A linkage punching system

A linkage, punching machine technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of inconvenient use, low automation and low efficiency of punching equipment, and achieve economical equipment and maintenance costs. The effect of durable service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

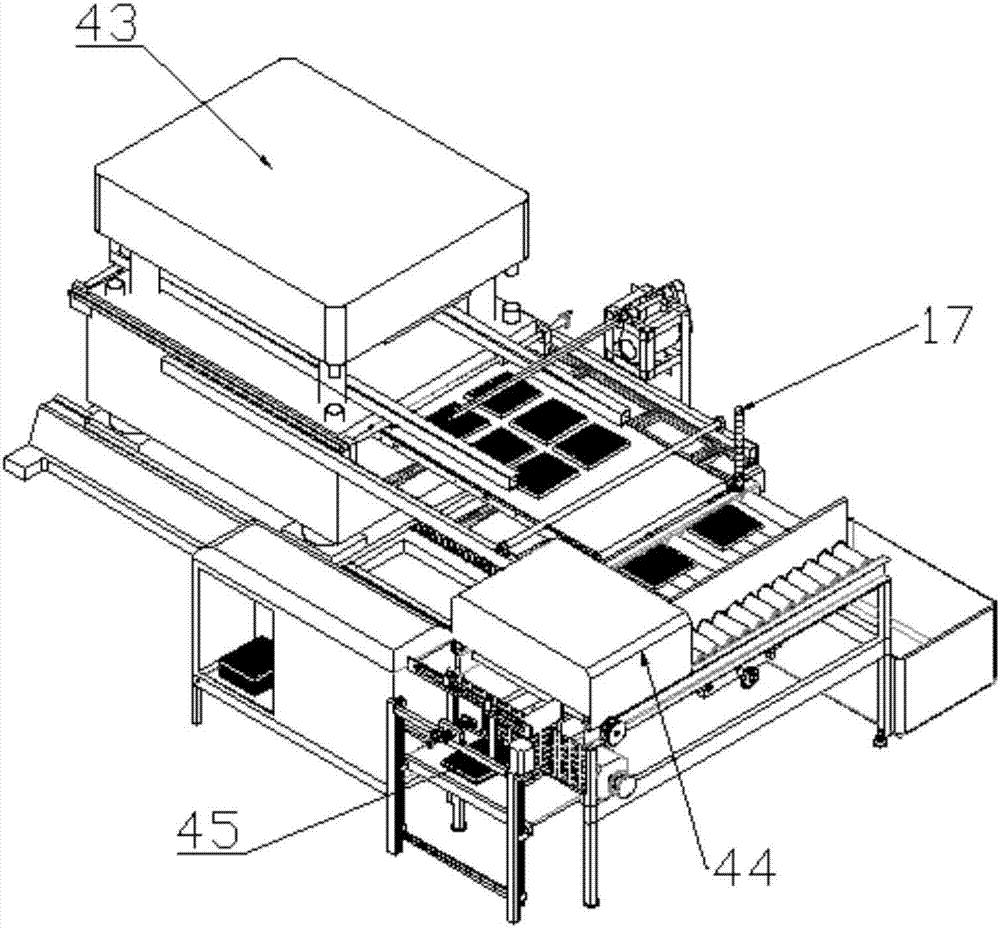

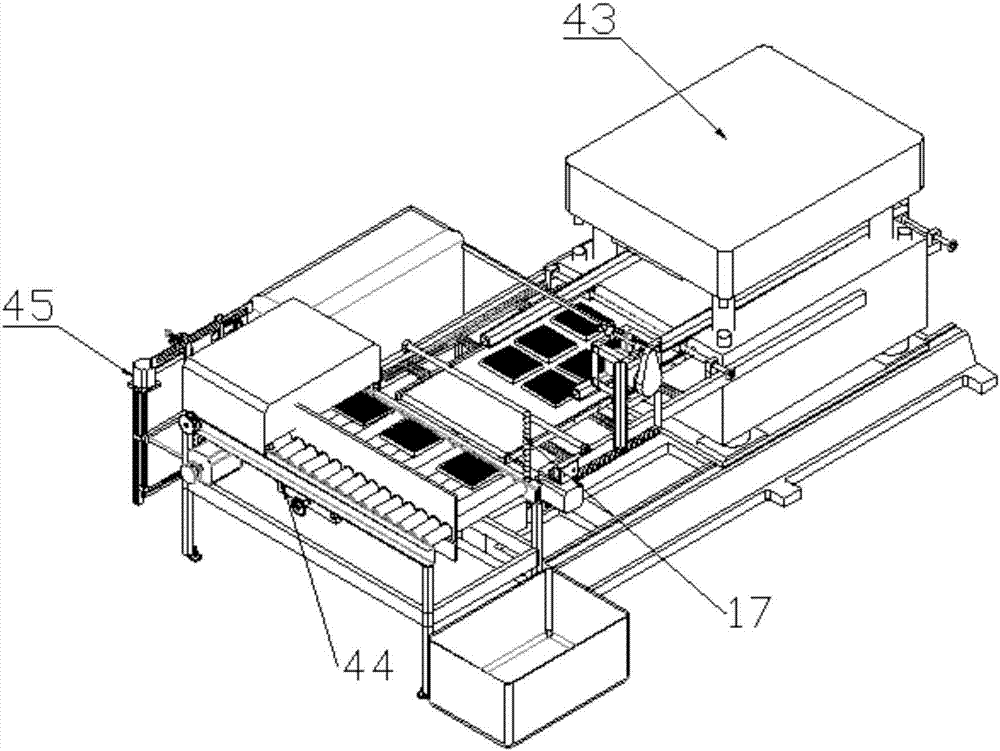

[0042] like figure 1 and 2 As shown, a linkage punching system includes a punching machine system 43 , a dust removal system 44 and a receiving system 45 .

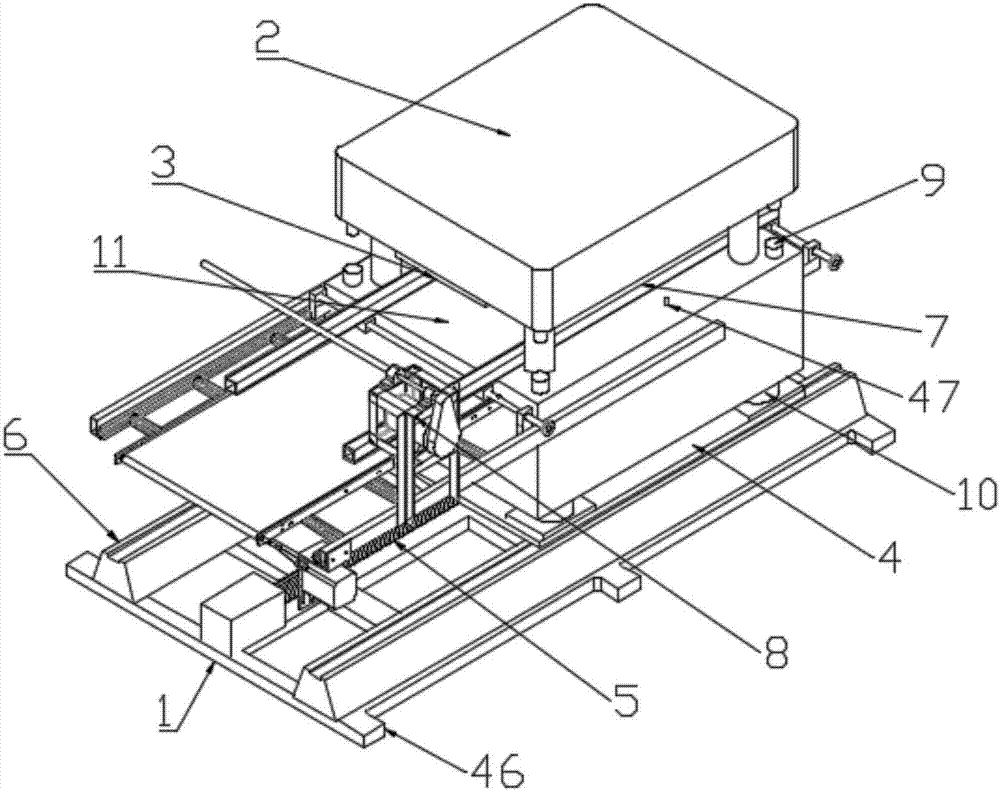

[0043] like image 3 and 4As shown, the punching machine system includes a base 1, horizontal guide rails 6 are provided on both sides of the base 1, and a servo motor is provided at one end of the base 1, and the servo motor is connected to a pressure plate through a sliding screw rod 5 4. Both sides of the pressure bearing plate 4 are located on the horizontal guide rails 6 on both sides of the base 1, so that the pressure bearing plate 4 can slide on the horizontal guide rails 6, and a hydraulic punching machine 2 is correspondingly installed on the horizontal guide rails 6 Above the pressure bearing plate 4, a die structure 3 is provided below the upper hydraulic plate of the hydraulic punching machine 2, and the die structure 3 includes a die absorption plate, and a laser cutting knife is adsorbed on the die absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com