Solid type thermocouple specially for aluminum anode roasting and producing method

A technology of thermocouples and thermocouple wires, applied in the direction of using electric devices, thermometers using directly heat-sensitive electric/magnetic elements, using electromagnetic means, etc., can solve the problem of easy wear, oxidation, and easy breakage of protective tubes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

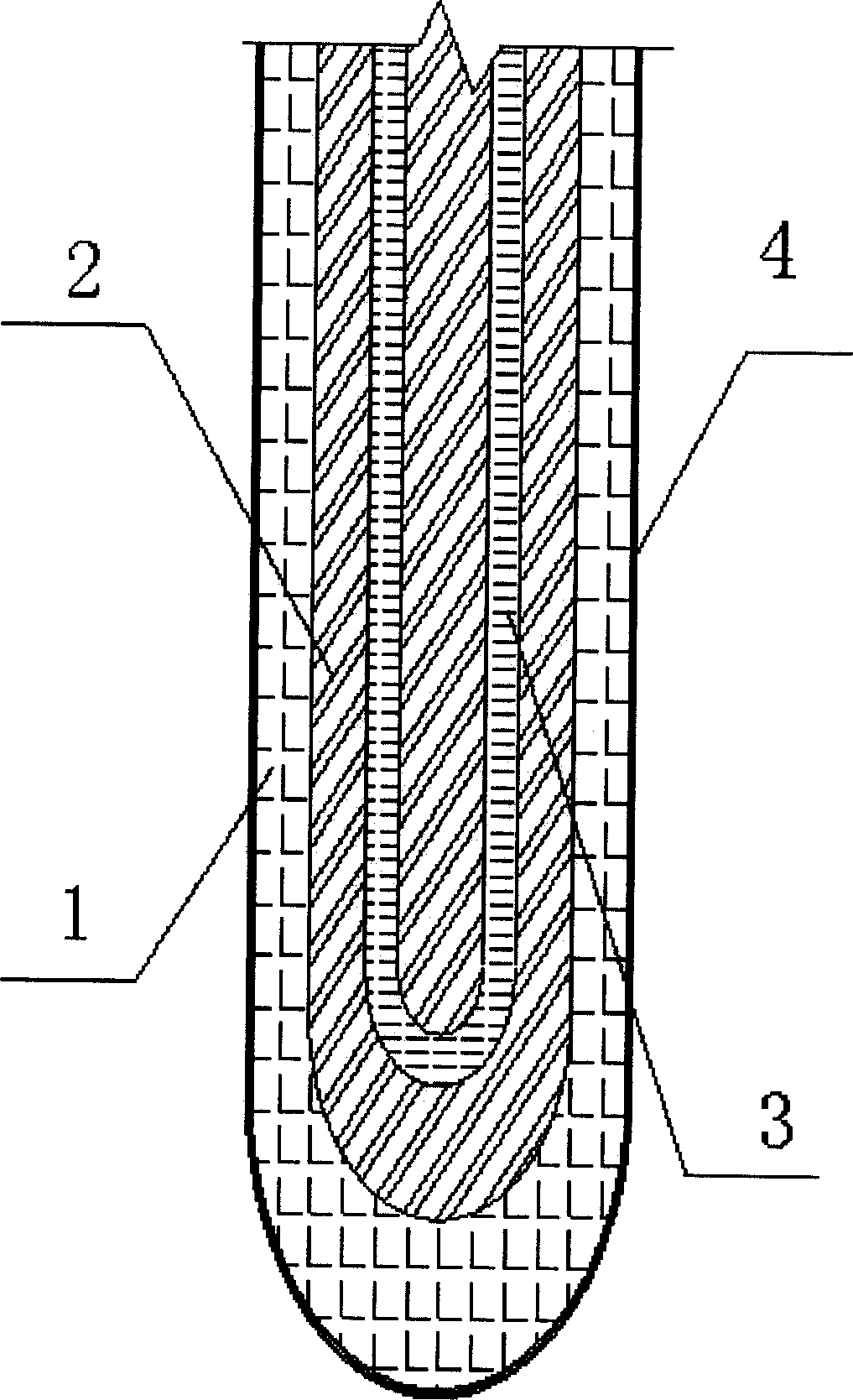

[0015] Embodiments of the present invention: the manufacturing method of the integral thermocouple is as follows: first, high-purity magnesium oxide powder, that is, an insulating, heat-transfer and temperature-resistant material (2), is sintered into a magnesium oxide column, and two holes are reserved in the middle for wearing a thermocouple wire (3 ). Next, the thermocouple wire (3) and the high-temperature alloy protection tube (1) are processed according to the calculated size, and the thermocouple wire (3) is threaded into the magnesium oxide column. Then put the magnesium oxide column with the thermocouple wire (3) into the high-temperature alloy protection tube (1), and draw it with special equipment. After repeated stretching, the size of the high-temperature alloy protection tube (1) becomes smaller, the diameter of the thermocouple wire (3) becomes smaller, the magnesium oxide column becomes magnesium oxide powder, and the three become a non-detachable one. Finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com