Large-capacity decelerating clutch for full automatic washing machine

A fully automatic washing machine and deceleration clutch technology, applied in the field of clutches, can solve the problems of the clutch being unsuitable for large-capacity washing machines, the increase of axial clearance, the influence of service life, etc., and achieve the effects of improving rigidity, high bearing capacity, and light wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

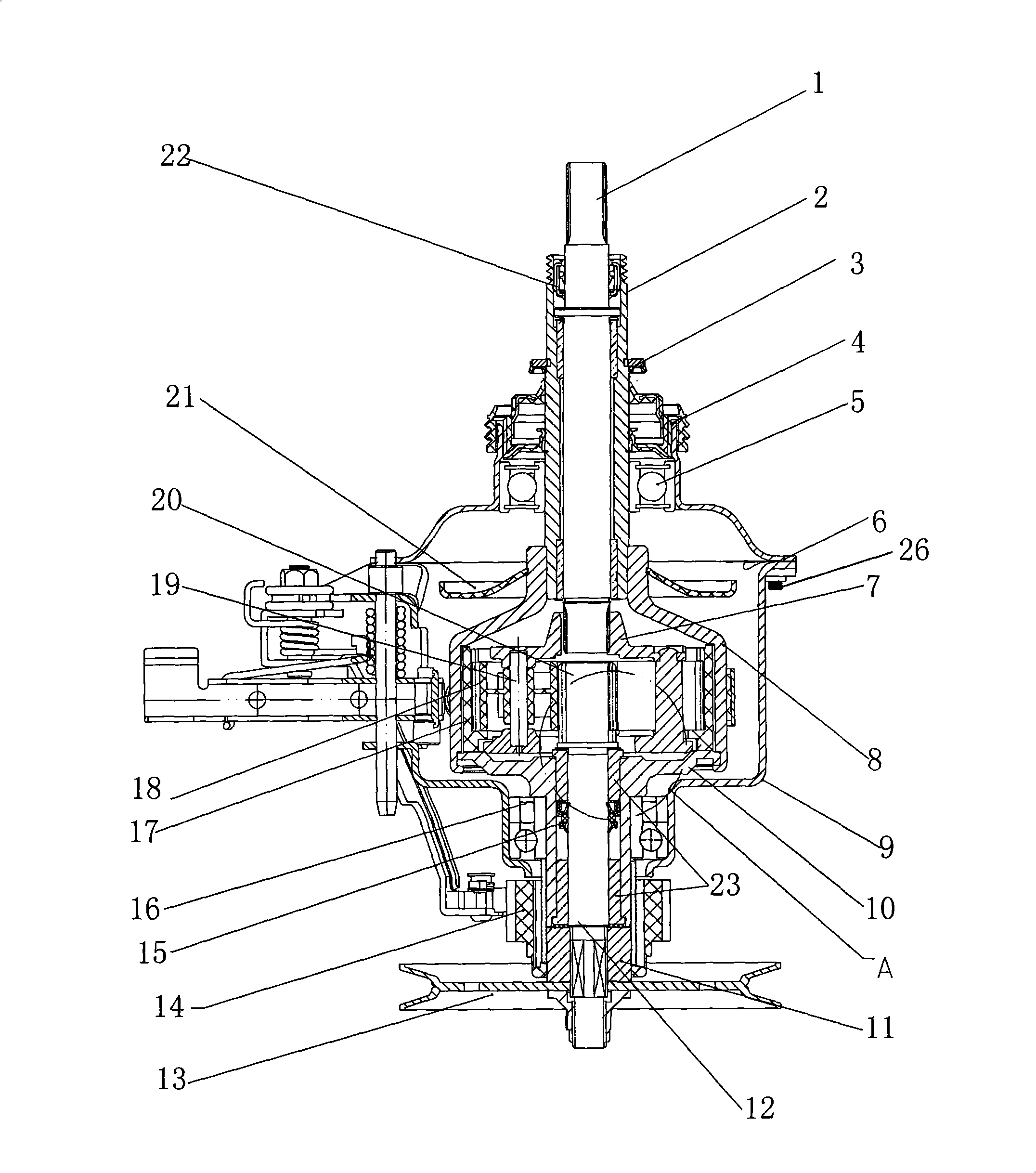

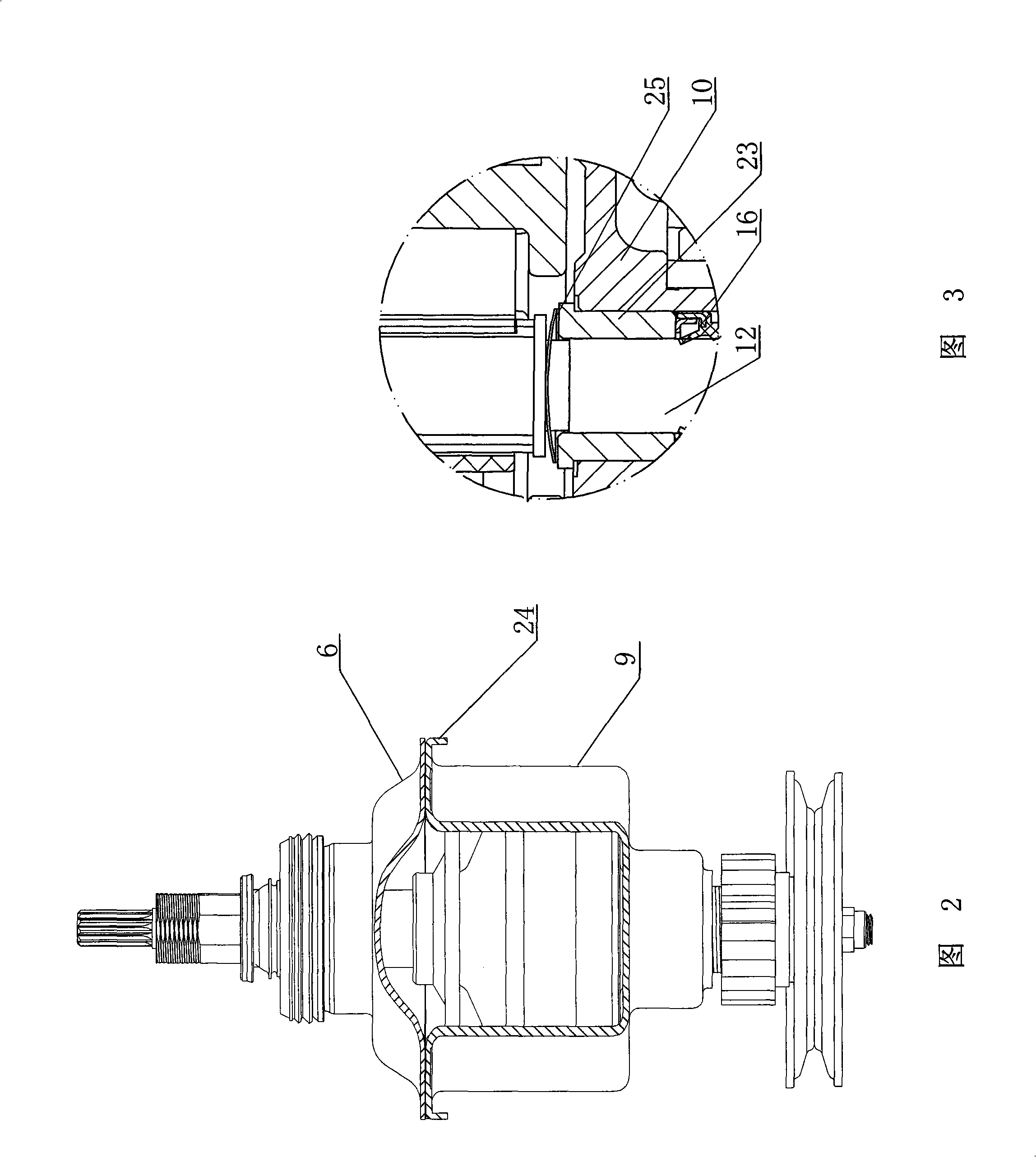

[0015] See figure 1 , the present invention comprises input shaft 12, output shaft 1, dehydration shaft 2, input shaft 12 is connected with output shaft 1, dehydration shaft 2 through the gear structure inside the gear box 8, the outside of the gear box 8 is the shell assembly, the gear structure in The center wheel 20, the planetary gear 18, and the external gear 17 are respectively spur gears, and the center wheel 20, the planetary wheel 18, and the external gear 17 adopt NGW transmission, and the NGW transmission is the internal meshing gear pair (N), the external meshing gear pair (W ), a planetary gear transmission mechanism composed of a common planetary gear (G), there are at least three planetary wheels 18, the center distance between the planetary wheel 18 and the center wheel 20 is greater than 20 millimeters, and the standard center distance is 20 millimeters. The mounting bracket 7 of the planetary gear 18 meshes with the output shaft 1, the external gear 17 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com