Large diving electric pump

A submersible electric pump, large-scale technology, applied in the direction of pumps, pump devices, pump components, etc., can solve problems such as difficult maintenance work, achieve the effects of environmental stability, improve safety and reliability, and reliable service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

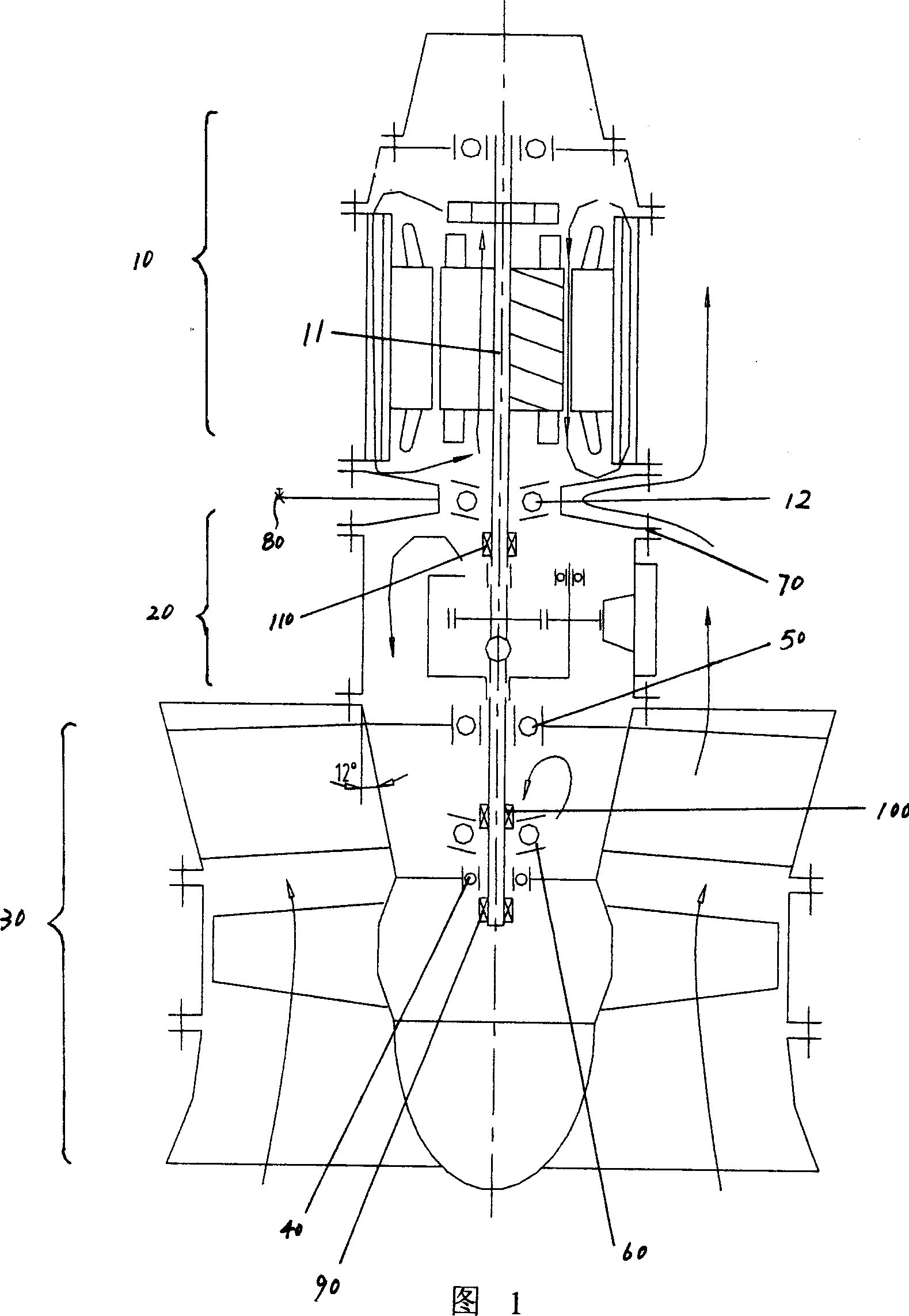

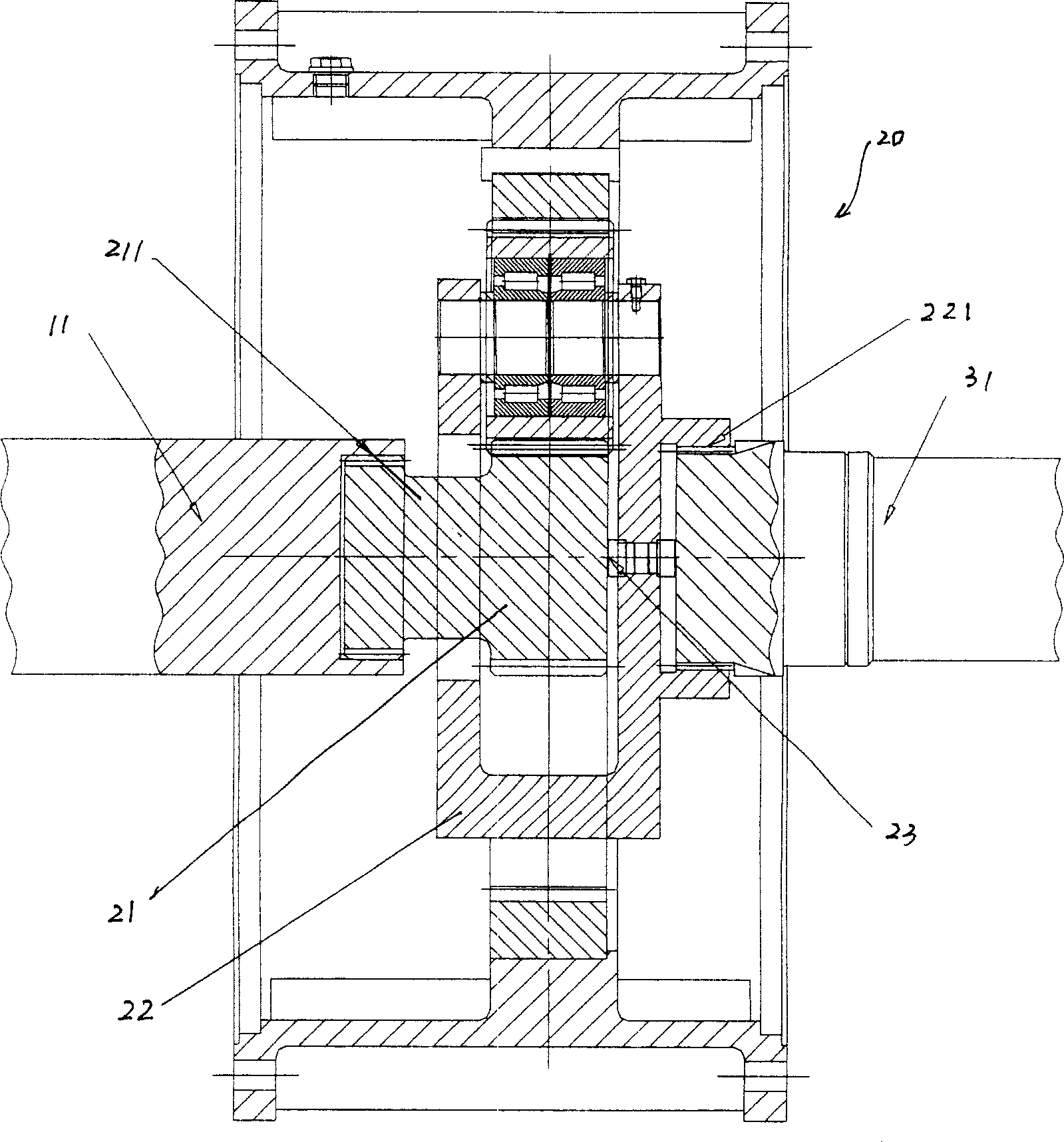

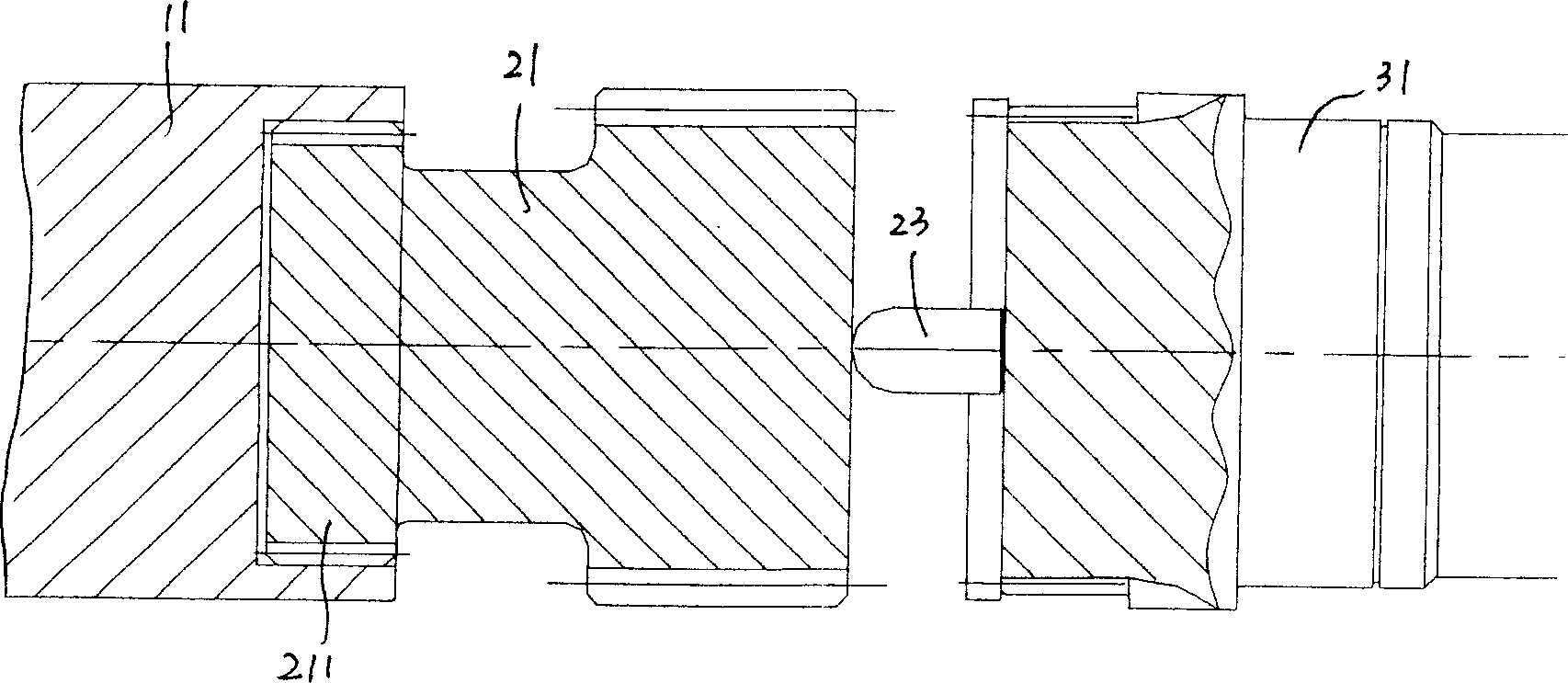

[0011] As shown in FIG. 1 , at least two mechanical seals are provided in the present invention. The first mechanical seal 90 is located at the shaft extension end of the water pump shaft 31 , and the second mechanical seal 110 is located at the shaft extension end of the motor shaft 11 .

[0012] A third mechanical seal 100 is provided between the first mechanical seal 90 and the second mechanical seal 110 , and the third mechanical seal 100 is located in the cooling lubricating oil cavity of the water pump shaft 31 .

[0013] The first mechanical seal 9 is used to prevent the working water from entering the oil cavity of the cooling lubricating oil; the second mechanical seal 100 prevents the cooling lubricating oil from heating up and expanding; the third mechanical seal 110 prevents the cooling lubricating oil from entering the motor cavity. The use of three mechanical seals can strengthen the sealing effect of the submersible electric pump, such as improving the life of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com