Lead acid storage battery open failure test system and prediction method

A technology of lead-acid battery and test system, which is applied in the field of battery test, can solve the problems that the reliable service life of lead-acid battery cannot be predicted, and achieve the effects of shortening test time, increasing ambient temperature and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

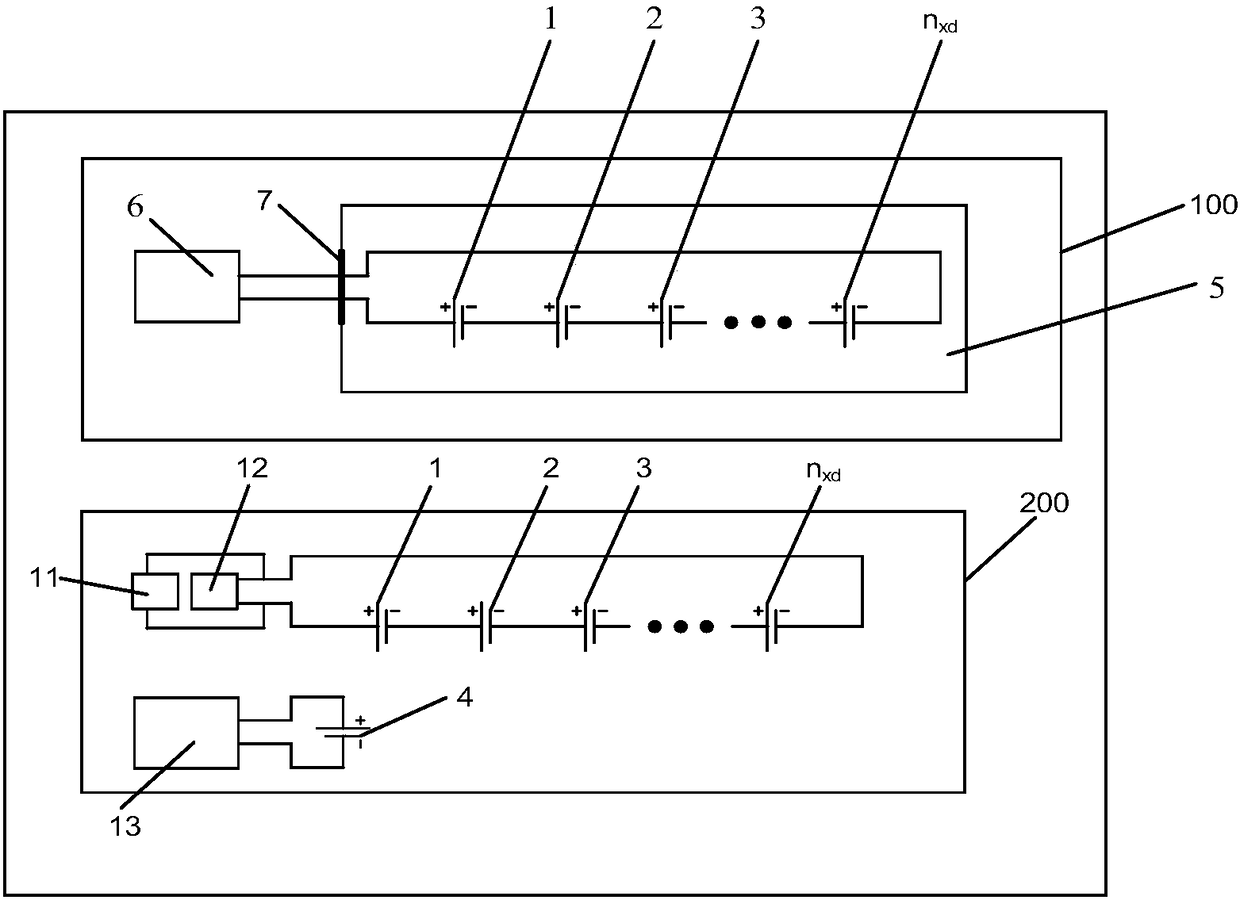

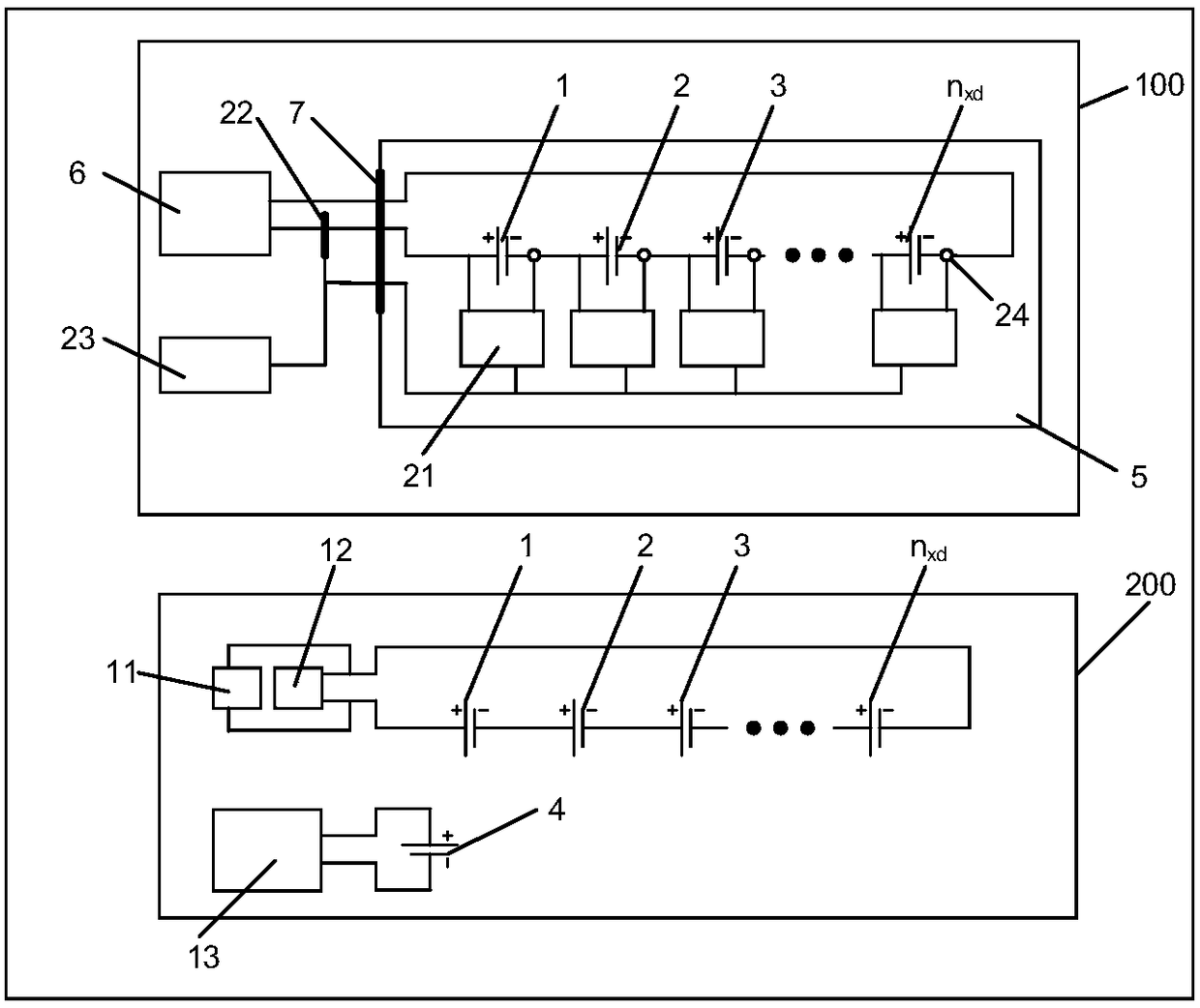

[0039] refer to figure 1 As shown, it is a schematic diagram of the first structure of the lead-acid battery open-circuit failure test system provided by the embodiment of the present invention. The lead-acid battery open-circuit failure test system provided in this embodiment includes: a lead-acid battery high-temperature accelerated corrosion subsystem 100 and a lead-acid battery room temperature charging and discharging subsystem 200 . The lead-acid battery high temperature accelerated corrosion subsystem 100 is used to continuously float-charge the lead-acid battery pack in a high-temperature environment, and accelerate the internal corrosion speed of the lead-acid battery during floating charging by increasing the ambient temperature, including the high-temperature test chamber 5 and the floating battery. charging device6. The charge and discharge subsystem 200 of the lead-acid battery at room temperature includes a constant current discharge load 11, a charging device 1...

Embodiment 2

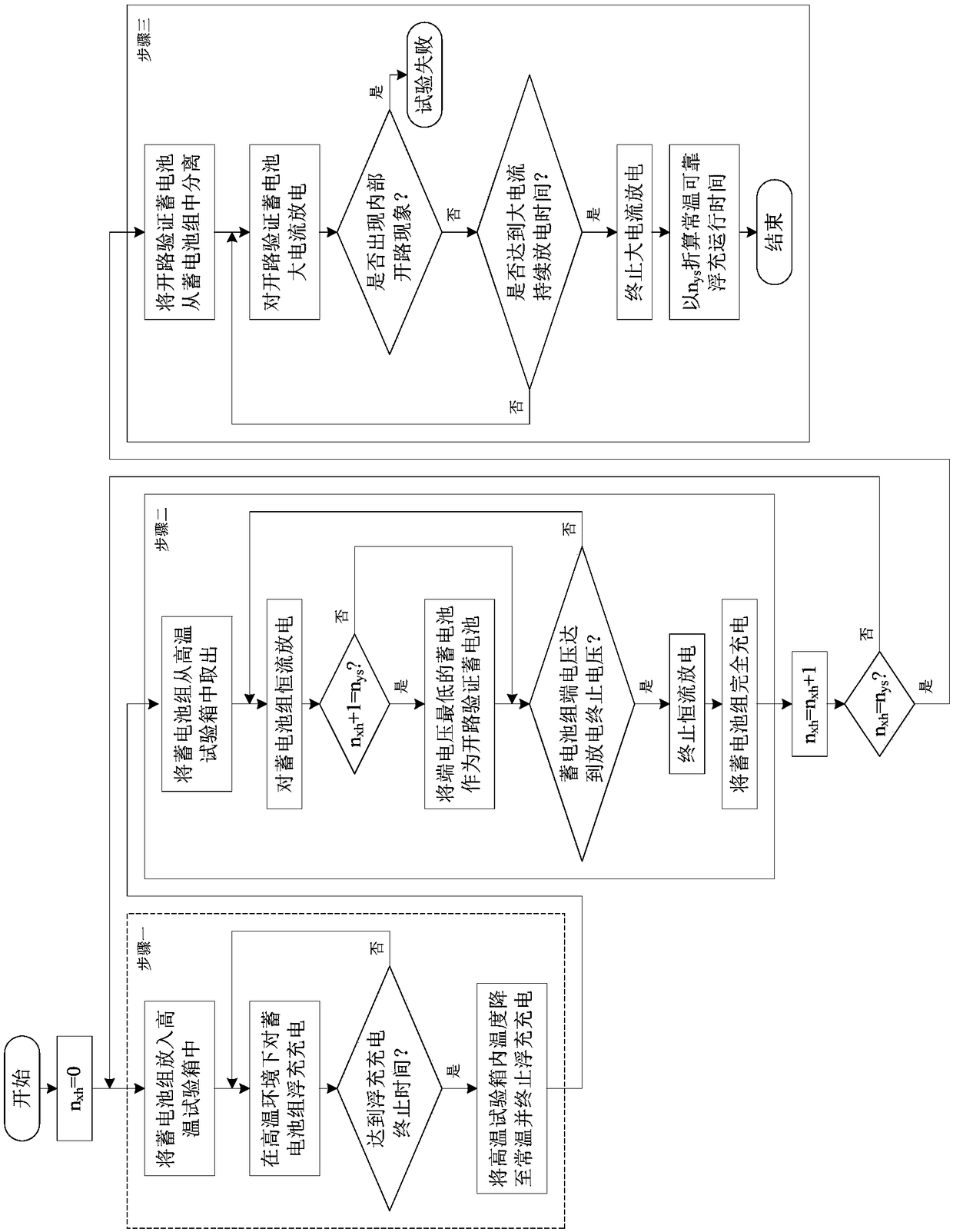

[0054] refer to image 3 , which is a schematic flow chart of the first method for predicting the open circuit failure of the lead-acid battery provided by the embodiment of the present invention. The process of the method for predicting the open-circuit failure of the lead-acid battery provided in this embodiment is divided into: step 1, step 2 and step 3.

[0055] Among them, in step 1, the lead-acid battery pack is continuously floated and charged in a high temperature environment; in step 2, the lead-acid battery pack is discharged at a constant current and fully charged in a normal temperature environment; The second open circuit verification battery is discharged with a large current in a normal temperature environment and judges whether it is open circuit.

[0056] In the process of the lead-acid battery open-circuit failure prediction method, the cycle consisting of step 1 and step 2 is repeated until the number of cycles is n xh Reach the preset number of cycles n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com