Venturi type steam trap

A Venturi type and steam trap technology, which is applied in steam traps, mechanical equipment, etc., can solve the problems of short online service life, high steam leakage rate, easy wear of valve core, etc., and achieve stable and reliable performance, long service life, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

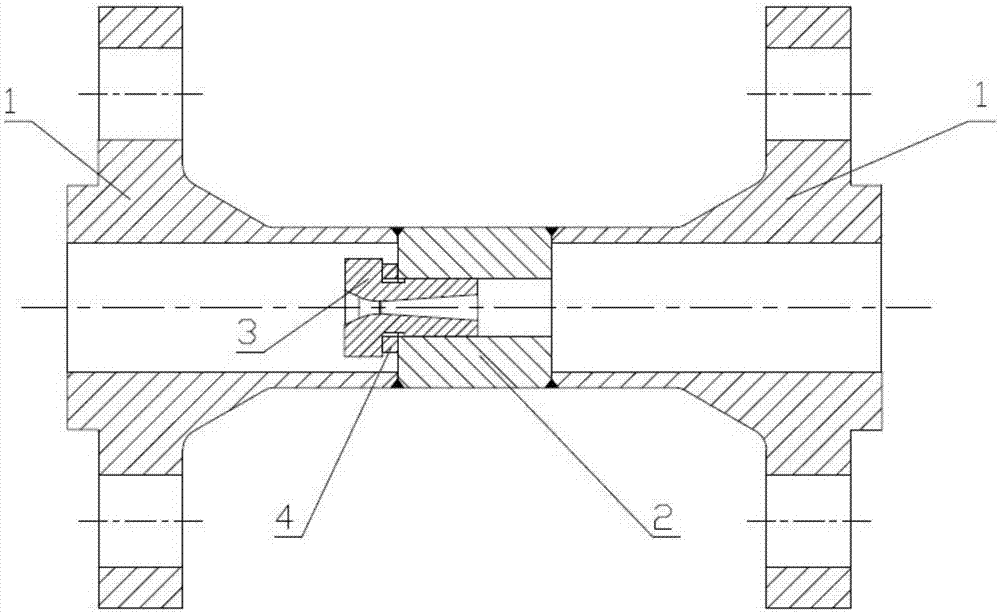

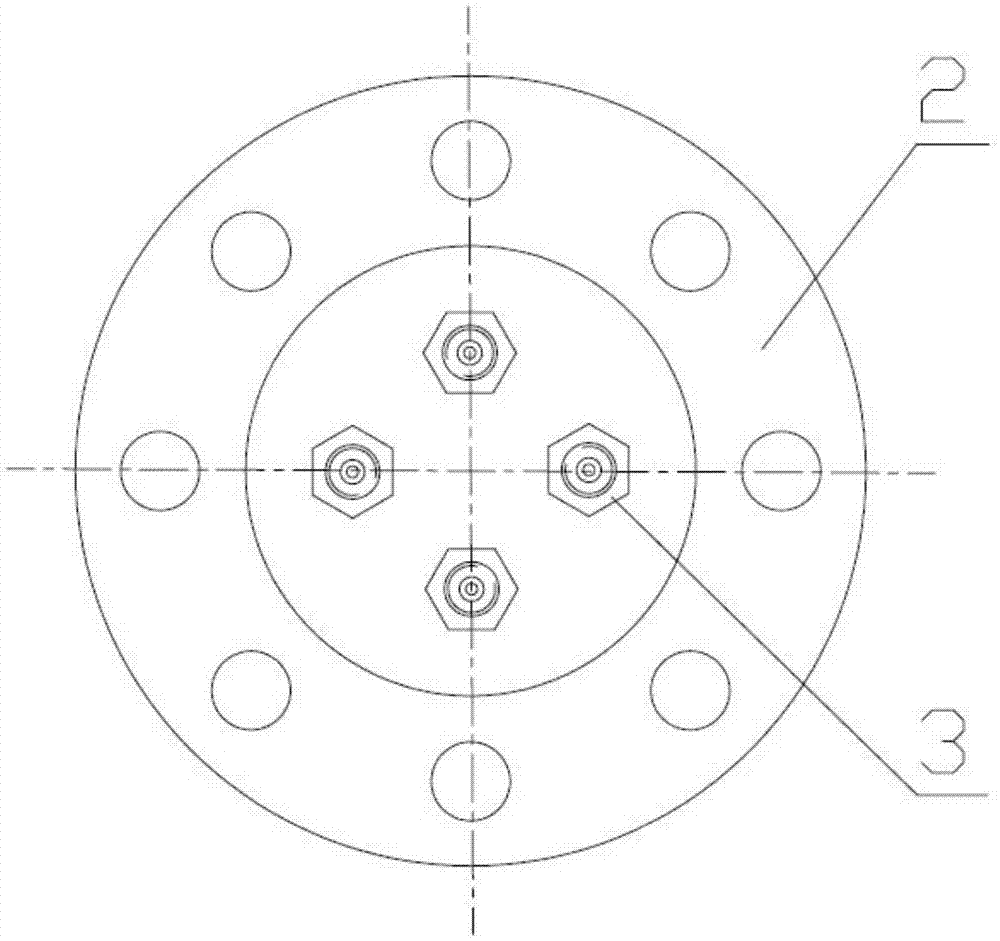

[0021] like figure 1 As shown, the valve core 3 is installed through threads in the valve cavity of the valve body 2, and a flange 1 is welded and installed on both sides of the valve body 2. The locking washer 4 between the valve body 2 and the valve core 3 ensures the reliability of the connection.

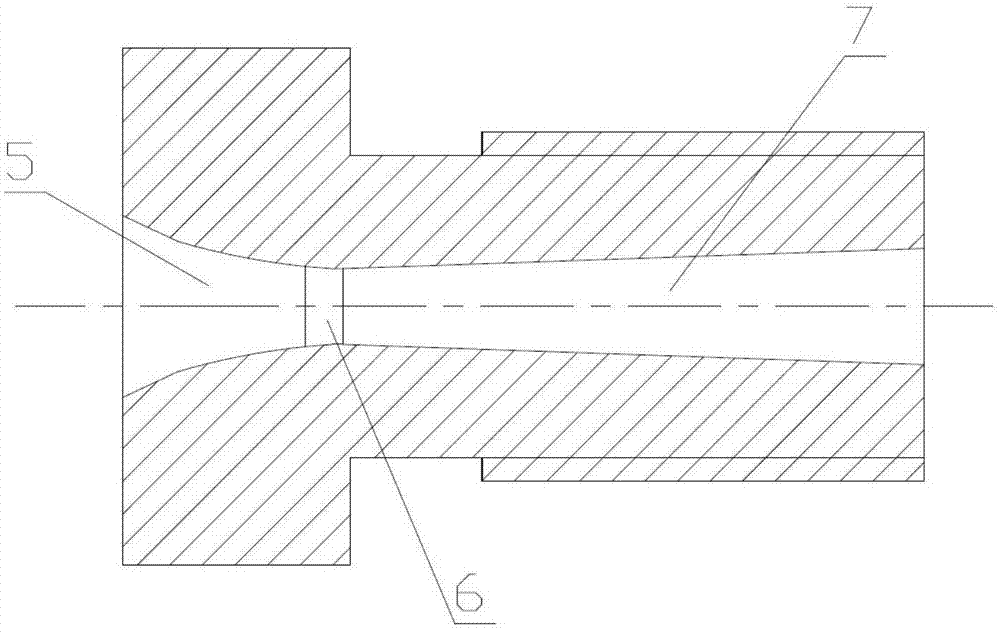

[0022] The main principle of Venturi steam trap is to use the flow resistance caused by the different specific volumes of steam and condensed water to achieve the effect of steam blocking and drainage. The ability of the medium to pass through the flow channel is inversely proportional to the specific volume. The specific volume of condensed water and steam is about two orders of magnitude different under the same pressure, which makes the displacement of condensed water dozens of times higher than that of The displacement of steam. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com