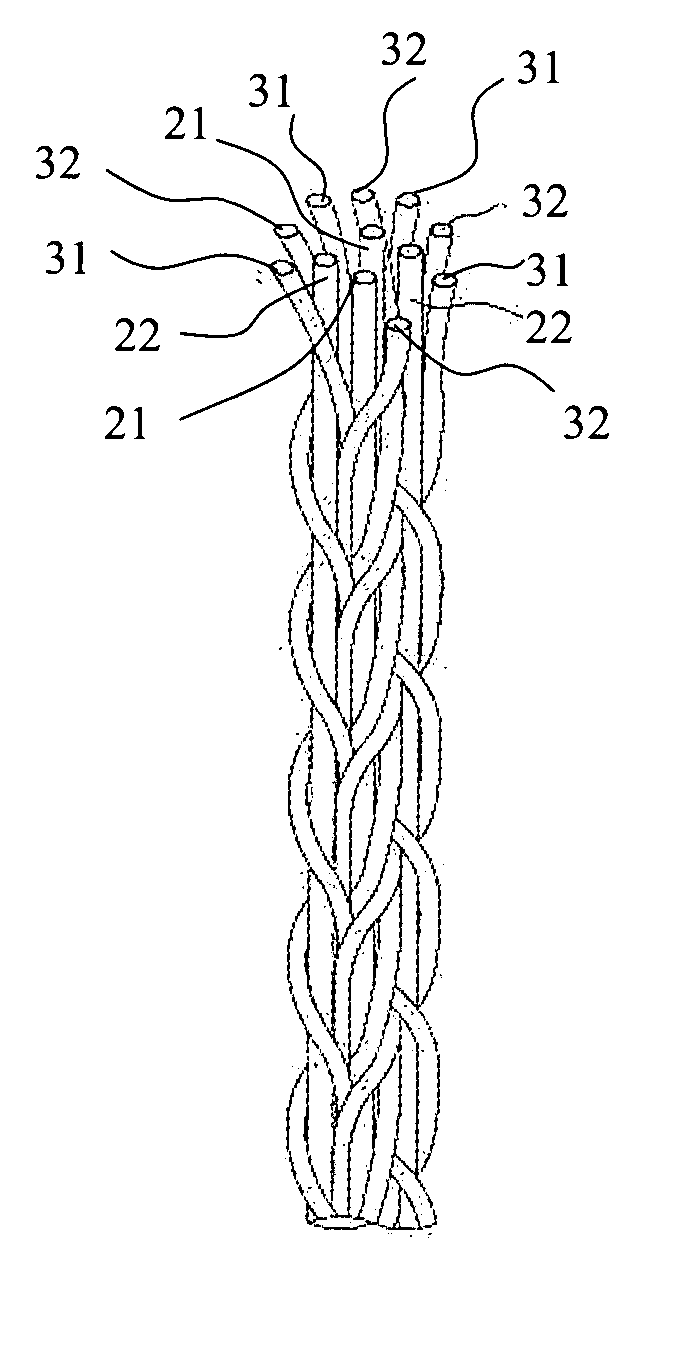

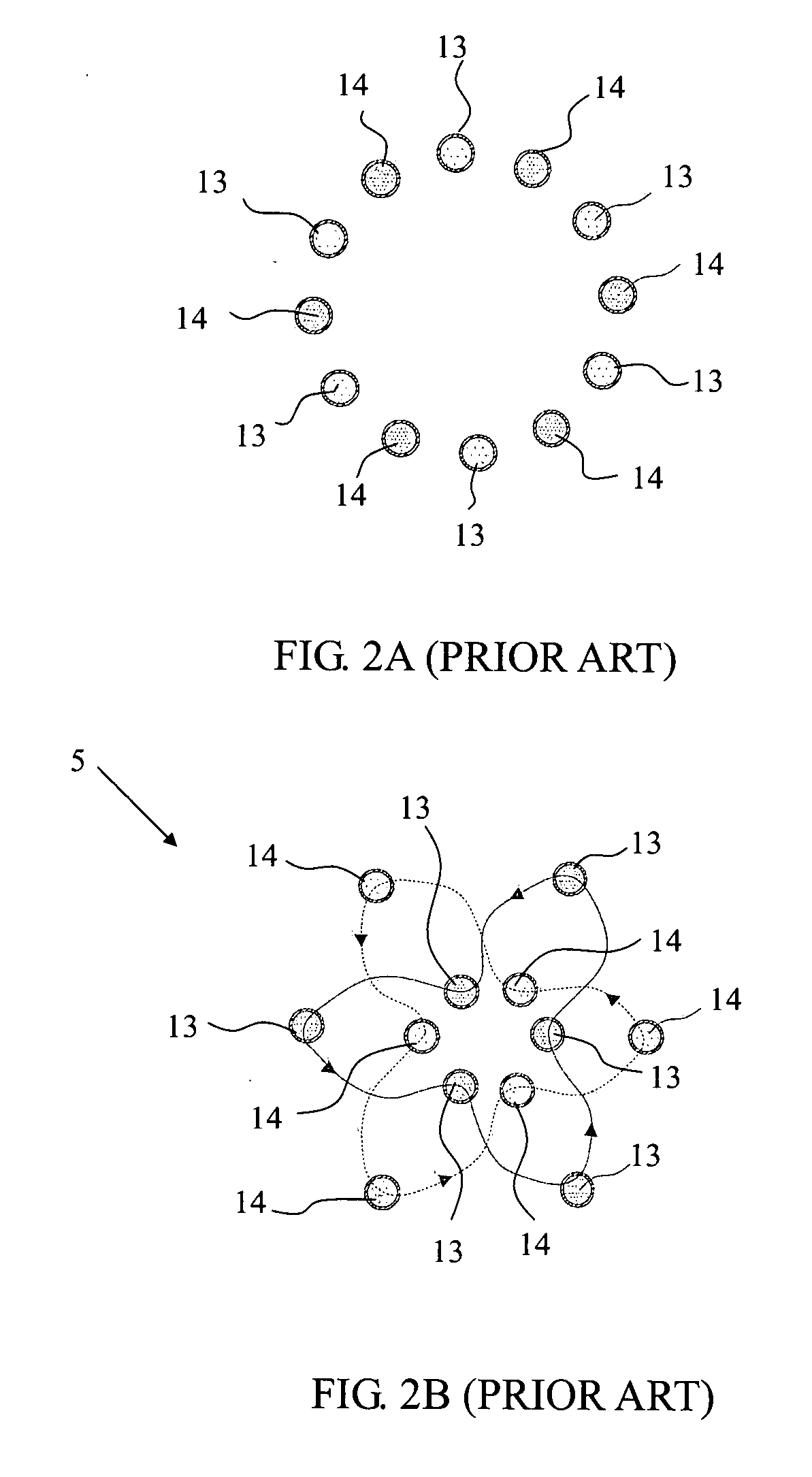

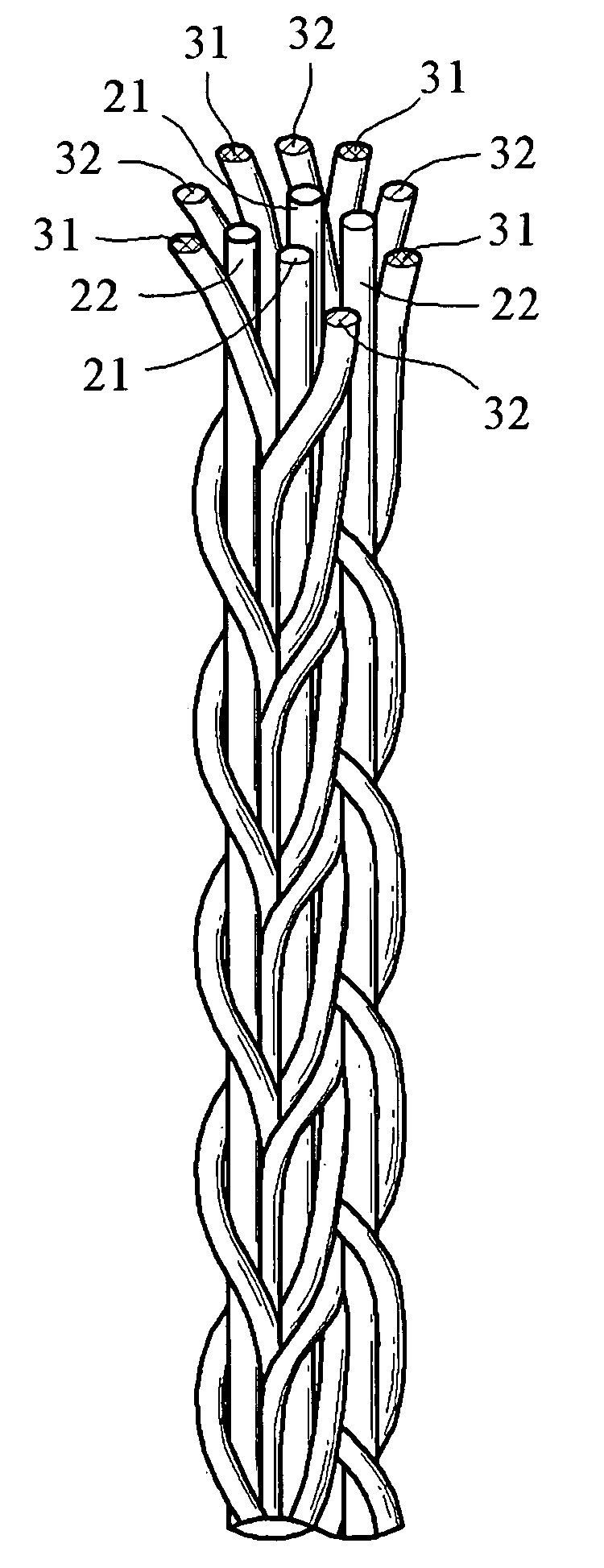

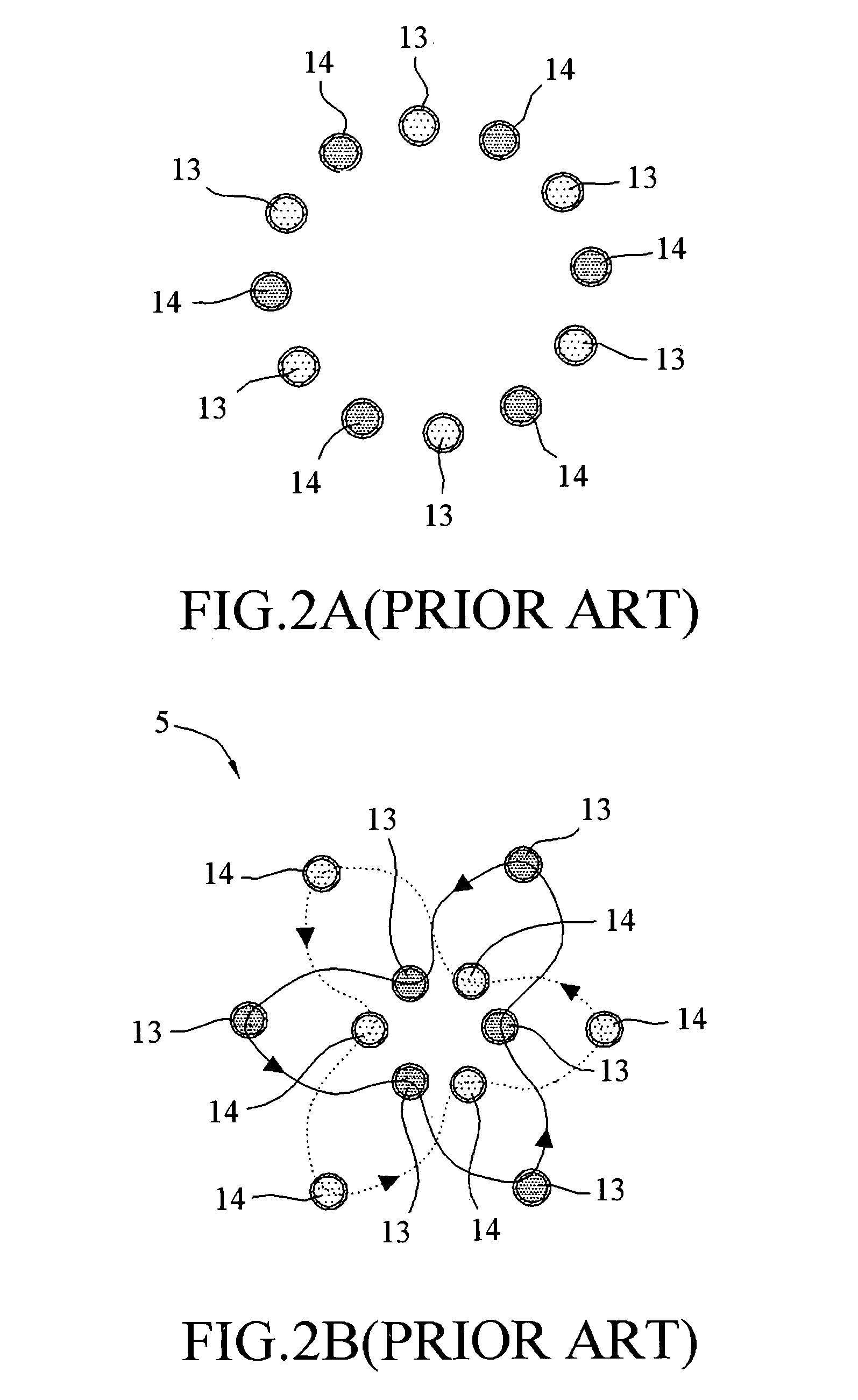

Sound signal wire and process for enhancing rigidity thereof

InactiveUS20050271235A1Improve rigidityEliminate generationNon-insulated conductorsCircuit lead arrangements/reliefPliabilityEngineering

A sound signal wire that has higher rigidity to prevent roping effect from reducing sound quality during vibration within a speaker frame, and / or also has a higher flexibility and tensile strength to make the vibrated sound signal wire more durable for use with a speaker for transmitting sound signals is disclosed. The sound signal wire is constructed from sets of weaving wire units which weave onto other sets of support wire units along specific paths, with acetal resin or polyurethane coating the surface of the wire. Each wire unit is comprised of an inner fiber and a conductive metal sheet encompassing the inner fiber, in which the inner fiber is a heat-resistant fiber that is made by a poly meta-aramid fiber mixed-woven with a poly para-aramid fiber.

Owner:TAIWAN MAEDEN

Sound signal wire and process for enhancing rigidity thereof

InactiveUS7141740B2Eliminate generationImprove rigidityNon-insulated conductorsCircuit lead arrangements/reliefAramidesEngineering

A sound signal wire that has higher rigidity to prevent roping effect from reducing sound quality during vibration within a speaker frame, and / or also has a higher flexibility and tensile strength to make the vibrated sound signal wire more durable for use with a speaker for transmitting sound signals is disclosed. The sound signal wire is constructed from sets of weaving wire units which weave onto other sets of support wire units along specific paths, with acetal resin or polyurethane coating the surface of the wire. Each wire unit is comprised of an inner fiber and a conductive metal sheet encompassing the inner fiber, in which the inner fiber is a heat-resistant fiber that is made by a poly meta-aramid fiber mixed-woven with a poly para-aramid fiber.

Owner:TAIWAN MAEDEN

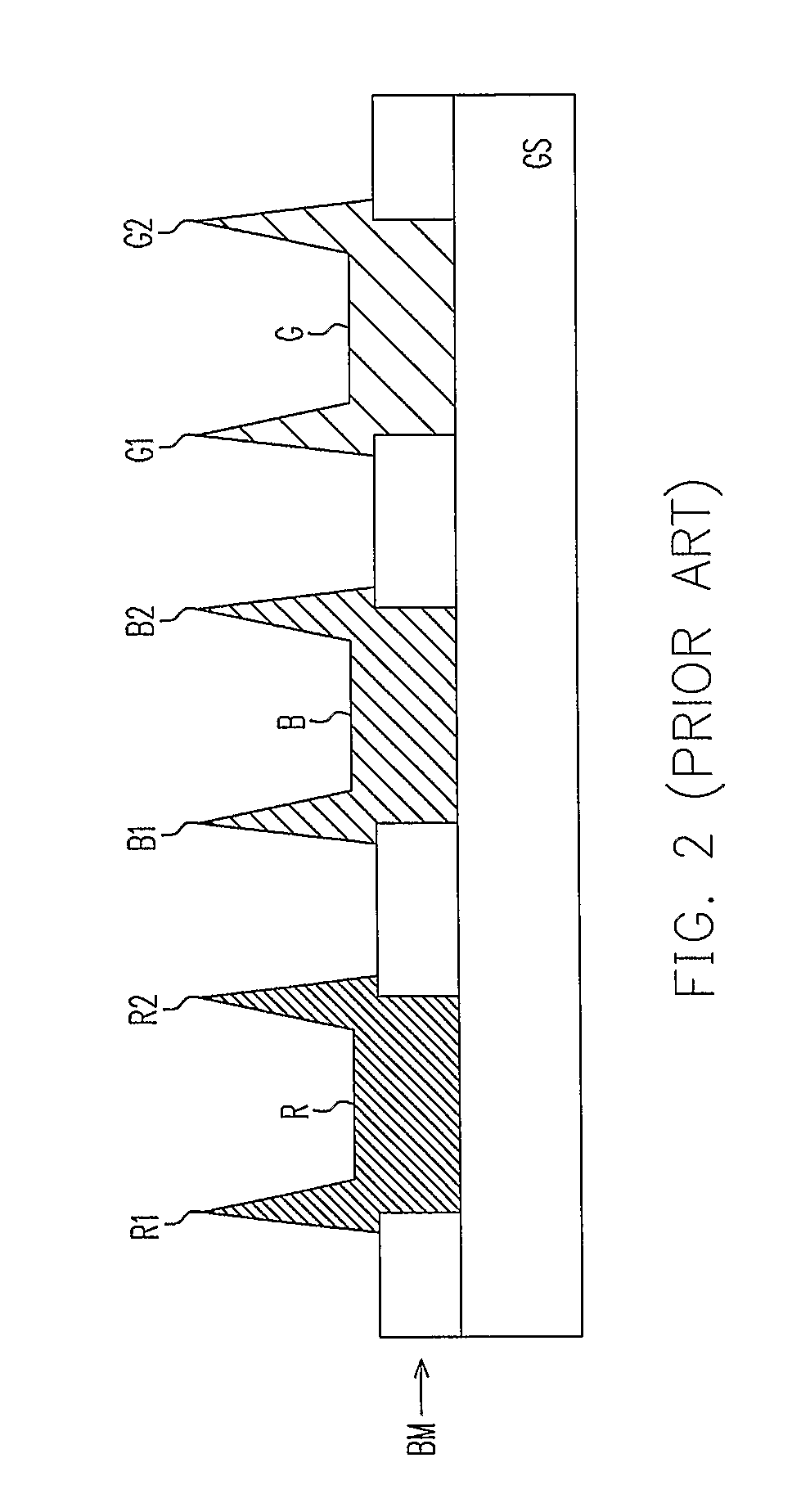

Slurry Composition For Color Filter Polishing

InactiveUS20080207091A1Reliability and service life of be ensureManufacture stability for be improvePigmenting treatmentPolishing machinesChemistryTitanium dioxide

The invention provides a slurry composition for polishing color filters. The slurry composition at least includes an abrasive, a buffer solution and an additive. The abrasive is selected from the group consisting of alumina, ceria, magnesia, silica, titania, zirconia, cupric oxide, ferric oxide, zinc oxide and the mixture thereof. The buffer solution is used for adjusting pH to a desired range. The additive is used for stabilizing the polishing composition and also improving the polishing performance.

Owner:BASF SE

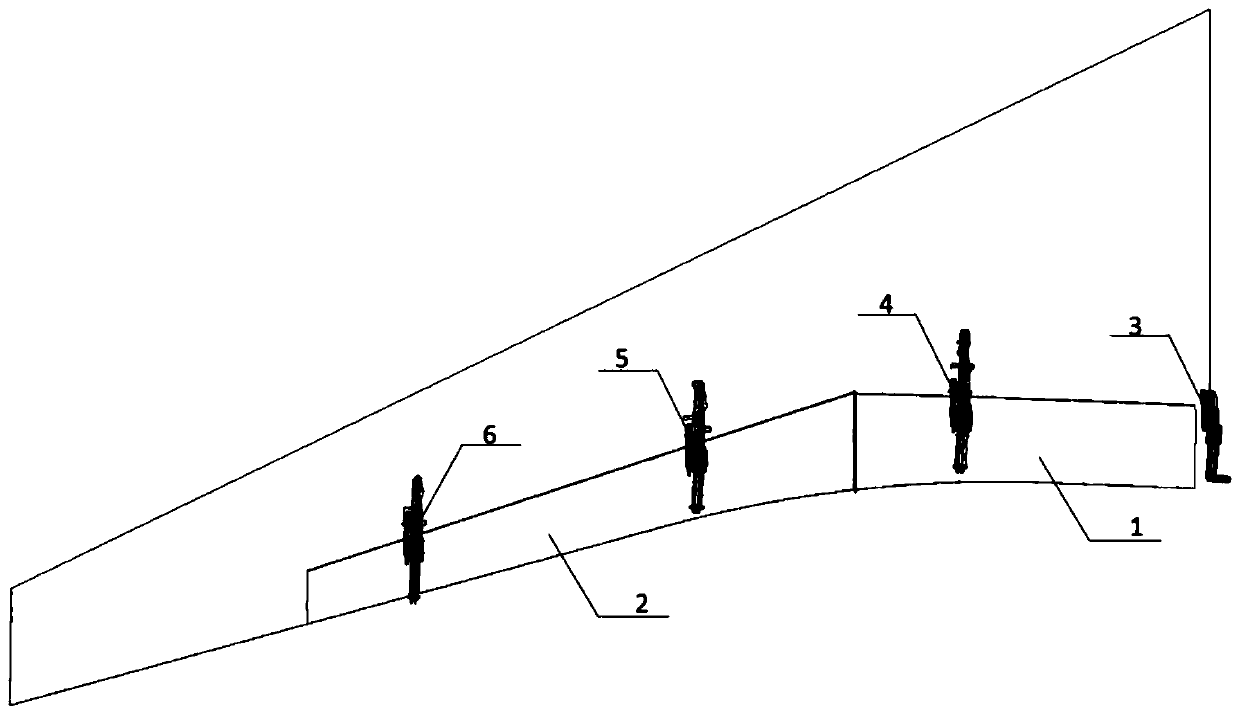

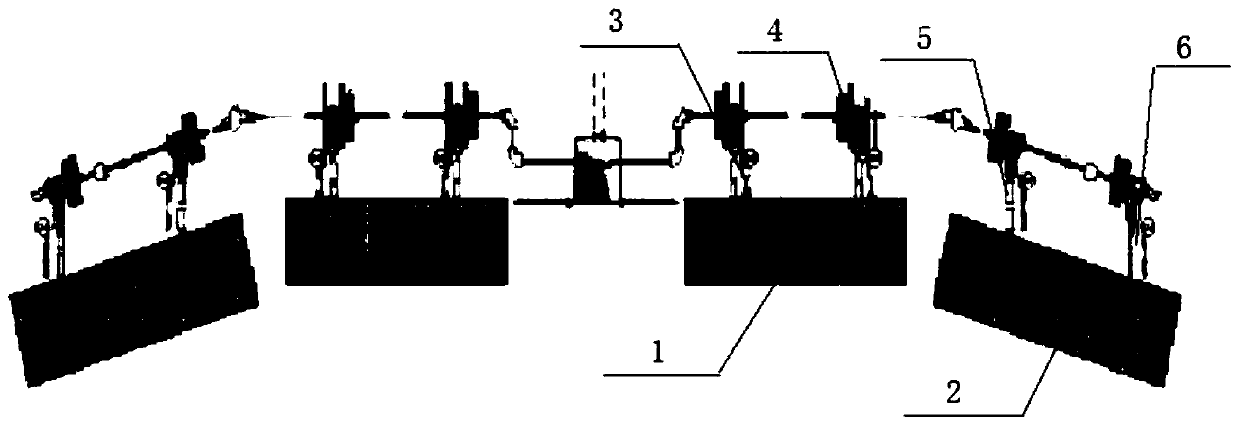

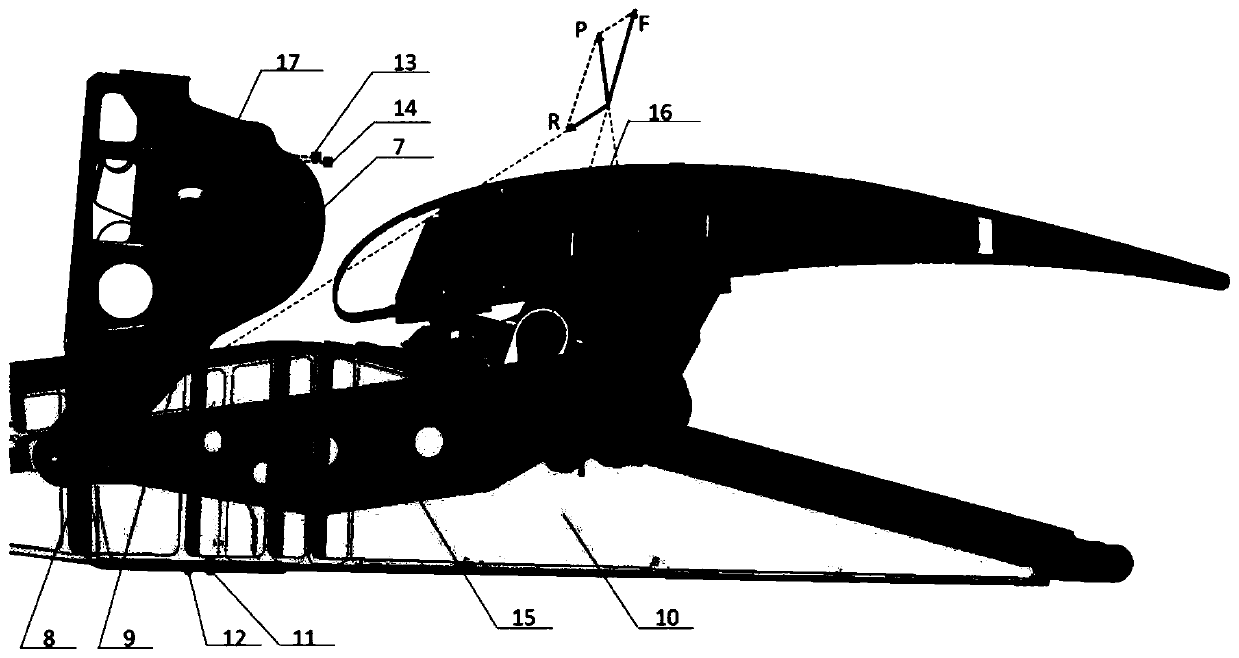

Motion mechanism, measurement system and method for wing flap load trial flight verification

ActiveCN110498062AModification technology is simpleLow costAircraft components testingGratingStrain sensor

The invention provides a motion mechanism for wing flap load trial flight verification. The motion mechanism is arranged between wing flaps and a wing structure and used for controlling motion of thewing flap relative to the wing structure. The motion structure comprises a load bearing component and a testing optical fiber, wherein the load baring component comprises a component used for bearingstress when driving the wing flaps to move relative to the wing structure, and further comprises bragg grating strain sensors and a bragg grating temperature sensor are arranged on stress measurementpoints; the testing optical fiber is used for connecting the bragg grating strain sensors and the bragg grating temperature sensor on the load bearing component of the motion mechanism in series; andthe testing optical fiber comprises an input end and an output end. The invention further provides a measurement system for wing flap load trial flight verification, a method for wing flap load trialflight verification and a computer storage medium.

Owner:COMAC +1

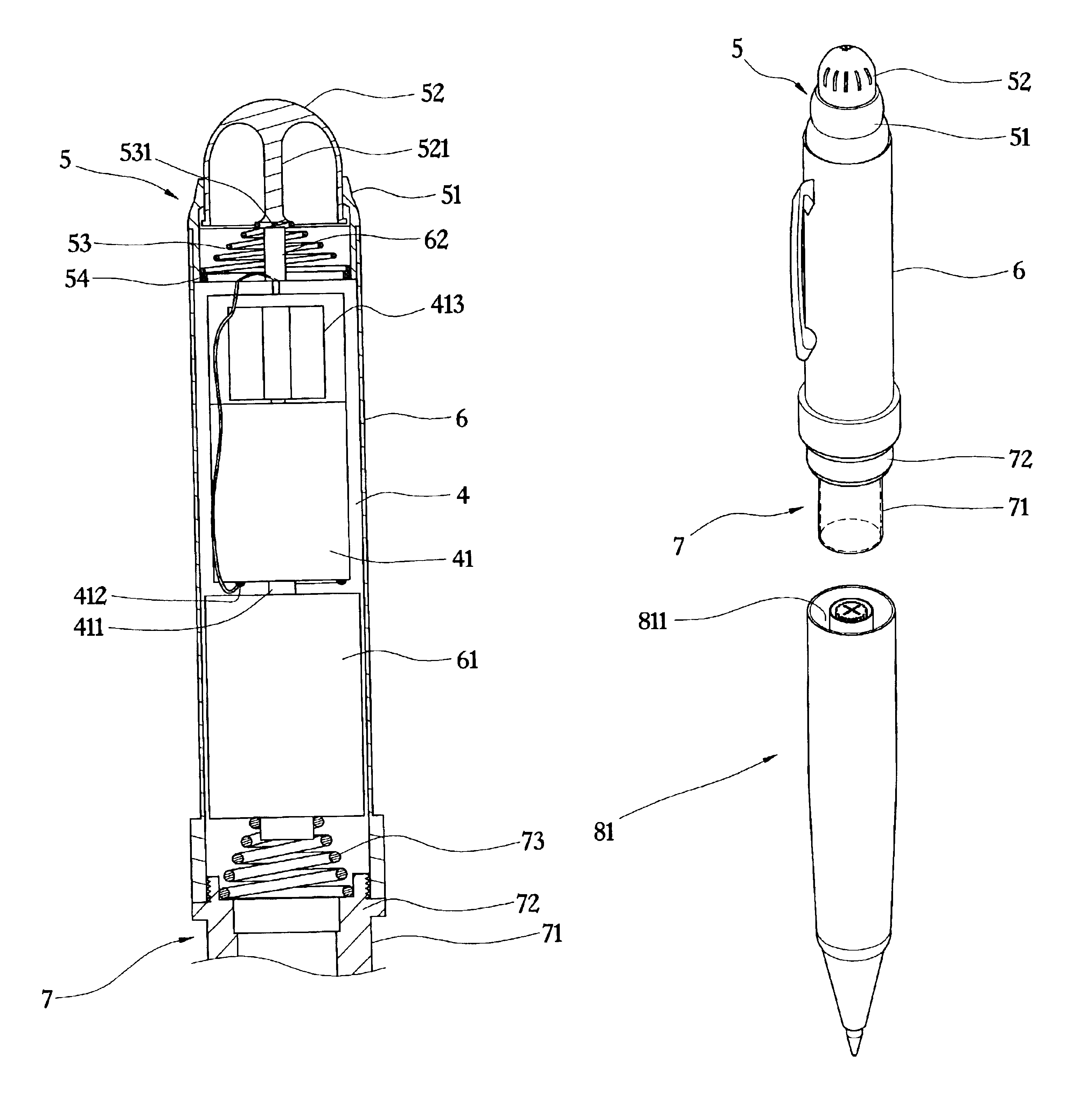

Multi-functional massage device

InactiveUS6802818B2Avoid deformationQuality improvementWriting implementsChiropractic devicesMassageEngineering

Owner:WANG KUAN YUN +2

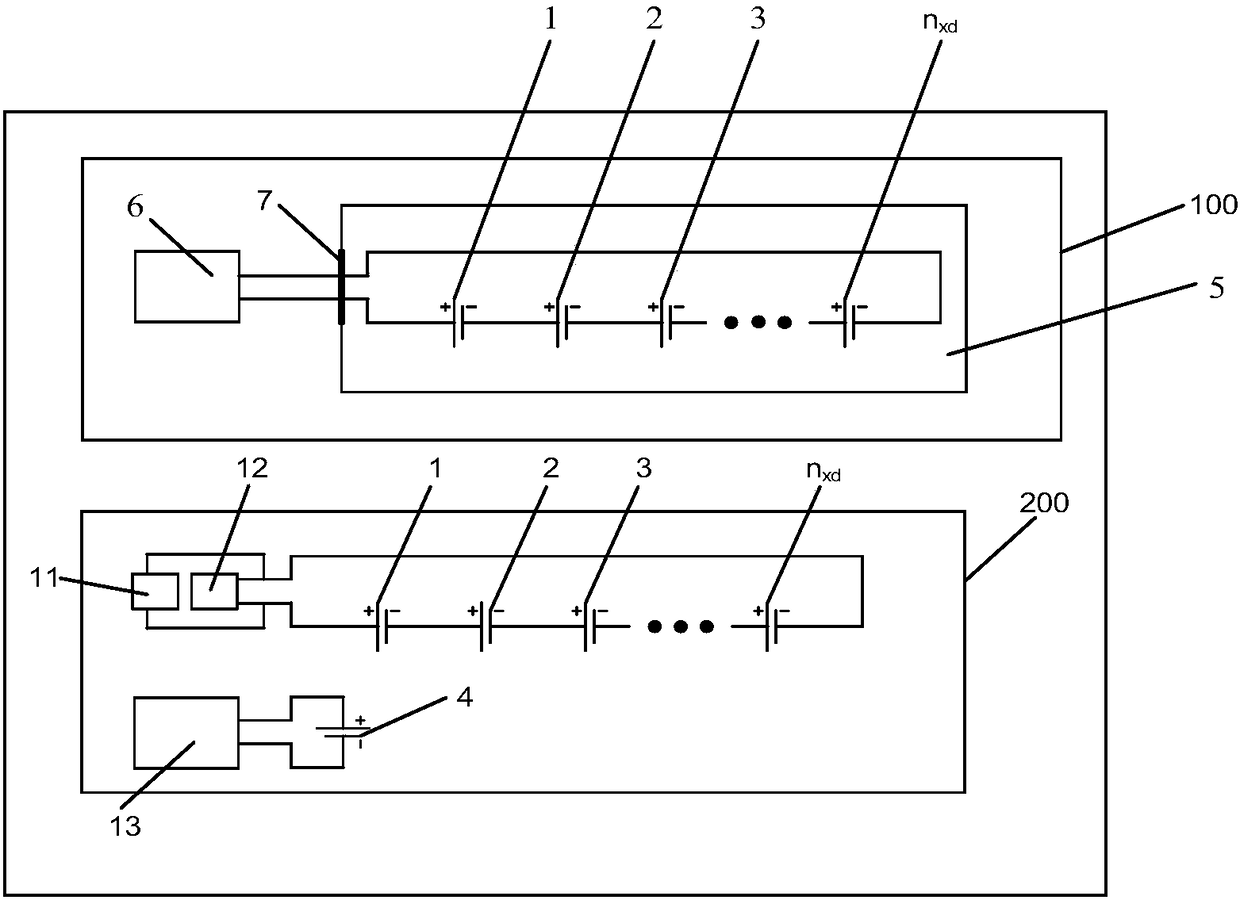

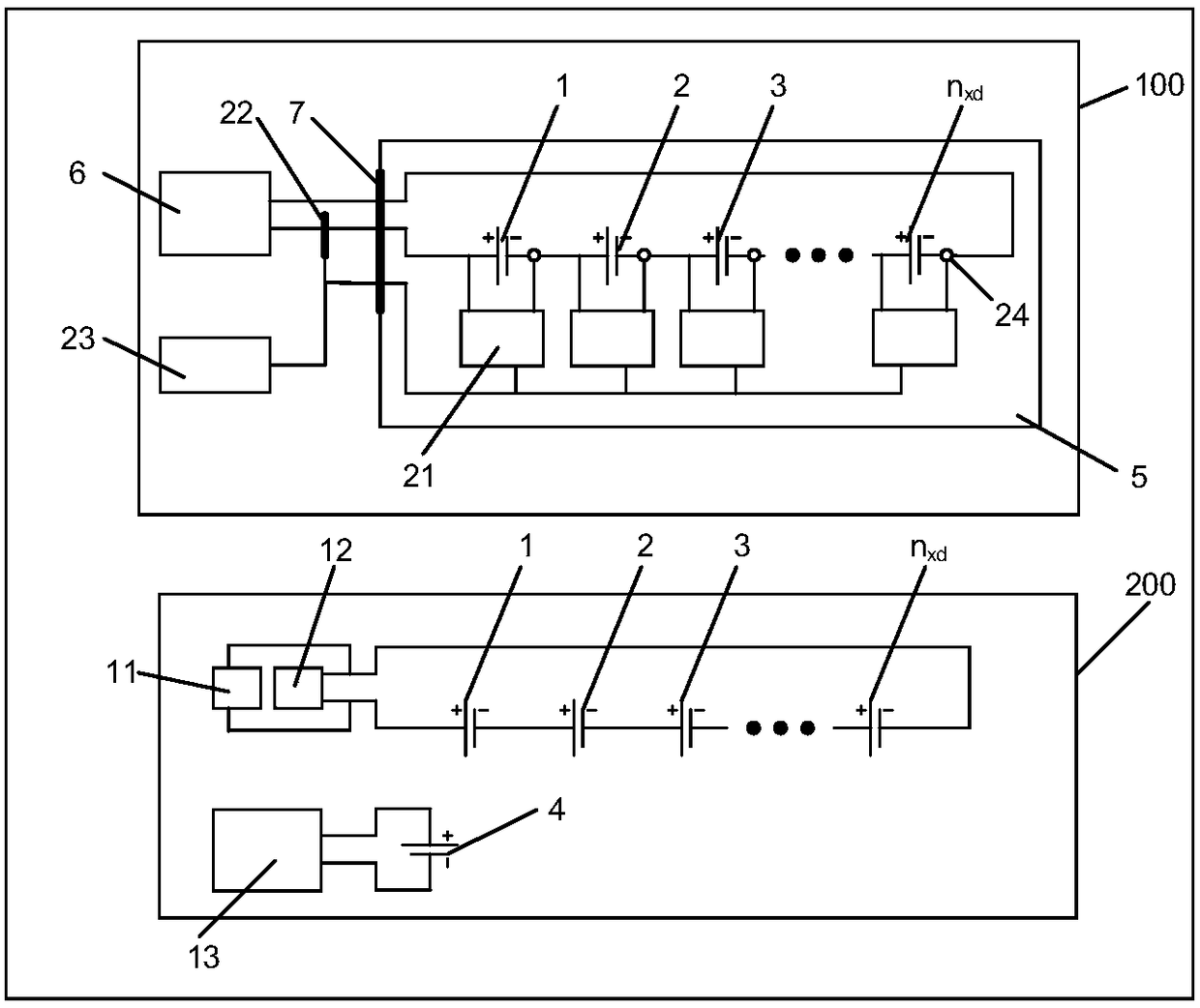

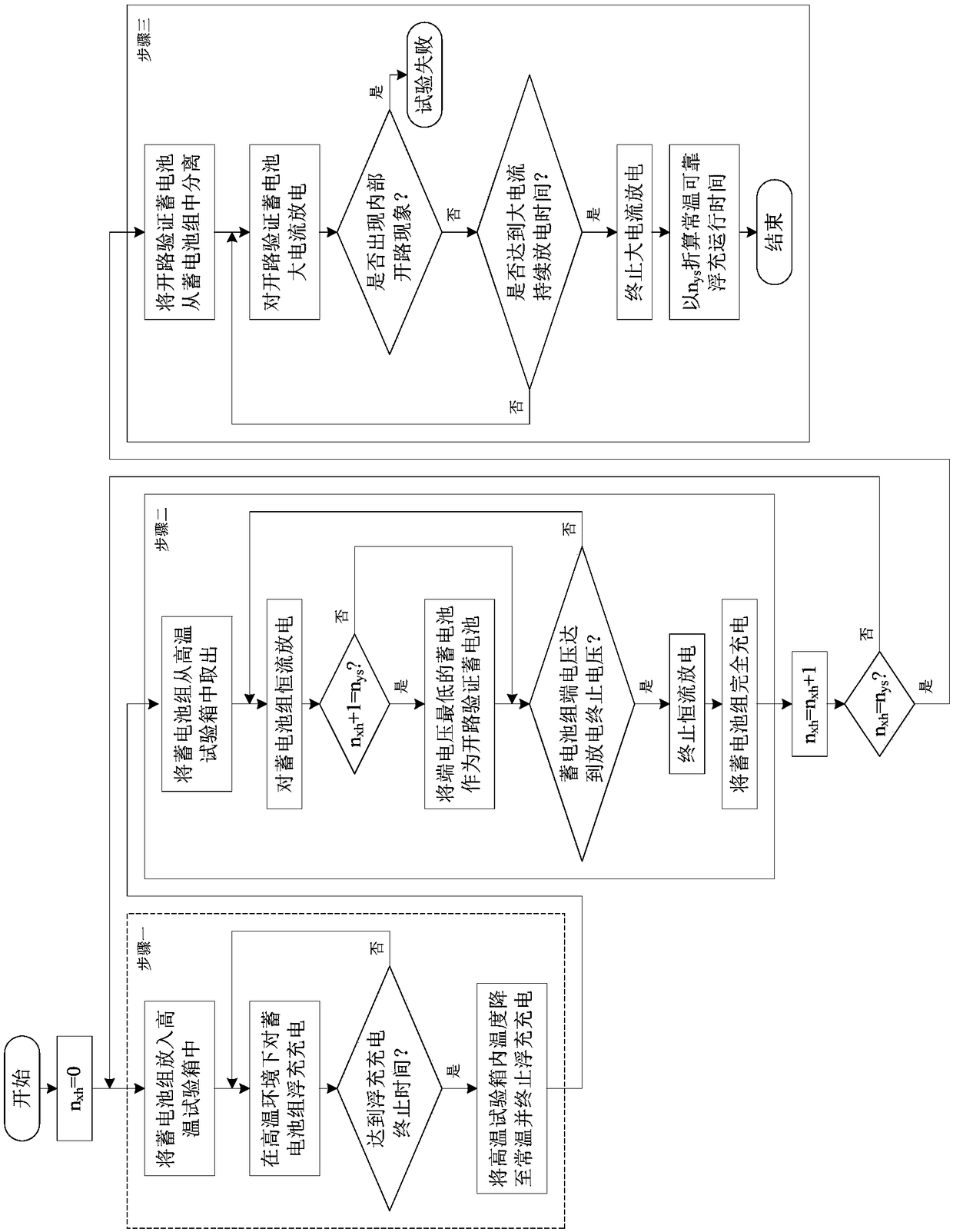

Lead acid storage battery open failure test system and prediction method

ActiveCN108445413AIncrease temperatureSpeed up corrosionElectrical testingFloating chargeEngineering

The invention provides a lead acid storage battery open failure test system and prediction method. The lead acid storage battery open failure test system comprises a lead acid storage battery high temperature accelerated corrosion subsystem and a lead acid storage battery normal temperature charge and discharge subsystem. The lead acid storage battery high temperature accelerated corrosion subsystem is used for performing constant floating charging to the lead acid storage battery pack under the high temperature environment and comprises a high temperature test box, a floating charging deviceand a storage battery monitoring device. The a lead acid storage battery normal temperature charge and discharge subsystem is used for performing the discharge or charge test on the lead acid storagebattery pack or the open verification storage battery under the normal temperature environment and comprises a constant current discharge load, a charging device and a high current discharge load. Compared with the systems and the methods in the prior art, the lead acid storage battery open failure test system and prediction method have the beneficial effects that the reliable service life of thelead acid storage battery before open failure caused by internal corrosion under the condition of constant floating charging under the normal temperature environment can be predicted.

Owner:CHINA ELECTRIC POWER RES INST +2

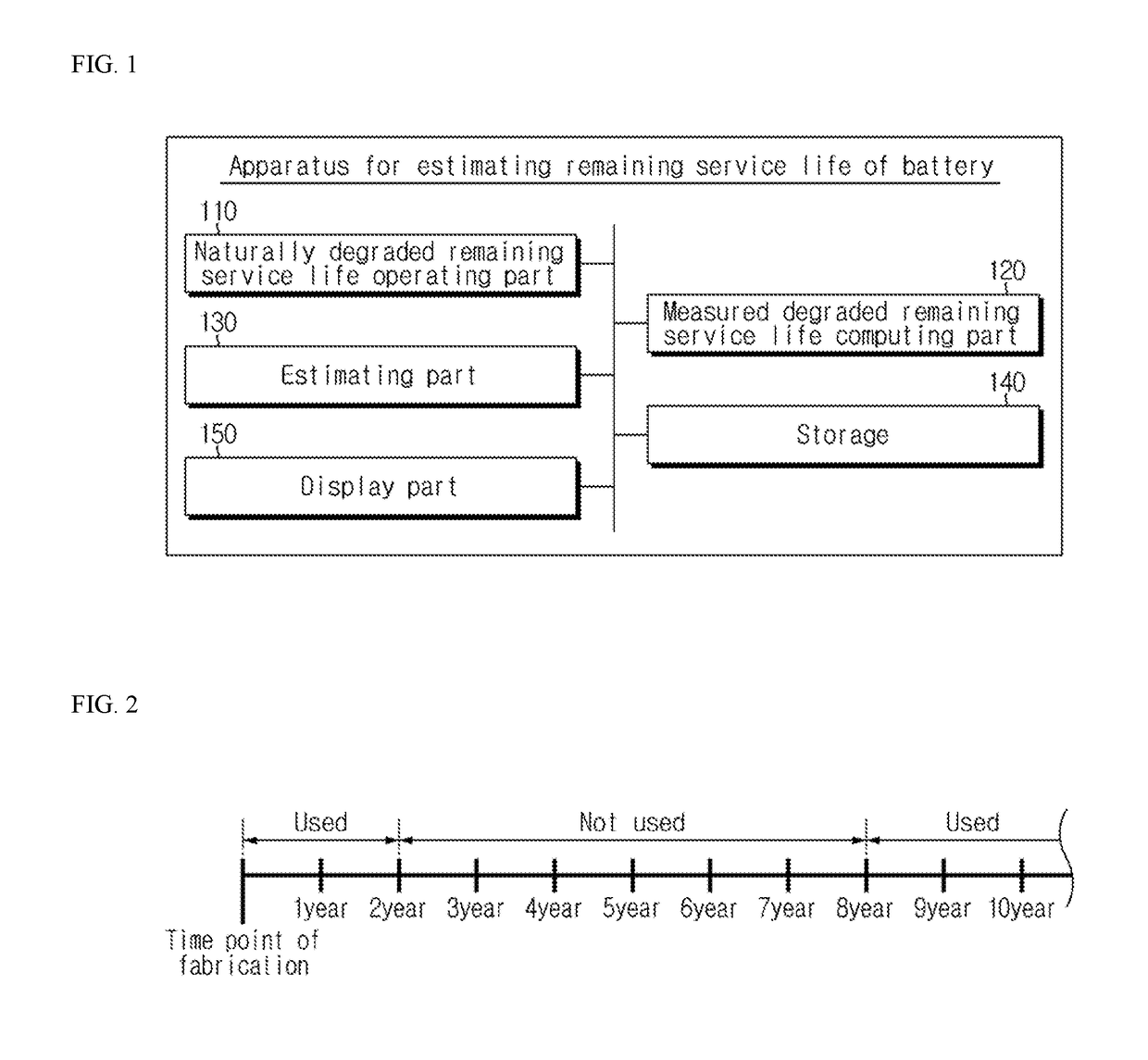

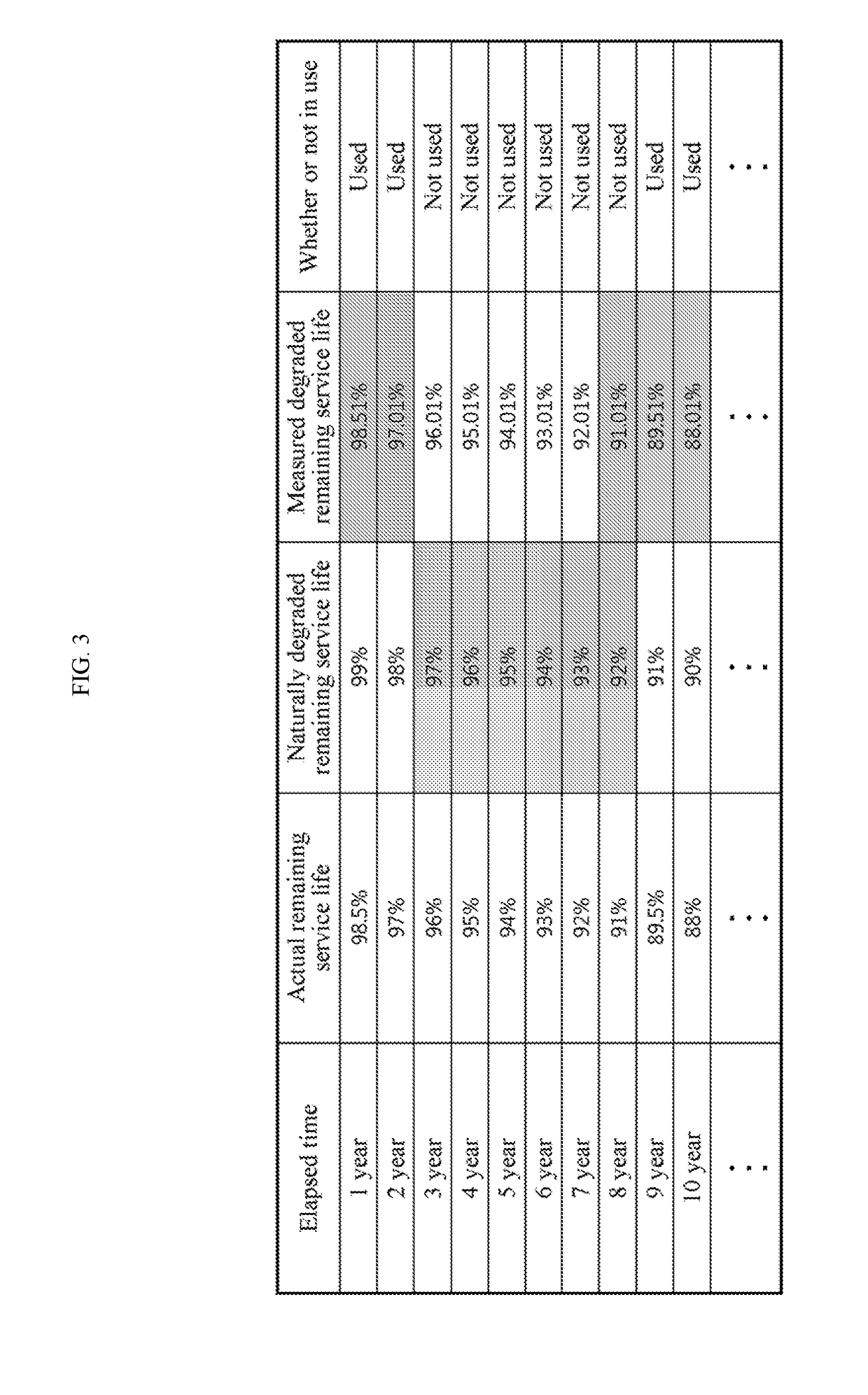

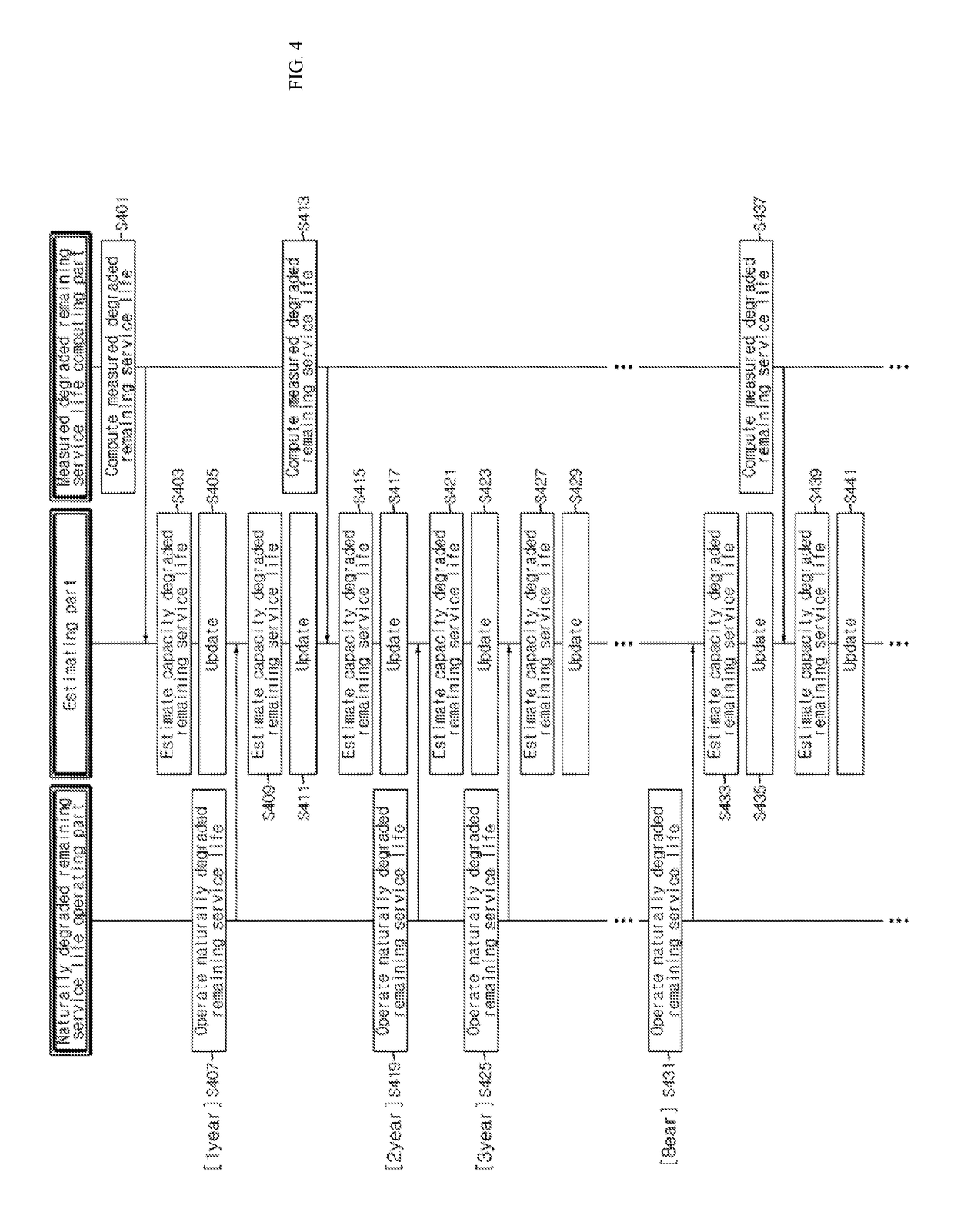

Apparatus and method for estimating remaining service life of battery

ActiveUS20170199248A1Reliable service lifeReduce decreaseElectrical testingReliability engineeringService life cycle

Owner:LG ENERGY SOLUTION LTD

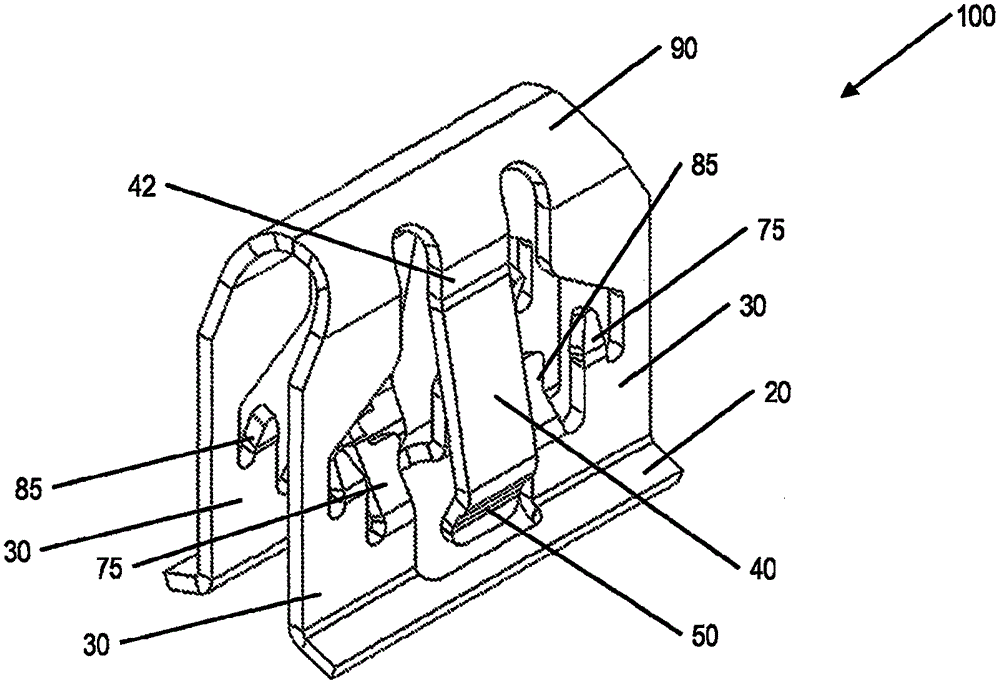

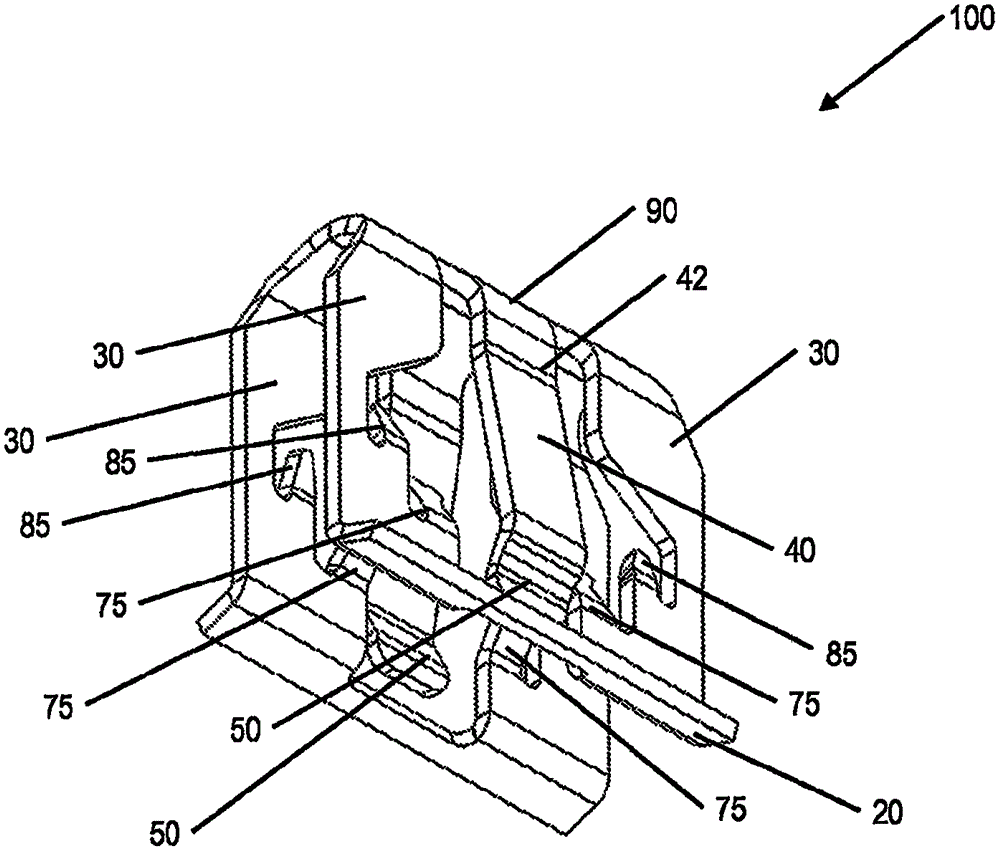

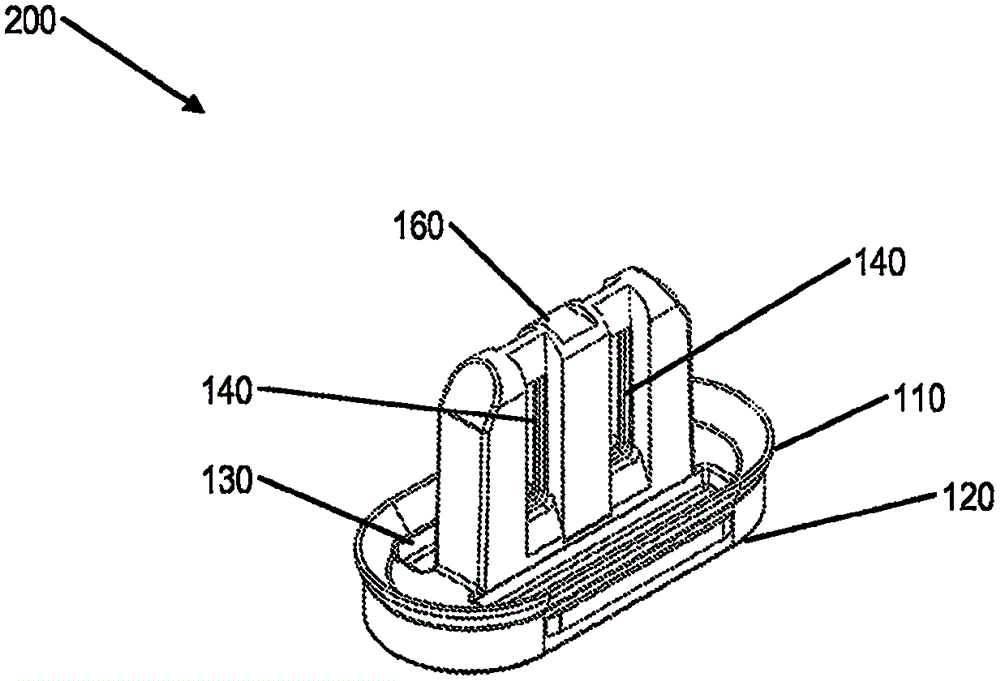

Fastener clip over carrier

ActiveCN106369032AEasy to attachHigh level of extractionSnap-action fastenersSheet joiningEngineeringBiomedical engineering

The invention relates to a fastener clip over a carrier. A fastener clip system includes the carrier and the fastener clip configured to fit over the carrier. The fastener clip includes at least one wing. The wing includes an engagement region that includes a depressed portion configured to be secured against a slot.

Owner:TERMAX CORP

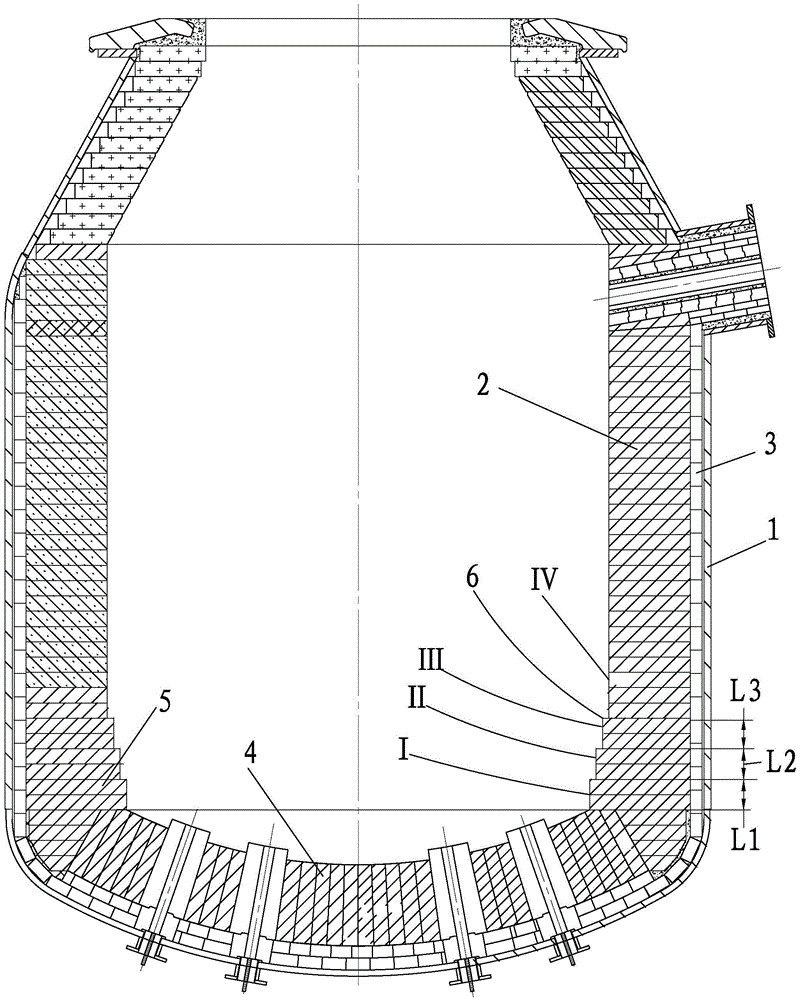

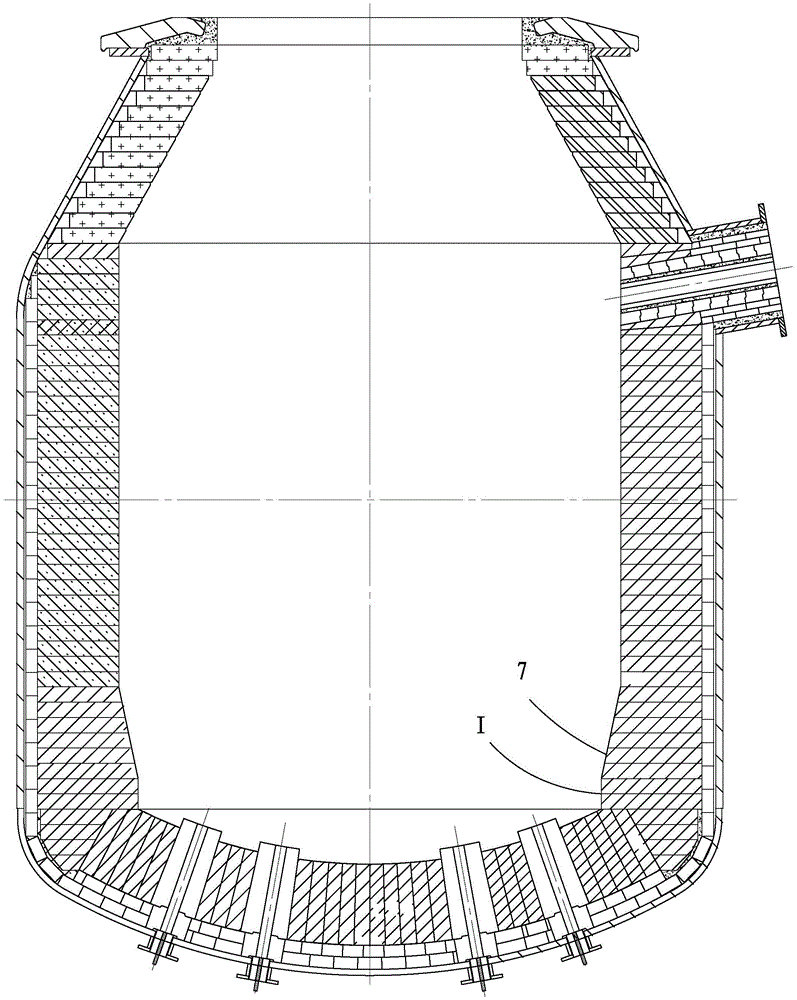

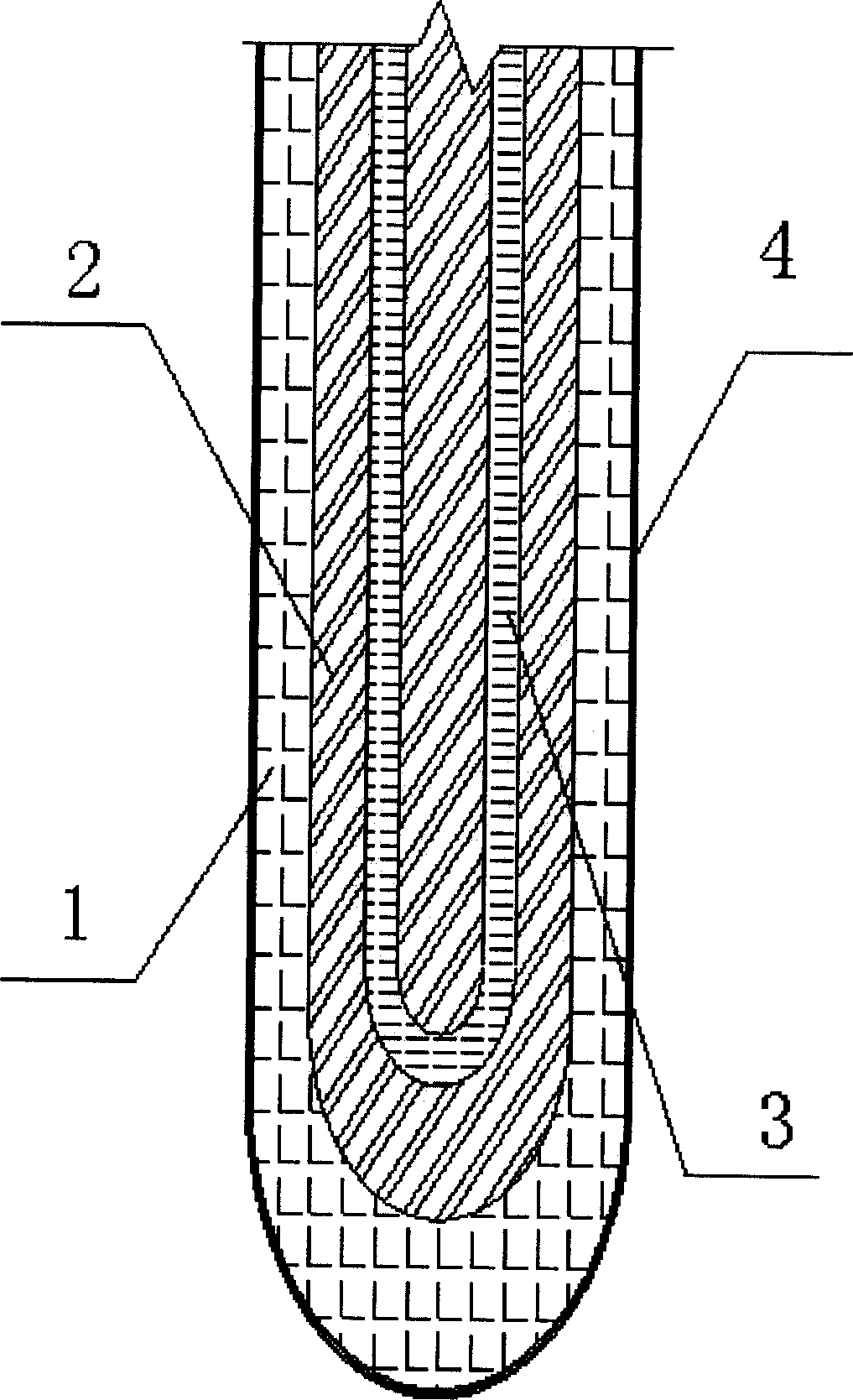

Converter lining structure

InactiveCN105603149AImprove corrosion resistanceImprove safety and reliabilityManufacturing convertersMelting tankBrick

The invention discloses a converter lining structure. The converter lining structure comprises a converter body at the outer side and a permanent layer lining connected with the converter body, wherein a working layer lining is arranged at the inner side of the permanent layer lining, the working layer lining comprises a converter bottom and a molten bath, the bottom of the molten bath is connected with the converter bottom, a plurality of layers of annular magnesium carbon brick bodies are superposed in the height direction of the molten bath to form a molten bath integral structure, the horizontal length of the plurality of layers of annular magnesium carbon brick bodies is gradually increased from an upper layer to a bottom layer, the thickness of the molten bath is gradually increased from the upper layer to the bottom layer, and the diameter of an inner cavity of each layer is gradually reduced from the upper layer to the bottom layer. By adopting the converter lining structure, the erosion speed of the molten bath lining bricks can be slowed down, the service life of the converter lining is prolonged, the safety of the lining is guaranteed, and the consumption of a magnesium material and a repairing mass in the production process of a converter is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

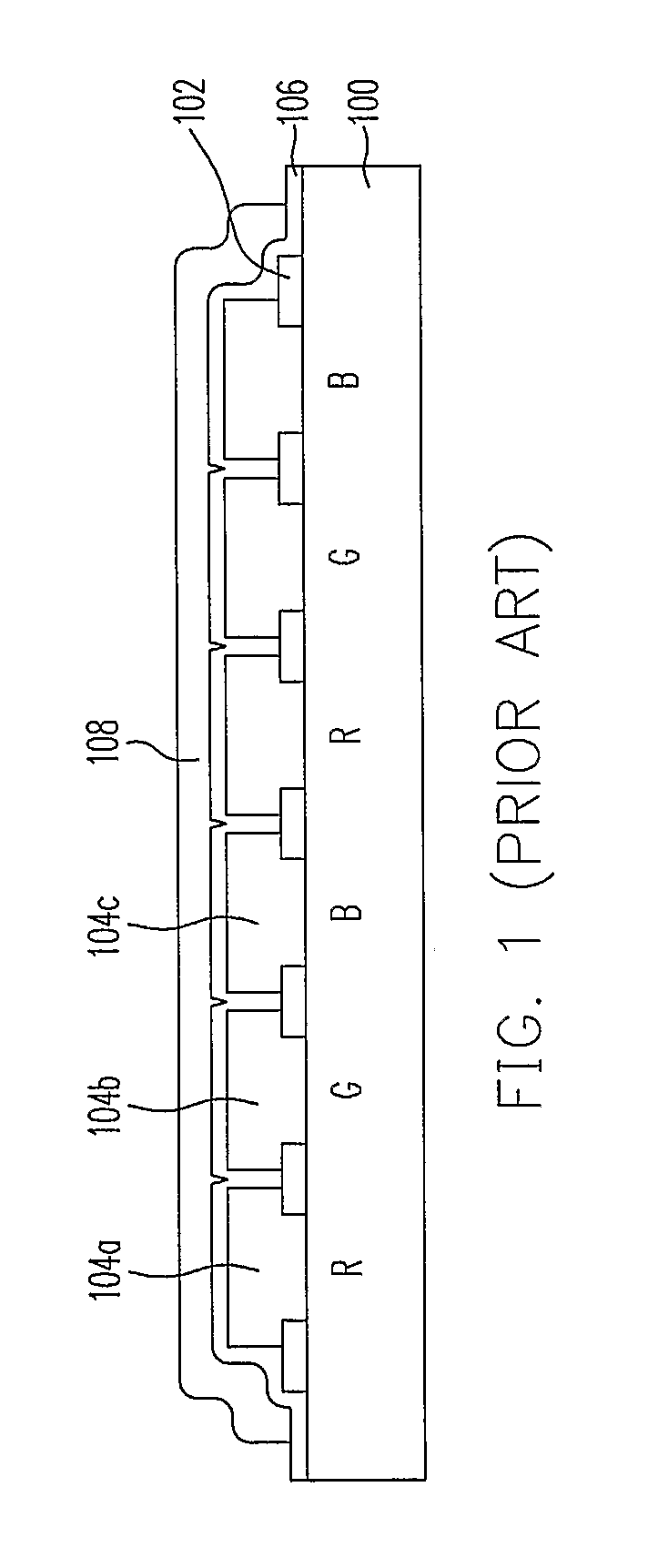

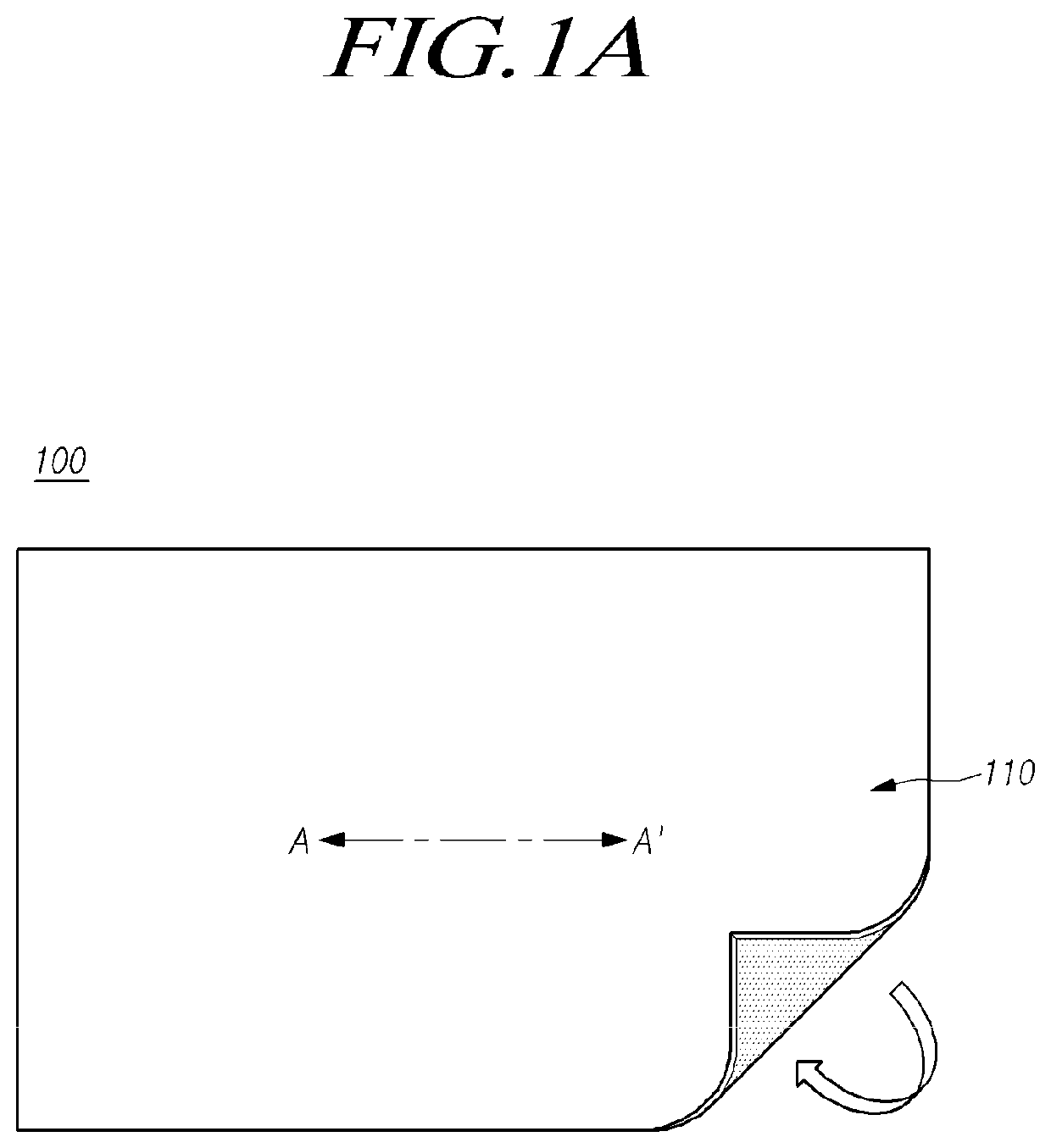

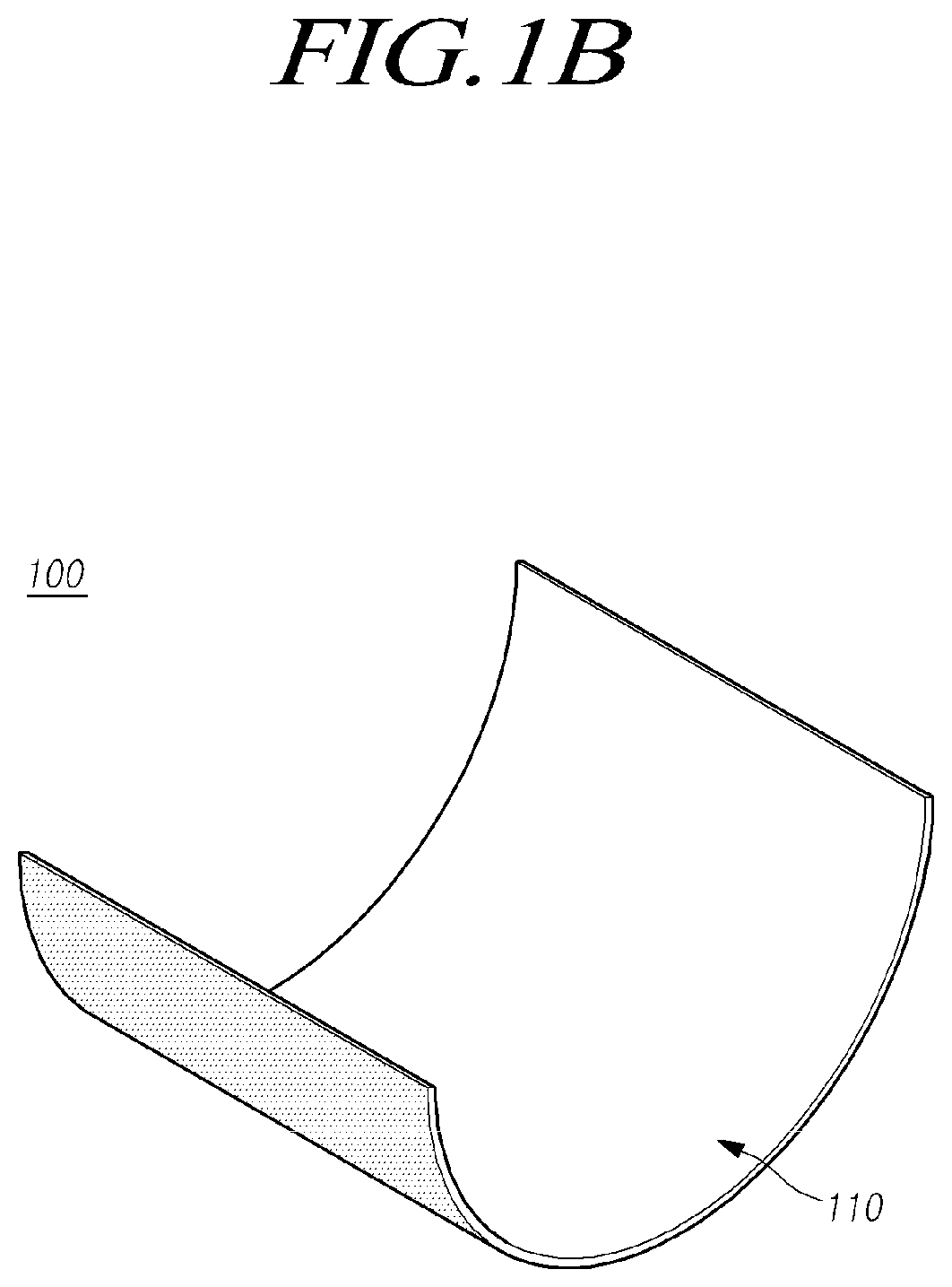

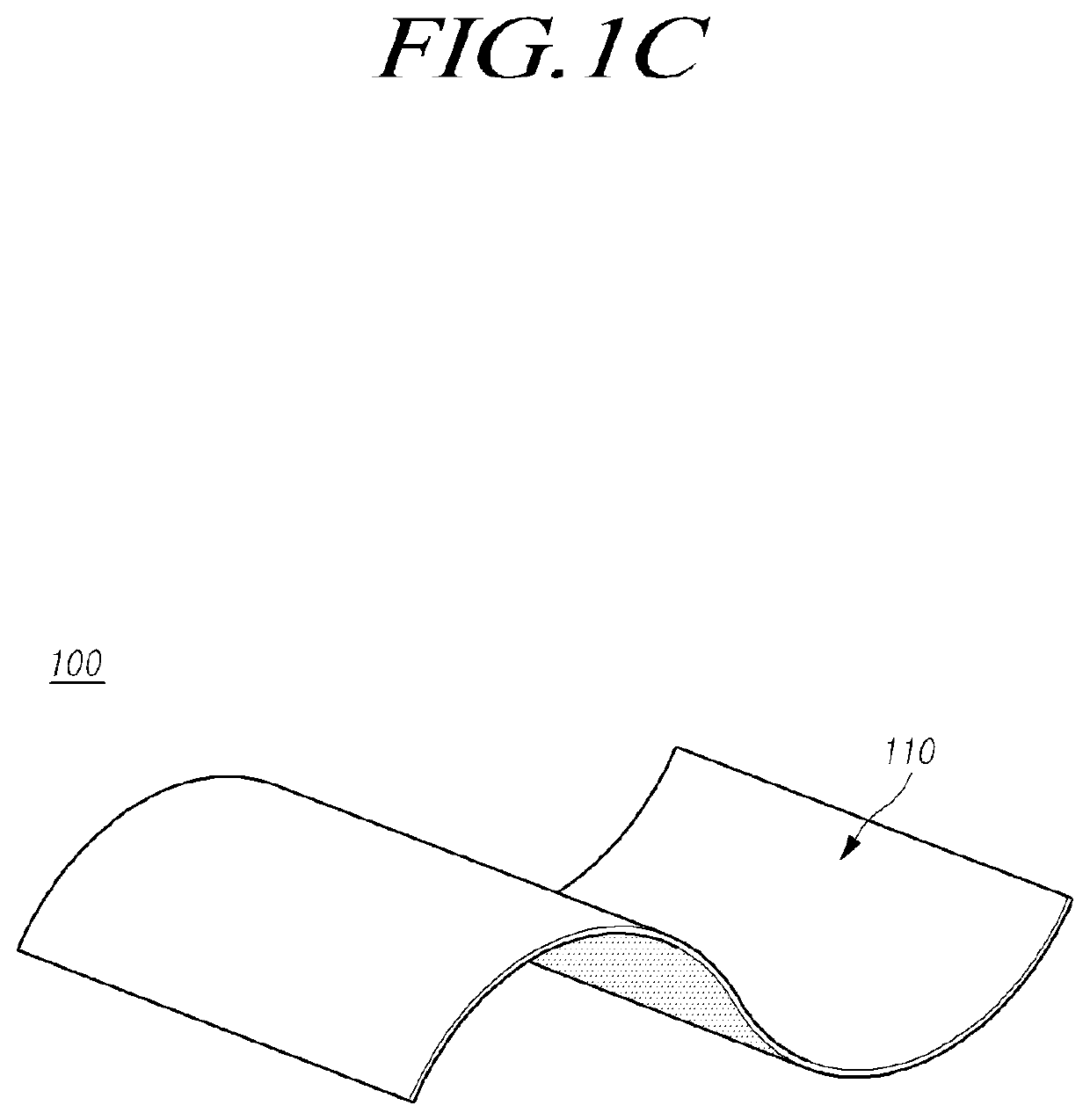

Flexible display apparatus

ActiveUS20200168823A1Reliable service lifeReduce harmSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayPhysics

A flexible display device including a well structure. An organic light-emitting element including a pixel electrode, an organic light-emitting layer, and a common electrode is disposed on a substrate. A bank layer is disposed on the pixel electrode, and is disposed to open at least a part of the pixel electrode. Further, at least one well structure is disposed on the bank layer. The well structure disposed on the bank layer can reduce or minimize a delamination phenomenon of an encapsulation layer which can occur due to compressive and tensile stress caused by bending of the flexible display device.

Owner:LG DISPLAY CO LTD

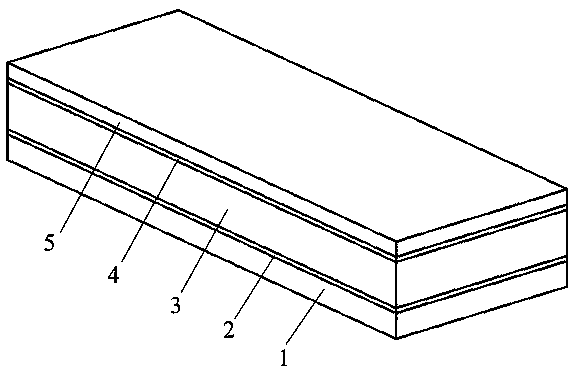

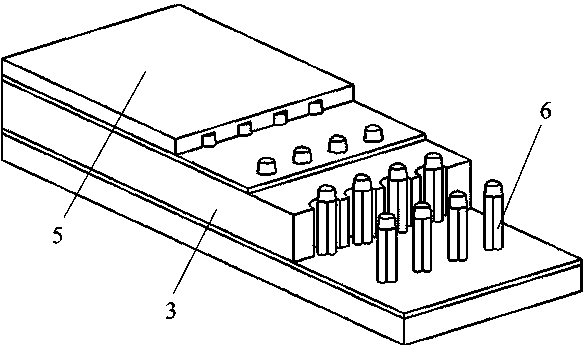

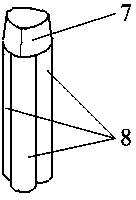

Bionic dolphin skin based on electroactive polymer artificial muscles

InactiveCN103832541AFlexible working mechanismFlexible working mechanism is controllableWatercraft hull designHydrodynamic/hydrostatic featuresManufacturing technologyBionics

The invention relates to the technical field of engineering bionics, in particular to bionic dolphin skin based on electroactive polymer artificial muscles. The bionic dolphin skin comprises a supporting base, a hardened conducting layer, a flexible resin layer, a flexible conducting layer, a smooth rubber layer and an artificial muscle stretching and contraction unit, wherein the artificial muscle stretching and contraction unit comprises a certain number of electroactive polymer artificial muscle bundles and stretching heads. Compared with the prior art, the electroactive polymer artificial muscles are used for simulating elastic mastoids in a dolphin skin structure, functions which are shown when the electroactive polymer artificial muscles are powered on and contract and very similar to those of biological muscles are used for simulating biological functions of the elastic mastoids in the dolphin skin structure, the flexible working mechanism of the bionic dolphin skin is more flexible and controllable, and beneficial examples are provided for engineering bionics technologies, particularly, bionic anti-drag surface manufacturing technologies in terms of structural and functional bionics.

Owner:SHANDONG UNIV OF TECH

Stainless steel pipe circular automatic welding member of heating radiator and manufacturing method thereof

ActiveCN107234356ASimple structureEasy to replaceWelding/cutting auxillary devicesAuxillary welding devicesCircular discSteam line

The invention provides a stainless steel pipe circular automatic welding member of a heating radiator. In a steel-channel-combined frame structure, a balancing cork base makes contact with a bottom port of a horizontal communicating pipe on the lower side of the heating radiator, an upper port of a horizontal communicating pipe on the upper side of the heating radiator makes contact with a welding gun fixed to a rotating shaft, an air cylinder guiding rod descends, the rotating shaft is inserted into a vertical stand pipe, and the rotating shaft is further provided with the welding gun; the welding gun rotates by a circle with the rotating shaft which is inserted into a polyurethane circular disc of the vertical stand pipe as the circle center, the rotating shaft and a pipe core bearing rotate, and the polyurethane circular disc does not rotate; a coupling is inserted into the upper part of the rotating shaft, and the coupling is connected with a lower main shaft of a reducer; the reducer is connected with a motor, and an upper main shaft of the reducer is connected with a circular disc spring; the main shafts of the reducer and the rotating shaft positively rotate by one circle, simultaneously, the welding gun and a steam line on the welding gun positively rotate by one circle, the circular disc spring is stretched, the main shafts of the reducer are stopped, a control button which electrically arranged is automatically twisted to a neutral position, the circular disc spring retracts, the main shafts of the reducer drive the rotating shaft and the welding gun to oppositely rotate by one circle, and the steam line of the welding gun is restored.

Owner:ZAOZHUANG FUYUAN ENVIRONMENTAL PROTECTION & ENERGY SAVING MACHINERY MFG CO LTD

Solid type thermocouple specially for aluminum anode roasting and producing method

InactiveCN1715845AReliable service lifeImprove protectionThermometers using electric/magnetic elementsUsing electrical meansAluminum anodeRefractory

The solid type thermocouple special for aluminum anode roasting furnace includes refractory protecting alloy tube, refractory electrically isolating and heat transferring material, thermocouple filament and refractory protecting coating. The making process of the solid type thermocouple includes making cylindrical refractory protecting alloy tube of 4-6mm thick wall, setting the thermocouple filament with ceramic beads and protecting corundum tube inside the refractory protecting alloy tube, filling refractory electrically isolating and heat transferring material inside the refractory protecting alloy tube in the compaction degree over 95 % in integral sealing and filling process, and final spraying refractory anticorrosive layer onto the refractory protecting alloy tube. The present invention has greatly prolonged service life and high production efficiency.

Owner:GUIYANG AL-MG DESIGN & RES INST

Sample collecting and sampling device for field rock geological survey

ActiveCN113640050AAchieve coolingImprove securityWithdrawing sample devicesClassical mechanicsElectric machinery

The invention discloses a sample collecting and sampling device for field rock geological survey. The sample collecting and sampling device comprises a device base body, a driving assembly, a sampling assembly and a controller, the device base body is provided with an operation holding rod, the driving assembly comprises a rotating motor, a moving motor, a moving disc, a lifting screw rod and a mobile power supply, the lifting screw rod is clamped with the inner wall of the device base body, the moving disc is arranged in the device base body and connected with the lifting screw through the rotating sleeve, the moving motor provides power for the lifting screw rod, the rotating motor provides power for the moving disc, and the mobile power source is electrically connected with the rotating motor and the moving motor. The sampling assembly comprises a first sampling barrel and a second sampling barrel, the second sampling barrel is arranged in the first sampling barrel in a sleeving manner, the first sampling barrel and the second sampling barrel are connected with the moving disc, a cutting blade is arranged on the second sampling barrel, and the controller is electrically connected with the electric equipment. The device is reasonable in structural design and convenient to operate, and creates convenient conditions for field rock geological exploration.

Owner:山东省地质矿产勘查开发局第四地质大队

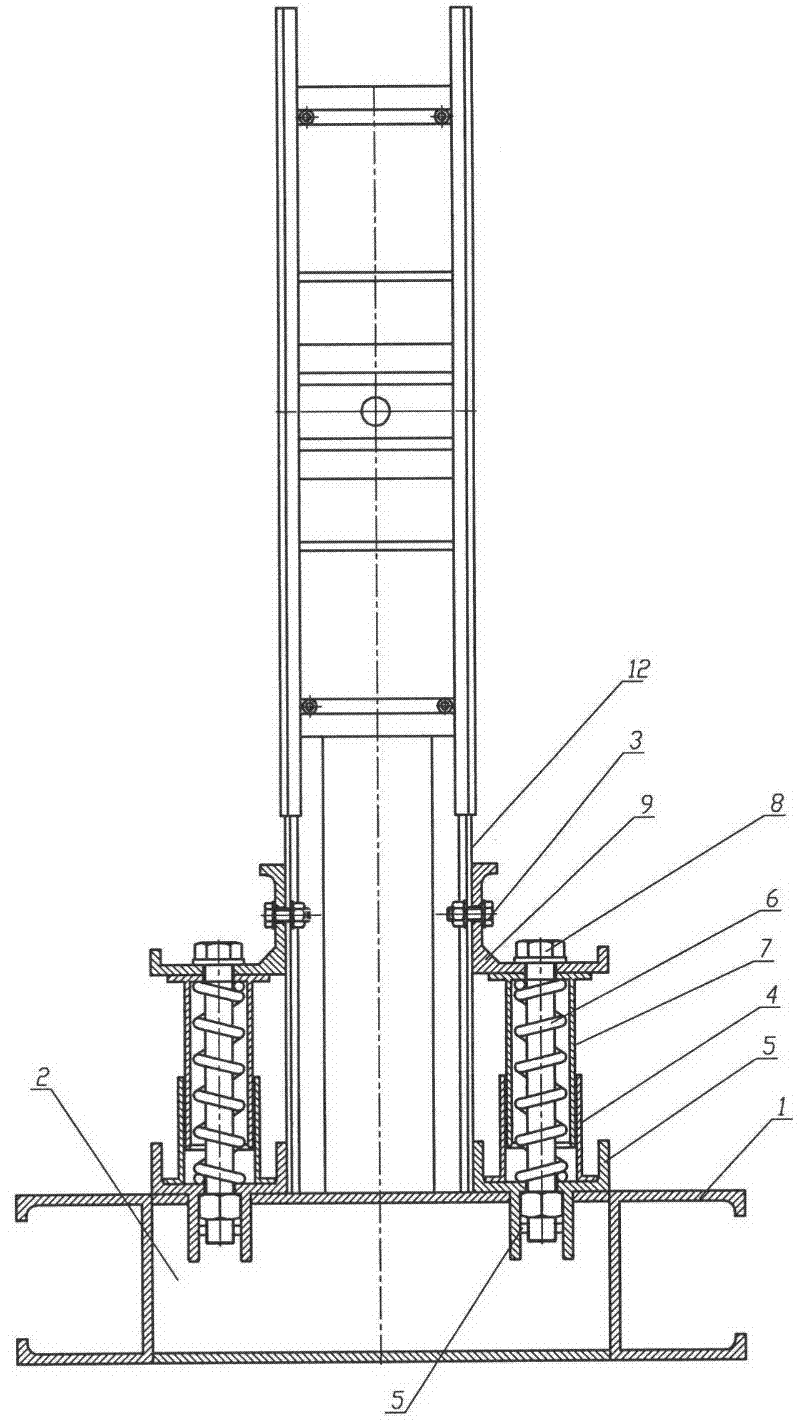

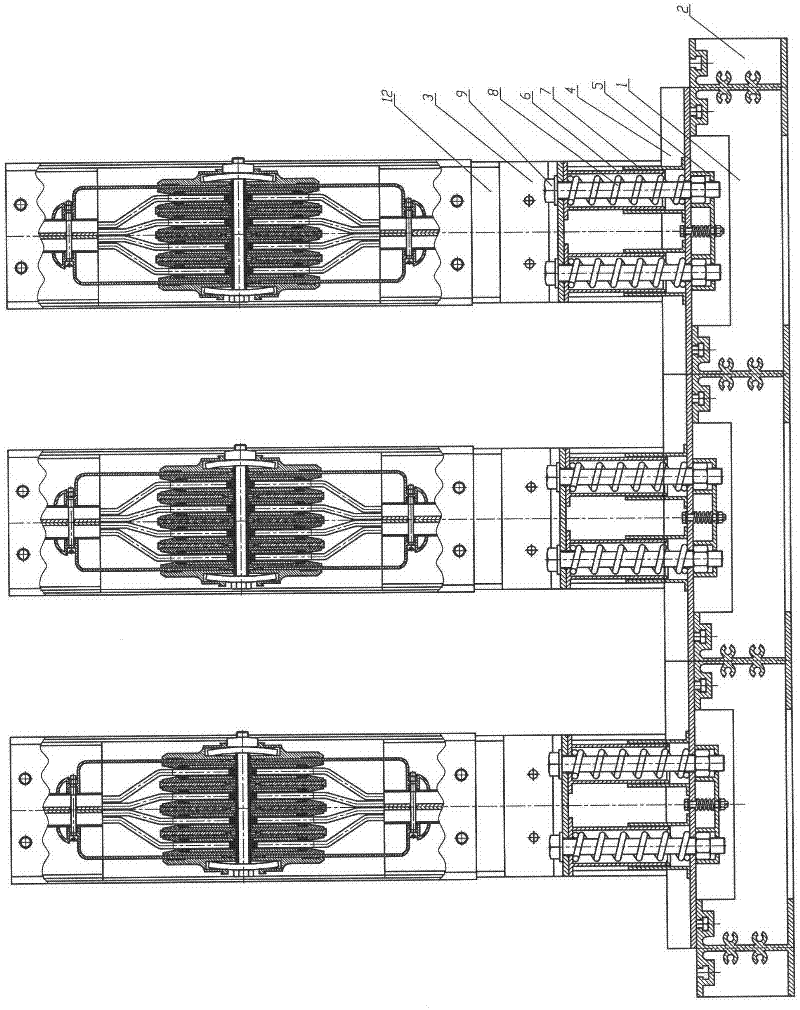

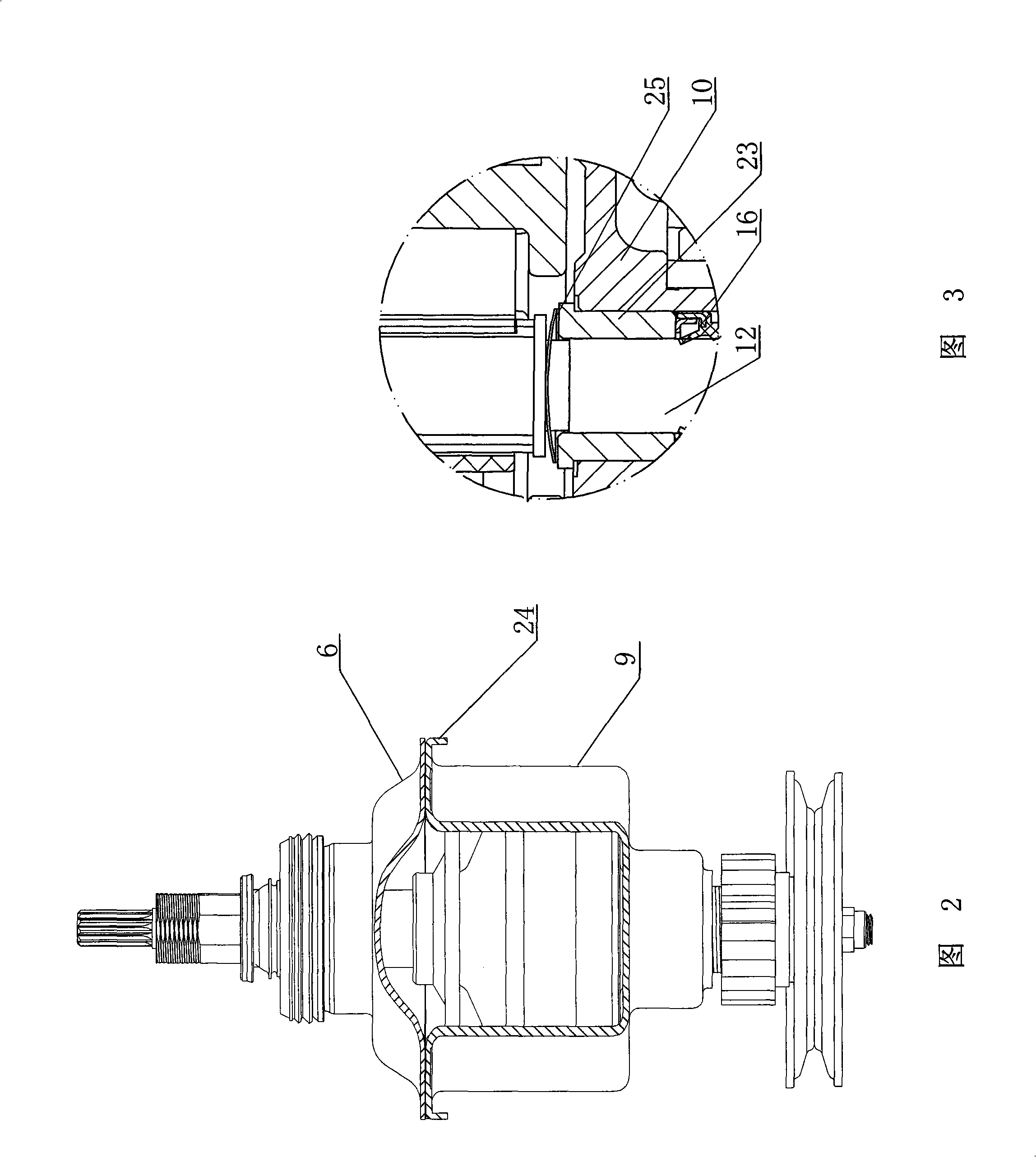

Large diving electric pump

InactiveCN1693714AImprove sealingImprove the safety of usePump componentsPump installationsEngineeringRelative stability

The invention relates to a large-scale submersible pump that at least includes two mechanical seals: one is at the shaft extension end of pump rotating shaft, and the other is at the shaft extension end of the electromotor rotating shaft. The sealing effect would be enhanced and the environment for the components is relative stability. The working reliability of the components is ensured. The safety of the submersible pump is improved.

Owner:HEFEI HENGDAJIANGHAI PUMP IND CO LTD

Spring support

InactiveCN102510034AFirmly connectedReduce curvatureOpen bus-bar installationsEngineeringMechanical engineering

The invention provides a spring support, which comprises U-aluminum profiles, I-shaped aluminum profiles, a connecting member, a connecting base, an M-shaped support, a spring upper sleeve, a spring lower sleeve, a spring, a hexagon bolt, edge sealing plates, middle sealing plates and the like. Two U-aluminum profiles and a plurality of I-shaped aluminum profiles surround a bus main body to form a basic supporting framework, the I-shaped aluminum profiles and the U-aluminum profiles are fixedly connected, the supporting framework is fixed above a floor, the base is fixed on the upper portion of the supporting framework, the connecting member is fixed on a bus cover plate, the hexagon bolt sequentially penetrates through the connecting member, the spring upper sleeve, and the spring, the spring lower sleeve and the base to be fastened by using a hexagon nut. A groove-shaped structure is arranged on the upper portion of the base, a groove-shaped foot is arranged on the lower portion of the base, and the M-shaped support is arranged in the groove-shaped foot on the lower portion of the base to be capable of preventing the hexagon bolt from being loosened caused by rotation of the hexagon nut. Gaps among the U-aluminum profiles, the I-shaped aluminum profiles, the base and a bus are plugged by using the edge sealing plates, and the middle sealing plates are used for plugging middle gaps of buses with large specifications so as to prevent chimney effect.

Owner:江苏华鹏母线股份有限公司

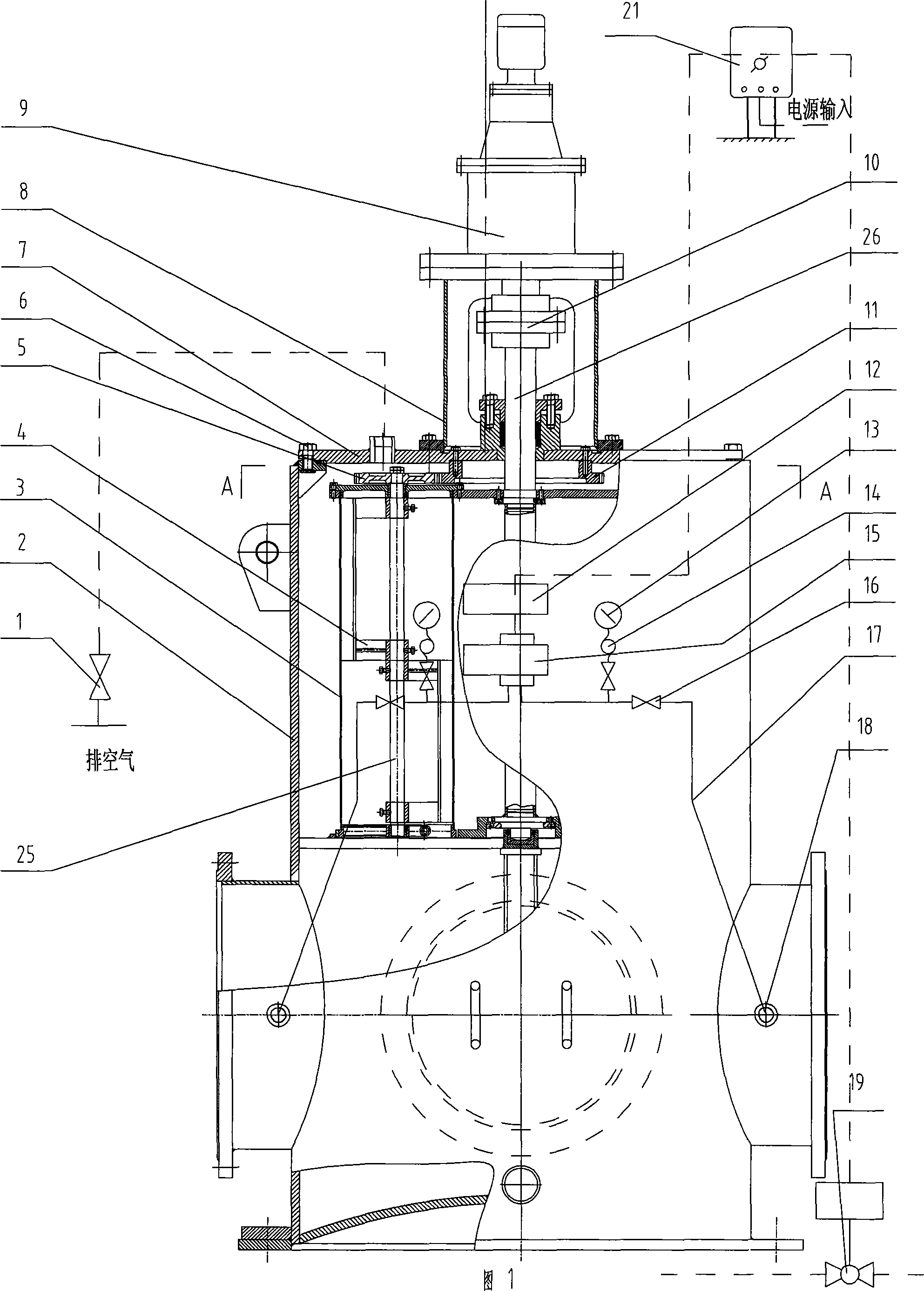

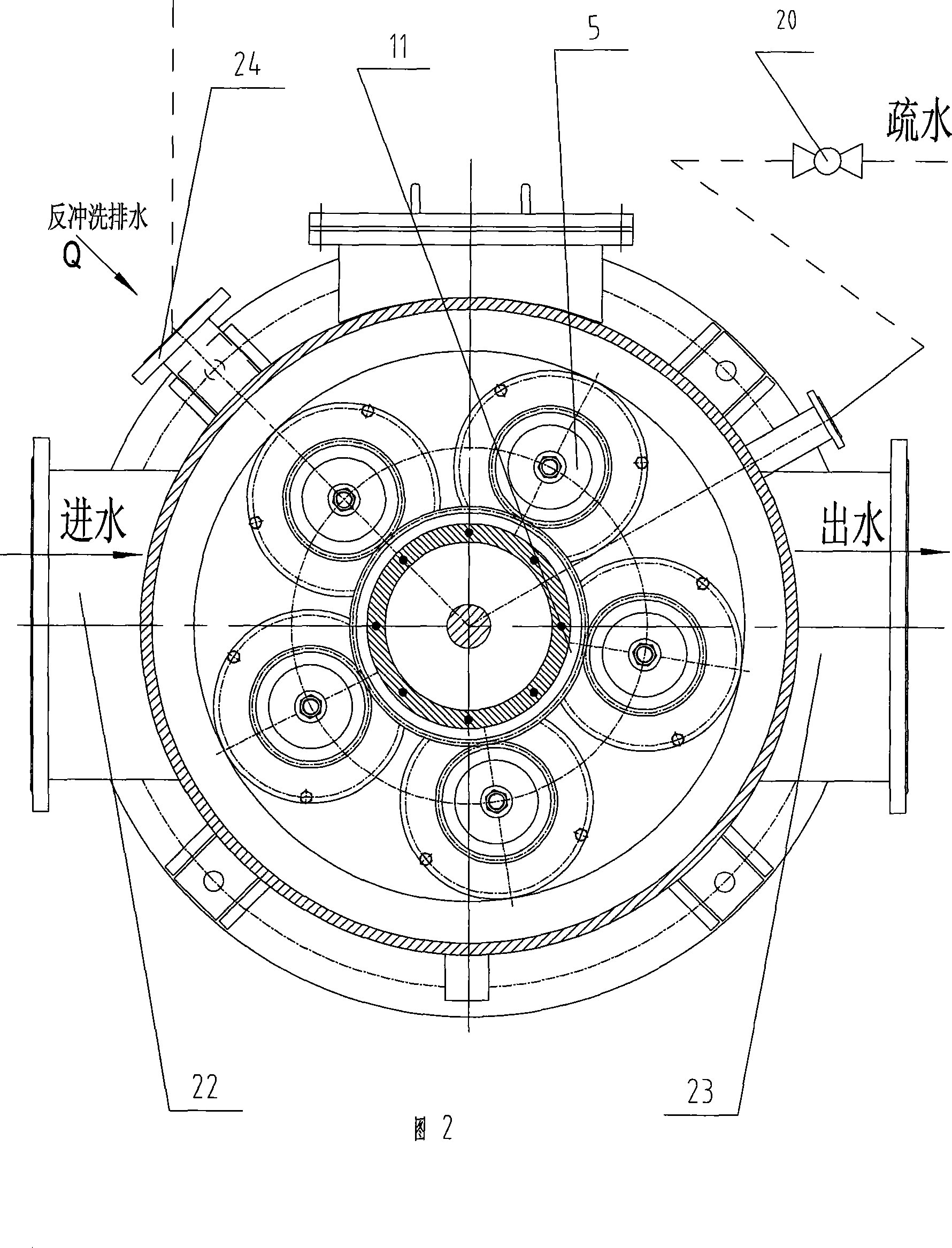

Full automatic corrupt brushing backwash water filter

InactiveCN101185815AEasy to cleanGood removal effectStationary filtering element filtersInsertion stentGear wheel

The invention relates to a filter equipment, in particular to a full automatic sewage-brushing and backwashing water filter. According to the technical proposal provided by the invention, a filter screen is arranged in a shell body. The invention is characterized in that a reducer is arranged on the shell body; a plurality of cylinder-shaped filer screens is uniformly arranged on a stent; the stent is connected with a main shaft; the main shaft is connected with the output end of the reducer; every filter screen is internally provided with a rotating shaft which is provided with a brush; the end of the brush is touched with the inner wall of the filer screen; the end of the rotating shaft extends out of the filter screen. The end of the rotating shaft is also provided with a planetary gear while every planetary gear is respectively meshed with a gearwheel fixed in the shell body. A water inlet, a water outlet and a backwashing pipe are arranged at the lower part of the shell body 2. The water filter backwashes the filter screen automatically after being used for a period of time, which ensures the normal operation of the water filter and alleviates the labor intensity of workers.

Owner:陆昕 +1

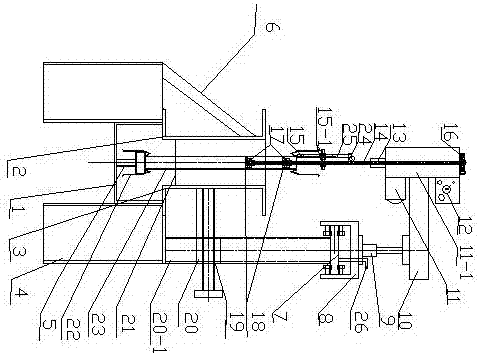

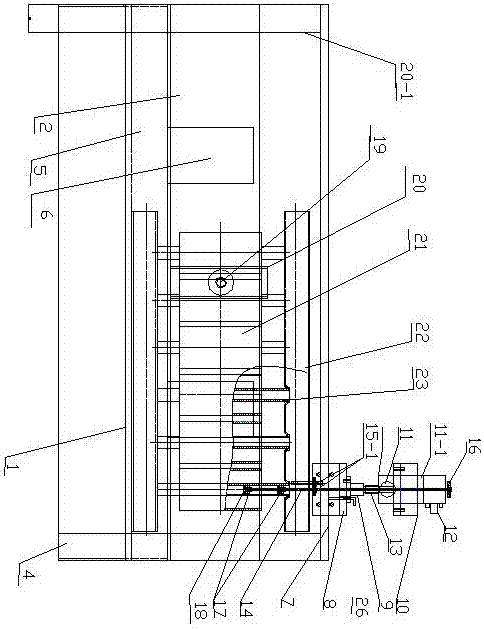

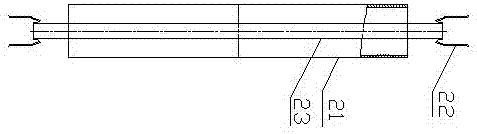

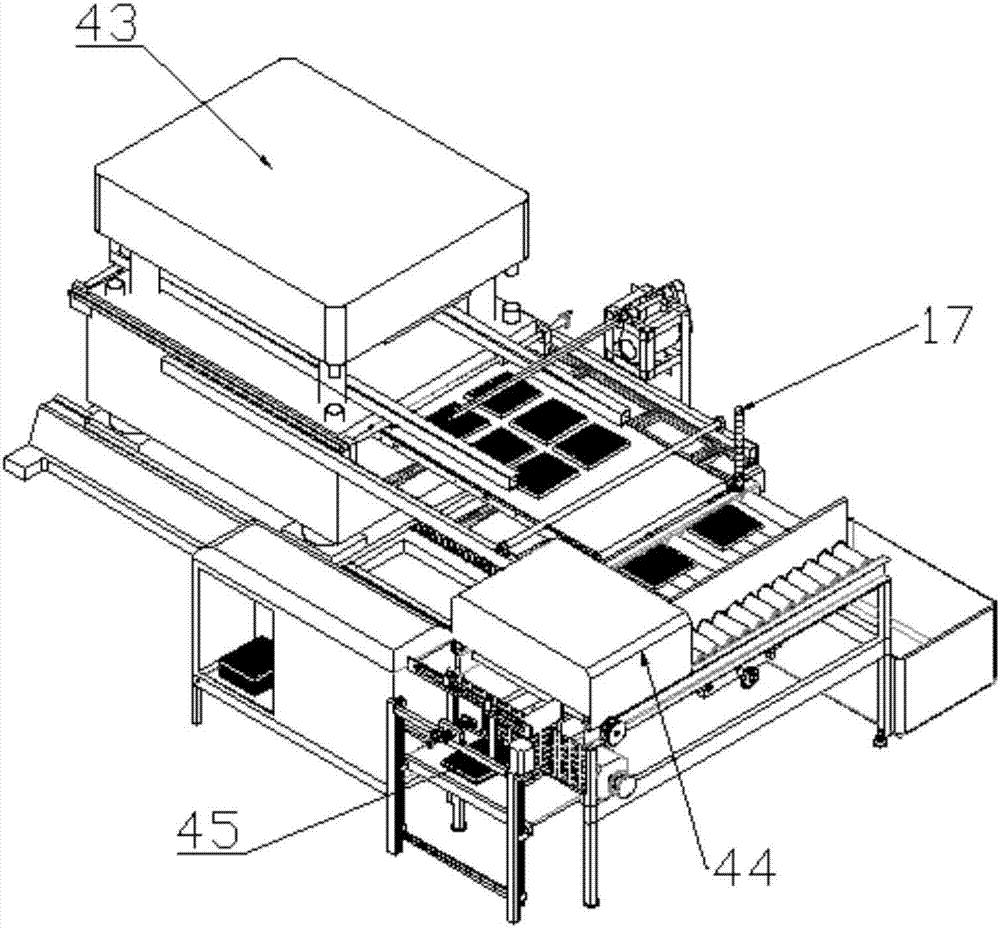

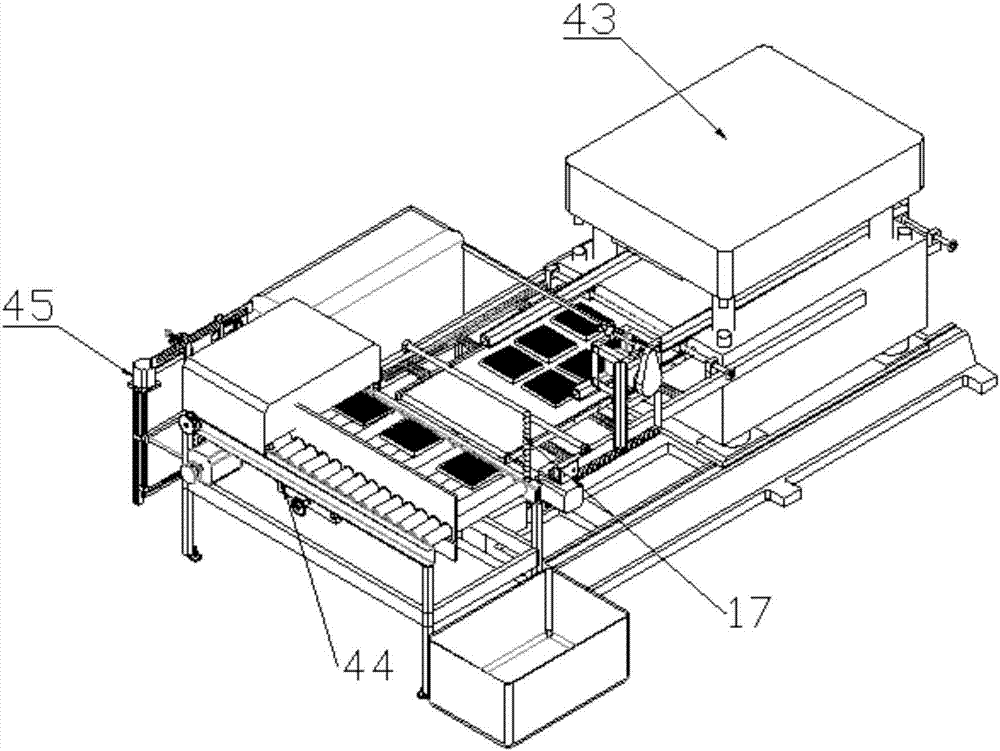

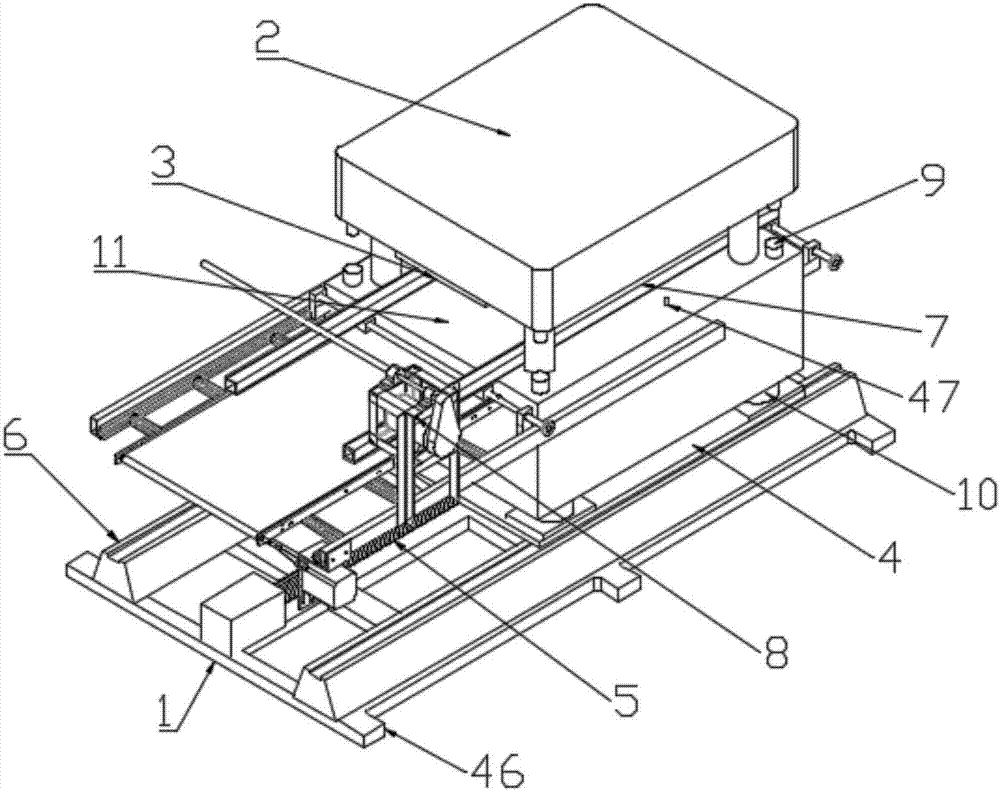

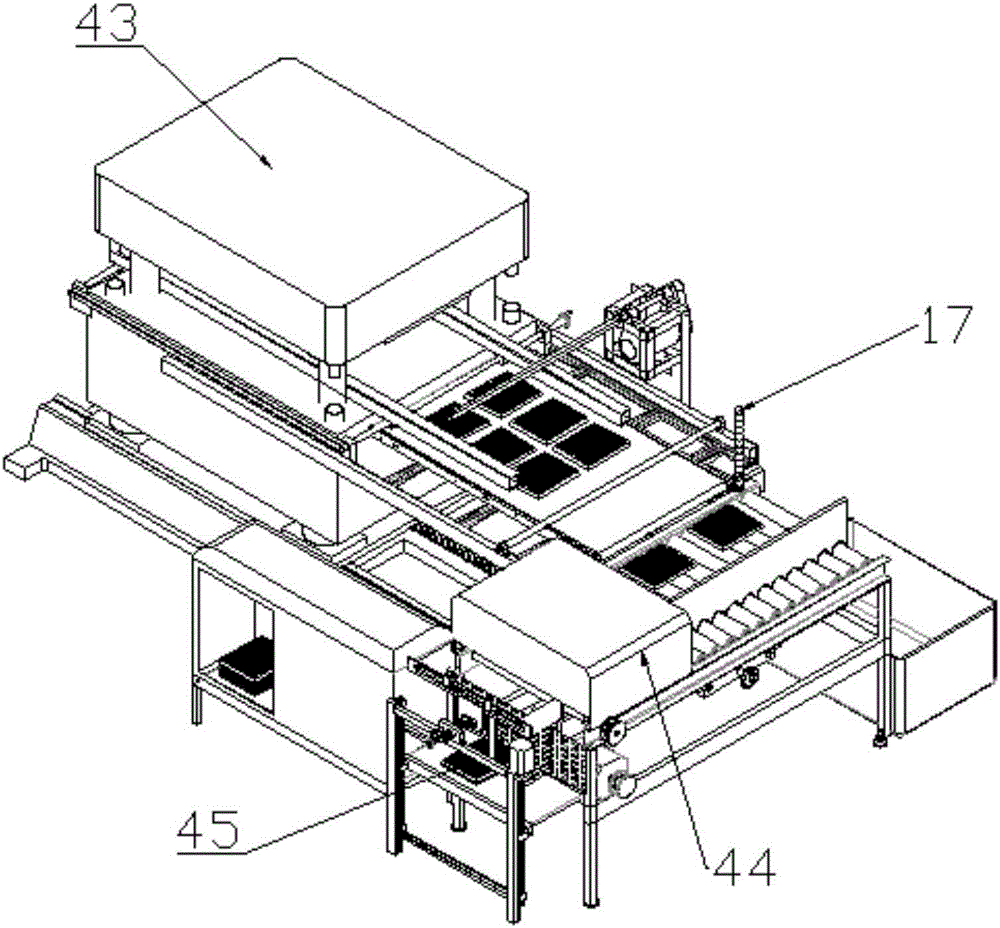

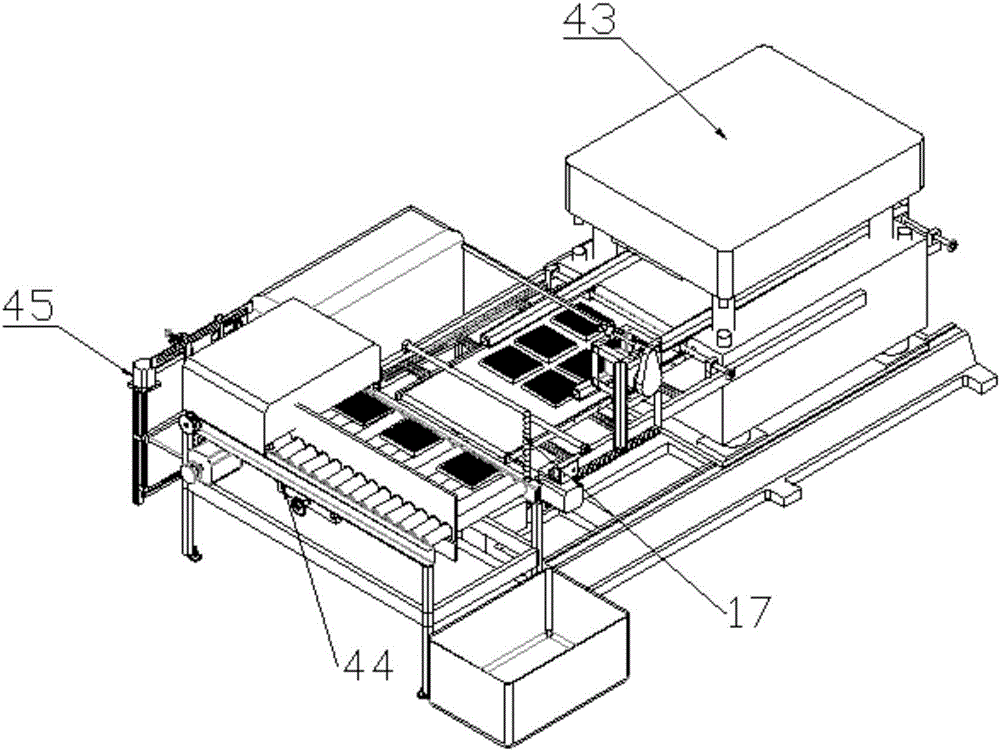

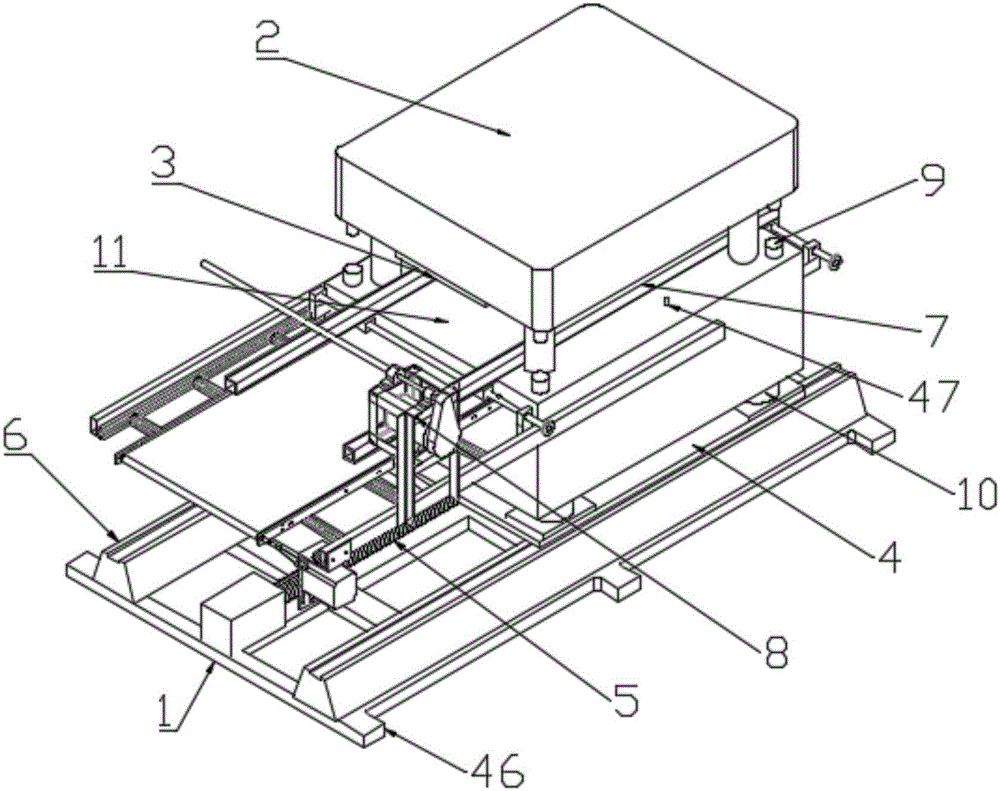

A linkage punching system

ActiveCN106041322BHigh precisionReliable service lifeLaser beam welding apparatusMachining systemPunching shear

Owner:苏州锐士达工业自动化有限公司

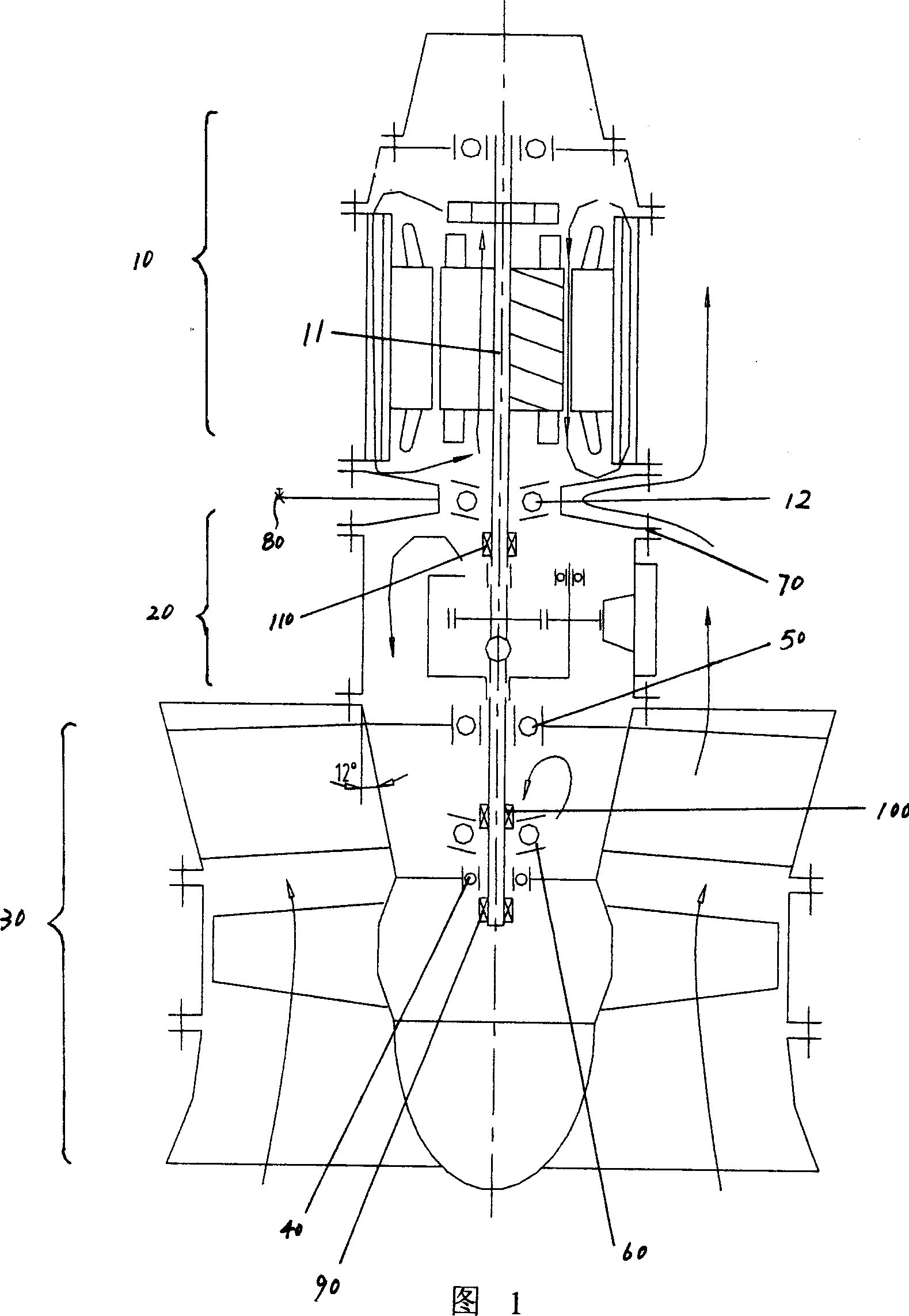

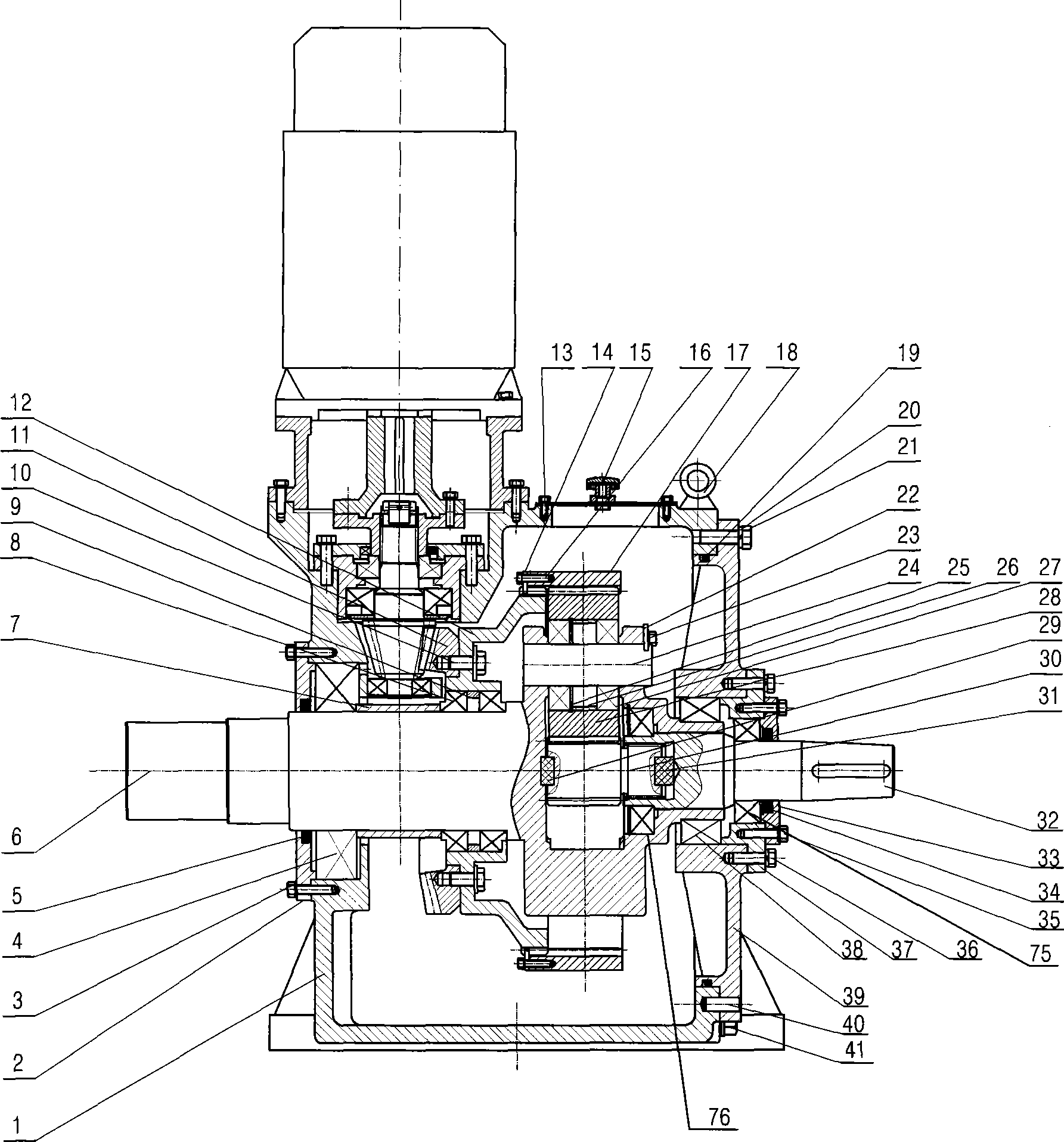

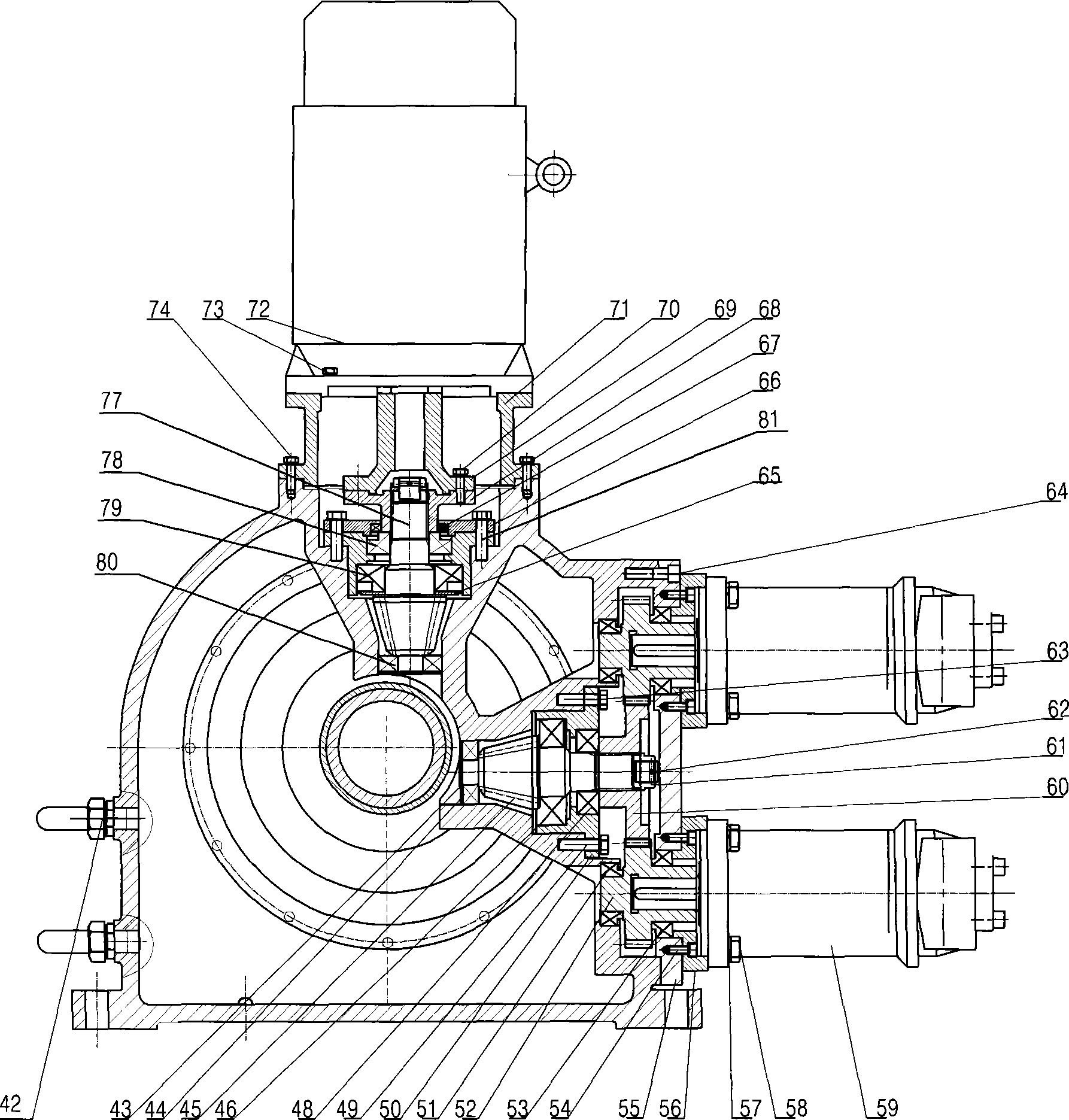

Mechanical electric liquid composite soft starting/stepless speed regulating transmission device for large power overloading equipment

InactiveCN101478278ASmall starting currentIncrease outlet pressureToothed gearingsGearing controlRotation functionControl theory

The invention relates to a mechanical-electrical-hydraulic compound soft-starting / stepless speed regulating drive mechanism on high-power heavy-duty equipment. The mechanism comprises a power input shaft sleeved on a planet carrier output shaft in a sliding manner. One end of the power input shaft is connected with a main electric motor, and the other end thereof is fixed in an inner hole of the planet carrier output shaft and is connected with a sun wheel shaft positioned in the inner hole of the planet carrier output shaft so as to form gear clearance float; at least two groups of planet wheels are fixed around the planet carrier output shaft through planet wheel shafts at one circle in a winding manner; each planet wheel is meshed with the sun wheel shaft peripherally, and is meshed with an inner ring gear positioned outside the planet carrier output shaft at the same time; a gear coupling which is connected with the inner ring gear along the gear direction to form radial gear clearance float is also included; a bevel gear fixed on the gear coupling is meshed with a conical tooth shaft connected with a low-power helper motor; and a bevel gear shaft for connecting the bevel gear and a hydraulic rotation function element are also arranged on the gear coupling at the same time. The mechanical-electrical-hydraulic compound soft-starting / stepless speed regulating drive mechanism integrates the functions such as soft-starting / stepless speed regulating, etc., and has the advantages of high transmission efficiency, small noise, compact structure, reliable performance and low cost.

Owner:李本平

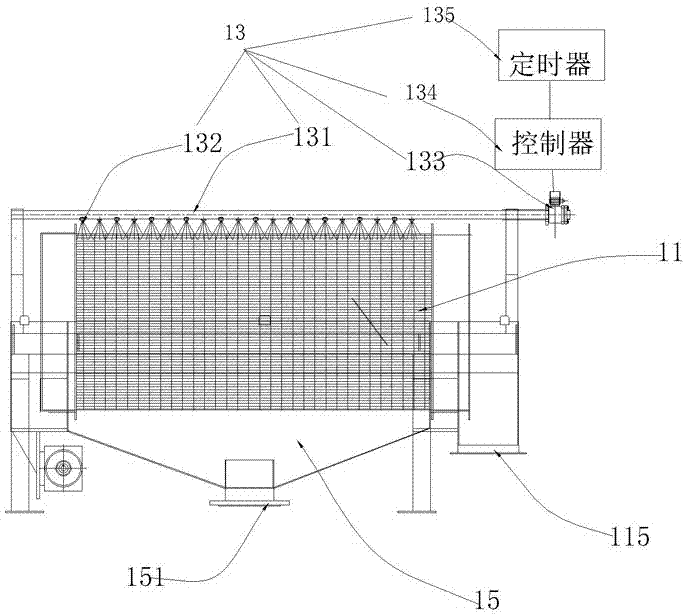

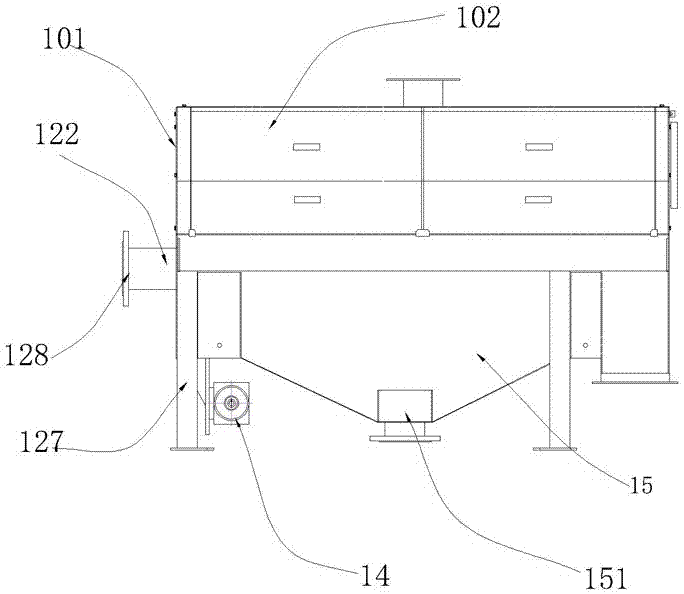

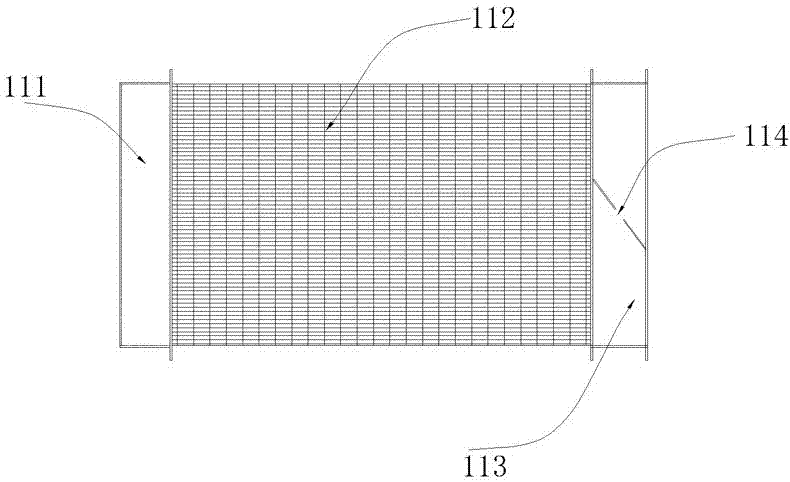

Rotary drum fine grid type solid-liquid separation equipment

The invention discloses a rotating drum fine grid type solid-liquid separation device, which comprises an integrated body, a rotating drum, a water equalizer, a spray mechanism and a driving mechanism; the rotating drum is installed in the body, and the water equalizer , spraying mechanism and driving mechanism are all installed on the machine body, and the driving mechanism is connected with the drum drive; the drum includes a water inlet drum head, a filter screen and a slag discharge drum head; The other end of the filter screen is connected to the slag discharge drum head, and a mud guide plate connected to the filter screen is arranged inside the slag discharge drum head, and a mud bucket is arranged at the end of the mud guide plate, and a slag discharge drum connected with the mud bucket is provided on the slag discharge drum head. The sewage with slag is pumped in by the water pump, and under the action of the water homogenizer, it is decompressed and buffered to form waterfall water, which is injected into the filter screen with a tangent line; the filtrate passes through the filter screen, is collected in the water collecting bucket and is discharged from the filtrate outlet , the slag stays at the bottom of the filter screen, after rotation, and under the action of the mud guide plate, it flows from the end of the water inlet drum head to the slag hopper end of the slag discharge drum head, and finally is discharged from the slag discharge port.

Owner:FUZHOU BETTER ENVIRONMENTAL PROTECTION EQUIP CO LTD

Preparation method of polyborosiloxane modified polyurethane waterborne coating

The invention discloses a preparation method of a polyborosiloxane modified polyurethane waterborne coating, and belongs to the technical field of coatings. Waterborne polyurethane is modified by polyborosiloxane, the characteristics of low VOC and environmental protection can be maintained, furthermore, water resistance, heat resistance, mechanical property and the like can be improved; and by the hydrophobic property, the anti-adhesion property of the surface of the coating to stains and bacteria is significantly improved. Moreover, the bactericidal property is further enhanced due to the existence of fluorine and boron in the molecule; and the surface has good hydrophobicity, and pollution loss caused by adhesion of the stains can be prevented. In addition, the coating disclosed by theinvention has the outstanding advantages of good toughness and flame-retardant characteristics, good hydrolysis resistance and heat aging resistance, wear resistance, corrosion resistance and brightness, softness and elasticity, good water resistance and mechanical property, and good weather resistance.

Owner:广东邦宁新材料科技有限公司

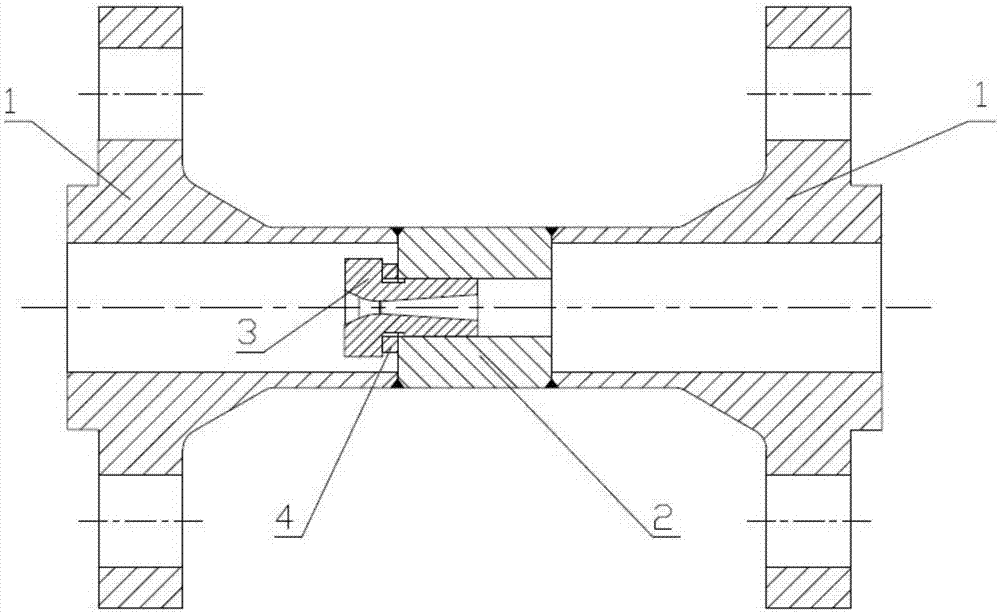

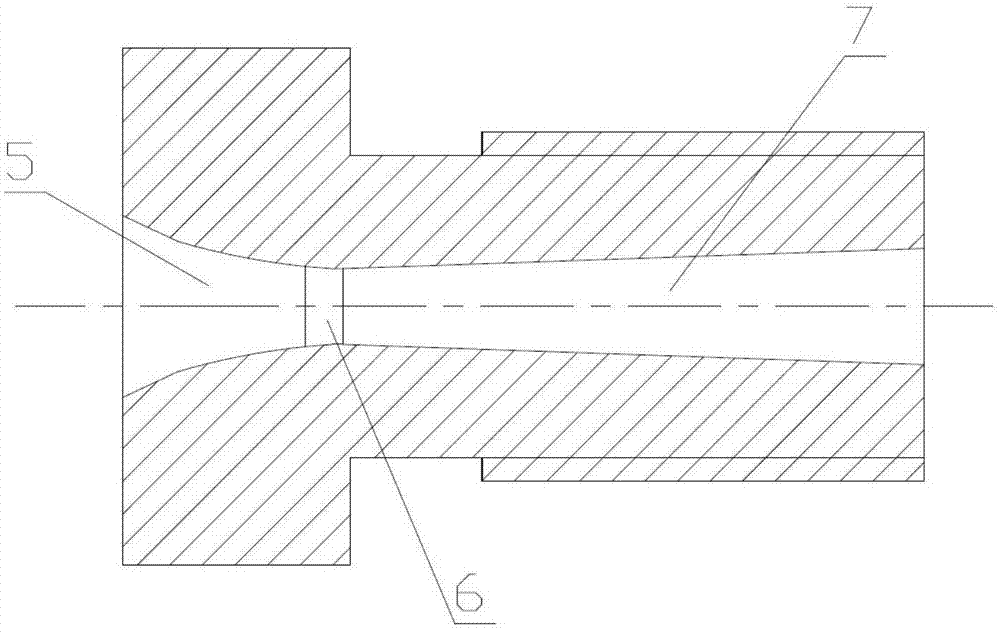

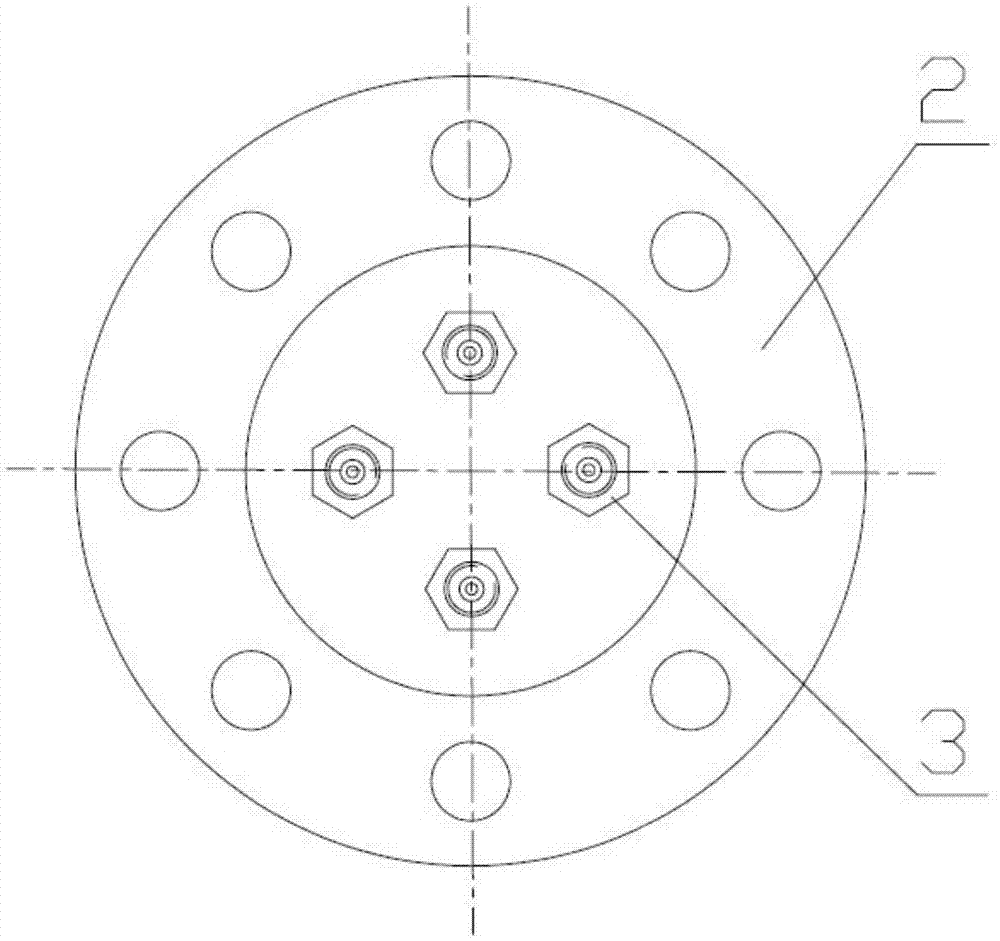

Venturi type steam trap

PendingCN107023745AReduce wear and tearMeet the needs of large displacement working conditionsSteam trapsDesign technologyEngineering

The invention relates to a valve design technique, and particularly discloses a venturi type steam trap. The venturi type steam trap comprises a valve body, a flange, a valve core and a locking washer, wherein the flange and the valve body are welded together, the valve core is in threaded connection to the valve body, and the connecting reliability can be guaranteed by virtue of the locking washer between the valve body and the valve core. The venturi type steam trap has the advantage of compact structure and is composed of four parts including the flange, the valve body, the valve core and the locking washer, compared with a traditional steam trap which is composed of dozens of parts, the number of the parts is greatly reduced, the stability of the steam trap is increased, the probability of failure is reduced, and the service life is long. In the same valve body, a plurality of groups of valve cores can be designed and installed, so that the displacement of condensation water is increased.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

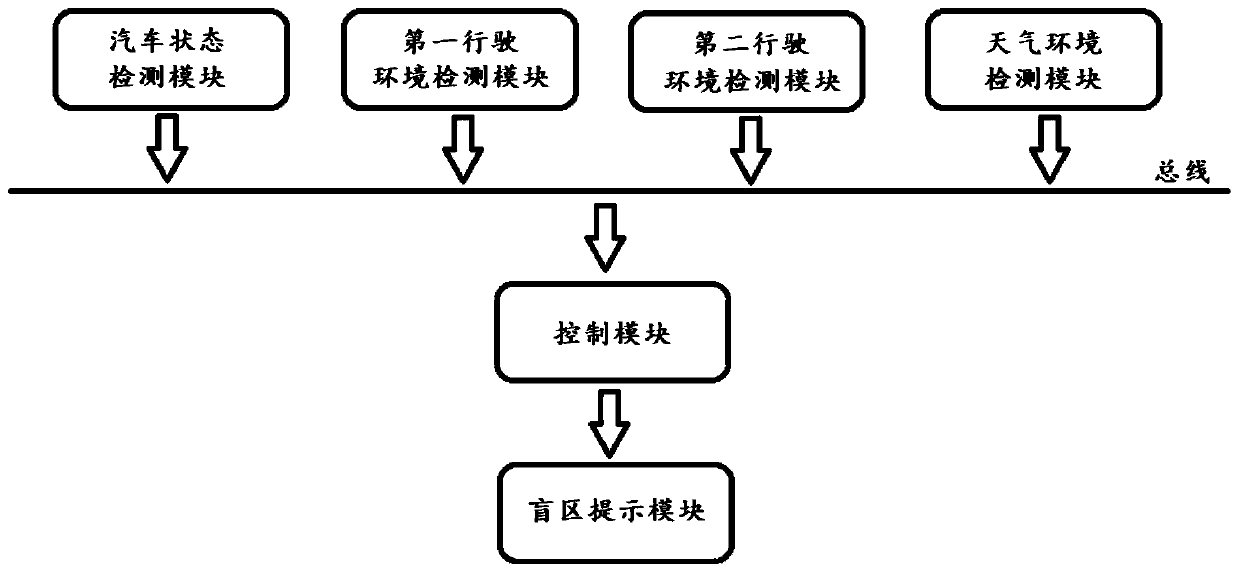

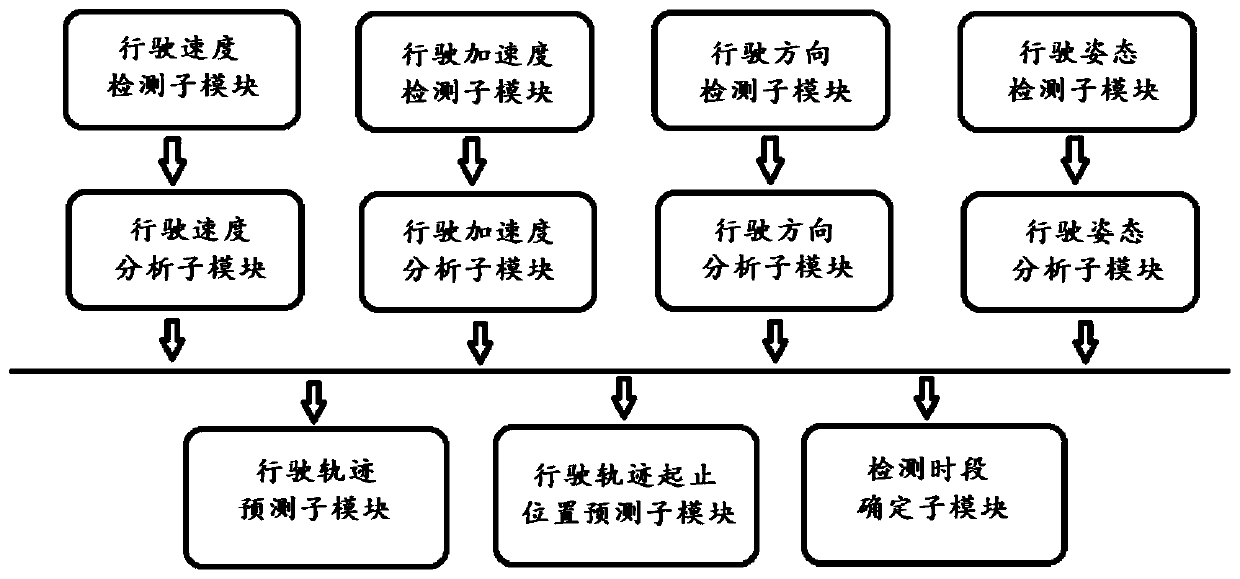

Automobile blind zone sensing system

ActiveCN110723070AGood material performanceSimple structureRainfall/precipitation gaugesPhotogrammetry/videogrammetryDriver/operatorEngineering

The invention provides an automobile blind zone sensing system. The automobile blind zone sensing system acquires running relevant element information of motion status information, first running environment information, second running environment information, visibility value and the like of an automobile respectively through an automobile motion status detection module, a first running environment detection module, a second running environment detection module and a weather environment detection module, confirms running blind zone distribution status of the automobile under current running status according to the running relevant element information, and can further perform real-time dynamic prompting for a driver according to the running blind zone distribution status, thereby guaranteeing that the driver can comprehensively master running view in the running process and improving running safety of the automobile.

Owner:成都长迪传感技术有限公司

Linked punching-shearing system

ActiveCN106041322AHigh precisionReliable service lifeLaser beam welding apparatusEngineeringMachining system

The invention discloses a linked punching-shearing system which comprises a punching-shearing machine system, a dust removal system and a material collecting system. Efficient and flexible work is realized in a manner that the punching-shearing machine system, the dust removal system and the material collecting system are cooperated.

Owner:苏州锐士达工业自动化有限公司

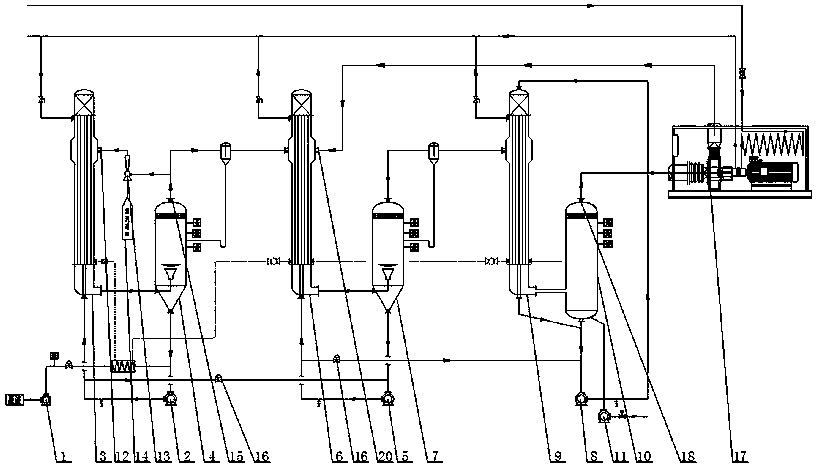

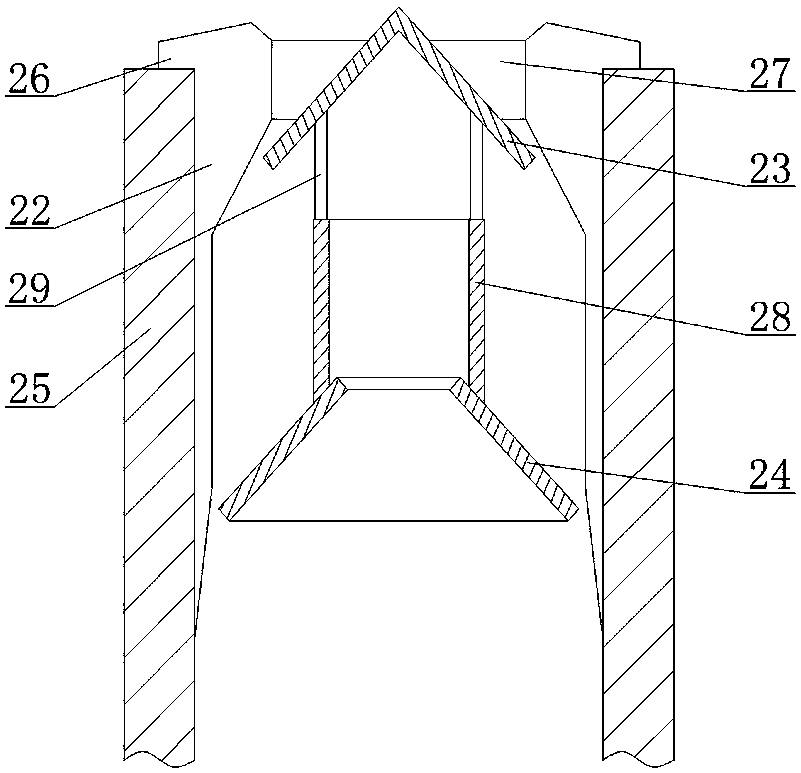

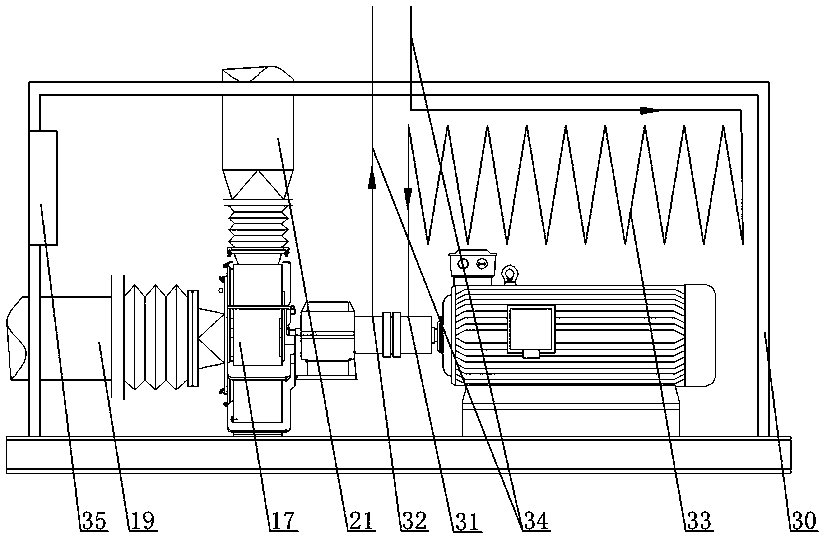

MVR (Mechanical Vapor Recompression) multiple effect evaporator

PendingCN107754362AImprove evaporation efficiencyHeating evenlyEvaporator accessoriesMultiple-effect evaporationEngineeringMultiple-effect evaporator

The invention discloses an MVR (Mechanical Vapor Recompression) multiple effect evaporator which comprises a feed pump, a single-effect forced circulation pump, a single-effect evaporator, a single-effect separator, a two-effect forced circulation pump, a two-effect evaporator, a two-effect separator, a three-effect forced circulation pump, a three-effect evaporator, a three-effect separator and adischarge pump connected in sequence by virtue of pipelines, wherein a steam port of the single-effect evaporator is connected with a heat pump; a steam inlet is formed in the other end of the heat pump; steam ports of the rest each-effect evaporators are sequentially connected to the steam outlet in the top of the last-effect separator; the bottom outlet of each-effect separator is connected with a corresponding each-effect forced circulation pump; the single-effect forced circulation pump can be communicated with the two-effect forced circulation pump by virtue of a valve; the two-effect forced circulation pump can be communicated with the three-effect forced circulation pump by virtue of a valve; the bottom of the three-effect evaporator is connected with the inlet of the discharge pump; the three-effect evaporator is a falling-film evaporator; and an MVR compressor is arranged between the three-effect separator and the two-effect evaporator. According to the MVR multiple effect evaporator, the steam utilization rate is high, so that the steam consumption is reduced, the membrane distribution effect is excellent, the noise is low, the heat dissipation performance is excellent,and the energy consumption is low.

Owner:叶春穗

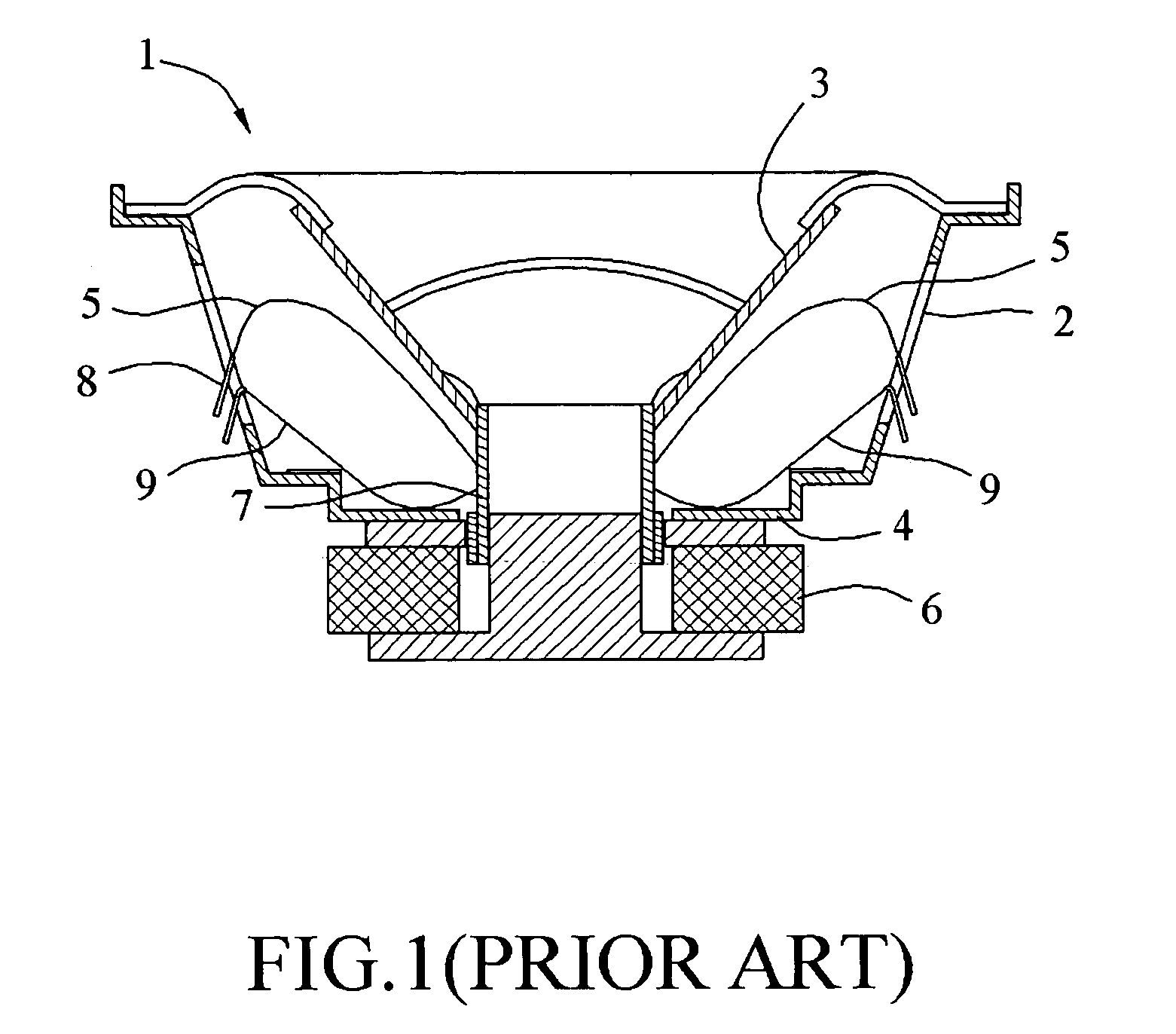

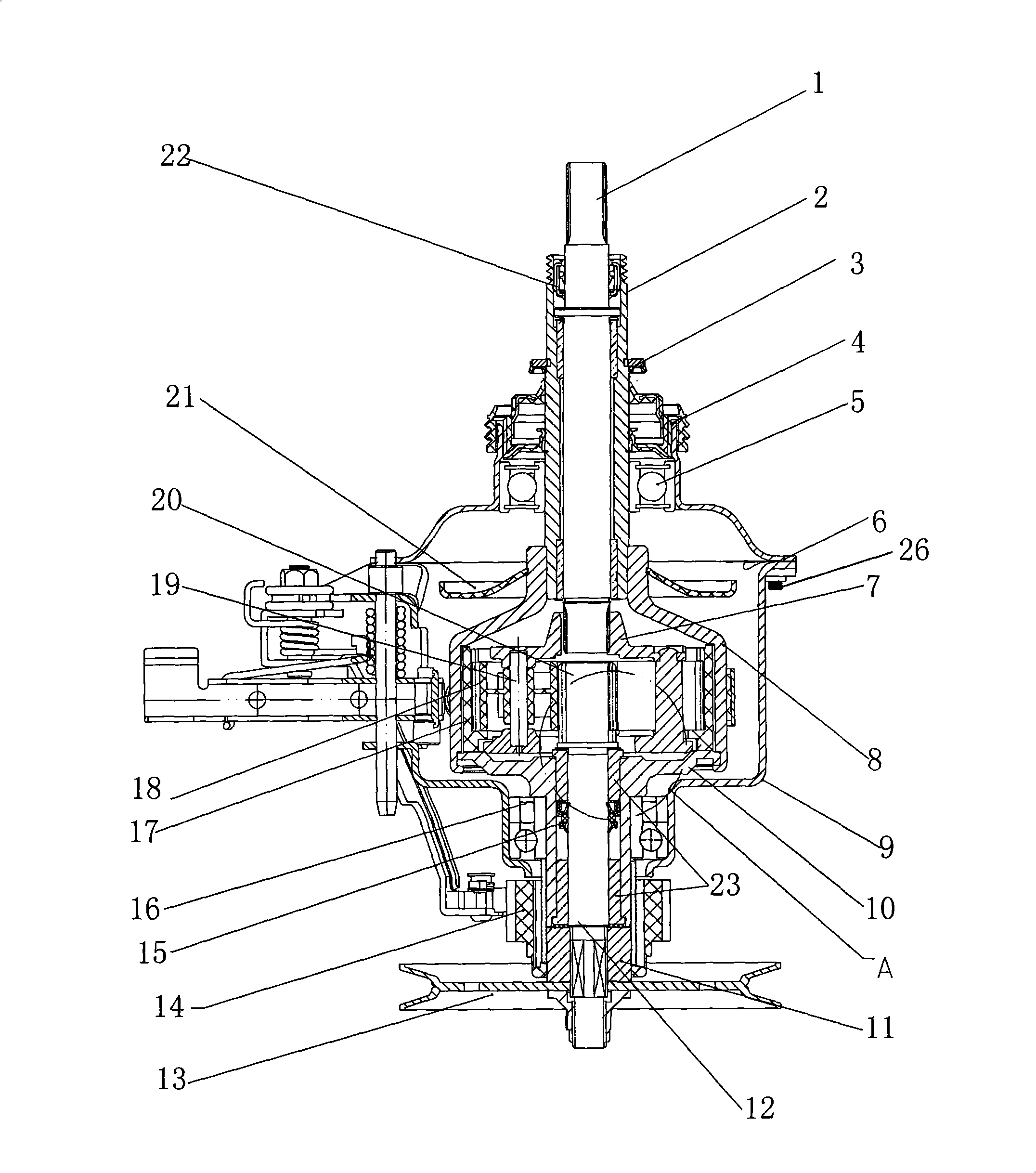

Large-capacity decelerating clutch for full automatic washing machine

InactiveCN101275355ALittle wearSmooth rotationOther washing machinesTextiles and paperGear wheelEngineering

The invention is a large-capacity speed-down clutch for a full automatic washing machine, whose washing rated capacity is from 6-15kg. The invention has strong rigidly, smooth and steady rotary, small noise, light abrasion and long service life. The invention includes an input shaft, an output shaft and a dewatering shaft, wherein, the input shaft is connected to the output shaft and the dewatering shaft through wheel gears in a wheel box, the outside of the wheel box is a shell component, a clutch shaft is sheathed on the input shaft, a clutch shaft sleeve is provided between the clutch shaft and the input shaft, which is characterized in that a corrugated gasket is provided between the clutch shaft sleeve and the shaft shoulder of the input shaft.

Owner:陈伟农 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com