Spring support

A technology of spring support and support frame, which is applied in the direction of open busbar installation, etc., which can solve the problems that it is difficult to ensure the curvature of the busbar duct, the processing of bracket parts is cumbersome, and the size error of parts, etc., to achieve a significant heat dissipation effect and a beautiful installation effect , reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

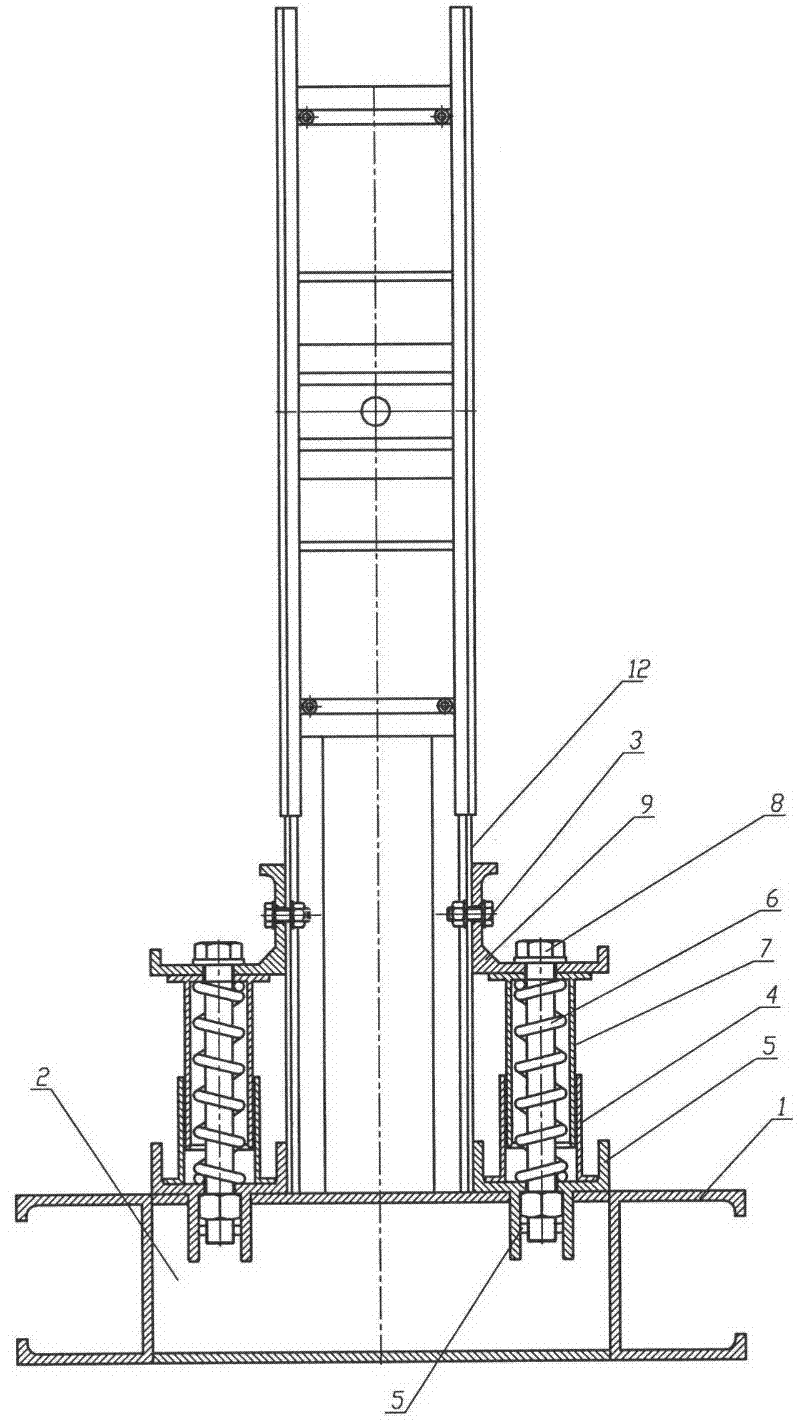

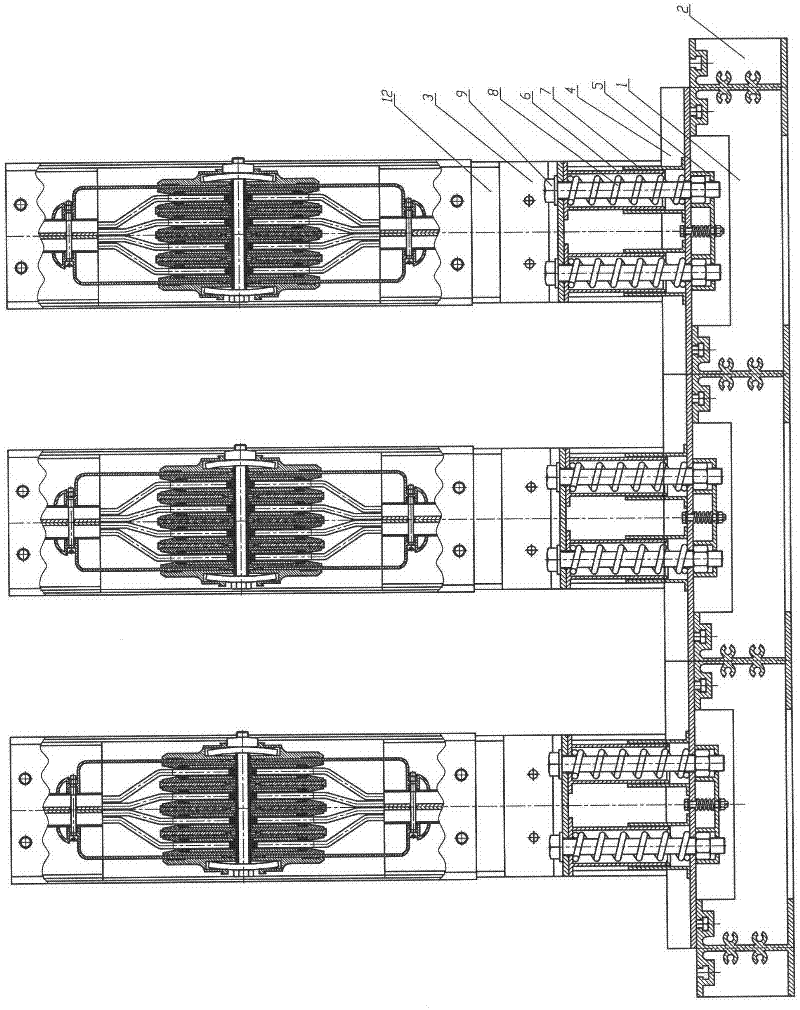

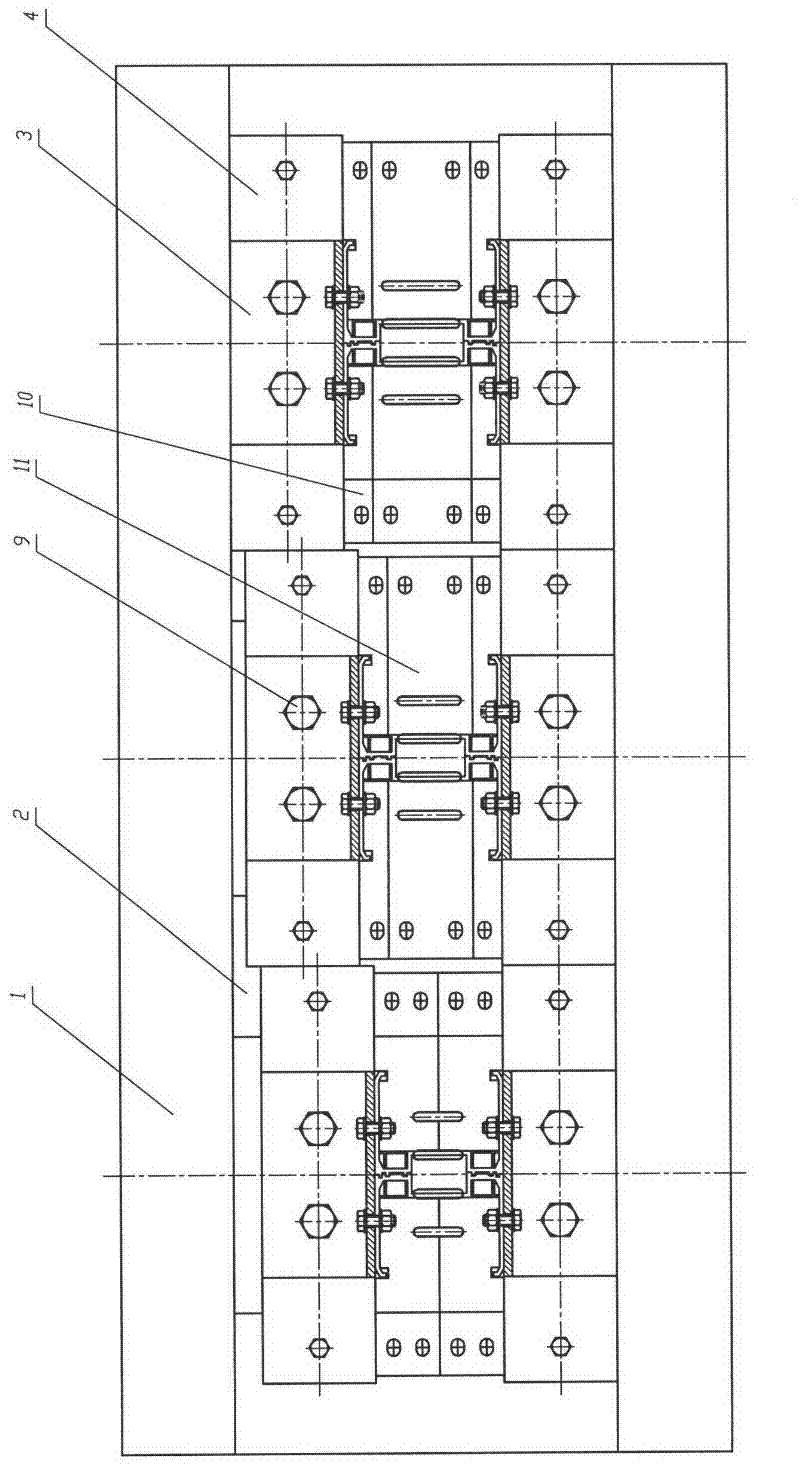

[0011] As shown in the figure, the spring bracket of the present invention includes a grooved aluminum profile 1, an I-shaped aluminum profile 2, a connector 3, a base 4, an M-shaped bracket 5, an upper spring sleeve 6, a lower spring sleeve 7, and a spring 8 , hexagonal bolts 9, side sealing plate 10, middle sealing plate 11, etc.; the basic support frame is composed of two grooved aluminum profiles 1 and multiple I-shaped aluminum profiles 2 surrounding the main body of the busbar, and the middle part of the I-shaped aluminum profiles 2 is provided with symmetrical The rib-shaped connecting hole is used for the fixed connection between the I-shaped aluminum profile 2 and the grooved aluminum profile 1; the inner side of the I-shaped aluminum profile 2 is provided with a shoulder-shaped step hole, and the shoulder size of the step hole is between the two symmetrical planes of the M6 hexagon nut. The distances are equal, before the support frame is assembled, M6 hexagon nuts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com