Rotary type steel pipe surface cleaning device

A surface cleaning and rotating technology, applied in the field of machinery, can solve the problems that affect the smooth progress of production, unsatisfactory ash removal effect, high misjudgment rate of flaw detectors, etc., to reduce auxiliary operation time, good ash removal effect, and large coverage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

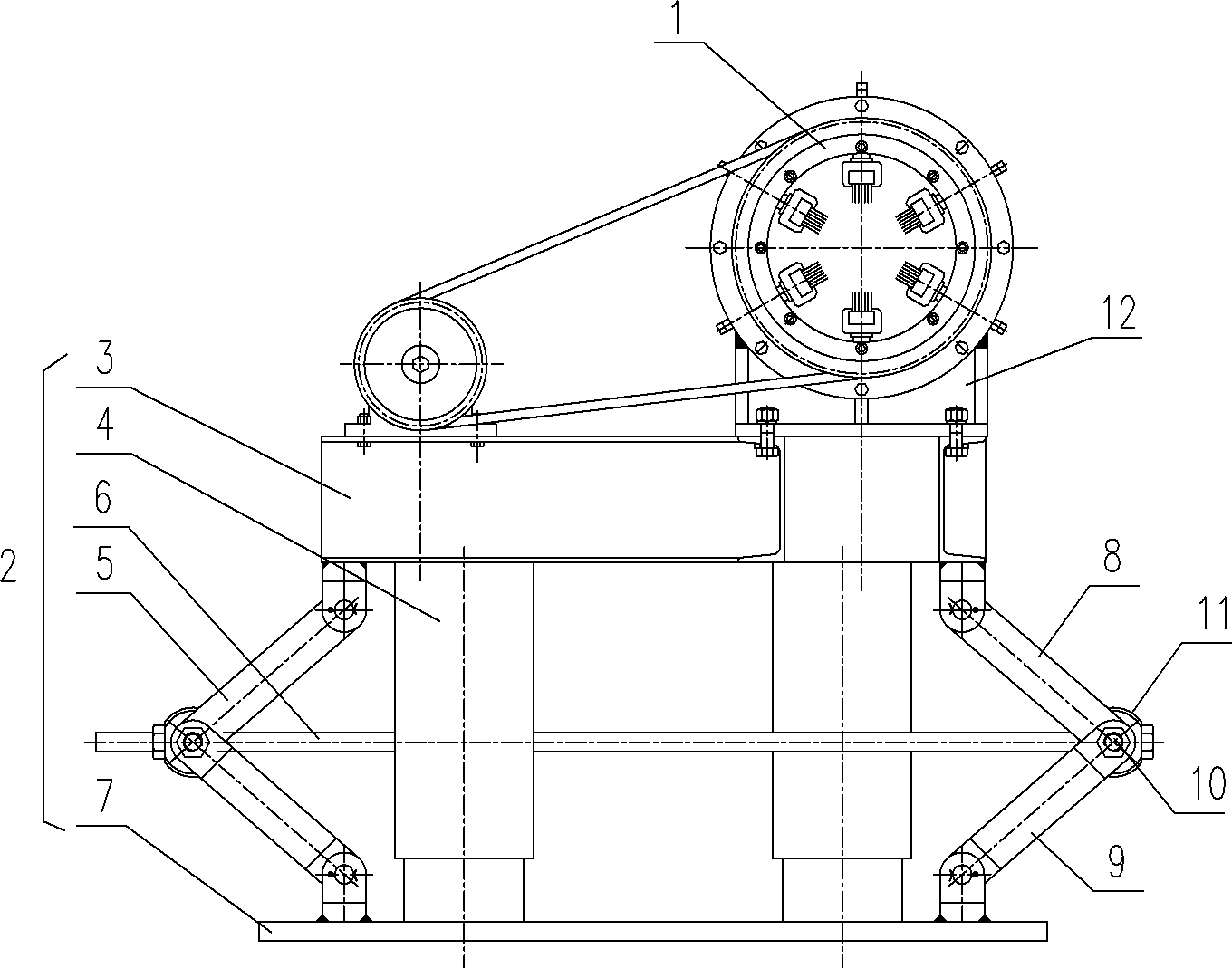

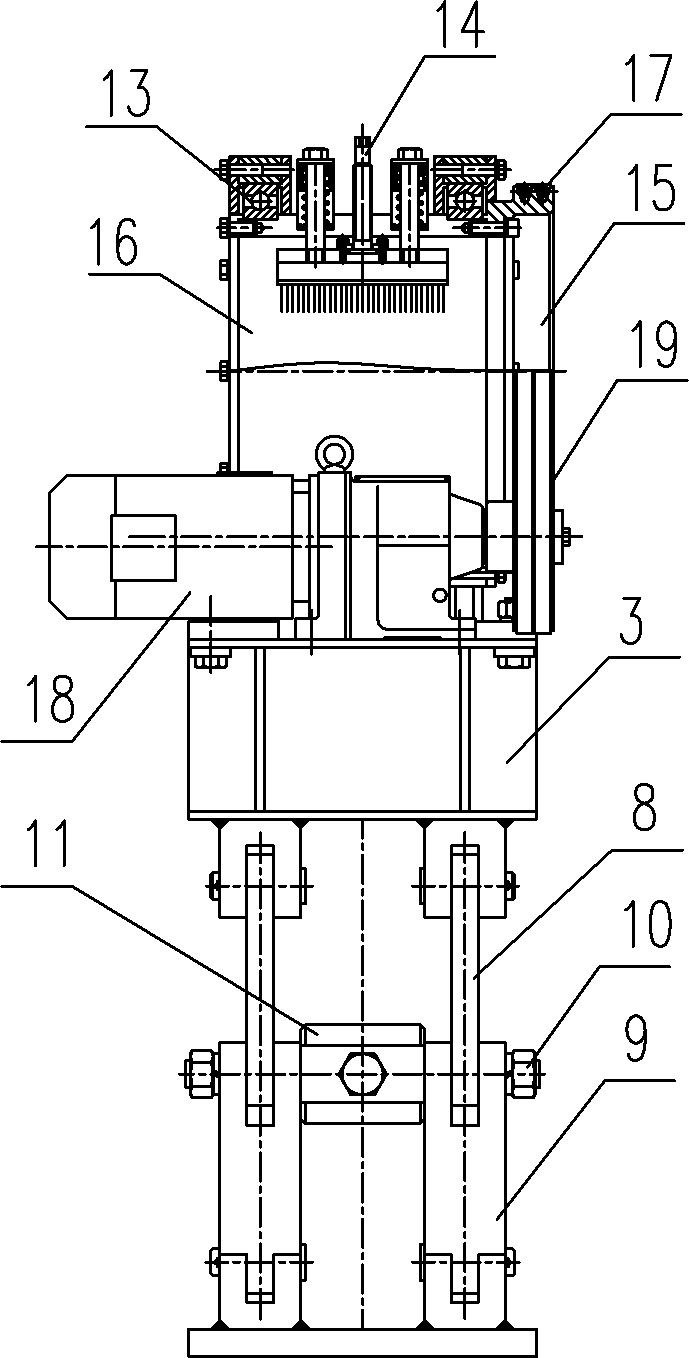

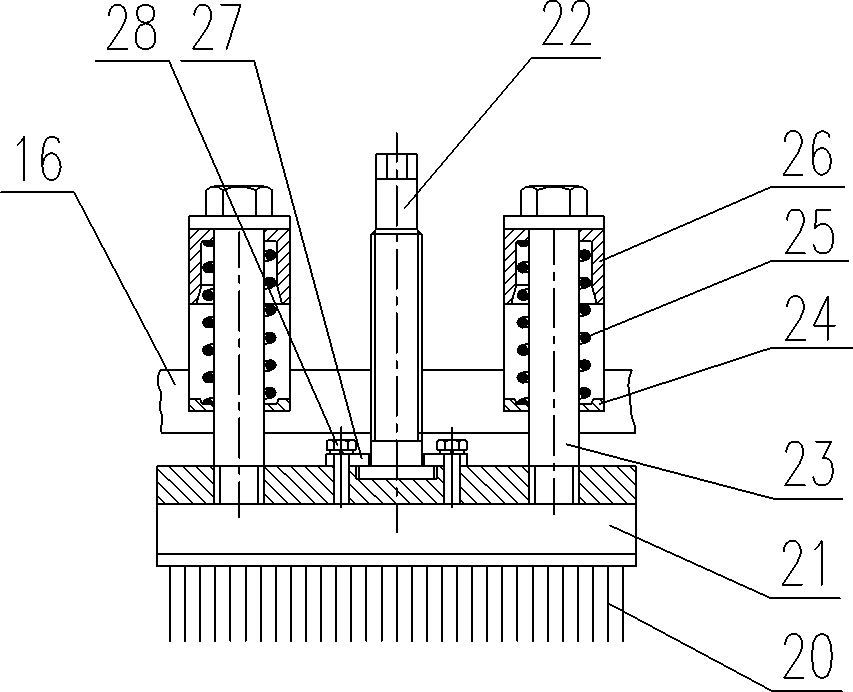

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] See figure 1 , figure 2 , is a structural schematic diagram of an embodiment of the rotary steel pipe surface cleaning device of the present invention. The device is arranged on the steel pipe conveying roller table and includes a rotating brush holder 1 and a lifting base 2. The rotating brush holder 1 is arranged on the lifting base 2. The lifting base 2 includes an upper platform 3, a lifting guide device 4, a lifting hinge 5, a screw adjustment mechanism 6, and a foot pad 7, and a lifting guide device 4 and a lifting hinge 5 are respectively arranged between the upper platform 3 and the foot pad 7 , the lifting hinge 5 includes an upper link 8 and a lower link 9, and a pin shaft 10 is arranged between the upper link 8 and the lower link 9, and the pin shaft 10 between the two groups of lifting hinges 5 is connected by a screw adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com