Concrete anti-freezing agent

An antifreeze and concrete technology, applied in the field of concrete antifreeze, can solve the problems affecting the use and appearance quality of buildings, the service life of buildings, and the quality of life, etc., and achieve good ecological safety and compatibility, good working performance, and solidification short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

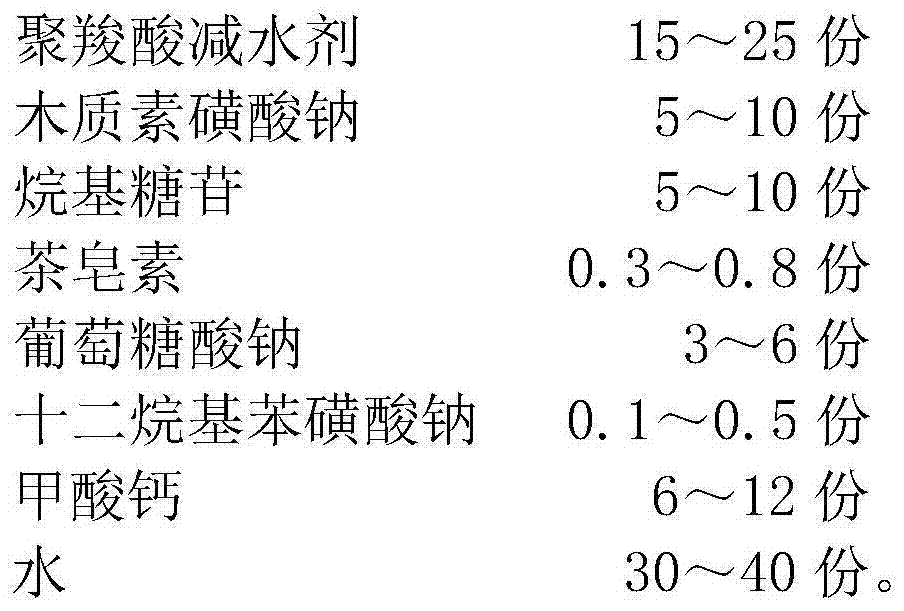

[0021] Weigh the raw materials by the following parts by weight:

[0022]

[0023] The preparation method of concrete antifreeze is as follows:

[0024] Put water into the reaction kettle, heat to 50°C, and then add calcium formate, sodium dodecylbenzenesulfonate, alkyl glycoside, tea saponin, sodium lignosulfonate, polycarboxylate water-reducing agent in sequence while stirring agent, sodium gluconate, react for 90min, and cool down to room temperature.

Embodiment 2

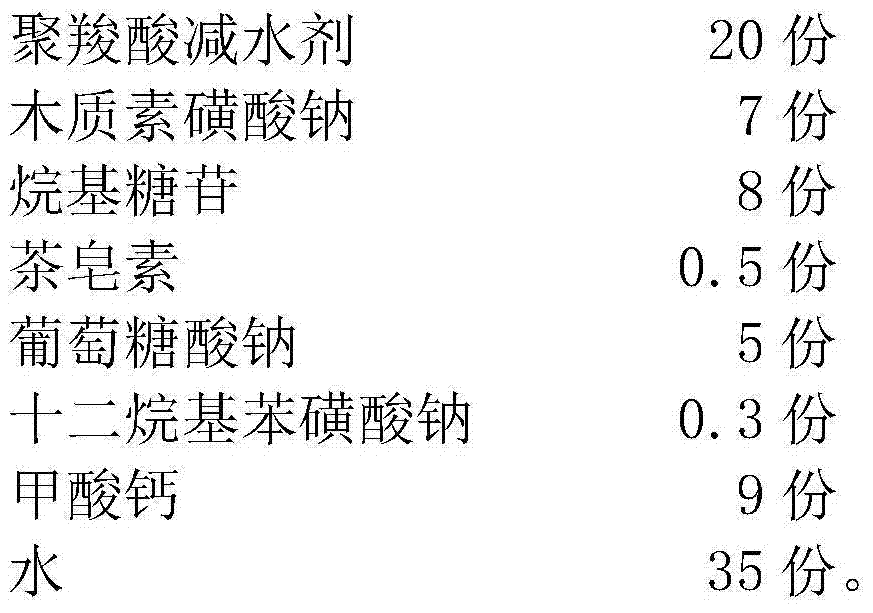

[0026] Weigh the raw materials by the following parts by weight:

[0027]

[0028] The preparation method of concrete antifreeze is as follows:

[0029] Put water into the reaction kettle, heat to 55°C, then add calcium formate, sodium dodecylbenzenesulfonate, alkyl glucoside, tea saponin, sodium lignosulfonate, polycarboxylate water reducing agent, sodium gluconate, react for 80min, and cool down to room temperature.

Embodiment 3

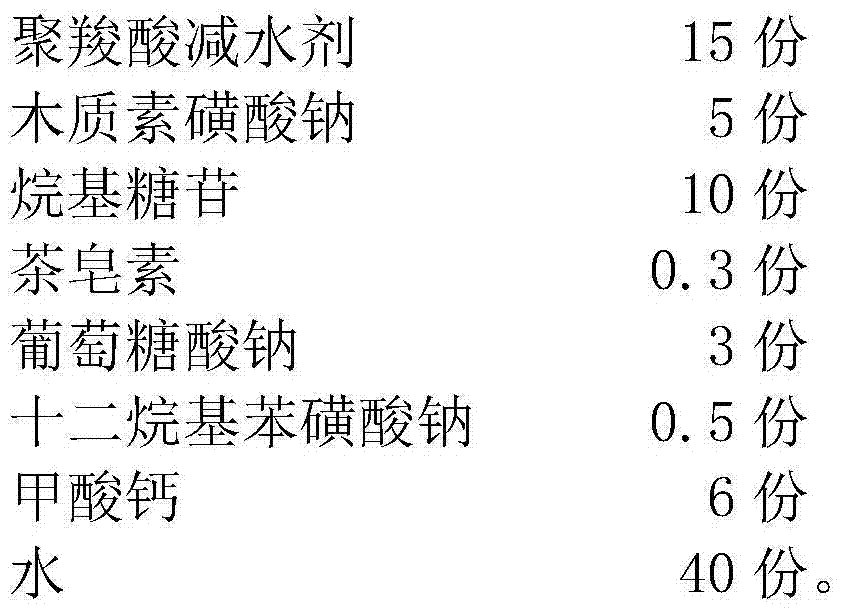

[0031] Weigh the raw materials by the following parts by weight:

[0032]

[0033]

[0034] The preparation method of concrete antifreeze is as follows:

[0035] Put water into the reaction kettle, heat to 60°C, then add calcium formate, sodium dodecylbenzenesulfonate, alkyl glucoside, tea saponin, sodium lignosulfonate, polycarboxylic acid water reducing agent, sodium gluconate, react for 70min, and cool down to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com