Patents

Literature

35results about How to "Flexible specifications" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

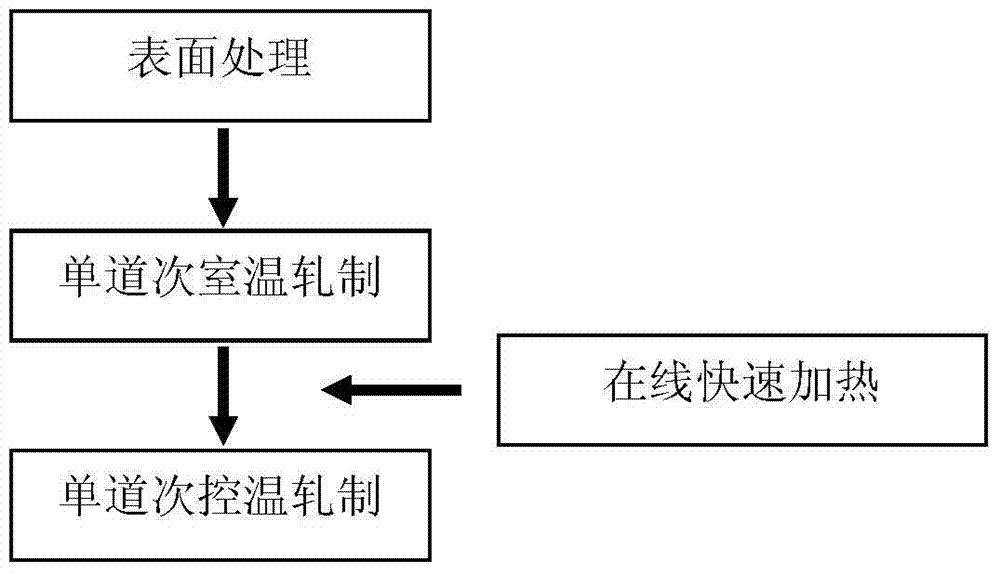

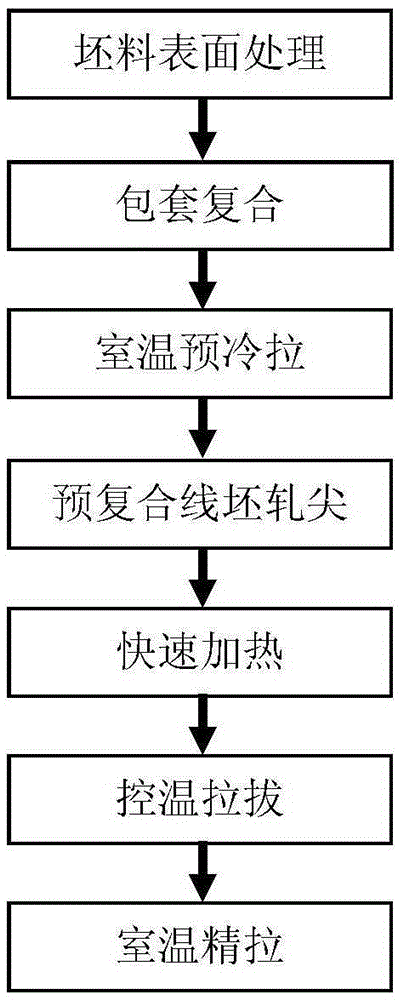

Short-process efficient production method for metal-layered composite board strips

ActiveCN103752611AIncrease profitReduce pollutionMetal rolling arrangementsTemperature controlMetal strips

The invention discloses a short-process efficient production method for metal-layered composite board strips and belongs to the technical field of production of the metal-layered composite board strips. The short-process efficient production method is characterized by including: subjecting to-be-composited double-layered or multilayered metal board strips subjected to surface treatment to single-pass room temperature rolling to obtain pre-composited metal-layered composite board strip plates; rapidly heating the pre-composited metal-layered composite board strip plates to the temperature (lower than recrystallization temperature of metal) required by subsequent rolling; continuing performing single-pass temperature-controlled rolling so as to prepare high-performance metal-layered composite board strips. The short-process efficient production method has the advantages of continuity and high degree of automation, short process, high production efficiency, small environmental pollution, energy conservation, circle-time reduction, freeness of potential safety hazards, high dimensional accuracy of products, flexible specifications, large degree of freedom in raw material combination, high material utilization, low requirements on equipment, low production cost and excellent product quality and performance, and the coiled metal strip plates or long-sized metal plates can be used as raw materials.

Owner:UNIV OF SCI & TECH BEIJING

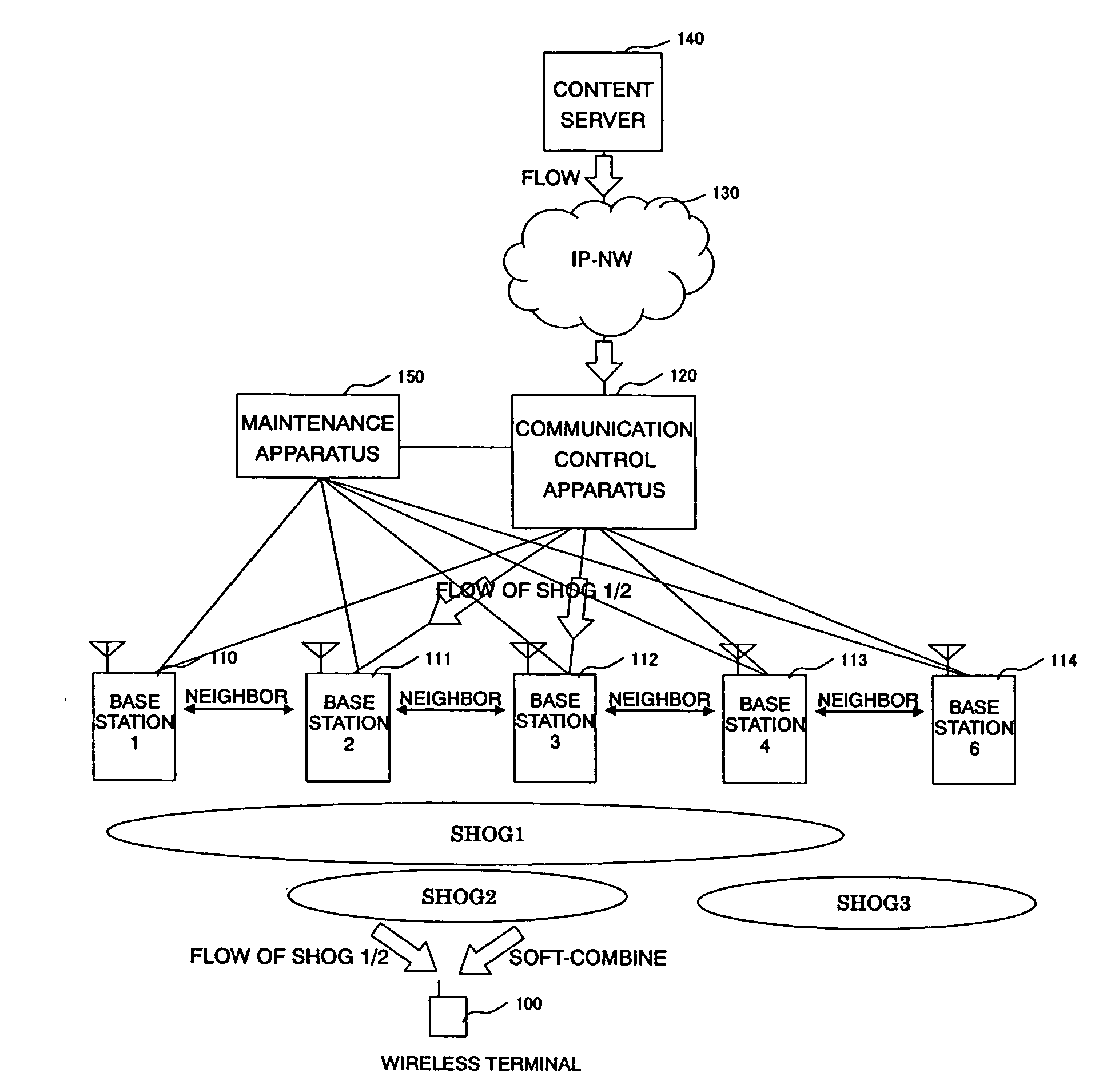

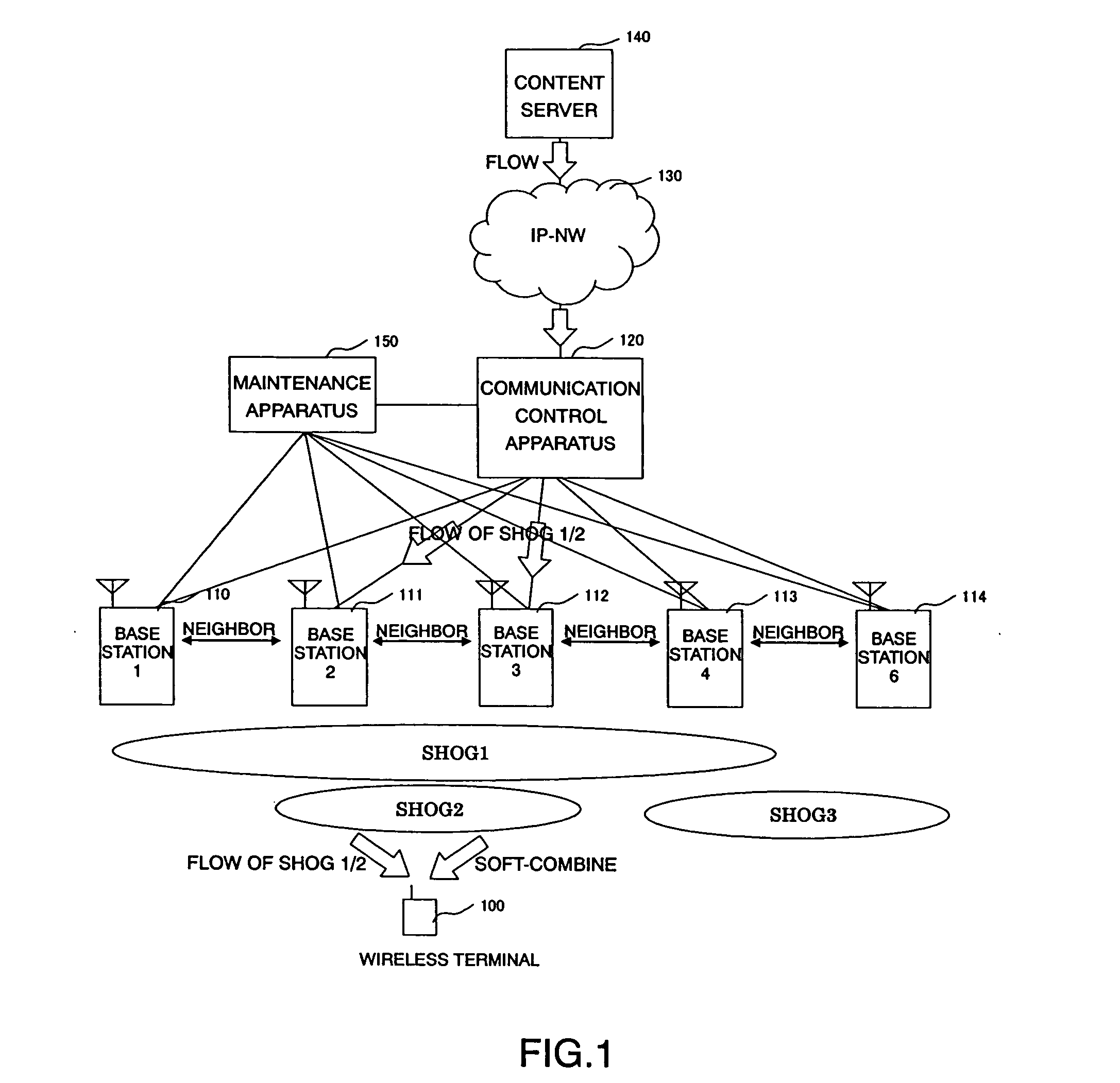

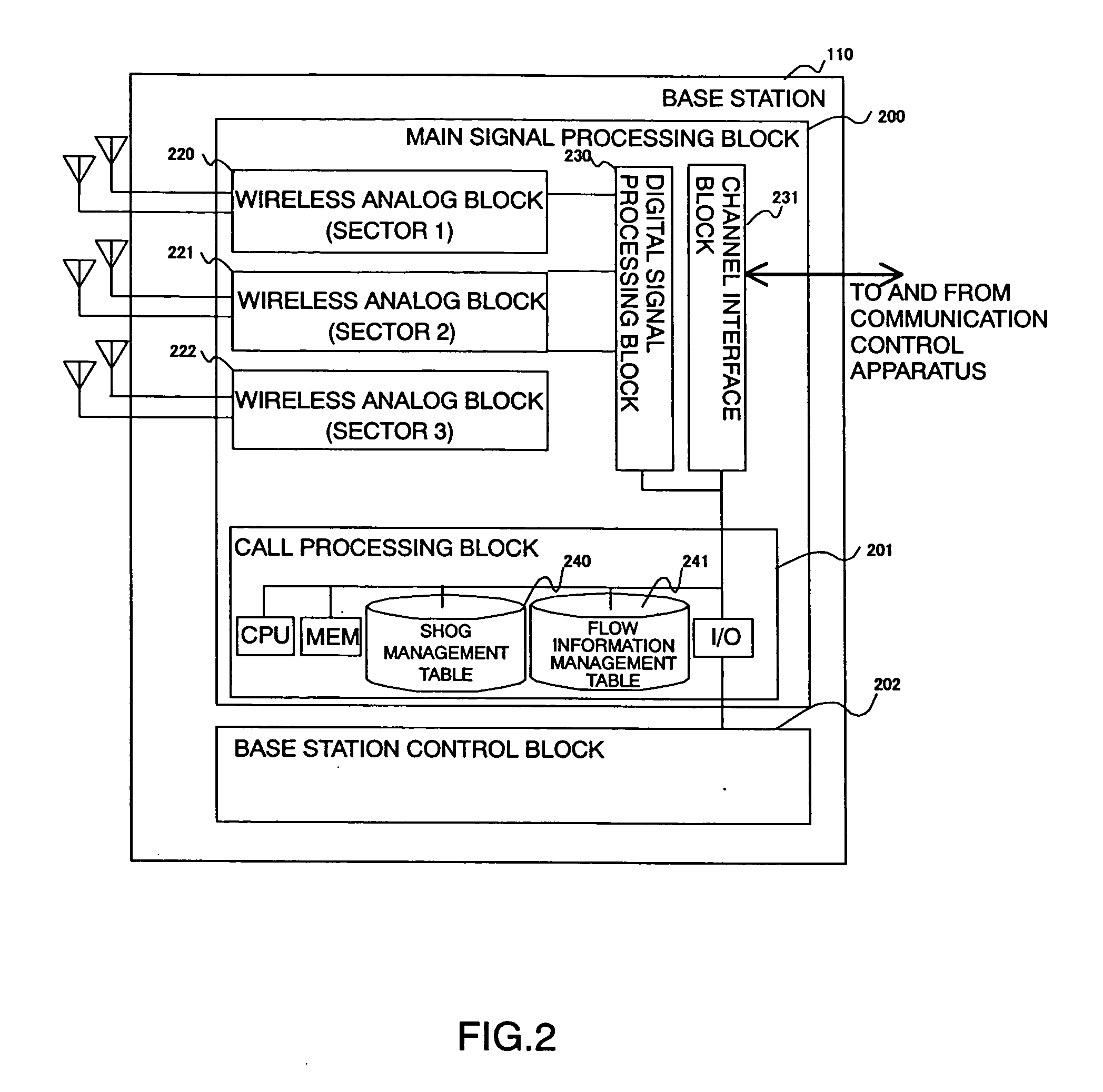

Area management system

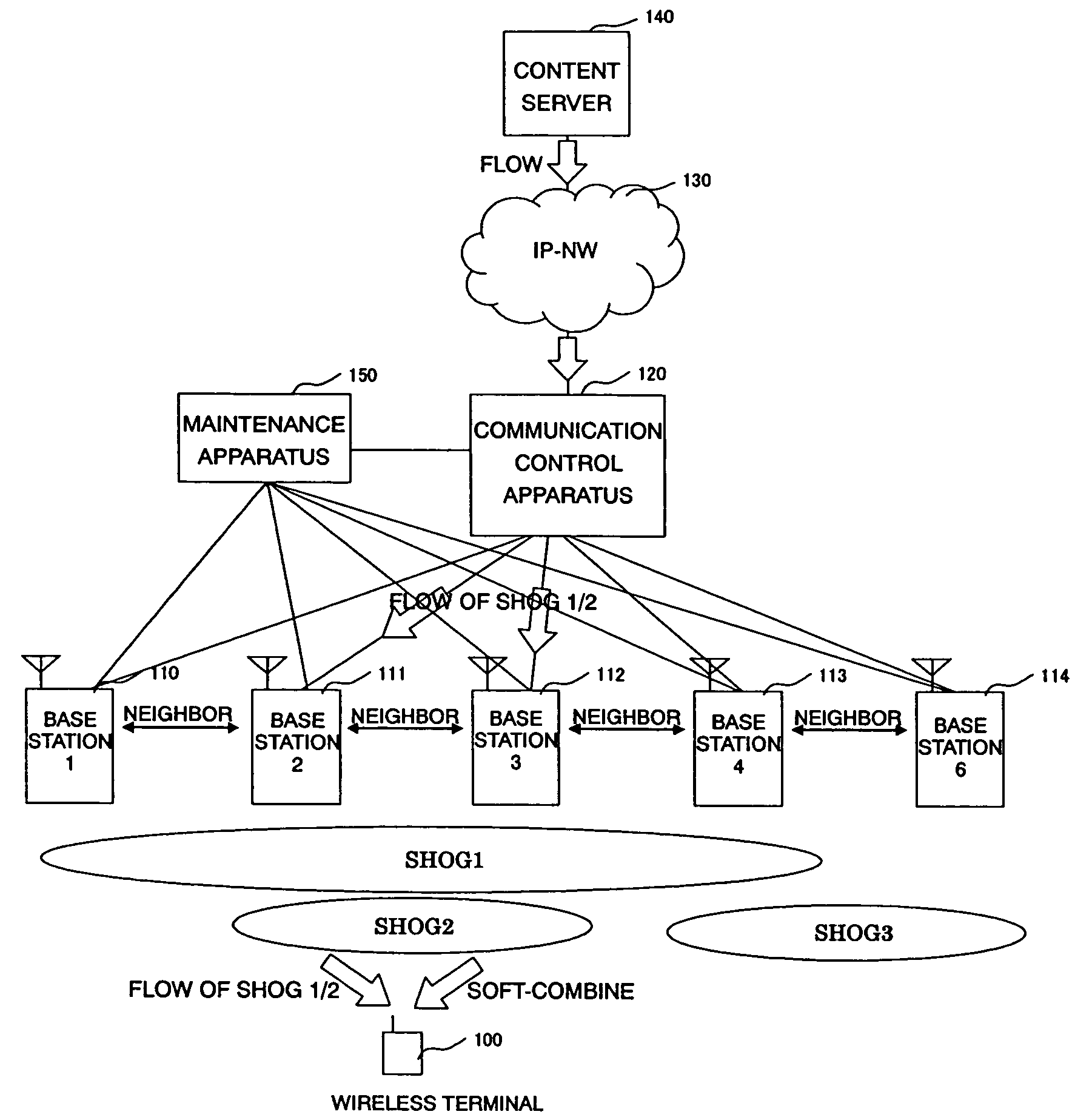

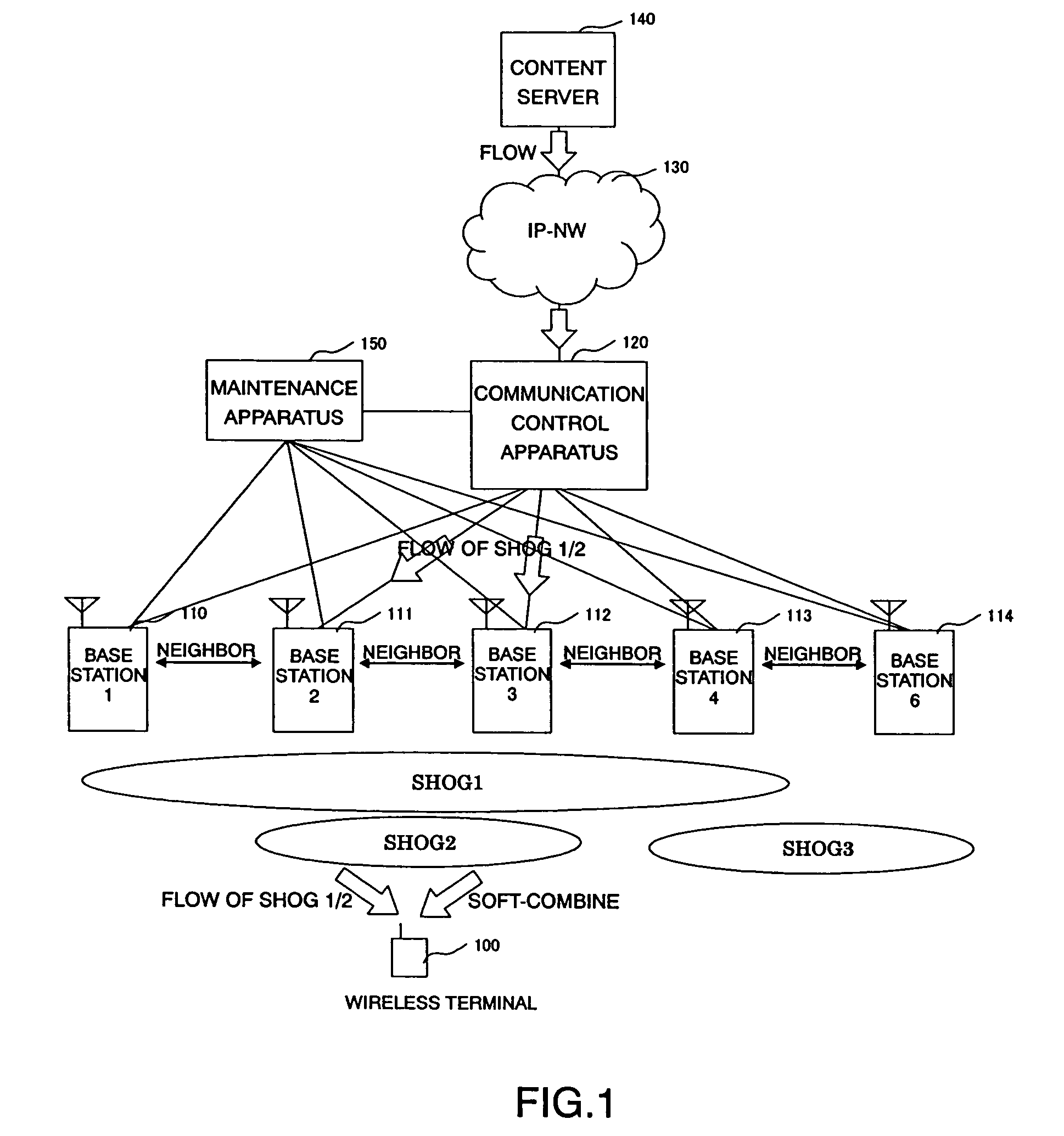

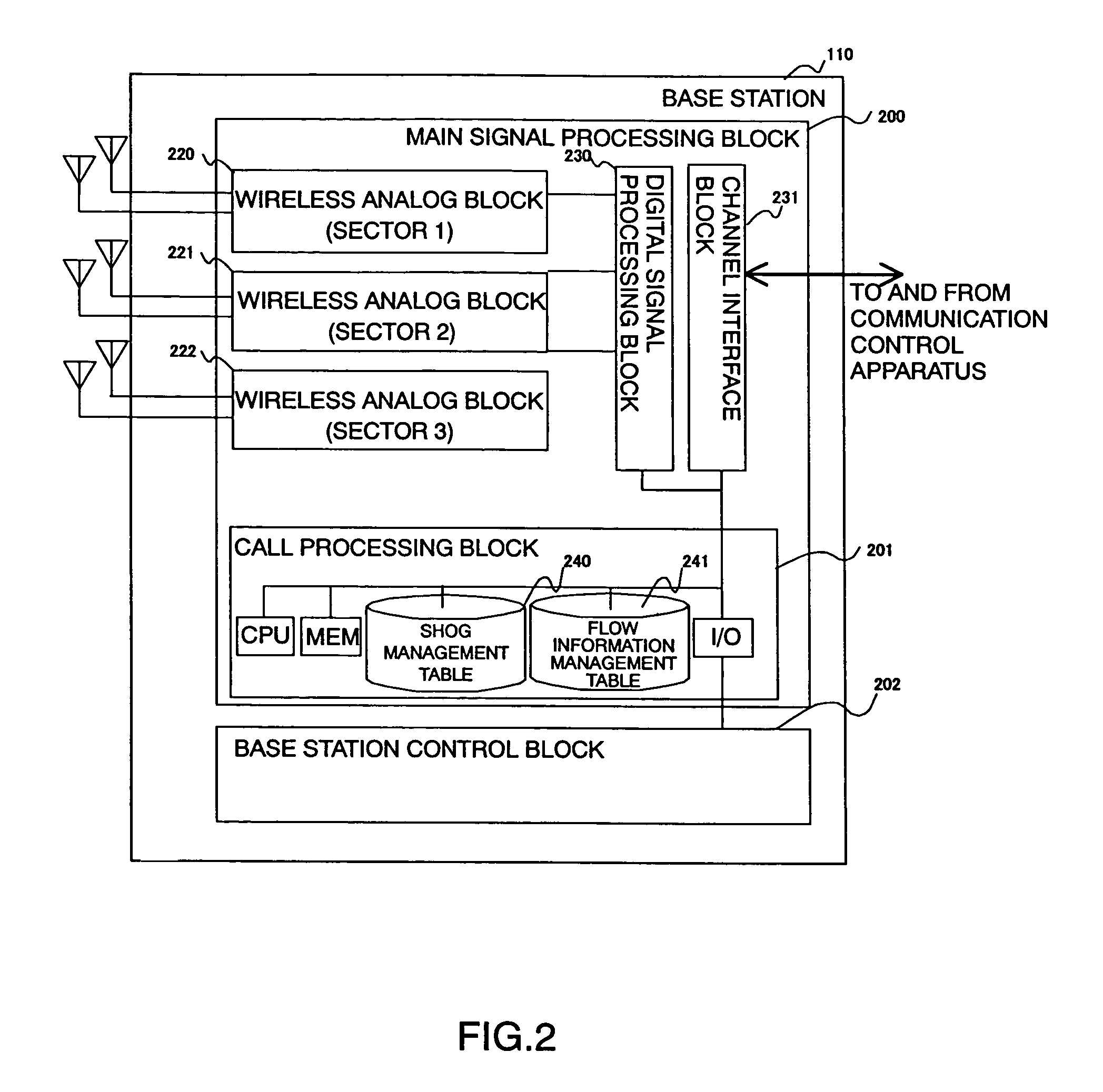

InactiveUS20070211665A1Easy to useImprove reception qualityNetwork traffic/resource managementBroadcast service distributionManagement systemBase station

A transmission area is specified flexibly in accordance with the contents of a flow. An area identification number (SHOG) is specified for each interlaced stream of wireless base stations. The same flow is sent at the same timing (or substantially at the same timing) in the interlaced stream specified for the same SHOG. A wireless terminal determines a neighbor sector or a neighbor wireless base station sending the same flow, in accordance with information given from the wireless base stations, and receives and combines the flows.

Owner:HITACHI LTD

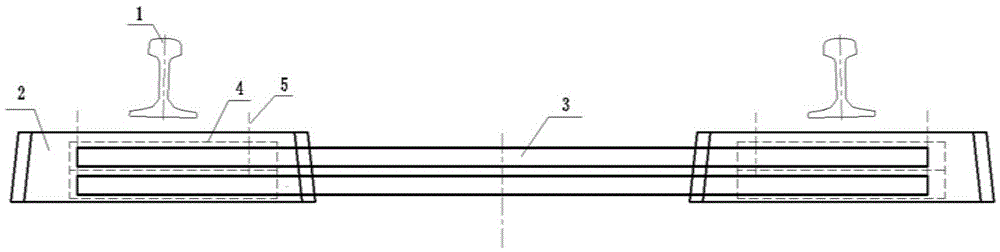

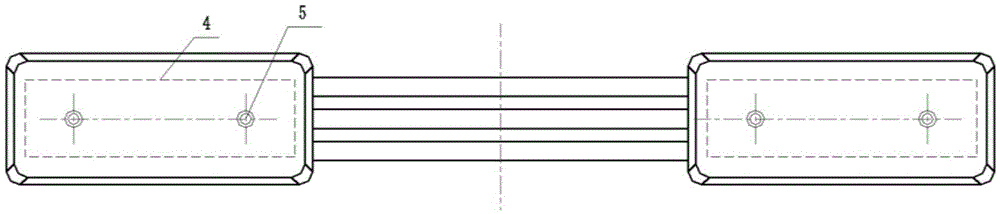

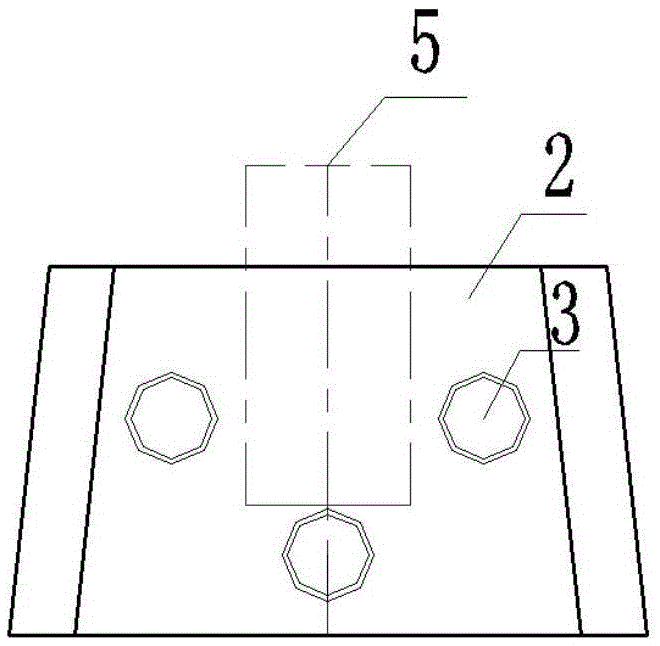

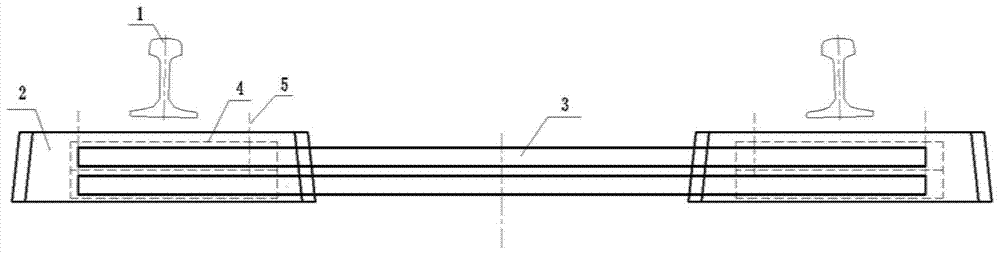

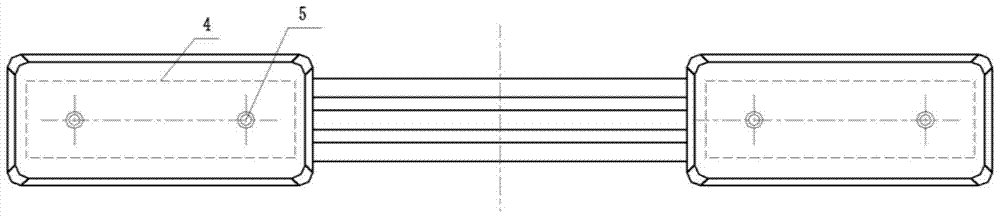

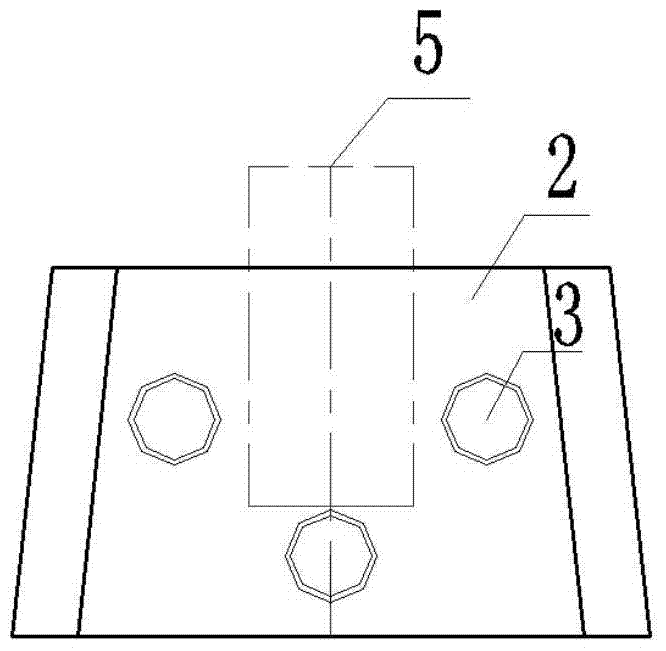

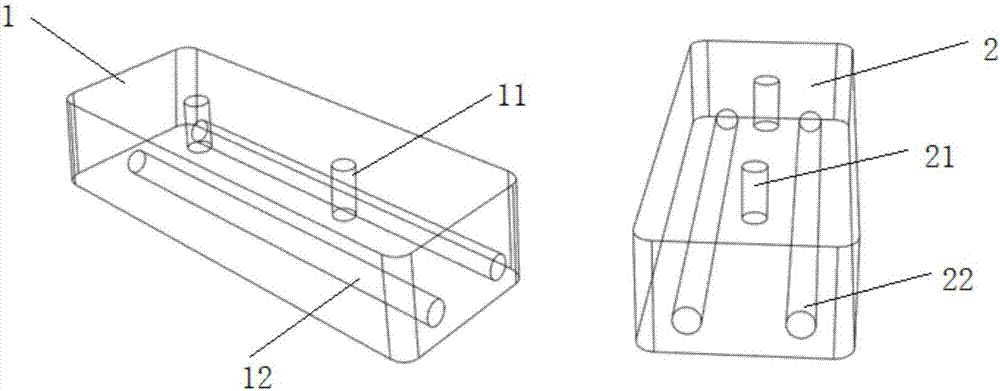

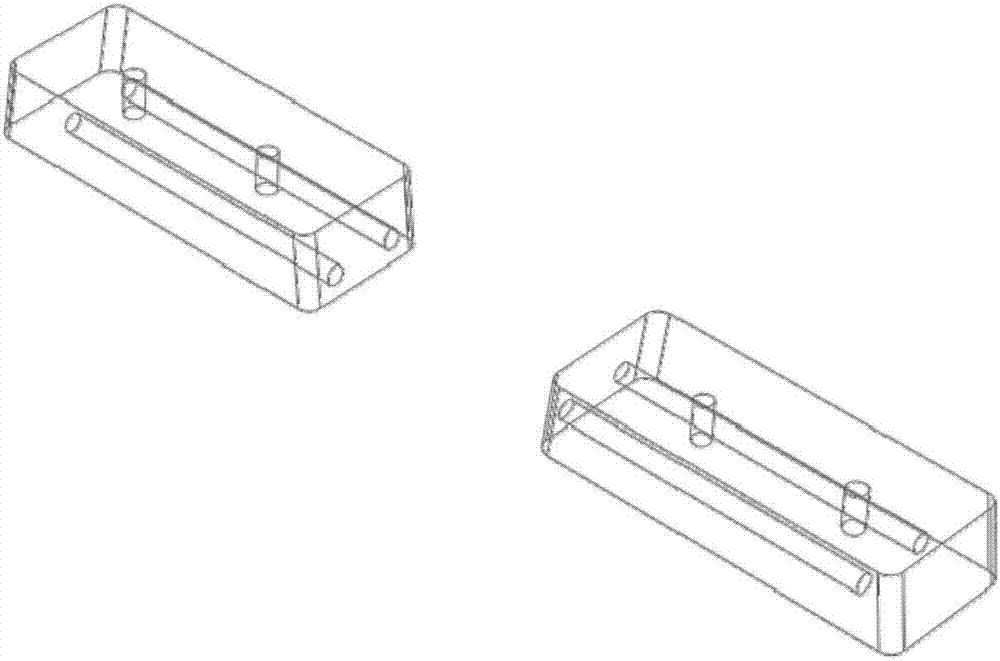

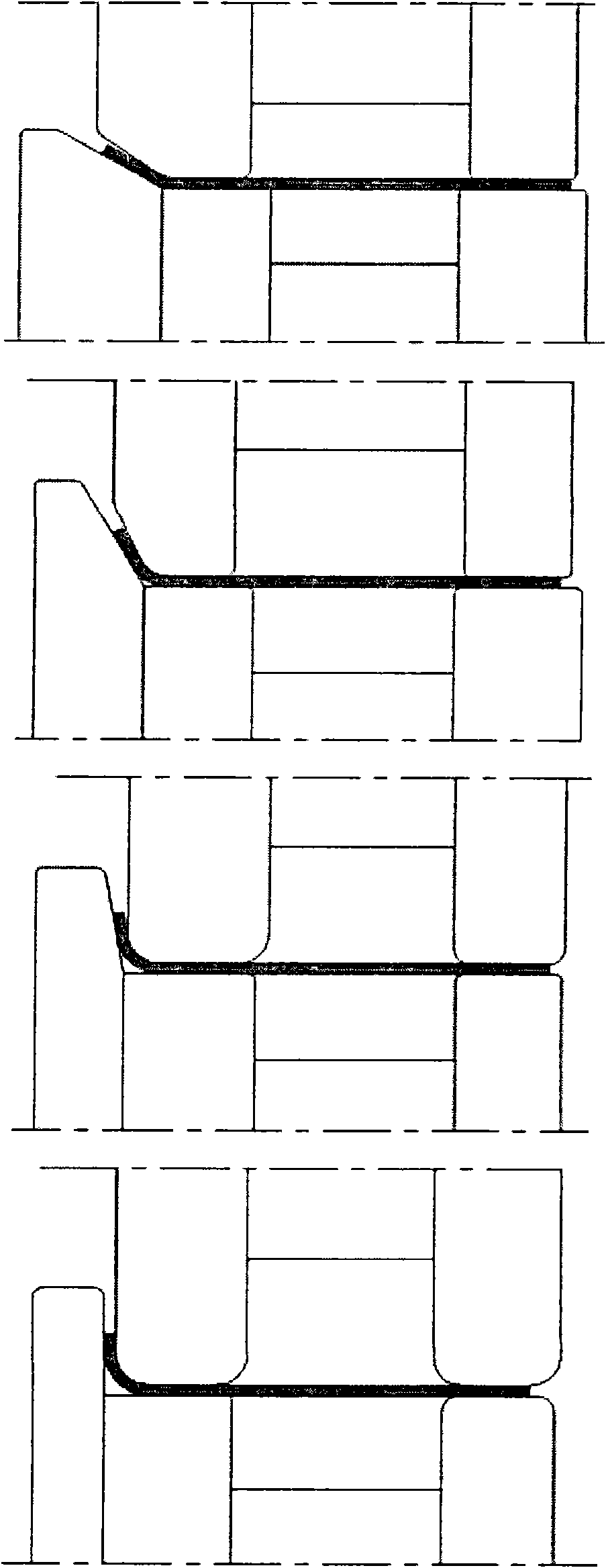

Concrete-filled steel tube sleeper for ballastless track

ActiveCN105463948ARelieve deformationMeet the requirements of bending and torsion resistanceBallastwayHollow coreSteel tube

The invention discloses a concrete-filled steel tube sleeper for a ballastless track. The concrete-filled steel tube sleeper for the ballastless track comprises two or more sleeper concrete blocks and sleeper connecting parts used for connecting the sleeper concrete blocks. Each sleeper concrete block is of a block-shaped structure and formed by pouring concrete, and each sleeper concrete block is internally provided with an embedded part for fixing the steel track and a steel-bar mesh or a stirrup connected with the corresponding sleeper connecting part. Each sleeper connecting part is composed of a plurality of hollow steel tubes transversely arranged between the corresponding sleeper concrete blocks. In the pouring process of the sleeper concrete blocks, the hollow steel tubes are filled with concrete at the same time, so that concrete-filled steel tubes are formed, and accordingly the sleeper connecting parts and the sleeper concrete blocks are integrated through pouring. The concrete-filled steel tubes are applied to the concrete sleeper for the ballastless track, the concrete-filled steel tubes are used as the sleeper connecting parts, and the concrete-filled steel tubes and the sleeper concrete blocks are formed integrally, so that the geometry retention capacity of the sleeper is effectively improved, and steel consumption is reduced; the sleeper has the advantages of being easy to manufacture, high in constructability and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A Steel Tube Concrete Sleeper Suitable for Ballastless Track

ActiveCN105463948BRelieve deformationMeet the requirements of bending and torsion resistanceBallastwayTrackwayArchitectural engineering

The invention discloses a steel pipe concrete sleeper suitable for ballastless tracks, which comprises two or more sleeper concrete blocks and a sleeper connecting piece for connecting the sleeper concrete blocks, the sleeper concrete block is in a block structure, and is made of concrete It is made by pouring, and there are embedded parts for fixing the rails and steel mesh or stirrups connecting the sleeper connectors; the sleeper connectors are composed of a plurality of hollow steel pipes arranged horizontally between the concrete blocks of the sleeper. During the block pouring process, the hollow steel pipe is filled with concrete at the same time to form the concrete filled steel pipe, and then the sleeper connector and the concrete block of the sleeper are poured into one body. In the invention, the concrete-filled steel tube is applied in the concrete sleeper of ballastless track, the concrete-filled steel tube is used as the connector of the sleeper block, and the concrete-filled steel tube and the concrete block of the sleeper are integrally formed, so as to effectively increase the geometric shape and position retention capacity of the sleeper, reduce the amount of steel, and have the advantages of simple preparation , Strong constructability and so on.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

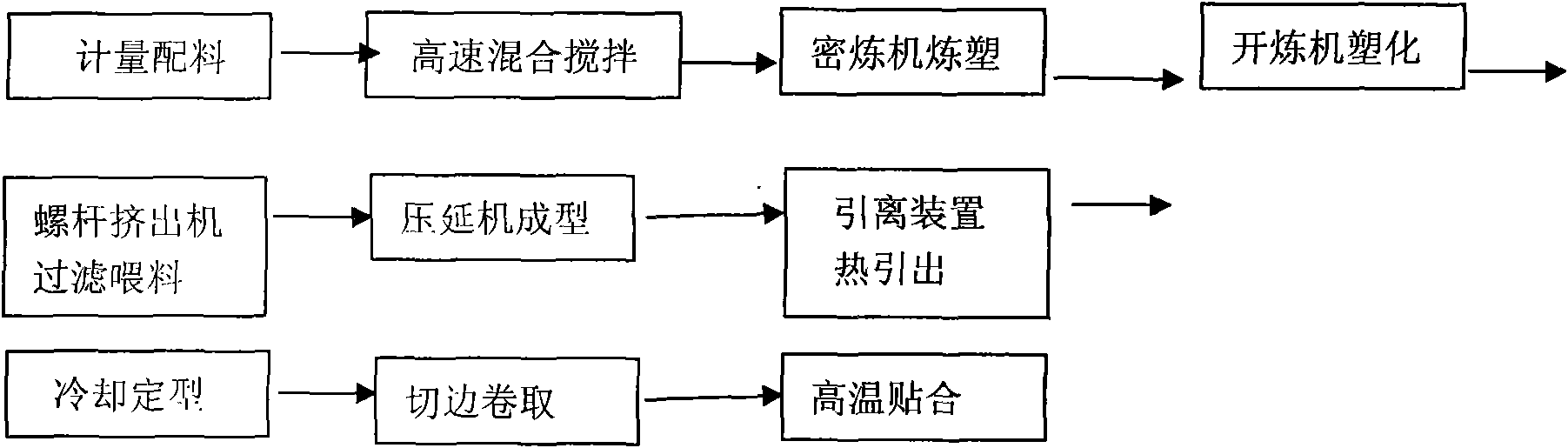

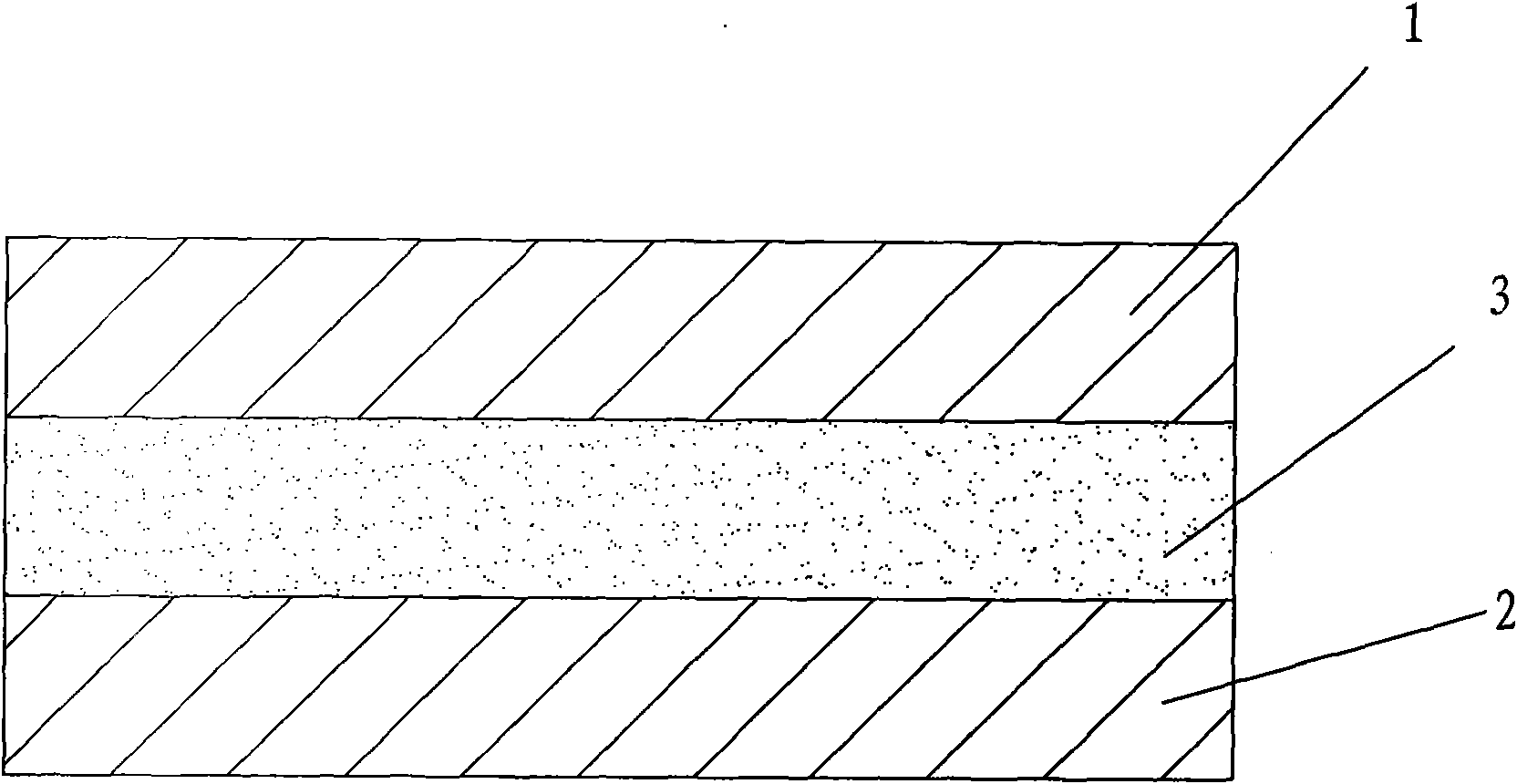

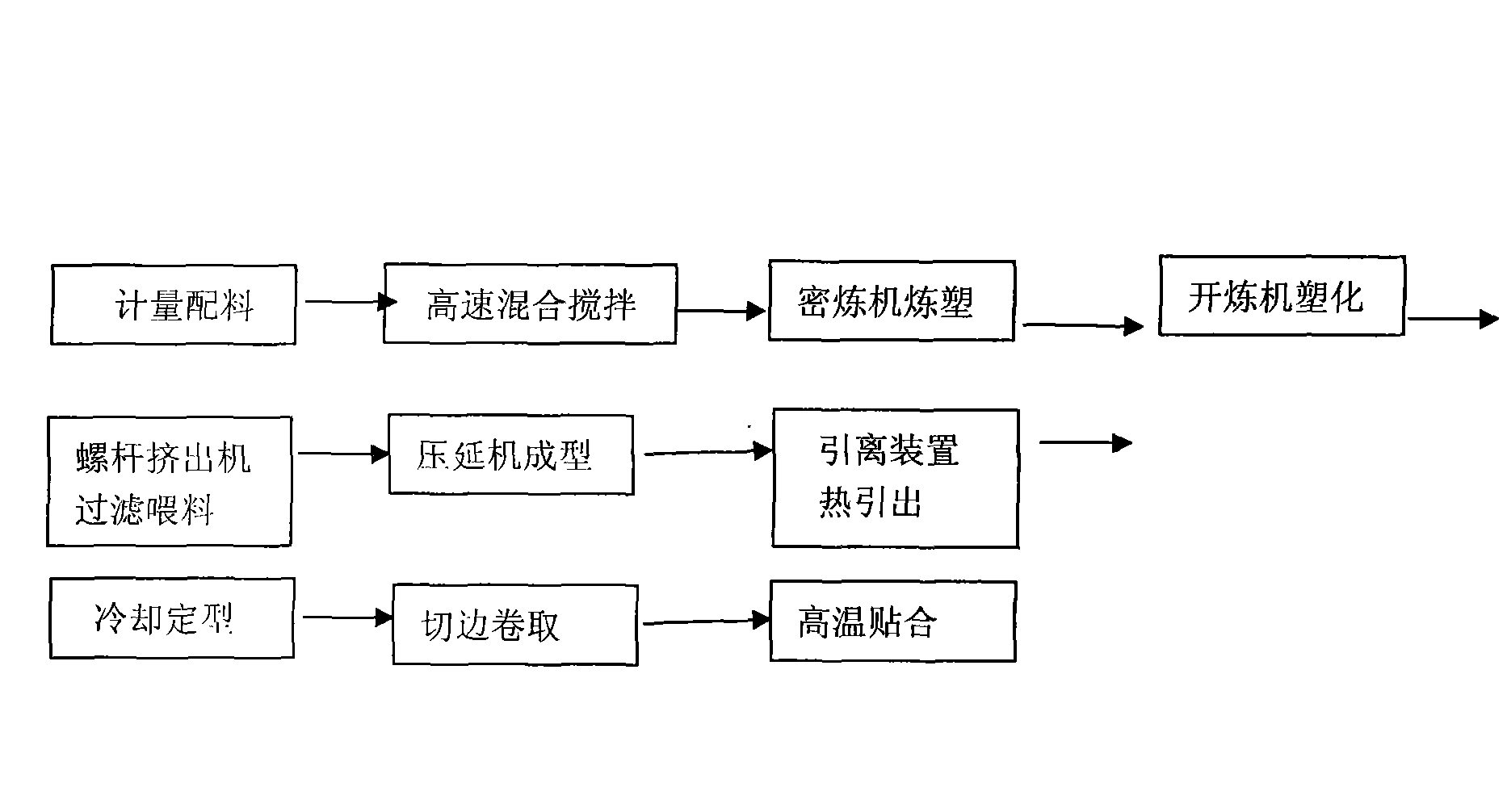

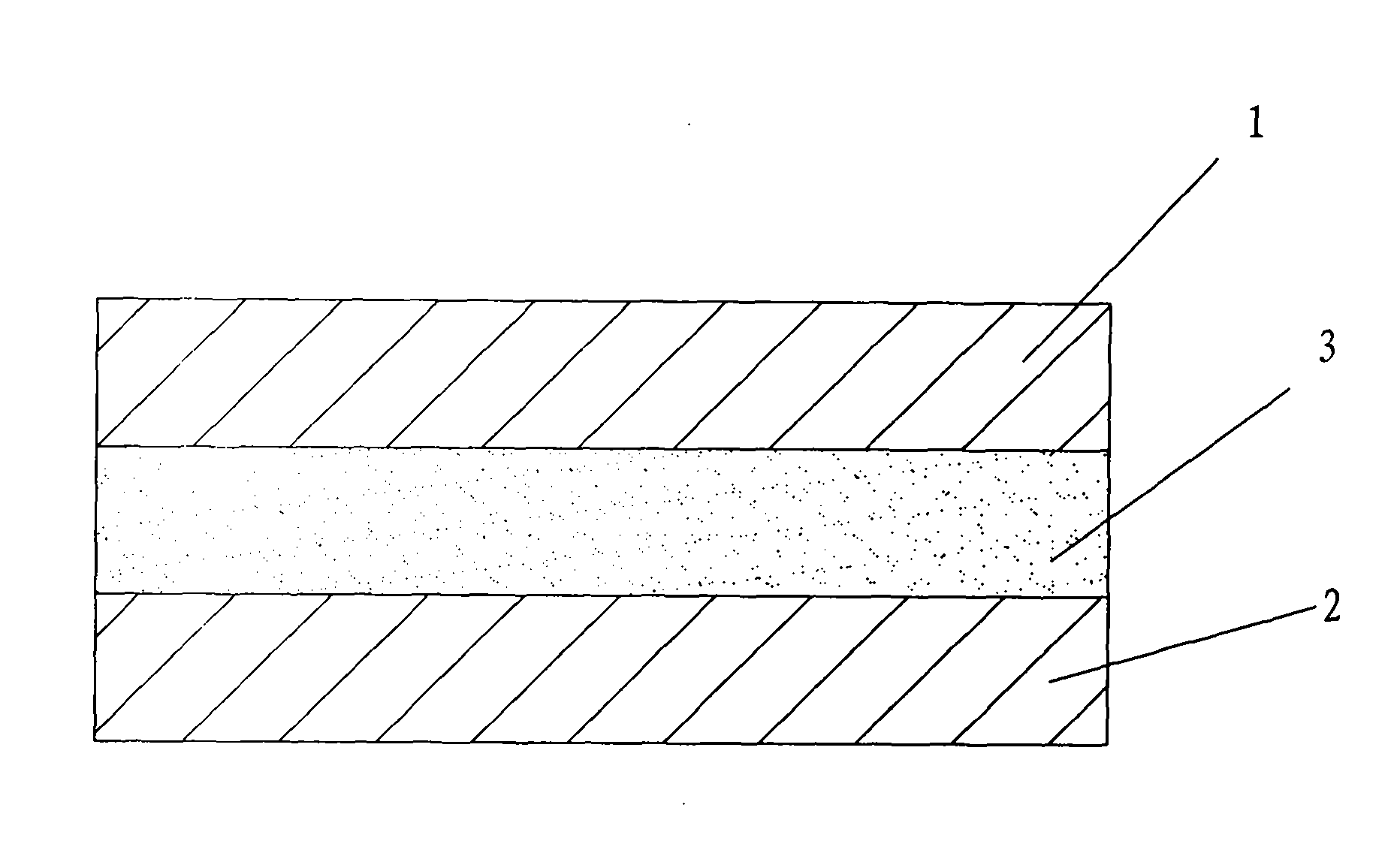

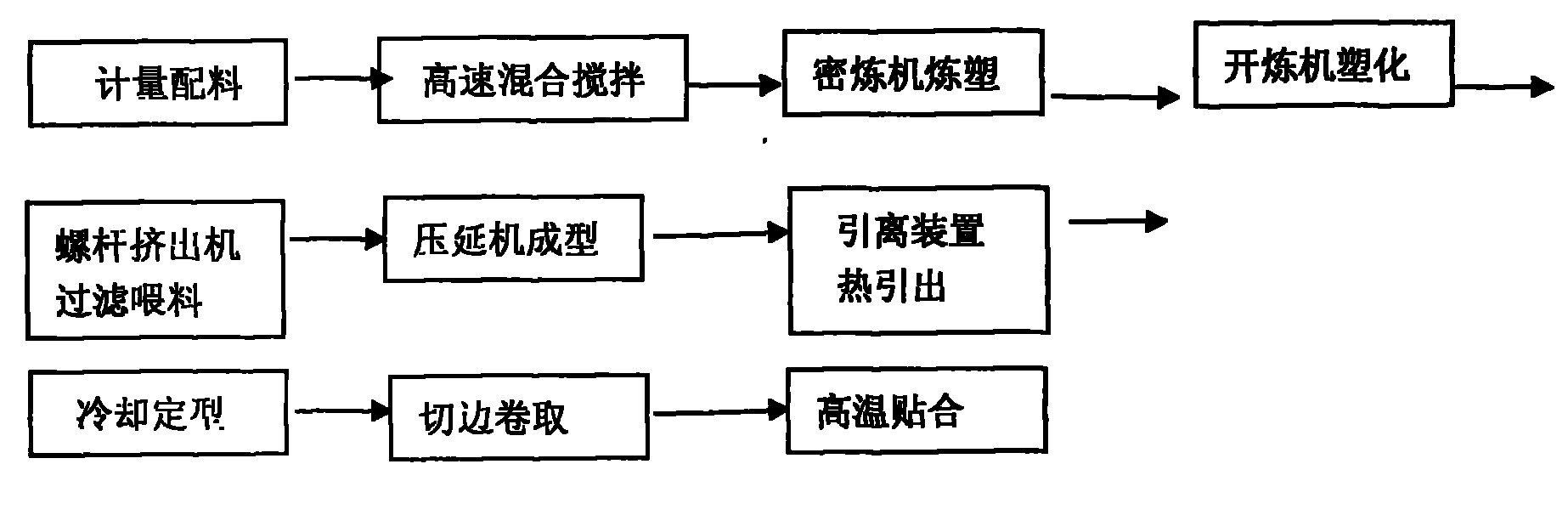

Composite red mud coiled material used for biogas project and preparation method thereof

ActiveCN101538801AHigh yieldAnti-agingSynthetic resin layered productsLaminationEnvironmental resistancePolyester

The invention discloses a composite red mud coiled material which has high lamination joint fastness and good physical and mechanical properties and is used for biogas project and a preparation method thereof. The composite red mud plastic coiled material consists of two layers of red mud modified plastic embryonic membranes and a layer of high-strength polyester fiberglass mesh composited between the two layers of red mud modified plastic embryonic membranes, wherein the red mud modified plastic embryonic membrane is prepared by raw materials with the following parts by weight: 100 parts of PVC resin, 35-50 parts of DOP plasticizer, 5-10 parts of DOP low-temperature plasticizer, 5-15 parts of other modified additives, 10-15 parts of red mud modified additive with the fineness being more than 350 meshes, 0.3-0.5 part of photooxidation stabilizing agent and 2.5-4 parts of environment-protection composite heat stabilizer. The composite red mud coiled material used for biogas project has the advantages of environment-friendly formula, ageing resistant products, corrosion resistance, flame retardance and more than ten years of service life.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

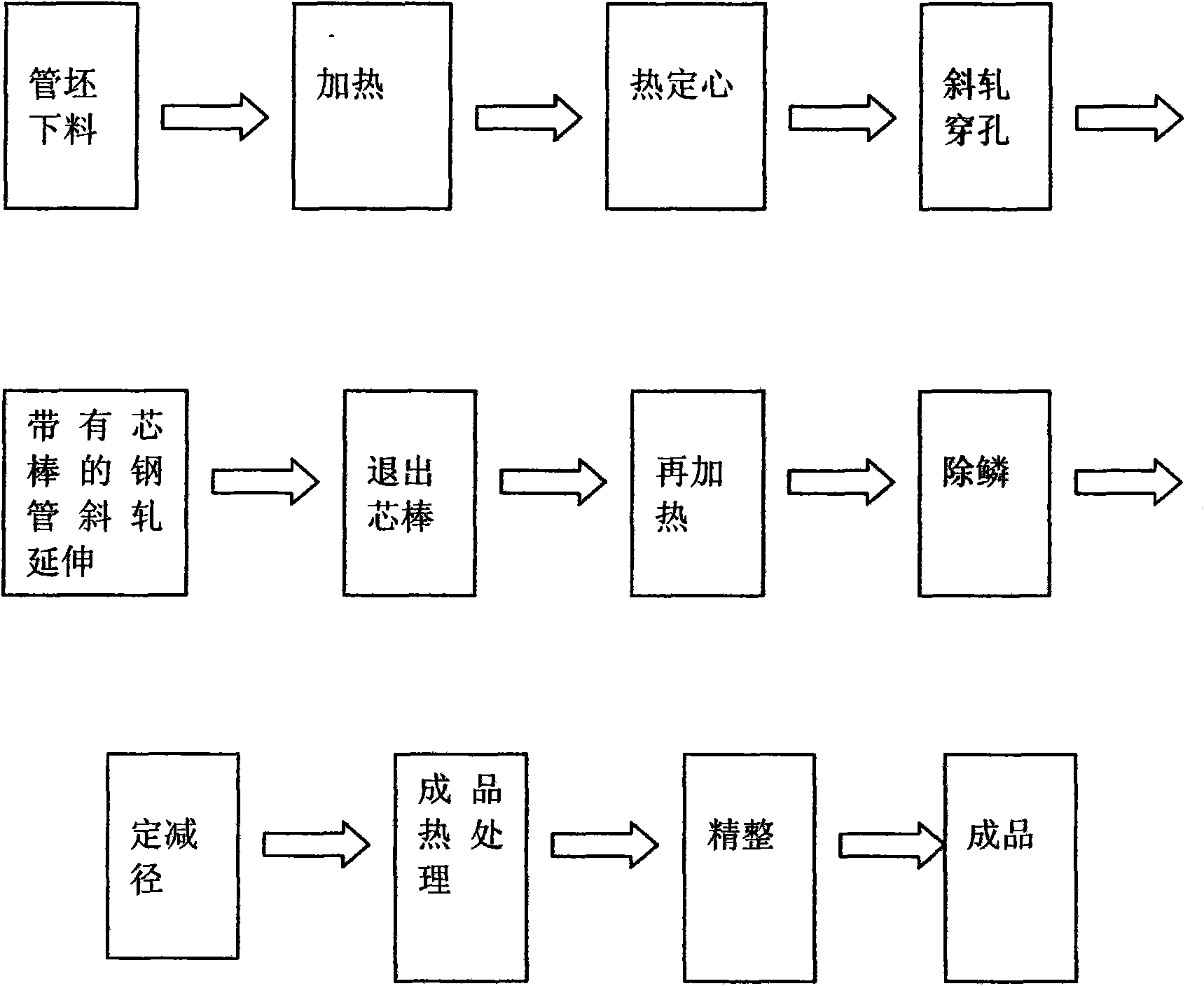

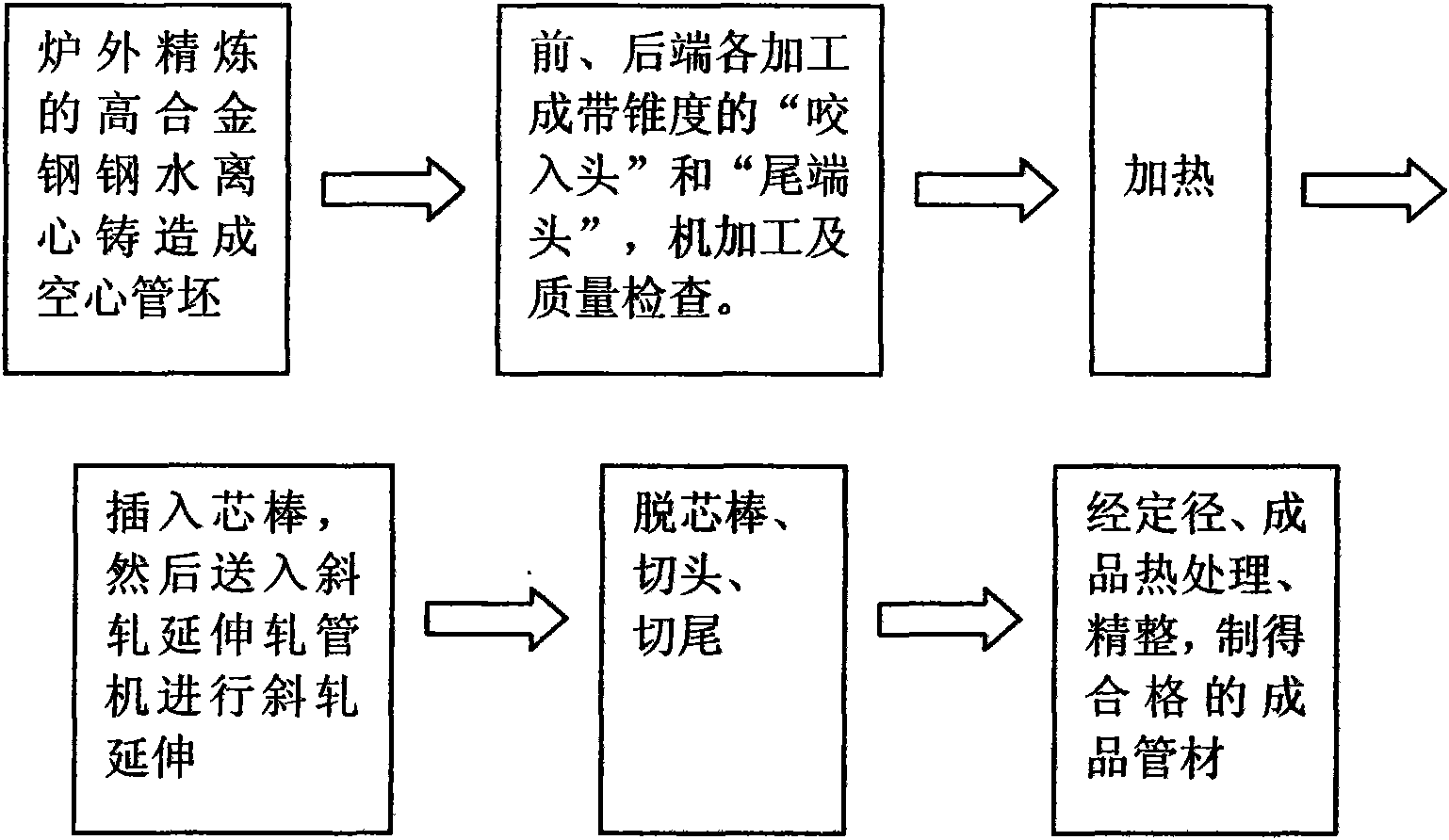

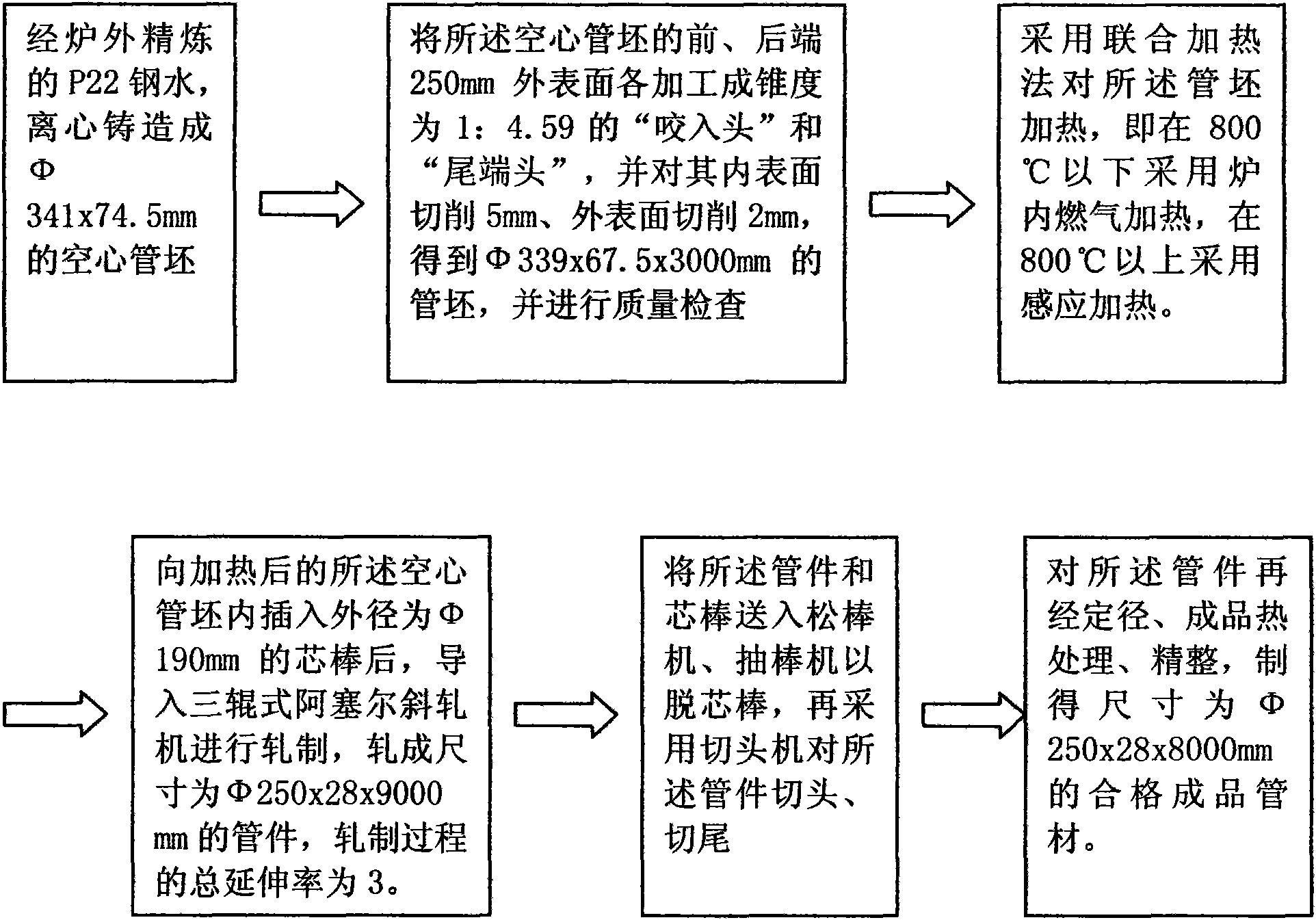

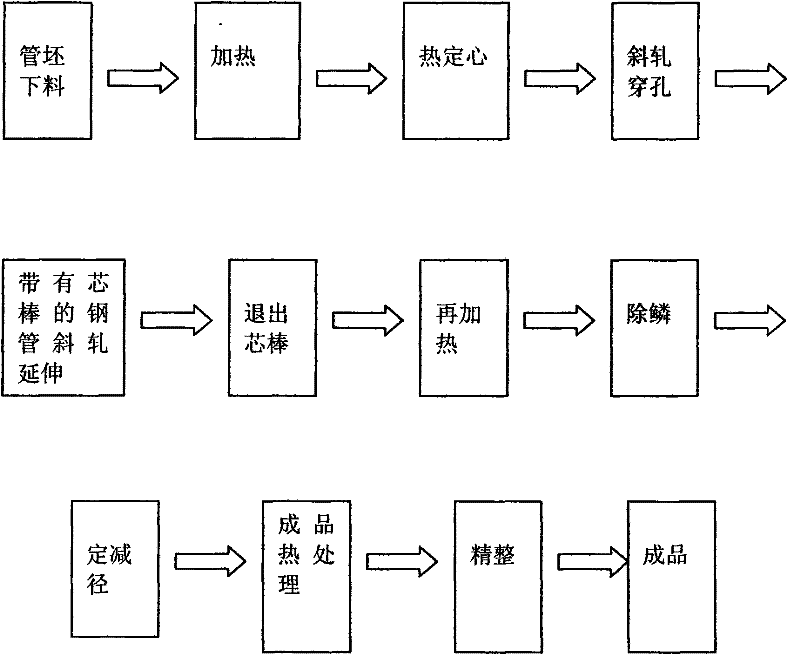

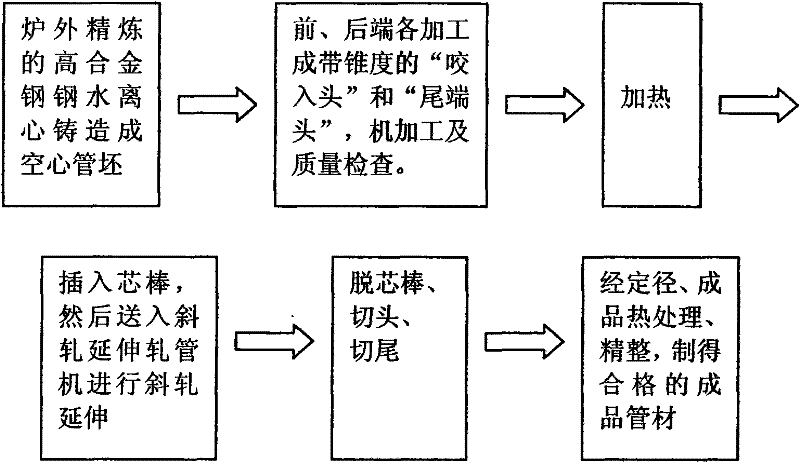

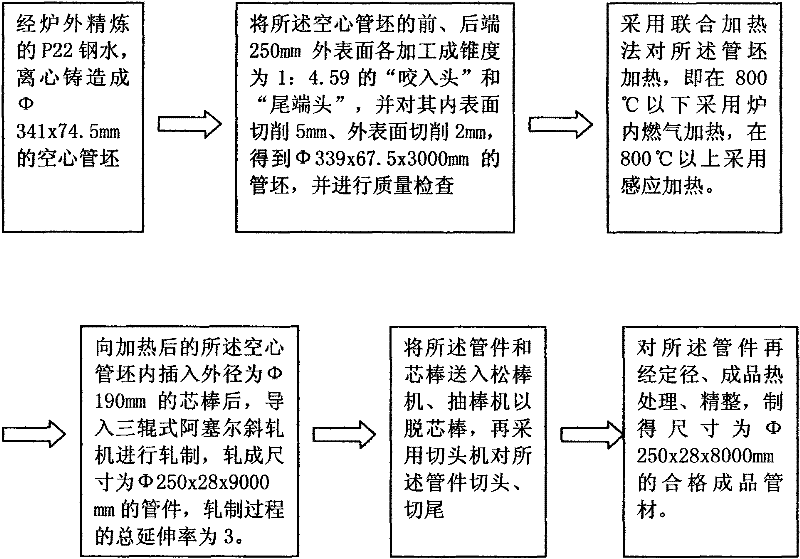

New technique for producing high alloy steel high-end pipe by adopting cross rolling elongation technology

InactiveCN101579702ALow equipment investment costLow running costMandrel separation arrangementsMetal rolling arrangementsPipe fittingMaterial Perforation

The invention relates to a new technique for producing a high alloy steel high-end seamless pipe by adopting cross rolling elongation technology without perforation, comprising: molten high alloy steel which is externally refined is made into a hollow shell by centrifugal casting; the outside surfaces of the front and the rear ends of the hollow shell are respectively processed to be a 'gripping head' and a 'tail end head' with conicity, and machining and quality inspection are carried out on the inside and the outside surfaces as well as the 'gripping head' and the 'tail end head' of the hollow shell; heating is carried out; a mandril is inserted into the heated hollow shell, and then the hollow shell is sent into a cross rolling elongating mill for cross rolling, so that the pipe fittings having the wall thickness, the diameter and the length being in accordance with the requirements can be produced; the mandril is removed, and the head and the tail are cut off; finally, the qualified finished pipes can be obtained after sizing, heat treatment for finished product and finishing operation. The technique has short process flow and does not need cross rolling perforation, thus reducing the cost and improving the quality; due to small tapered treatment for the front and the rear ends, 'tail triangle' is avoided when the medium-thick walled pipes are produced, and the performance of secondary gripping is improved, thus improving the quality of the product and the production efficiency.

Owner:北京蓝海科融新技术有限公司

Assembled steel pipe concrete double-block type sleeper

PendingCN107217551AMeet the requirements of bending and torsion resistanceImprove retentionBallastwaySlurryBlock type

The invention belongs to the technical field of a ballastless track, and discloses an assembled steel pipe concrete double-block type sleeper. The assembled steel pipe concrete double-block type sleeper comprises a first concrete sleeper block, a second concrete sleeper block and a plurality of supporting steel pipe concrete pillars which are processed independently; these components are separated in a transportation link and a warehousing link; after being conveyed to the construction site, the steel pipe concrete pillar is assembled with two concrete sleeper blocks together through a threading method or binding slurry on site. Through the invention, the fixing and assembling processes can be realized with high precision at the construction site rapidly, the use of the connector can be significantly reduced while the sleeper has good morpheme hold facility; particularly, the assembled steel pipe concrete double-block type sleeper has outstanding advantages of reducing technical difficulties in manufacturing, warehousing, construction and other links, improving technical efficiency and reducing cost.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

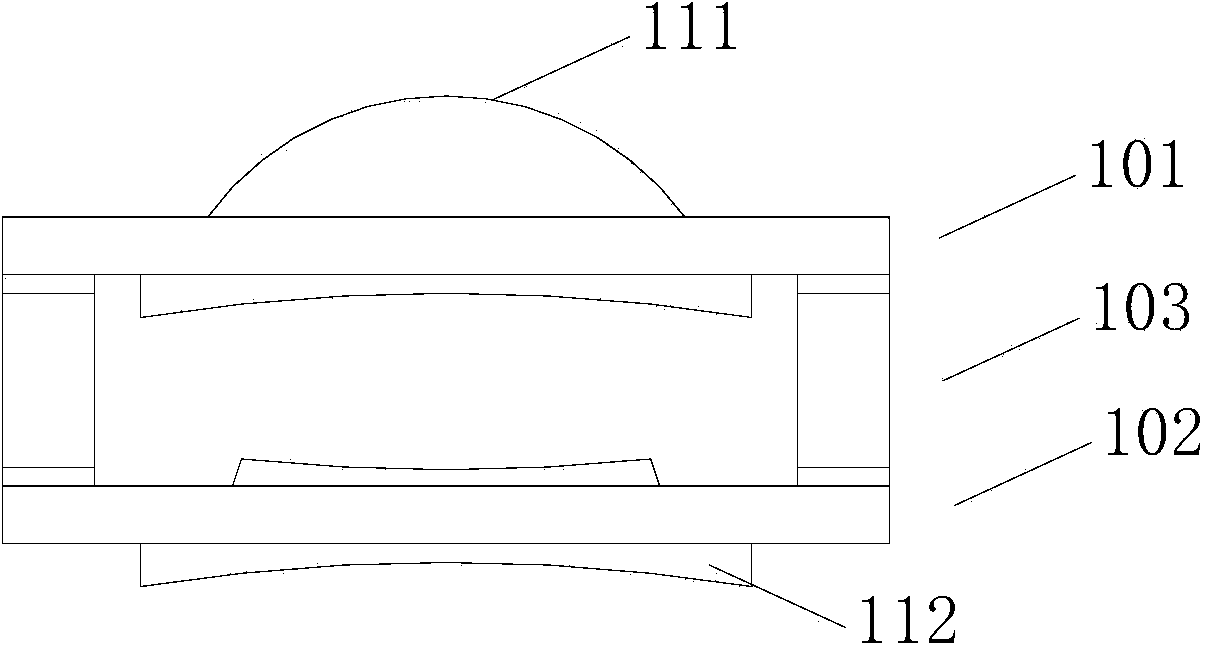

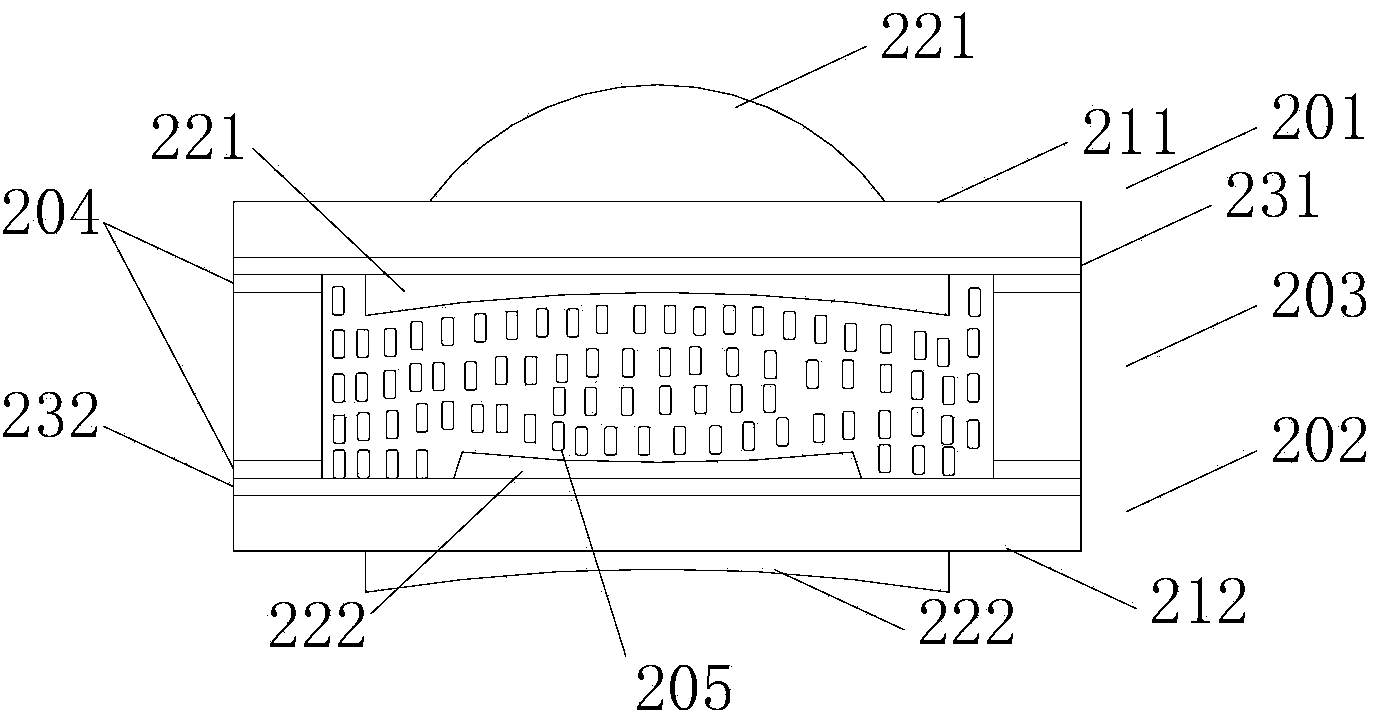

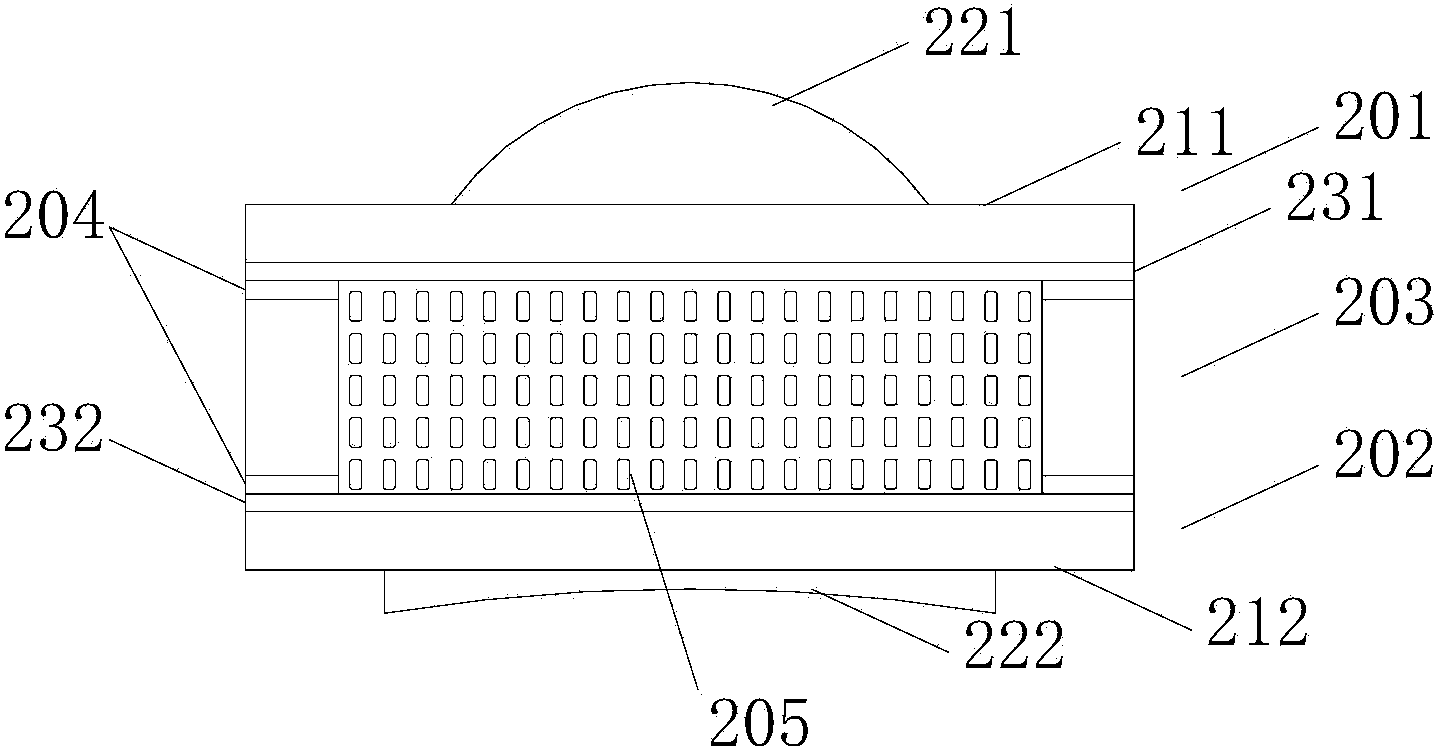

Wafer-level zoom lens module and production method thereof

ActiveCN103969857AFlexible specificationsAchieve the purpose of zoomingNon-linear opticsFilling-inLens plate

The invention provides a wafer-level zoom lens module and a production method thereof. A photo refraction material such as liquid crystal is filled in a cavity formed by two adjacent layers of lens sets and a gasket arranged between the two adjacent layers of lens sets, transparent conductive film is arranged in the two lens sets respectively and is connected with a changeable voltage source to be used as a pair of parallel potential plates, an electric field between the parallel potential plates can be formed, and the photo refraction materials generate a photoelectric effect under the action of the electric field to change the refractive index or the abbe number, accordingly, the whole optical lens module focus is changed, and variable focuses are achieved.

Owner:HOWE OPTOELECTRONICS TECH SHANGHAI

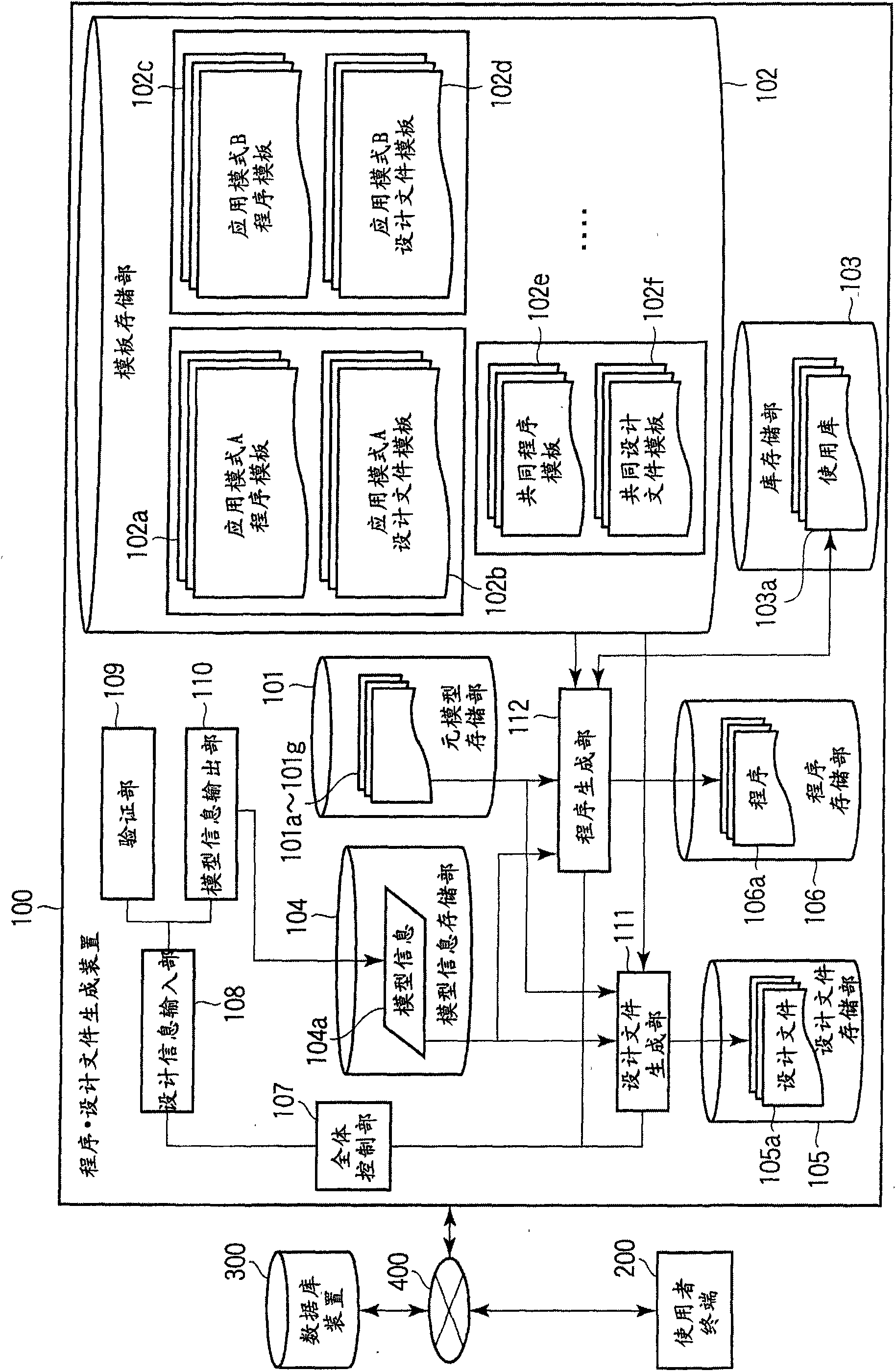

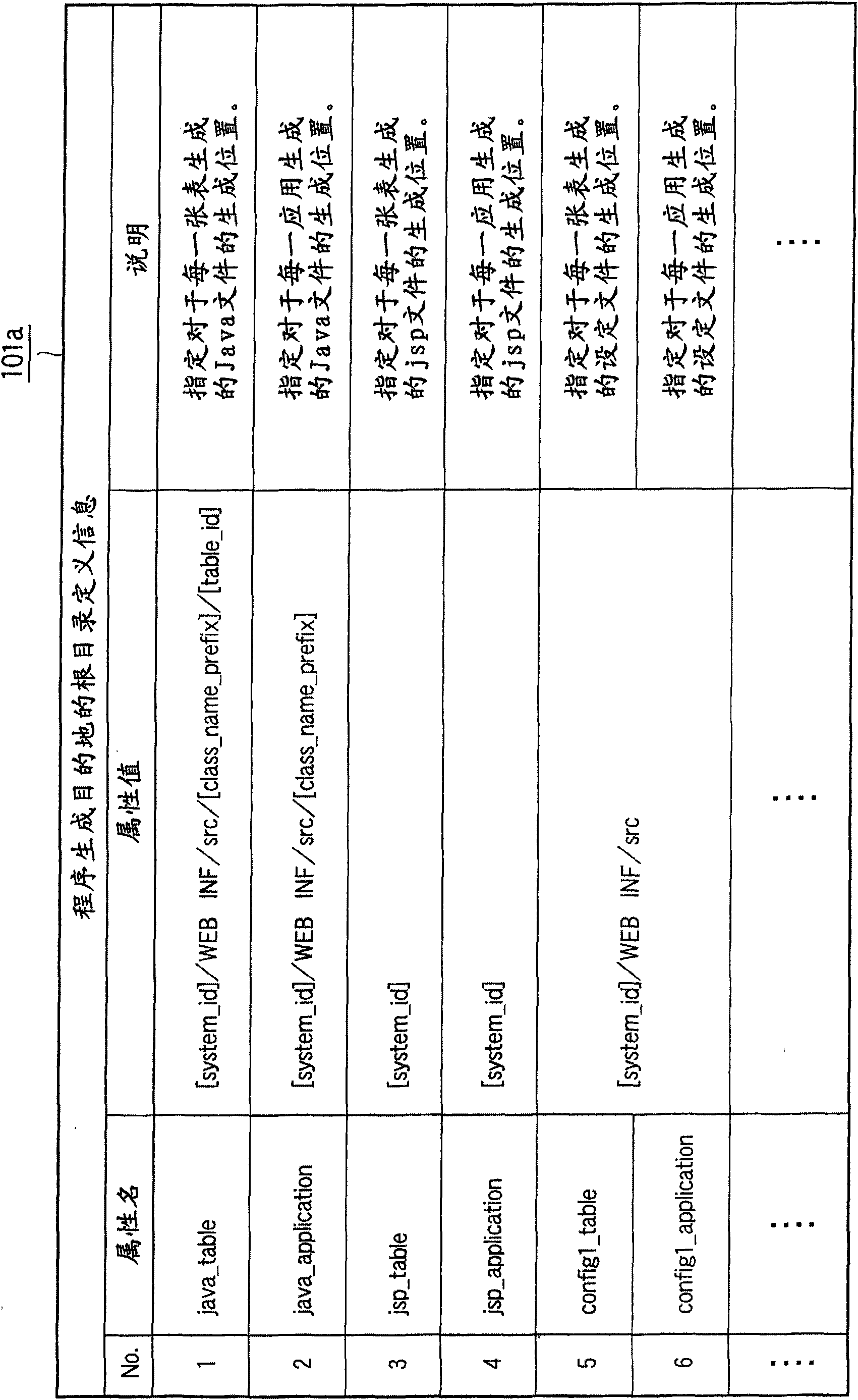

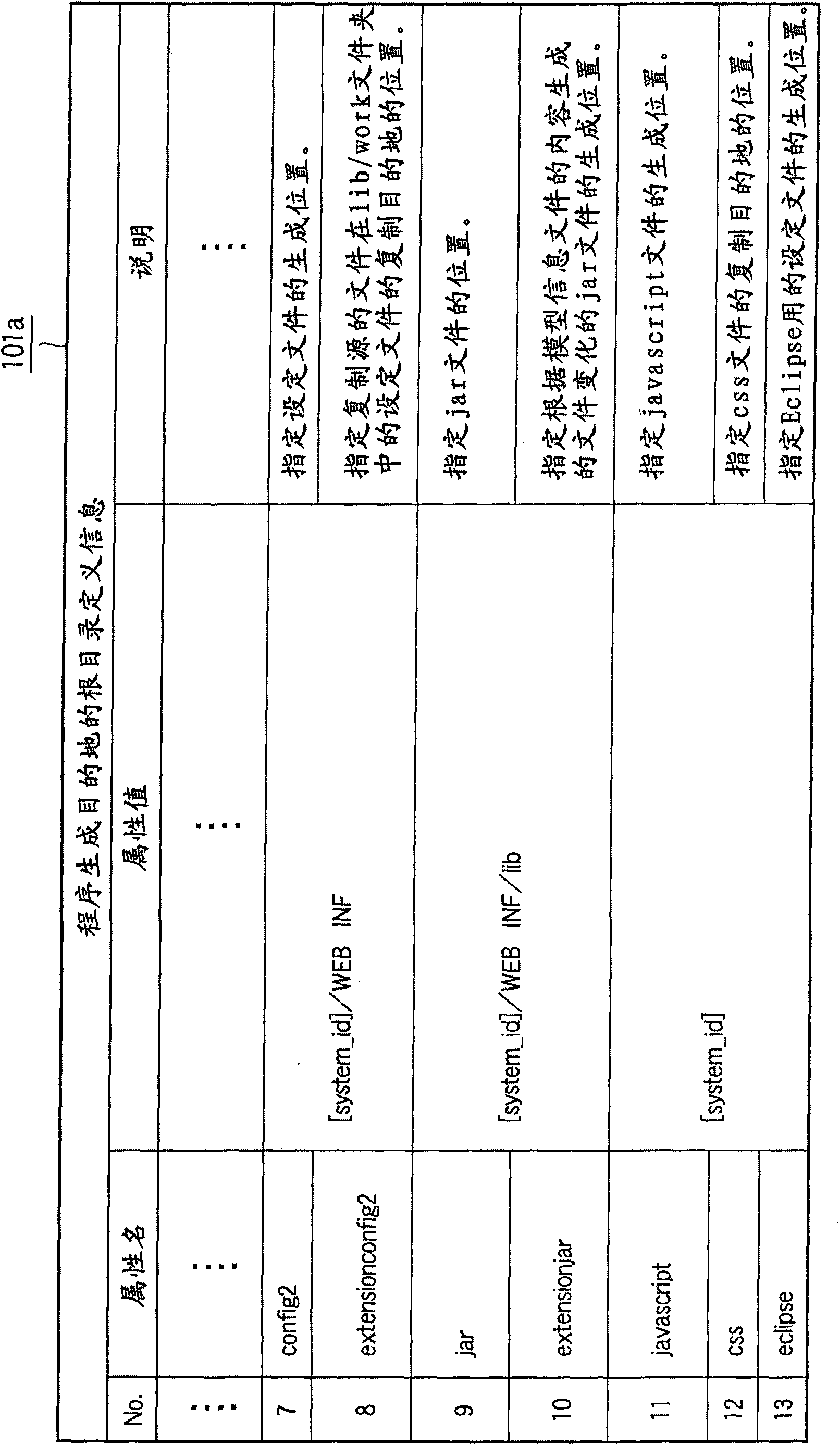

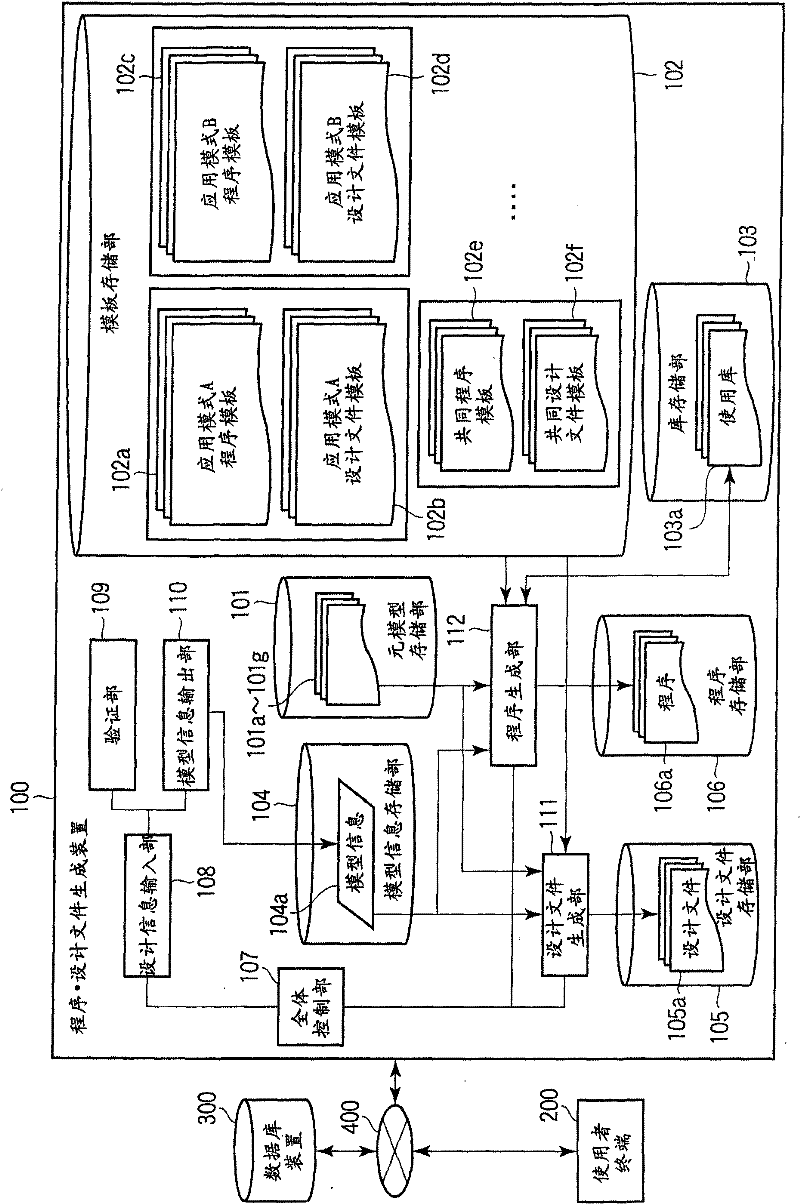

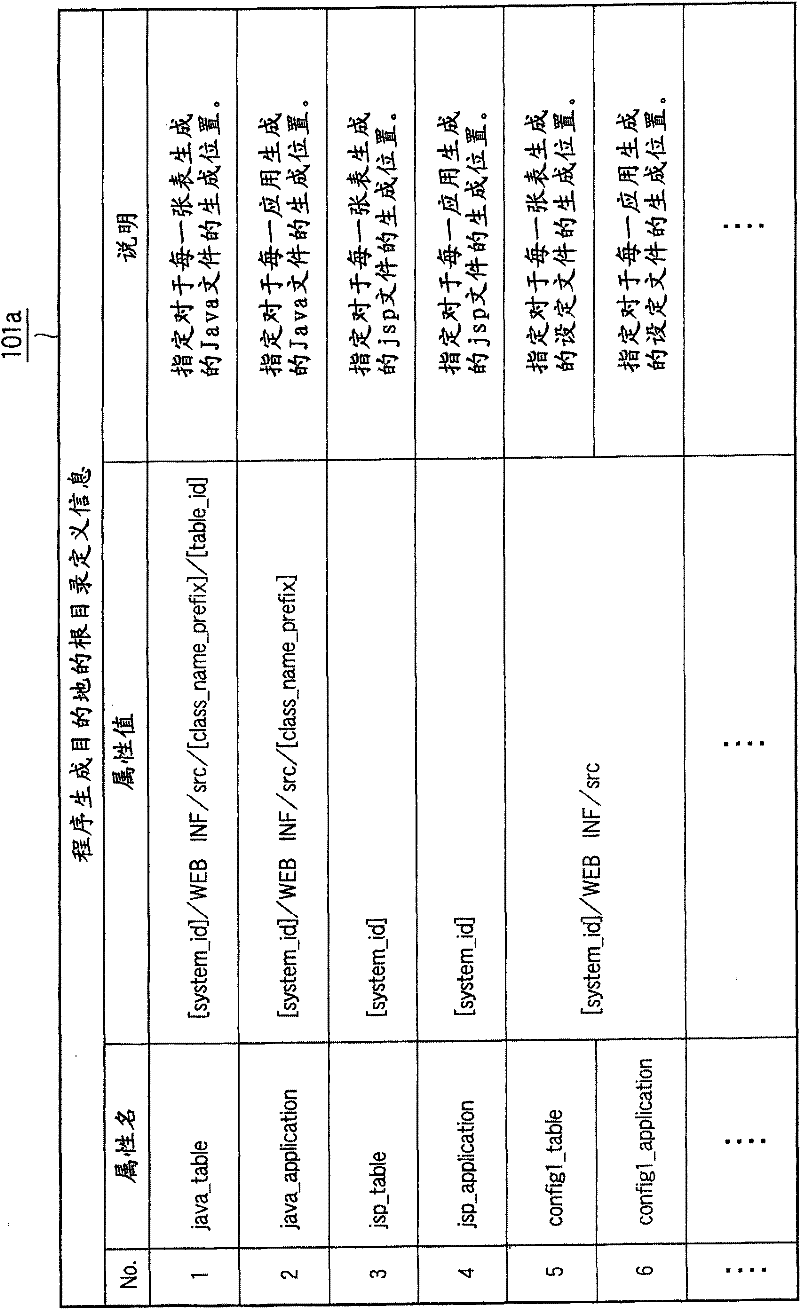

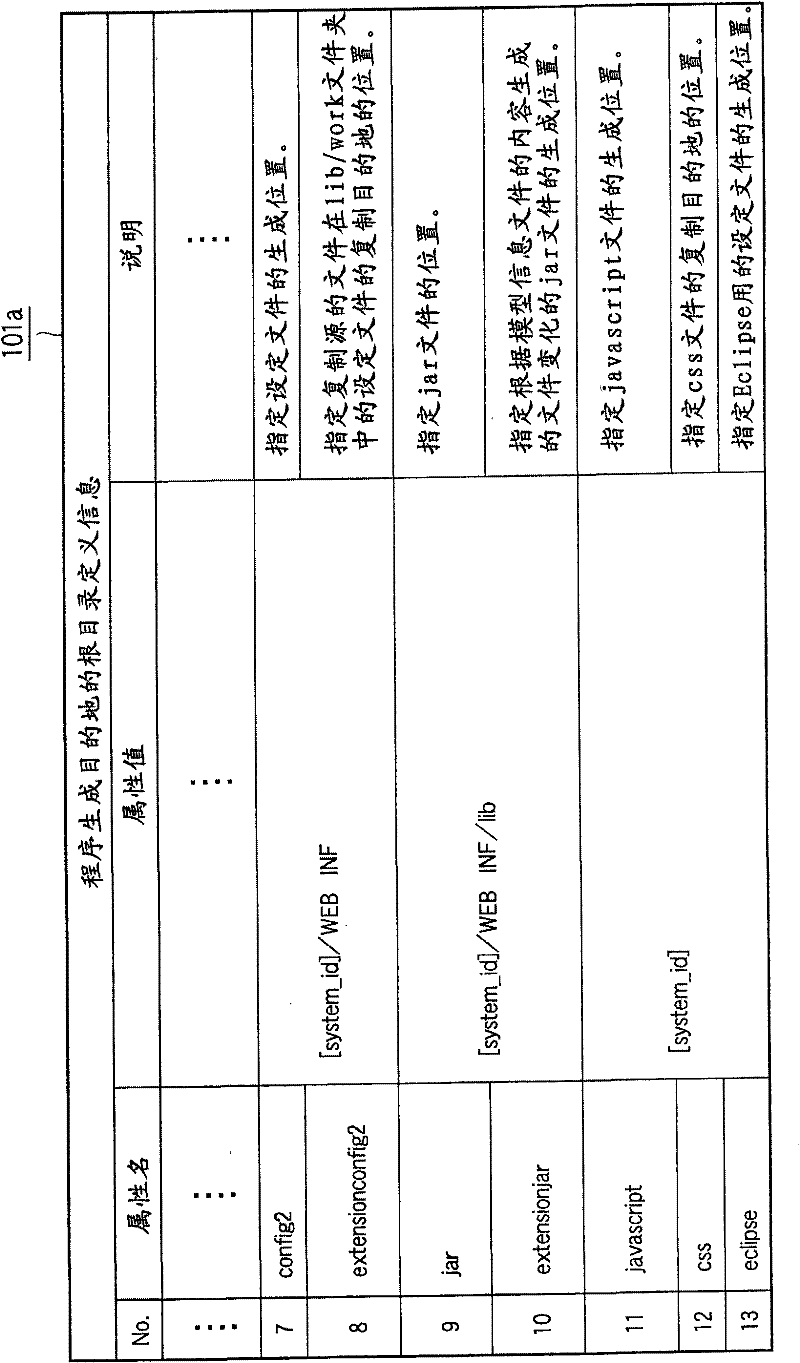

Generating device of program design documents

ActiveCN101599014AImprove productivityFlexible specificationsSpecific program execution arrangementsProduction rateGame design document

The invention provides a generating device of programs and design documents used for generating programs and design documents thereof. The generating device of programs and design documents (100) converts input design information into abstract formal model information (104a) in specific standard independent on each program and then the information is output, the design documents are generated according to specific model of the model information, meta model information and design documents and are written in the memory part (105) of design documents, simultaneously the specific model documents inside a template memory part (102) are determined according to the model information (104a) and the meta model information, and the program (106a) is written in the program memory part (106) according to the meta model information through the model information (104a), the meta model information and the determined specific model document. Therefore, programs and design documents can be generated, the standard generating the object can be set flexibly, and the production efficiency of application and development can be improved.

Owner:KK TOSHIBA +1

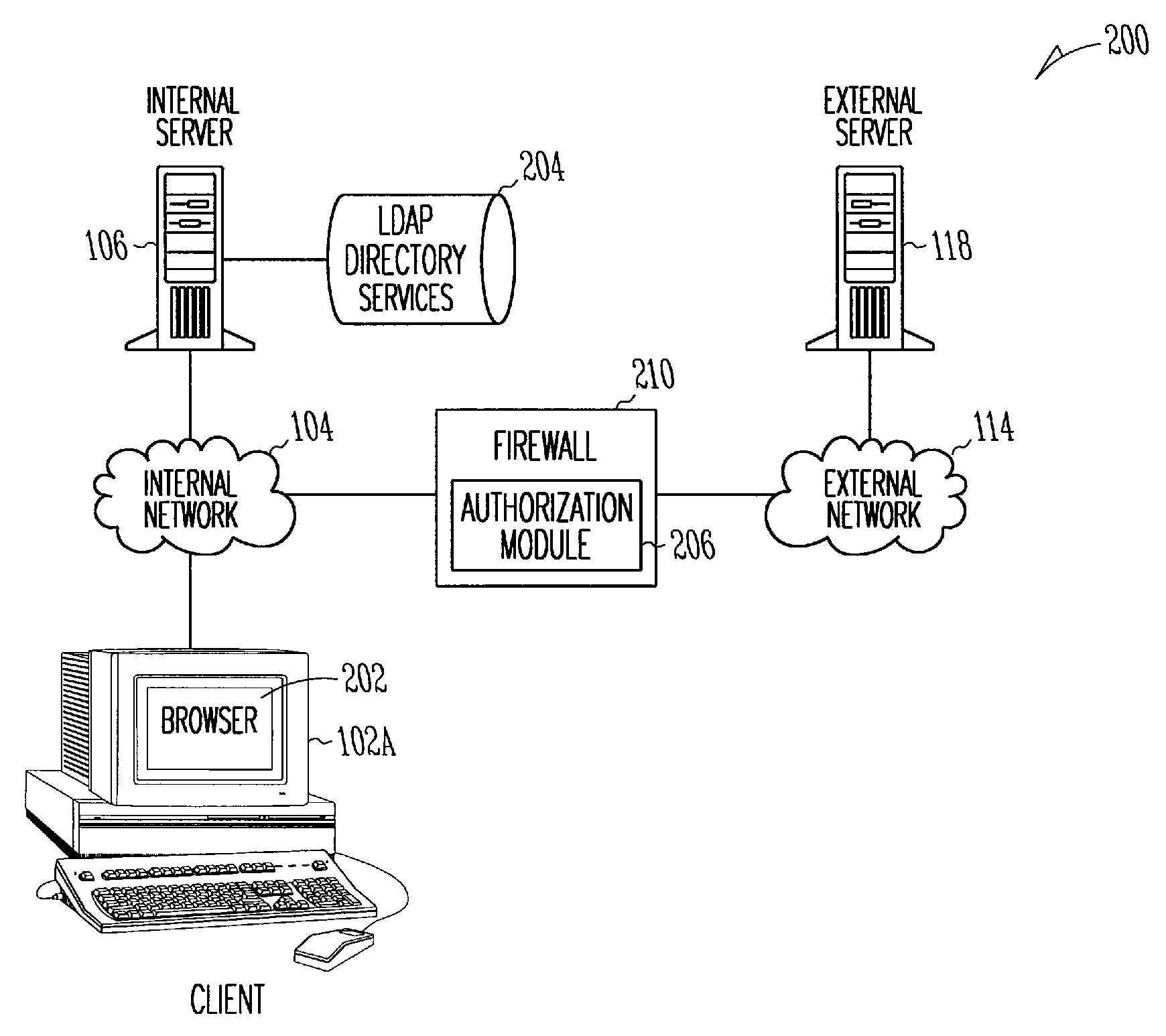

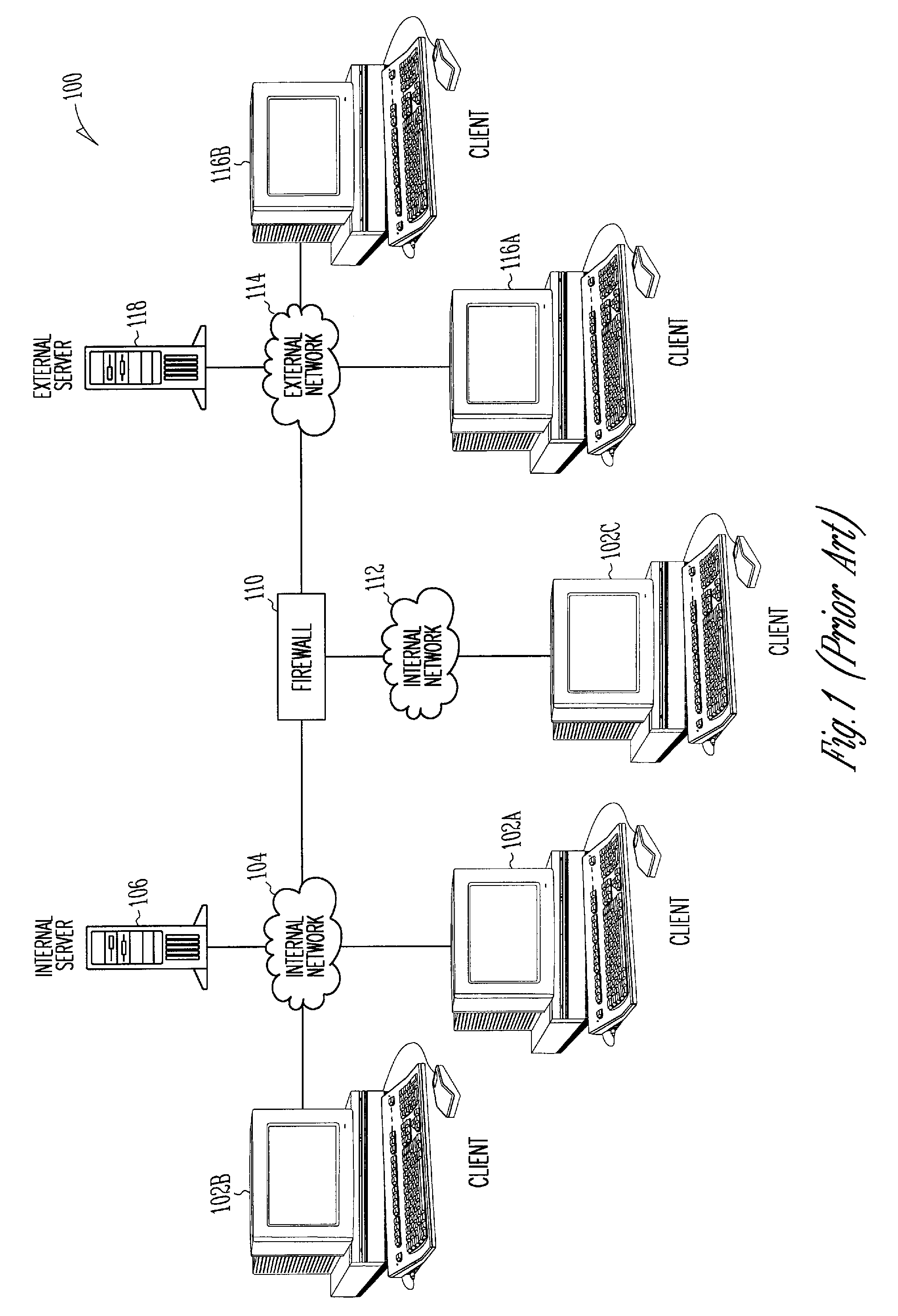

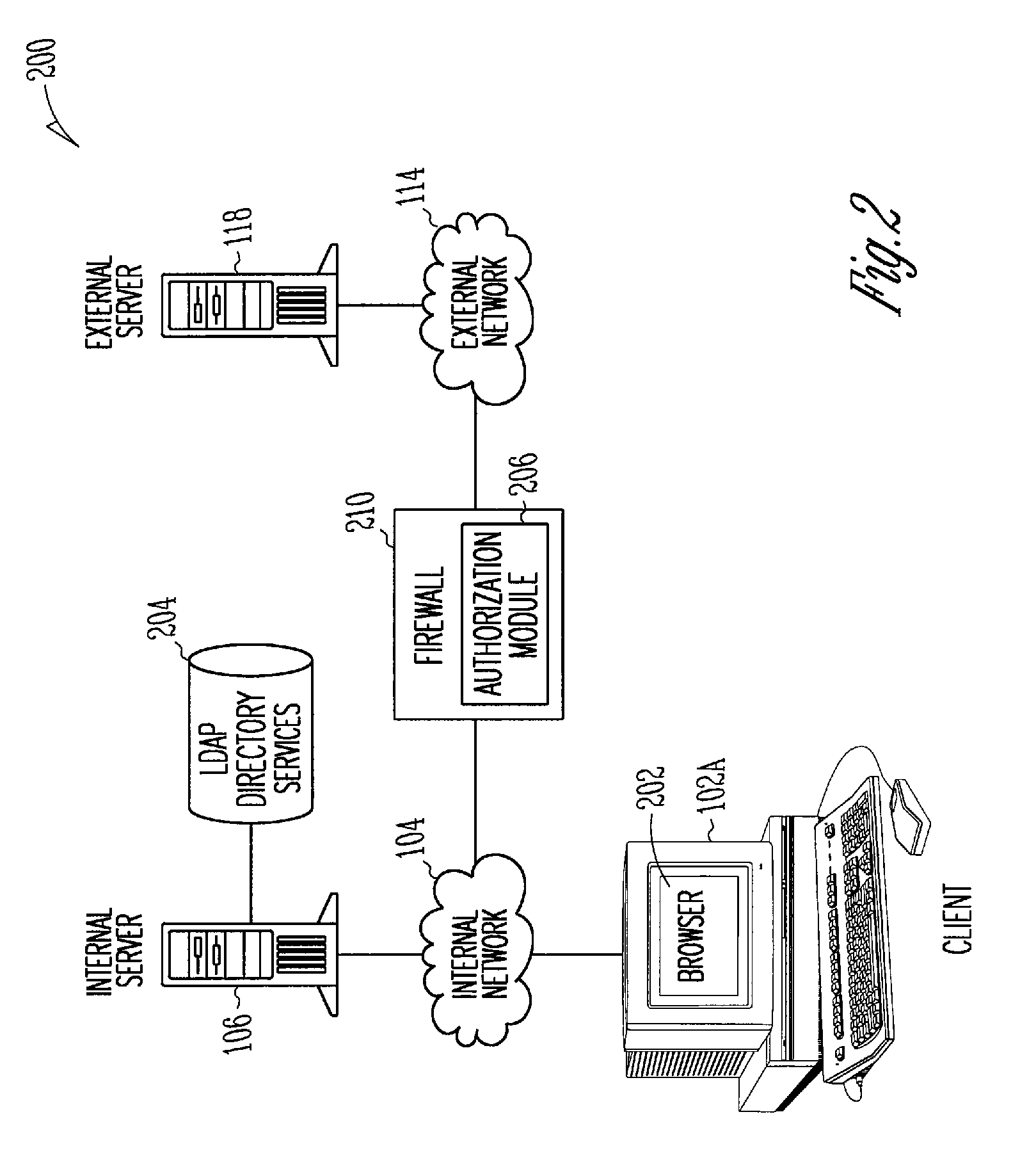

System, method and computer program product for authenticating users using a lightweight directory access protocol (LDAP) directory server

InactiveUS20070136803A1Great degreeFlexible specificationsData processing applicationsDigital data processing detailsGraphicsGraphical user interface

A system, method and computer program product for providing authentication to a firewall using a lightweight directory access protocol (LDAP) directory server is disclosed. The firewall can be configured through a graphical user interface to implement an authentication scheme. The authentication scheme is based upon a determination of whether at least part of one or more LDAP entries satisfy an authorization filter.

Owner:MCAFEE LLC

Technology for producing single-crystal conductive copper rod with upward continuous casting method

ActiveCN107354507AImprove product qualityImprove continuityPolycrystalline material growthFrom frozen solutionsElectrolysisSingle crystal

The invention discloses a technology for producing a single-crystal conductive copper rod with an upward continuous casting method. The technology comprises steps as follows: an electrolytic copper raw material is put in a closed mixing melting furnace for melting, aluminum-antimony alloy powder, europium oxide powder and beryllium-aluminum alloy powder are added to a molten copper liquid, nitrogen and carbon monoxide mixed gas is introduced into the closed mixing melting furnace through a ventilation inlet in the bottom of the closed mixing melting furnace, and the mixed gas is discharged from a ventilation outlet in the top of the closed mixing melting furnace; a molten mixture is transferred into an upward continuous casting melting furnace and is enabled to enter an upward continuous casting crystallizer under the siphoning action, a crystallized conductive copper rod in the upward continuous casting crystallizer is drawn out of the top of the upward continuous casting crystallizer by a drawing device, and finally, the prepared conductive copper rod is packaged into coils. Compared with a polycrystalline conductive copper rod, the produced single-crystal conductive copper rod has the advantages that elongation percentage can be increased by 60%-80%, and specific resistivity can be reduced by 15%-20%.

Owner:江苏裕铭铜业有限公司

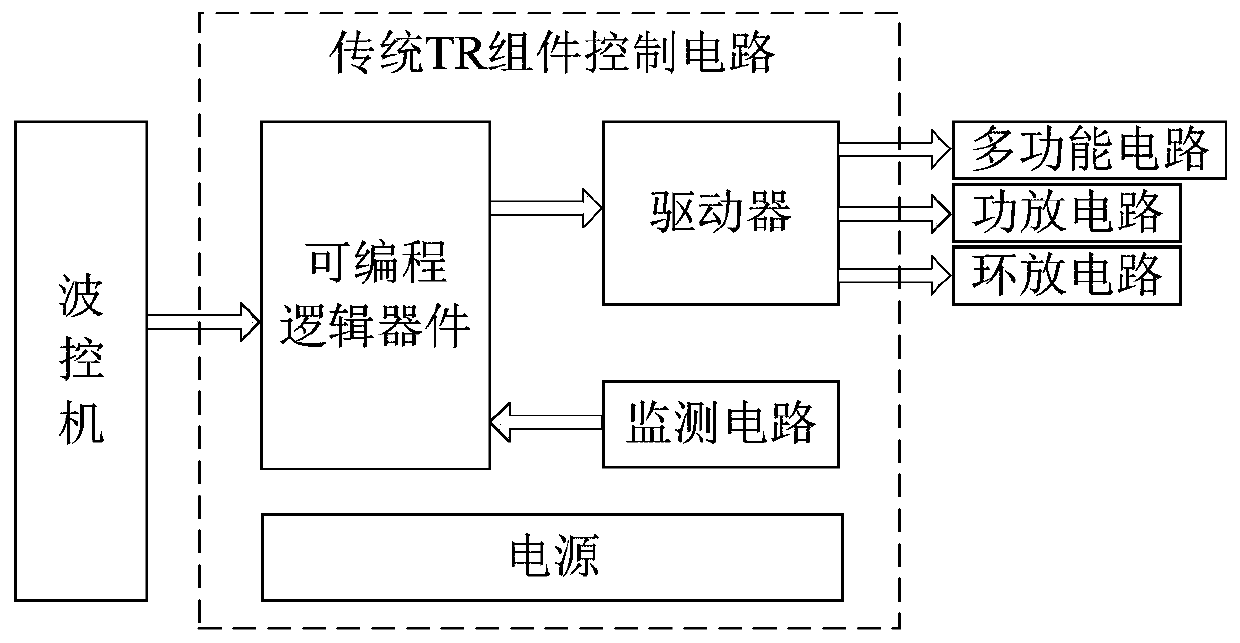

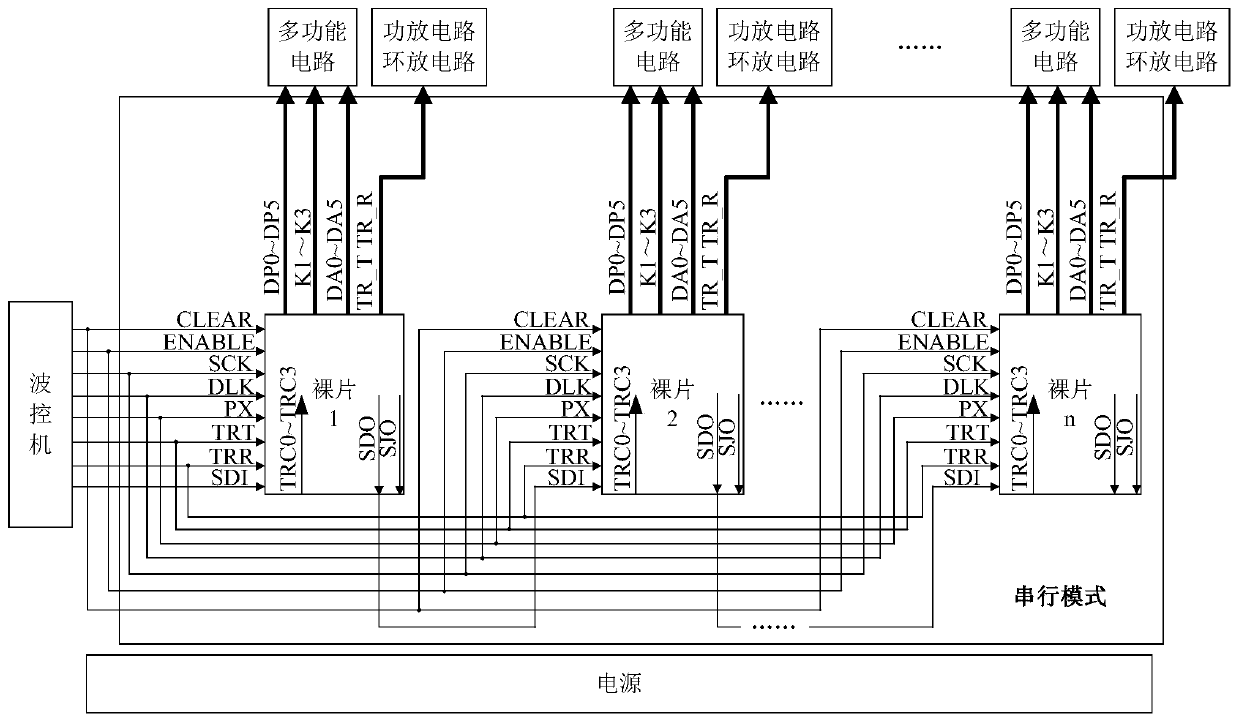

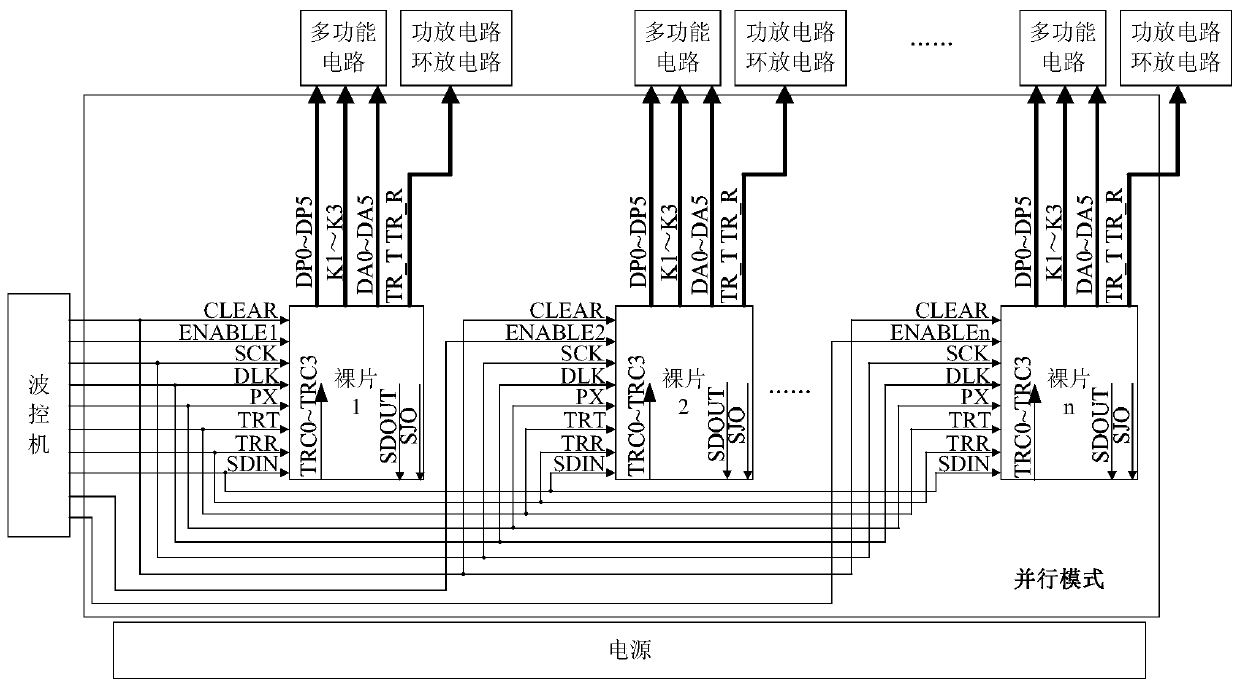

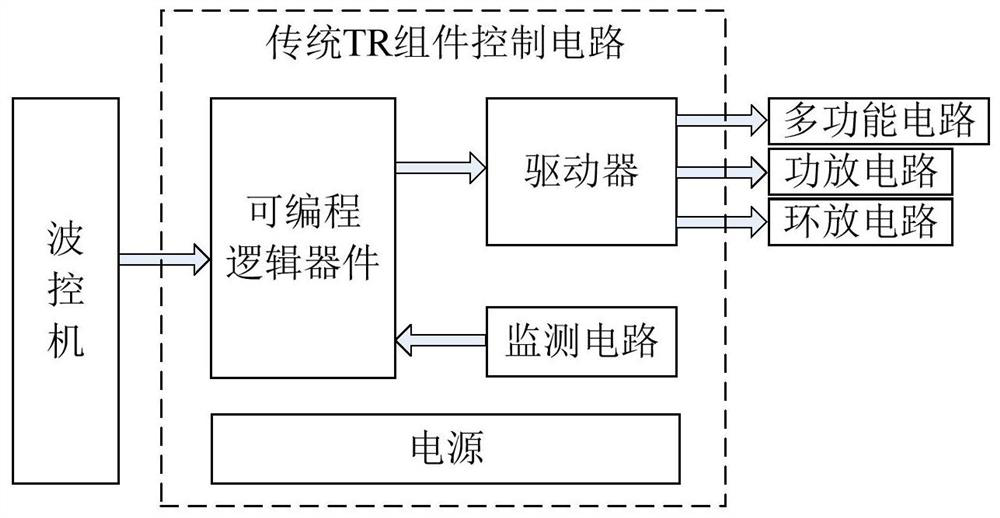

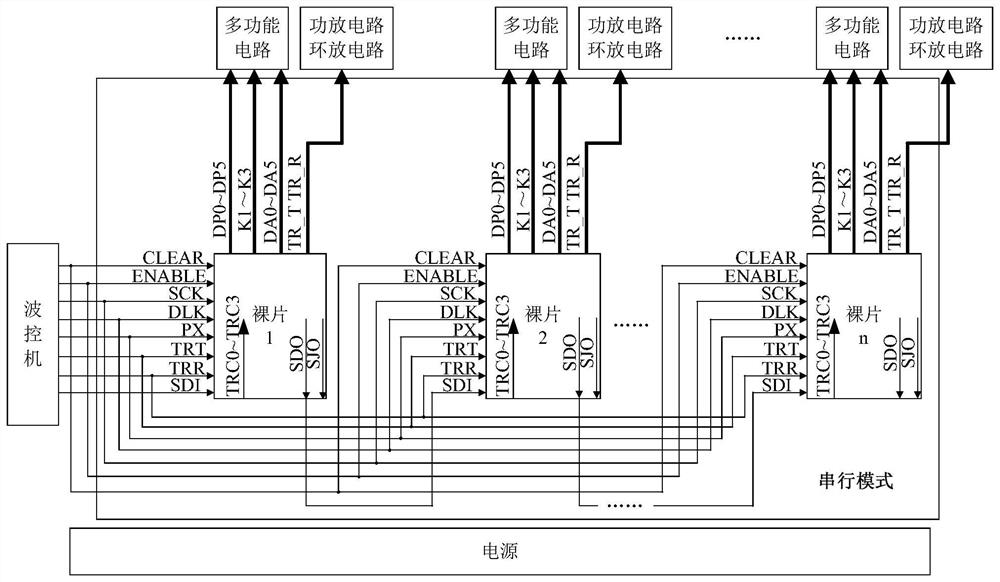

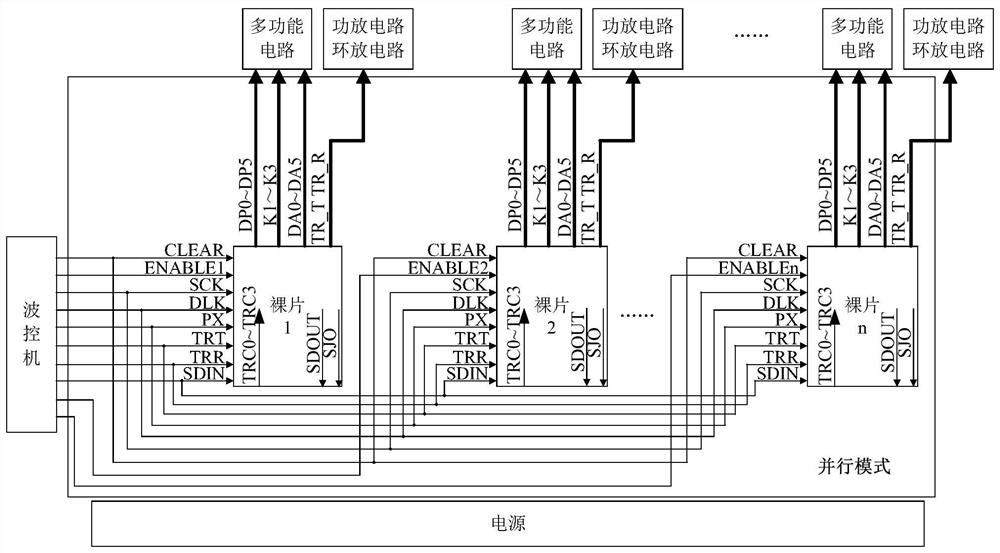

TR assembly control circuit based on full bare chip

ActiveCN111123207AImprove reliabilityPower on and load without failureWave based measurement systemsControl signalHemt circuits

The invention discloses a TR assembly control circuit based on a full bare chip. The circuit comprises a bare chip group which is used for receiving a control signal outputted by a wave control machine. The bare chip group comprises multiple stages of bare chips which are electrically connected in series, and each bare chip is electrically connected with a multifunctional sub-circuit, a power amplifier sub-circuit and a loop amplifier sub-circuit. According to the invention, the reliability of the TR assembly is improved.

Owner:BEIJING INST OF RADIO MEASUREMENT

Upward continuous casting technology for large-load electro-conductive copper bus bars

The invention discloses an upward continuous casting process for a large-load conductive copper busbar, which comprises the following steps: step 1, preparing recycled compressed copper material and electrolytic copper plate; step 2, feeding the electrolytic copper plate and recovered compressed copper material according to the proportion Melting and mixing; Step 3: Separating the unmelted recovered compressed copper material and electrolytic copper plate, so that the molten copper water enters the insulation cavity; Step 4: Through the siphon effect, the molten copper water in the insulation cavity enters the upper lead from the bottom In the casting crystallizer, cooling and crystallization is carried out through the cooling water system in the upward continuous casting crystallizer; step 5, the crystallized upward continuous casting copper material in the upward continuous casting mold is drawn from the upward continuous casting through the drawing and pulling device The top of the crystallizer is drawn out, and the up-drawing continuous casting copper material is drawn at a speed of 120-160 mm per minute, and finally the up-drawing continuous casting copper material is packaged into rolls. The invention can realize the recycling and reuse of copper materials, and can ensure good continuity of the production process and high production efficiency.

Owner:ANHUI XINXU NEW MATERIALS LTD BY SHARE LTD

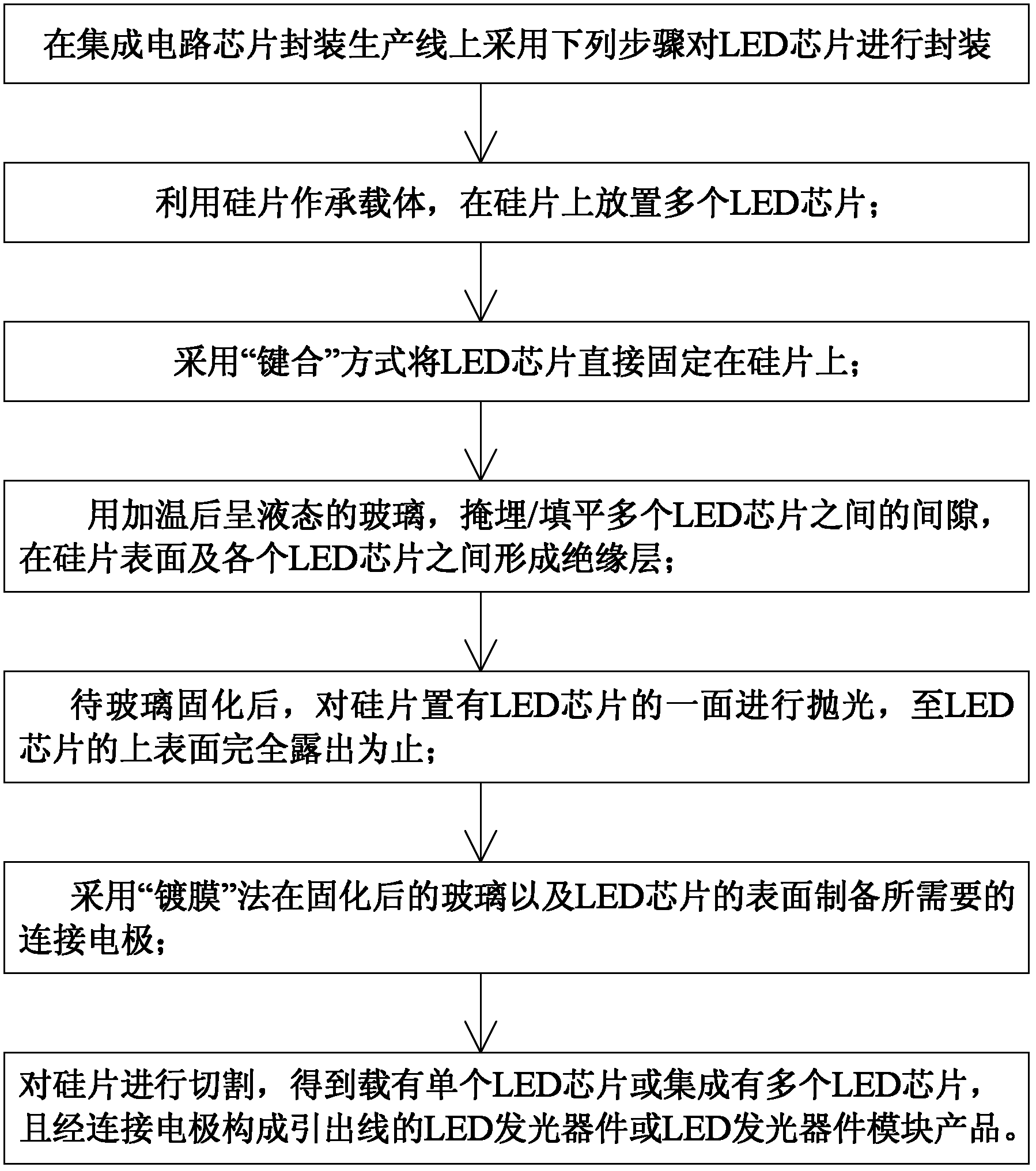

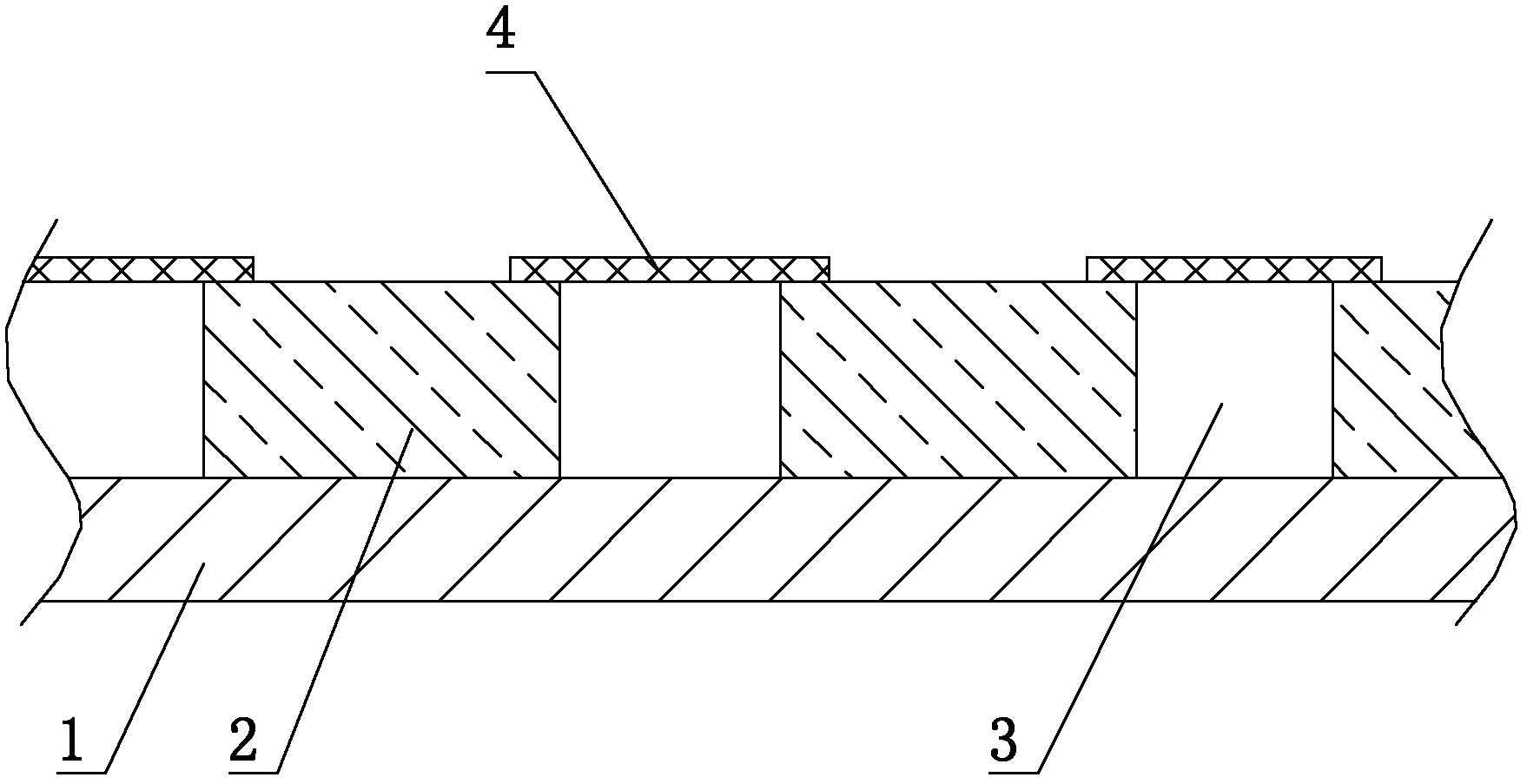

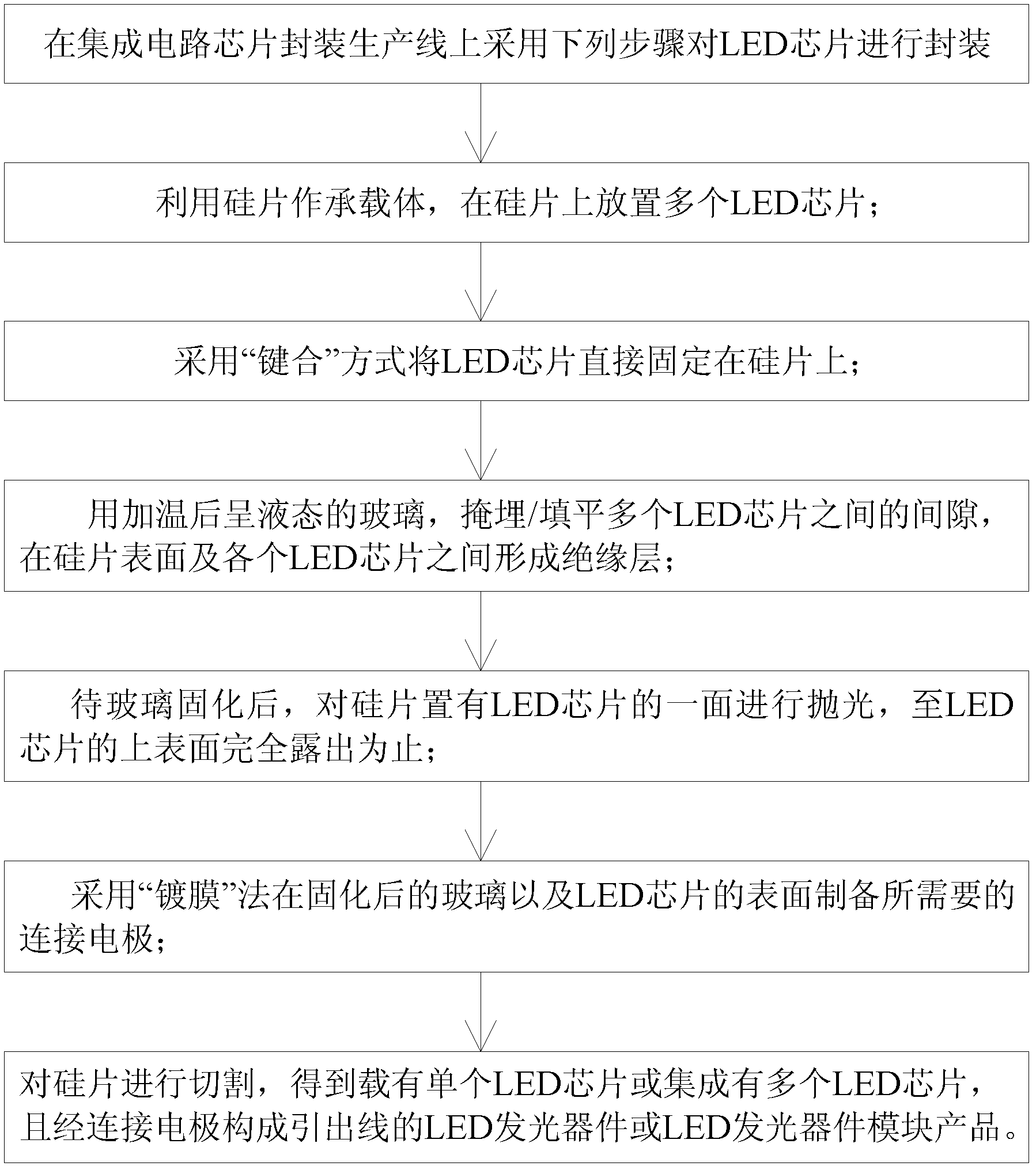

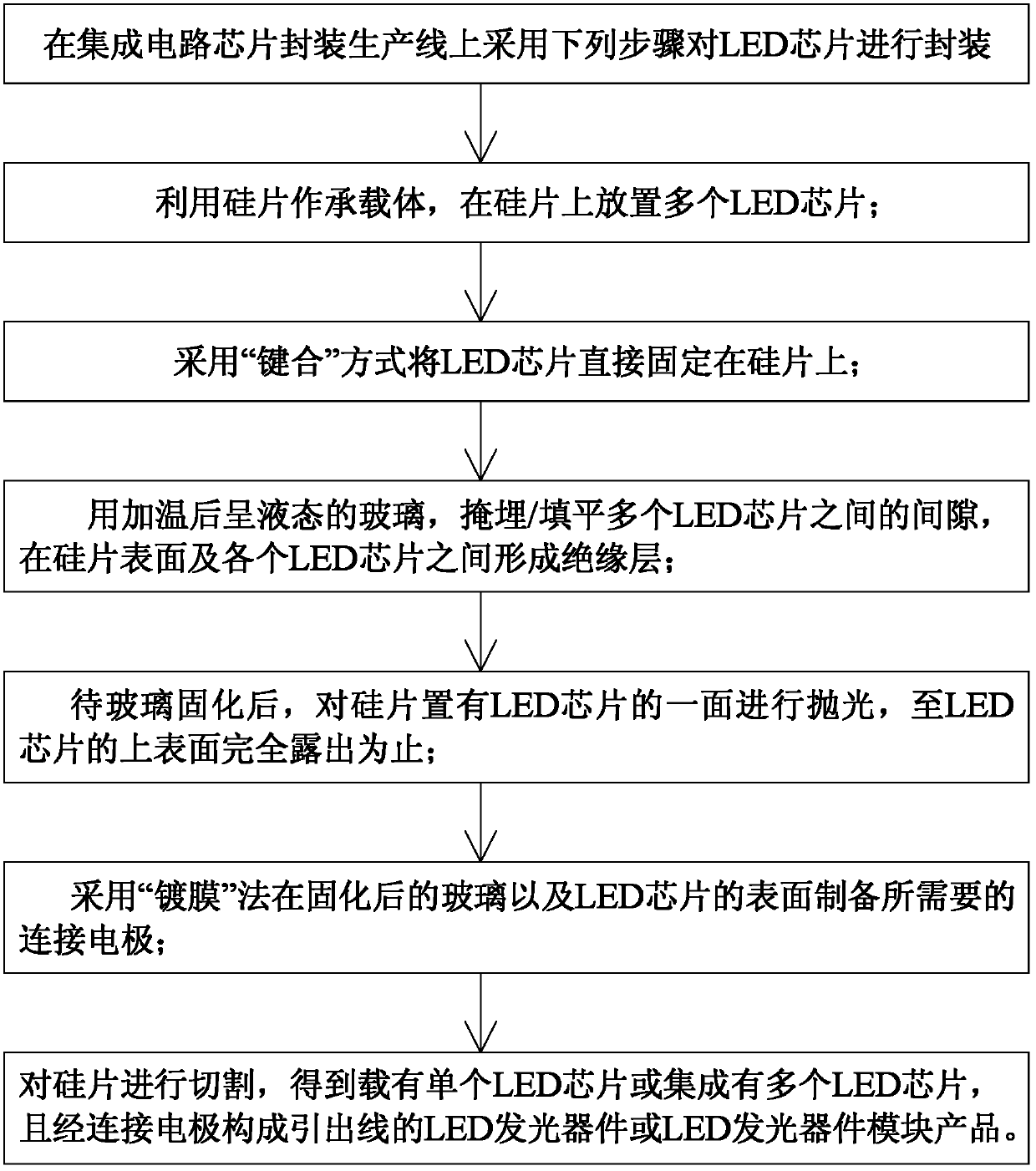

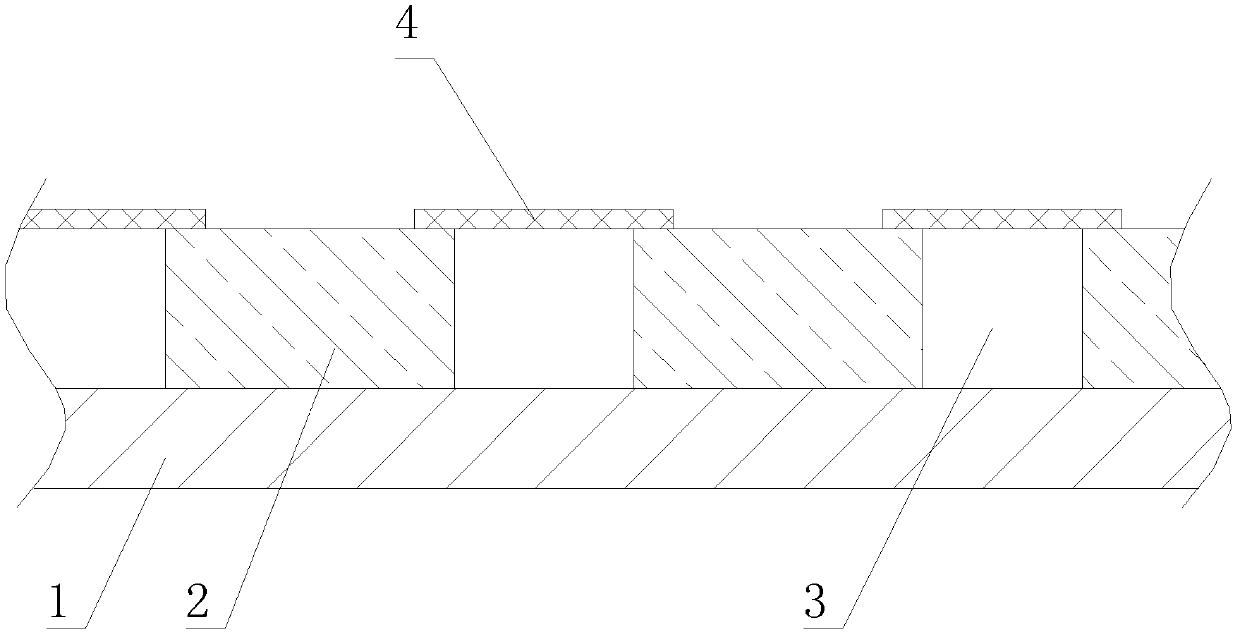

Silicon-based light emitting diode (LED) chip encapsulating method and LED chip luminous device

InactiveCN102623619AImprove luminous performanceImprove effectivenessSemiconductor devicesProduction lineInsulation layer

The invention relates to a silicon-based light emitting diode (LED) chip encapsulating method and an LED chip luminous diode, and belongs to the field of a semiconductor device. An LED chip is encapsulated on an intelligent card (IC) chip encapsulation production line: a silicon sheet is used as a carrier, and the LED chip is directly and fixedly arranged on the silicon sheet in a bonding manner; insulation layers are respectively formed on the surface of the silicon sheet and among different LED chips by liquid glass; the surface of the silicon sheet which is provided with the LED chip is polished; connection electrodes are respectively prepared on the surfaces of the solidified glass and the LED chips through a film coating method; and the silicon sheet is cut to obtain the LED luminous device or an LED luminous device module product. Due to the adoption of the silicon-based LED chip encapsulating method and the LED chip luminous diode, the encapsulation cost of an LED is reduced, a brand new field is developed for the application and the use of the existing integrated circuit IC chip encapsulation production line, the method is particularly suitable for the production of the LED luminous device with larger power, and larger optical power can be outputted under the same external environmental condition or under the situation with the same power. The method can be widely applied to the production and manufacturing fields of the LED luminous device.

Owner:SHANGHAI RES CENT OF ENG & TECH FOR SOLID STATE LIGHTING

Area management system

InactiveUS7729309B2Improve reception qualityIncrease the number ofNetwork traffic/resource managementBroadcast service distributionManagement systemBase station

A transmission area is specified flexibly in accordance with the contents of a flow. An area identification number (SHOG) is specified for each interlaced stream of wireless base stations. The same flow is sent at the same timing (or substantially at the same timing) in the interlaced stream specified for the same SHOG. A wireless terminal determines a neighbor sector or a neighbor wireless base station sending the same flow, in accordance with information given from the wireless base stations, and receives and combines the flows.

Owner:HITACHI LTD

Smelting device for single-crystal conductive copper rod

InactiveCN107354508AAdd evenlyEvenly blendedPolycrystalline material growthFrom frozen solutionsSingle crystalCopper

The invention discloses a smelting device for a single-crystal conductive copper rod. The smelting device comprises an upward continuous casting melting furnace and a closed mixing melting furnace, wherein a melting furnace closing top cap is arranged at the top of the closed mixing melting furnace; a reducing gas discharge pipe is arranged on the melting furnace closing top cap; a reducing gas blowing-in pipe, a molten copper liquid guide pipe and a guide pipe sealing guide sleeve are arranged at the bottom of the closed mixing melting furnace; the lower end of the molten copper liquid guide pipe is located below the liquid level of the molten copper liquid in the upward continuous casting melting furnace; the molten copper liquid guide pipe descends at a constant speed, so that the molten copper liquid in the closed mixing melting furnace flows into the upward continuous casting melting furnace at the constant speed, and mass of the molten copper liquid flowing through the molten copper liquid guide pipe in unit time is equal to that of the total mass of the molten copper liquid flowing through an upward crystallizer in unit time. With the adoption of the smelting device, uniform addition and blending of additive composition, prepared with a specific formula, in the single-crystal conductive copper material can be realized.

Owner:尚成荣

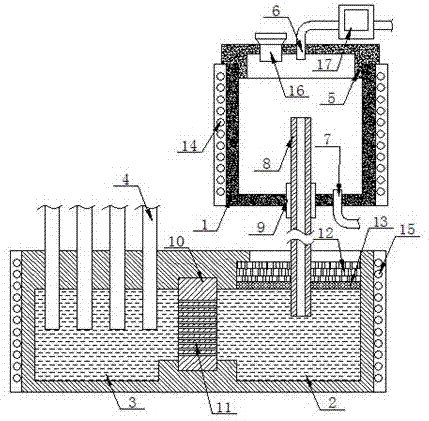

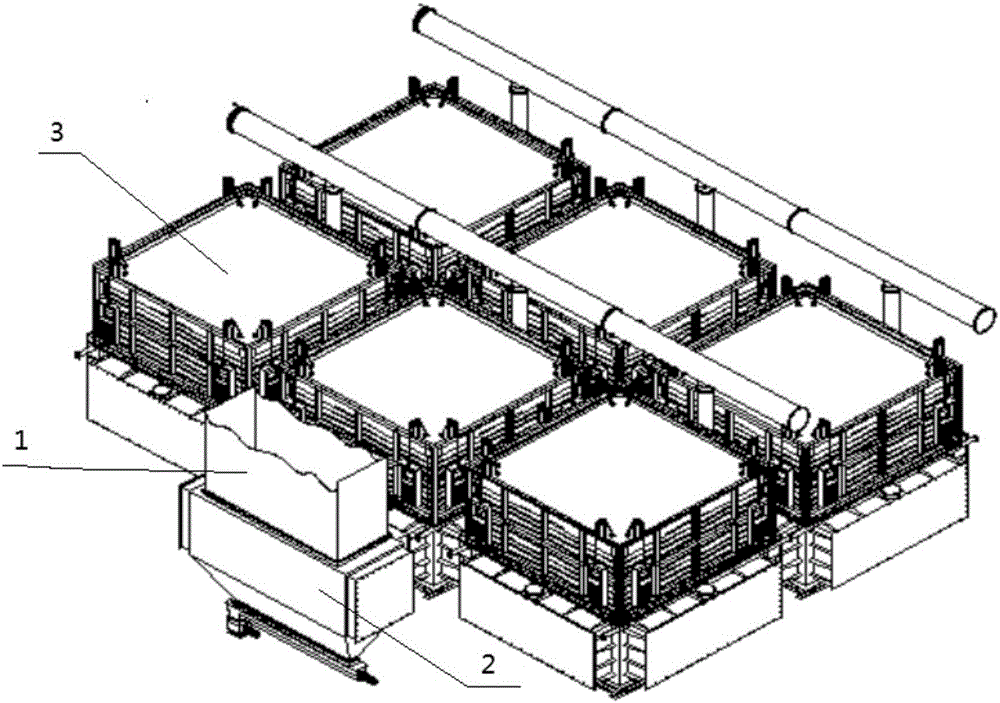

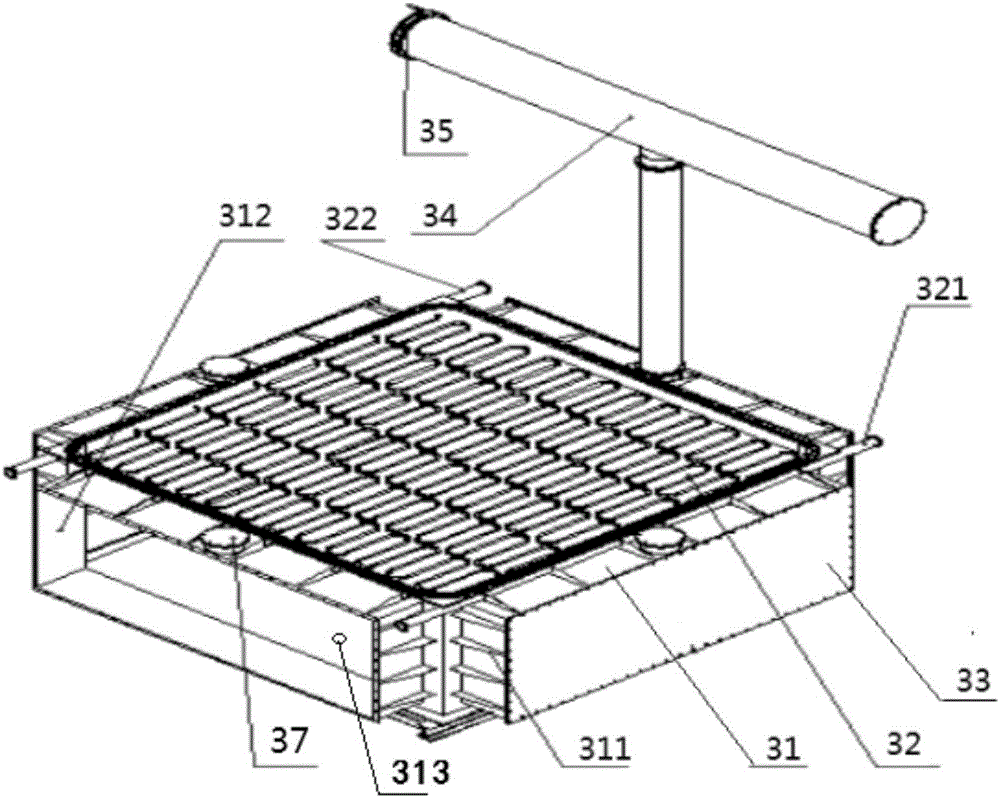

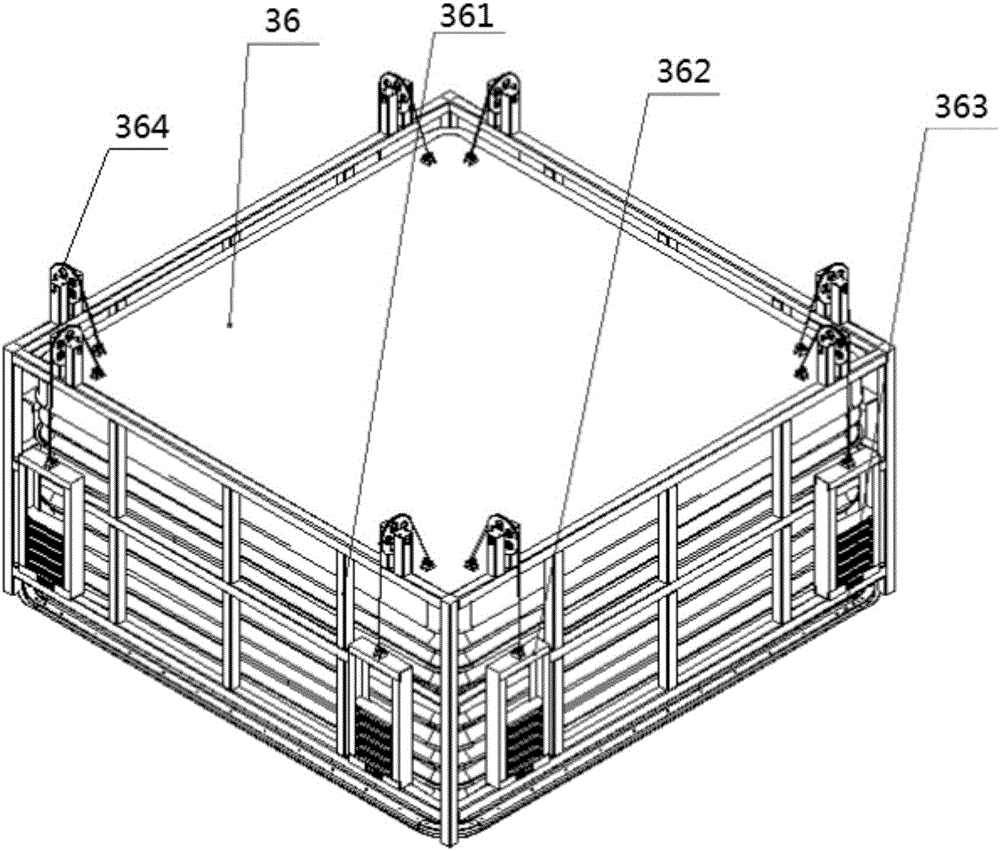

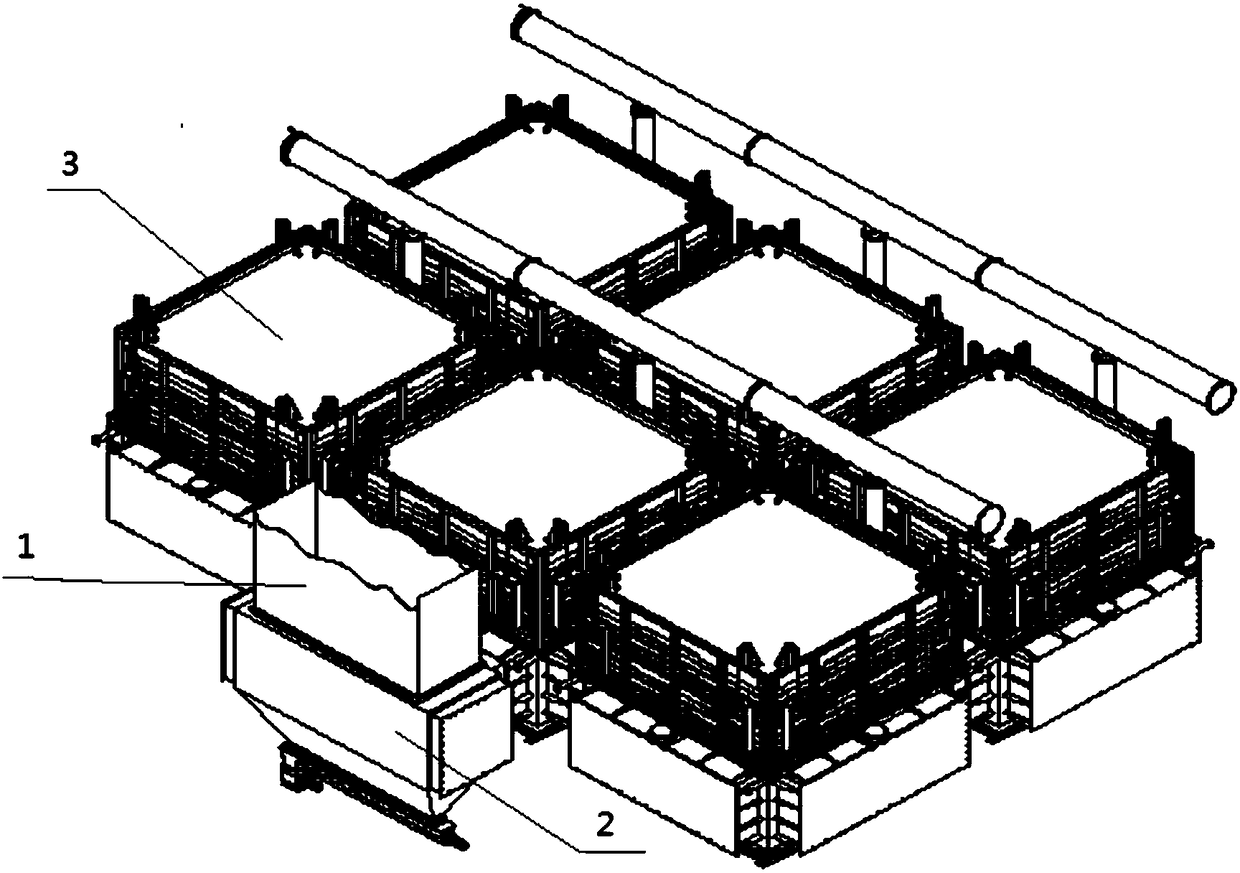

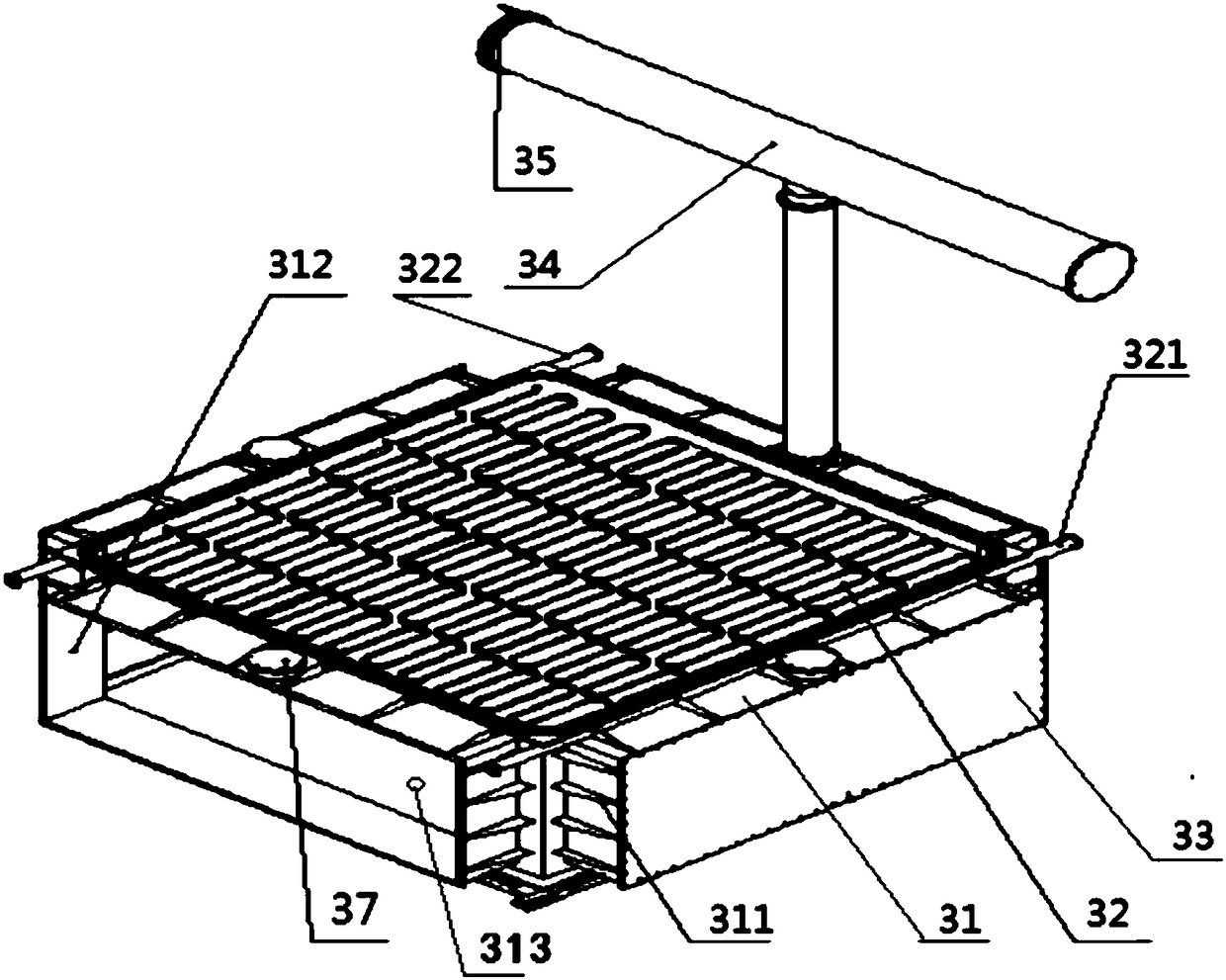

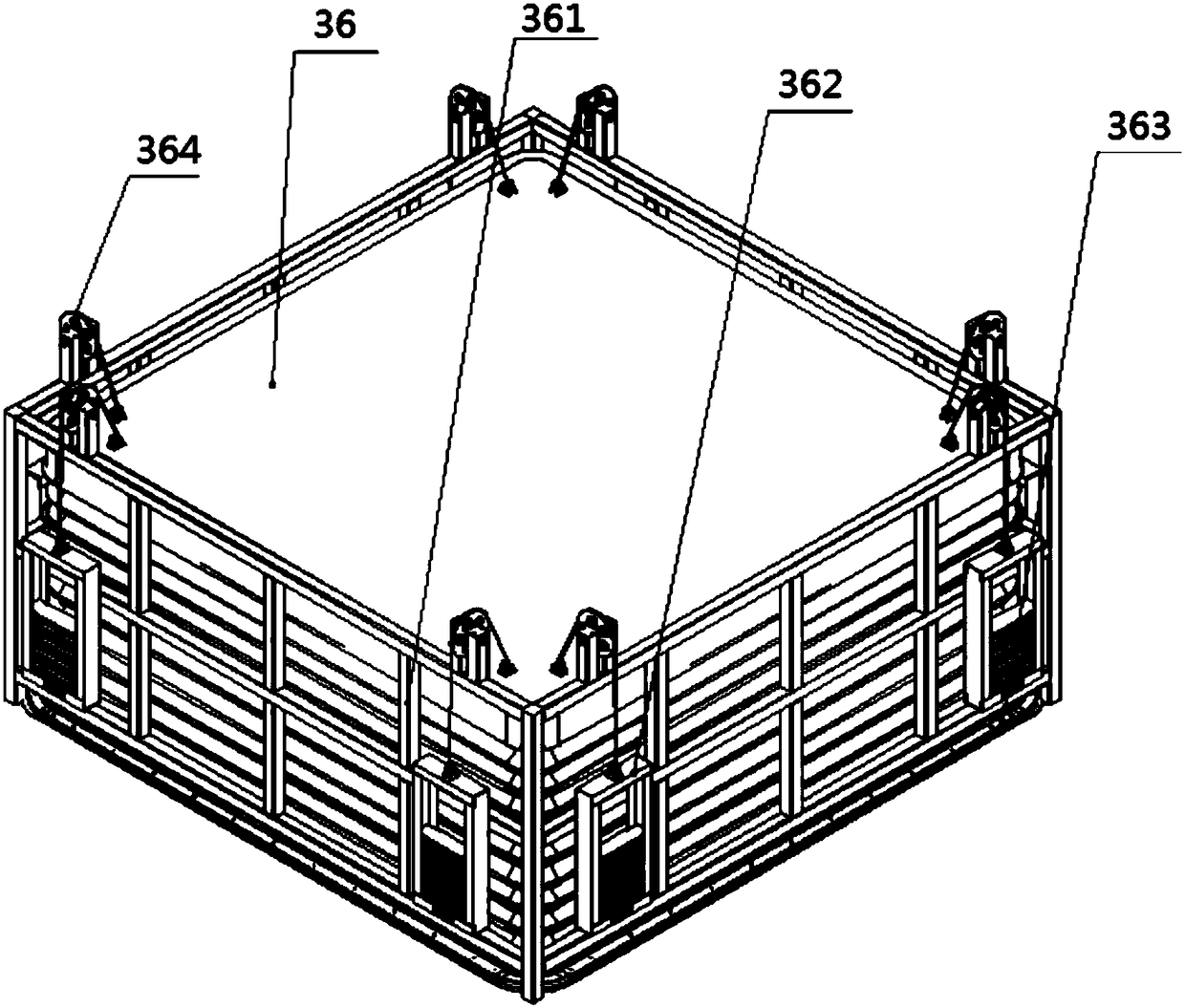

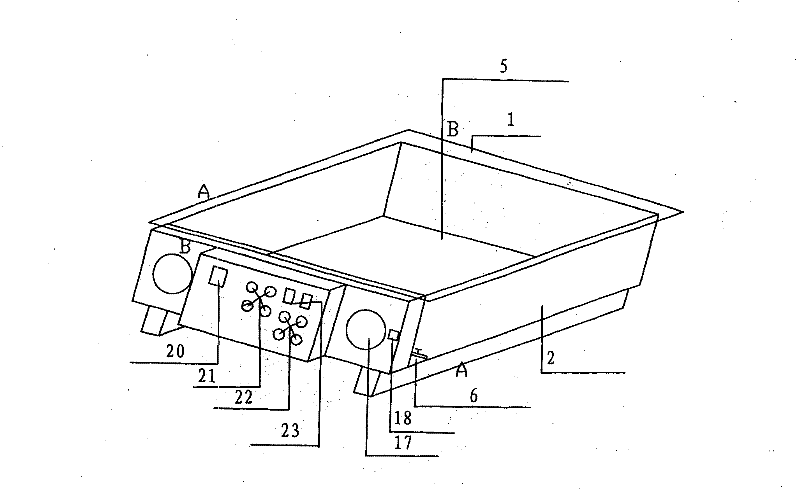

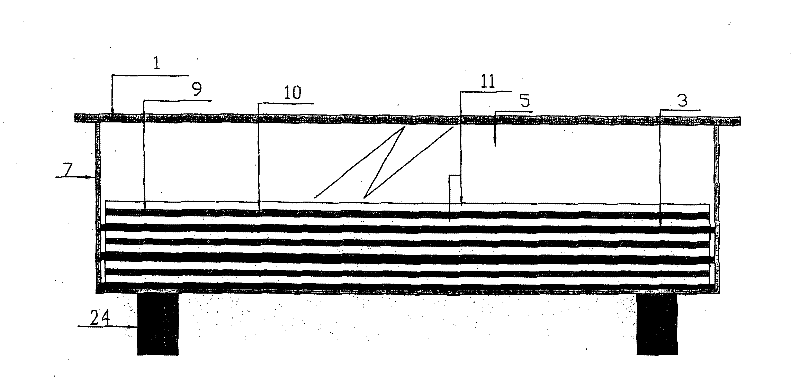

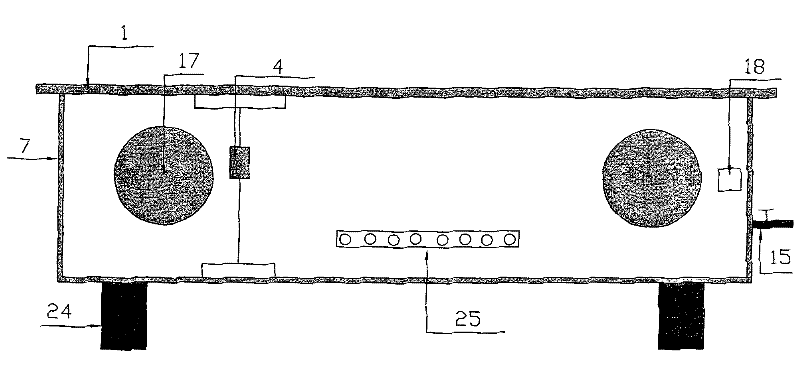

Collecting device for instantaneously-released high-temperature high-pressure high-humidity waste gas

ActiveCN106180112AIncrease profitImprove liquidityDispersed particle separationDirt cleaningGas collecting tubeHigh humidity

The invention provides a collecting device for instantaneously-released high-temperature high-pressure high-humidity waste gas, and belongs to the field of waste gas treatment. The collecting device comprises a gas collecting pipeline, an automatic separating unit and a plurality of buffer thermal exchange units; one end of the gas collecting pipeline communicates with the outer part, and the other end of the gas collecting pipeline is connected to an inlet of the automatic separating unit; one outlet of the automatic separating unit is connected to inlets of the buffer thermal exchange units; the plurality of the buffer thermal exchange units are arranged in a communication mode; and each buffer thermal exchange unit communicates with an external gas treatment device through a gas exhaust pipeline. The collecting device belongs to a modularized design, is simple in structure, and can be expanded according to practical needs, so that collection of different-displacement waste gas is realized.

Owner:关新华

High-temperature, high-pressure, and high-humidity exhaust gas collection device for instant release

ActiveCN106180112BIncrease profitImprove liquidityDispersed particle separationDirt cleaningGas collecting tubeHigh humidity

The invention provides a collecting device for instantaneously-released high-temperature high-pressure high-humidity waste gas, and belongs to the field of waste gas treatment. The collecting device comprises a gas collecting pipeline, an automatic separating unit and a plurality of buffer thermal exchange units; one end of the gas collecting pipeline communicates with the outer part, and the other end of the gas collecting pipeline is connected to an inlet of the automatic separating unit; one outlet of the automatic separating unit is connected to inlets of the buffer thermal exchange units; the plurality of the buffer thermal exchange units are arranged in a communication mode; and each buffer thermal exchange unit communicates with an external gas treatment device through a gas exhaust pipeline. The collecting device belongs to a modularized design, is simple in structure, and can be expanded according to practical needs, so that collection of different-displacement waste gas is realized.

Owner:关新华

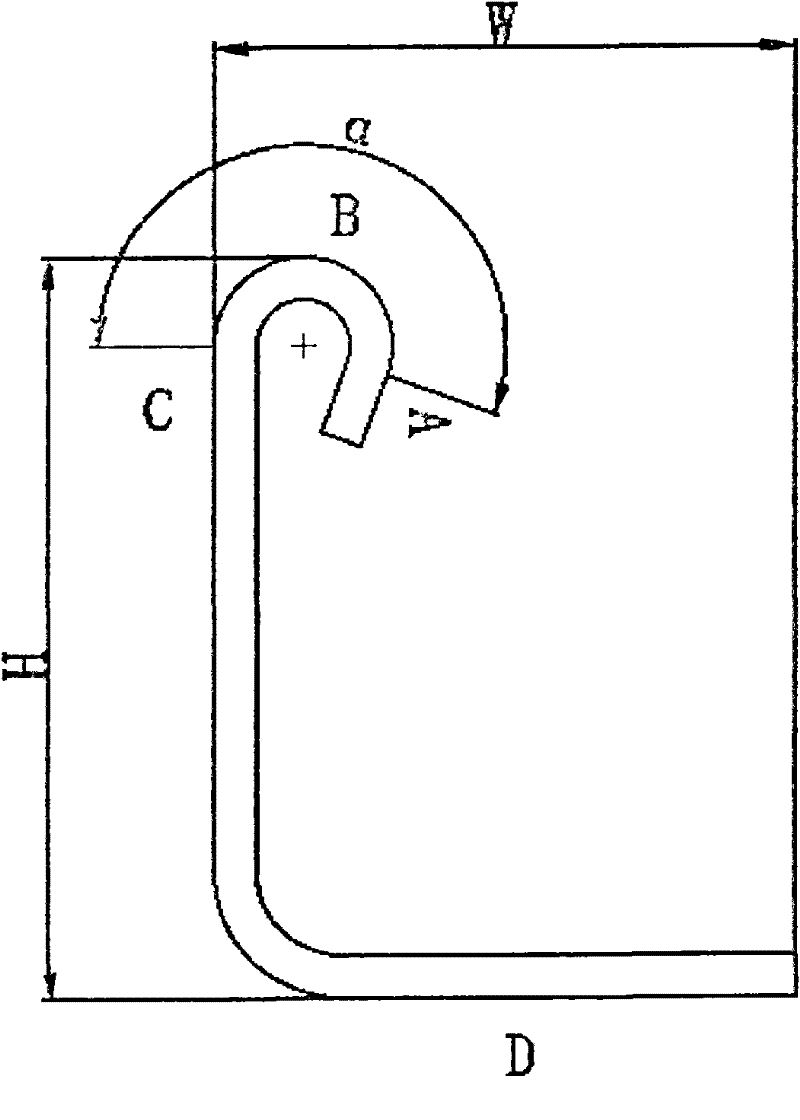

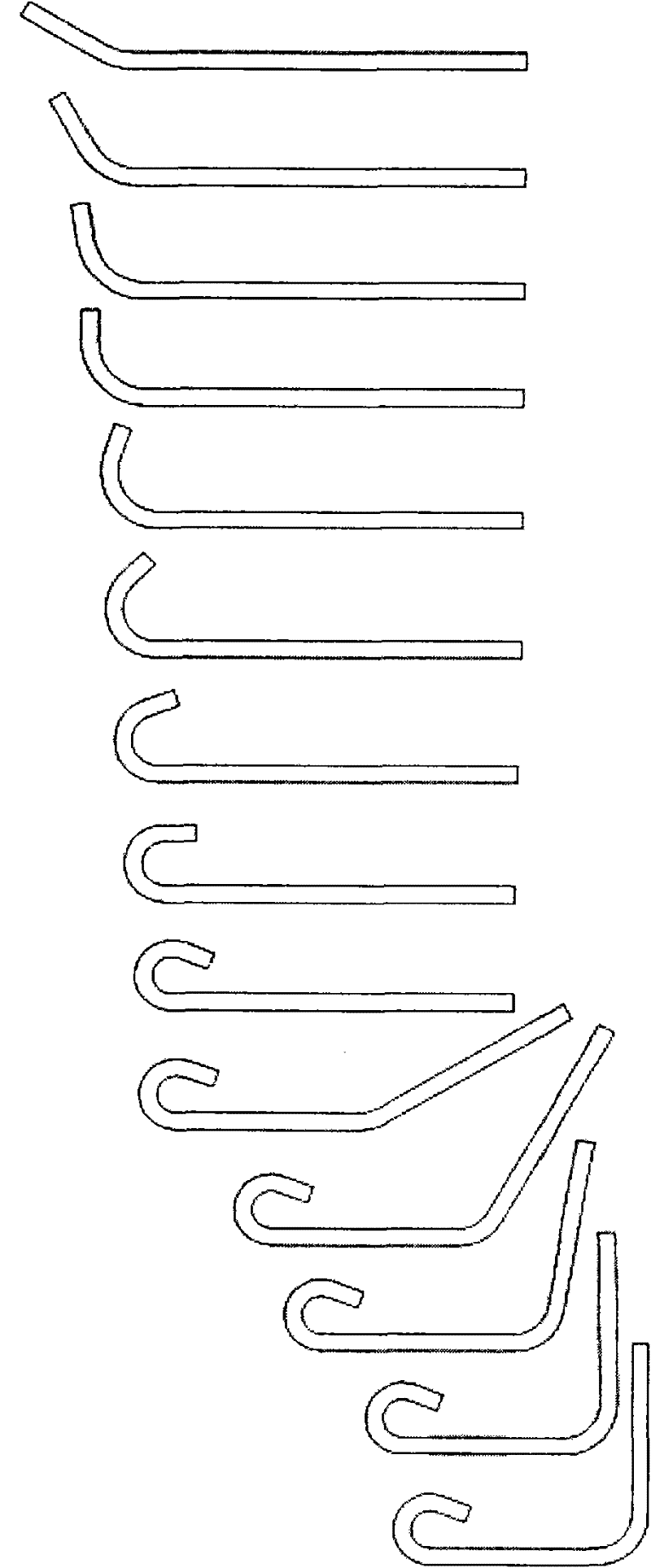

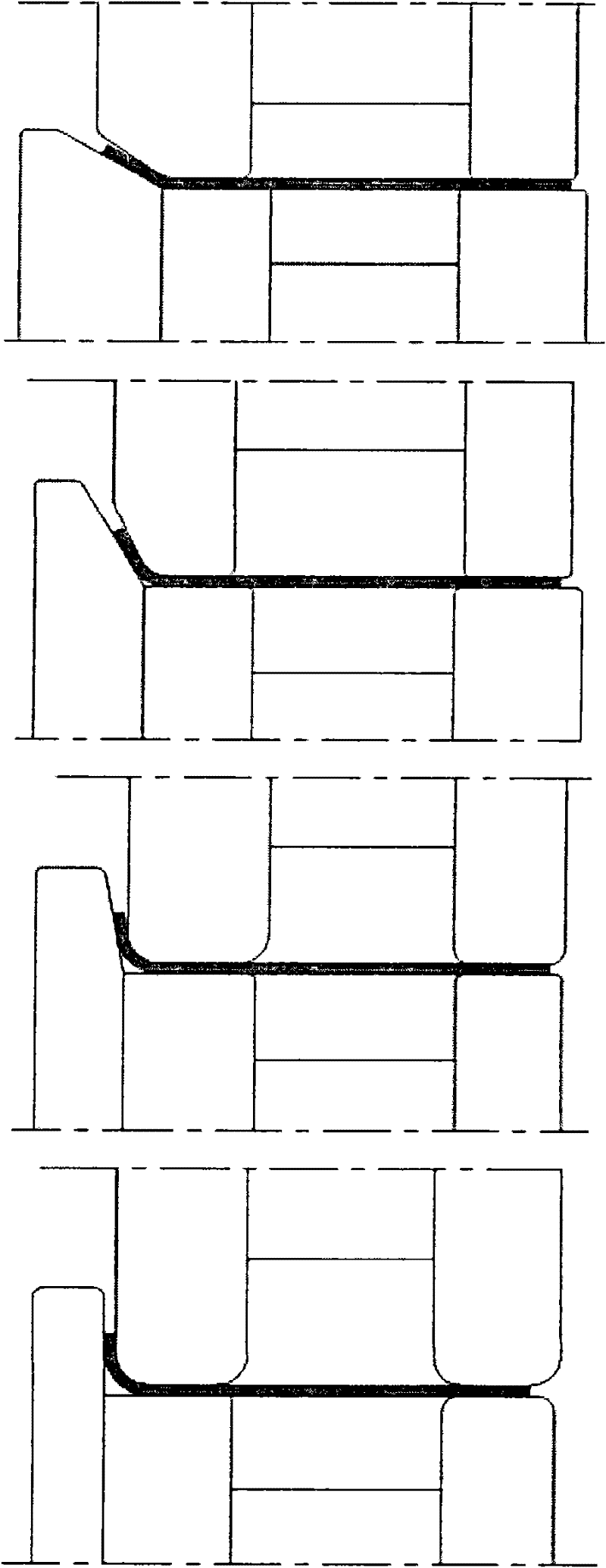

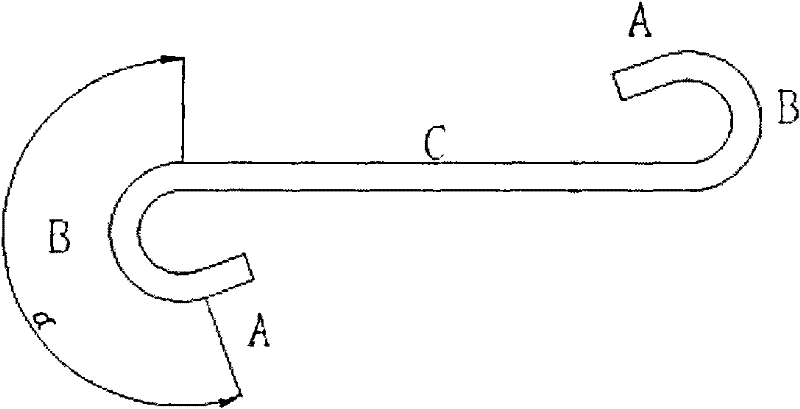

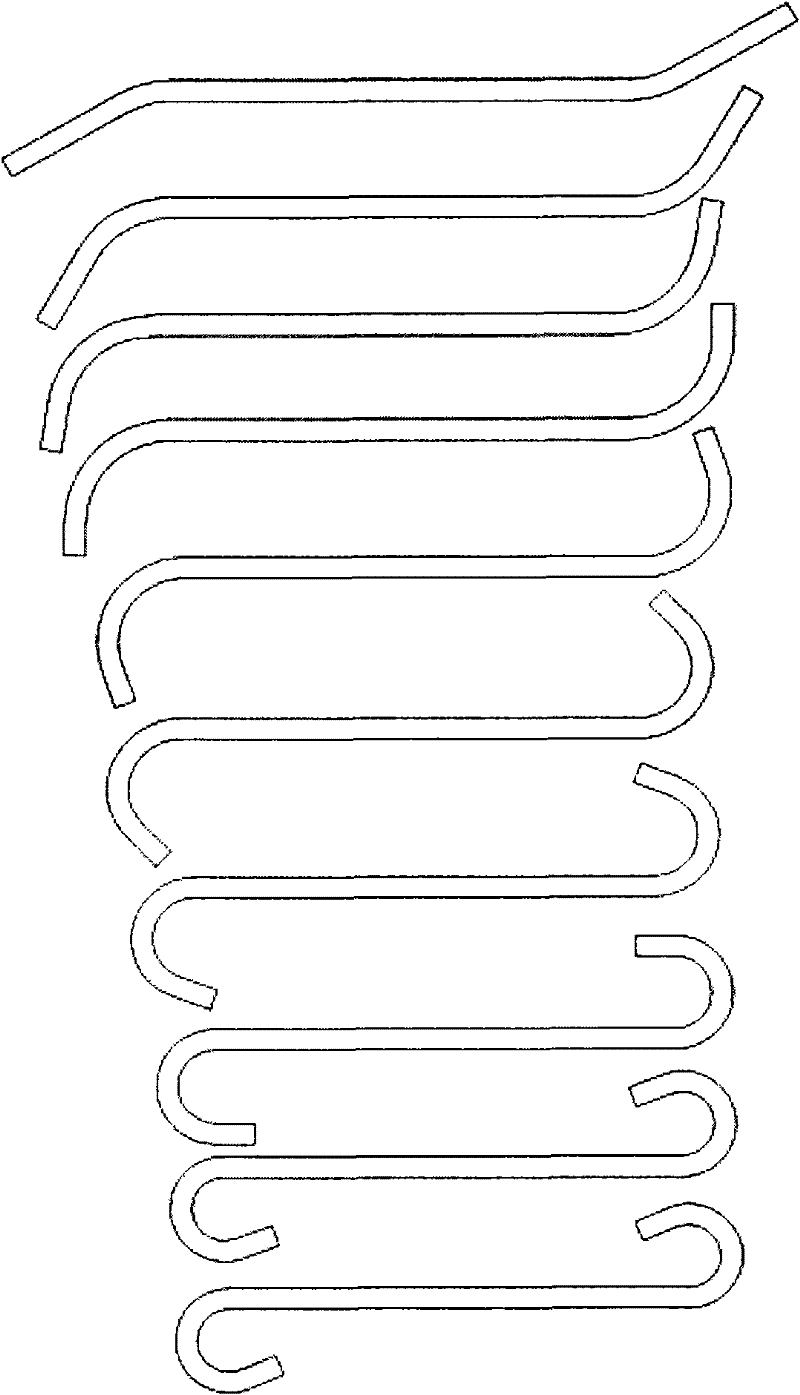

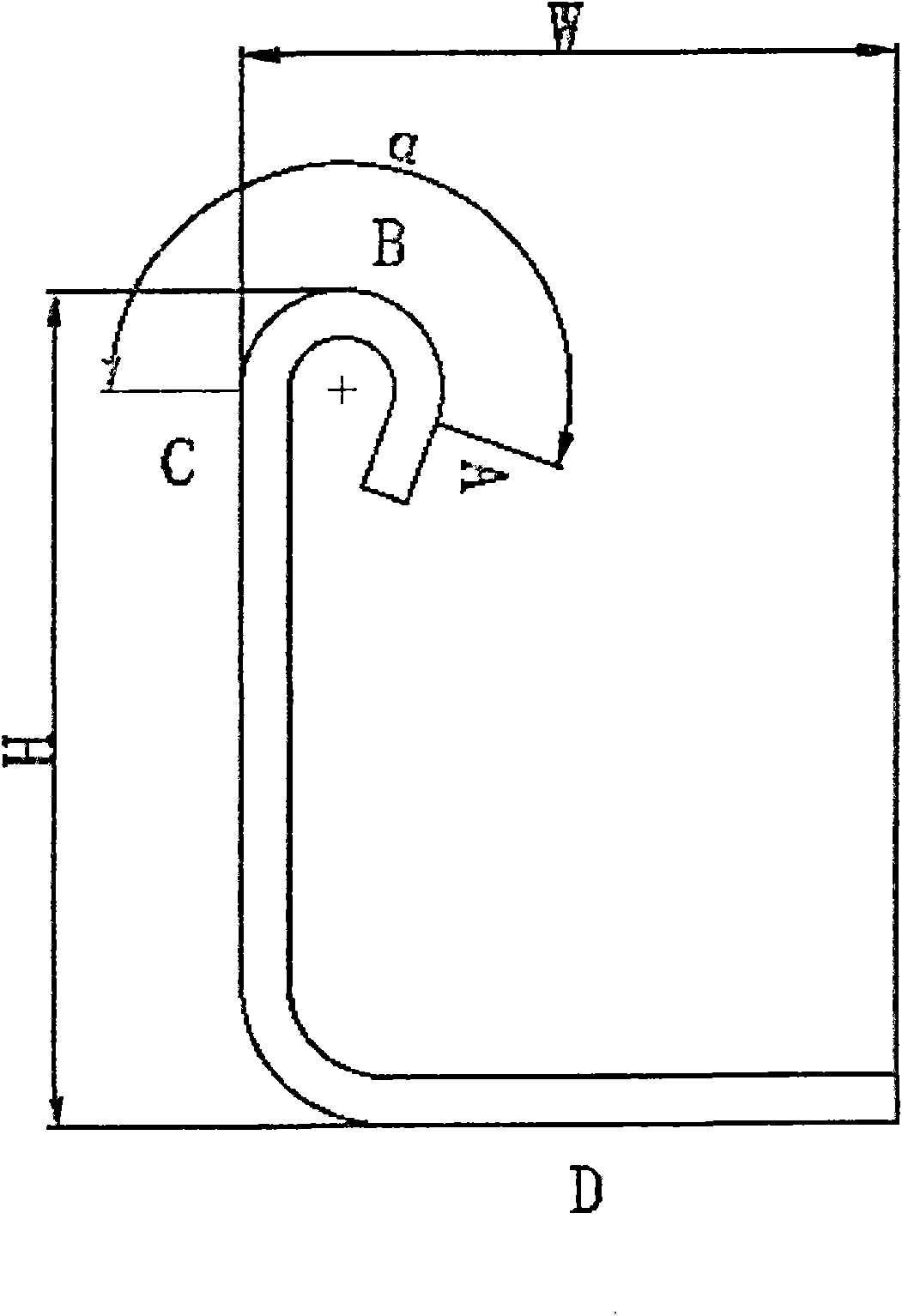

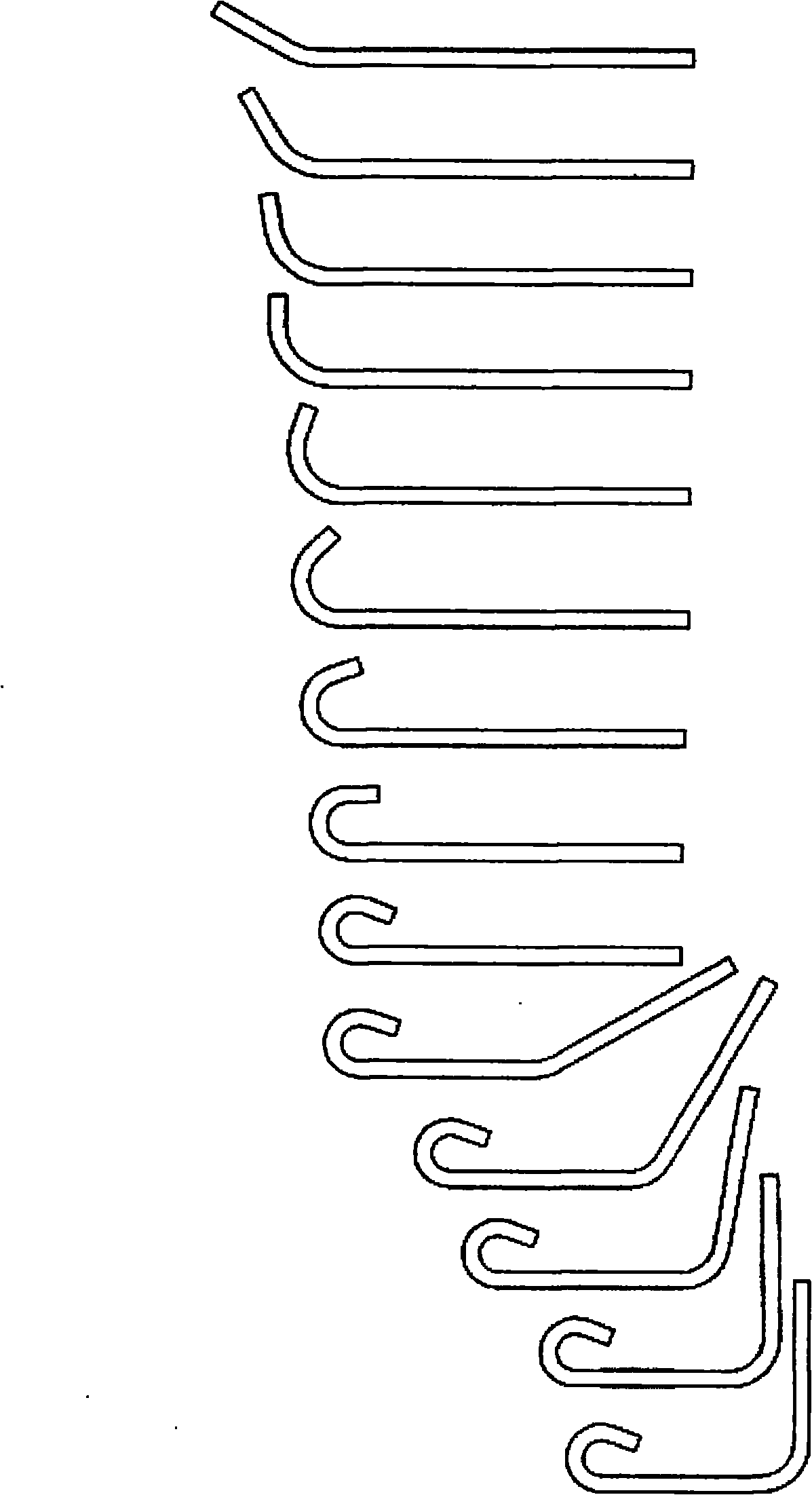

Continuous cold-roll-forming shaping method of straight-hook-shaped corner pile

InactiveCN101954398BIncrease productivityImprove project qualityBulkheads/pilesRoll formingStructural engineering

The invention provides a continuous cold-roll-forming shaping method of a straight-hook-shaped corner pile. The straight-hook-shaped corner pile consists of mutually perpendicular straight hook sides (C), an arc section (B) integrally connected with two hook sides and an oblique hook side (A) connected with the arc section (B), wherein the angle between the oblique hook side (A) and the straight hook side (C) is 200 degrees, and the shaping method of the straight-hook-shaped corner pile is characterized by comprising the steps of: preparing materials, performing 16 times of continuous cold-roll-forming shaping and cutting off process. The continuous cold-roll-forming shaping method of straight-hook-shaped corner pile has the advantages of high efficiency, stable quality and random length;besides, corresponding materials can be connected according to design requirements and various raw materials are available.

Owner:NANJING WANHUI STEEL SHEET PILING

New technique for producing high alloy steel high-end pipe by adopting cross rolling elongation technology

InactiveCN101579702BLow equipment investment costLow running costMandrel separation arrangementsMetal rolling arrangementsPipe fittingMaterial Perforation

The invention relates to a technique for producing a high alloy steel high-end seamless pipe by adopting cross rolling elongation technology without perforation, comprising: molten high alloy steel which is externally refined is made into a hollow shell by centrifugal casting; the outside surfaces of the front and the rear ends of the hollow shell are respectively processed to be a 'gripping head' and a 'tail end head' with conicity, and machining and quality inspection are carried out on the inside and the outside surfaces as well as the 'gripping head' and the 'tail end head' of the hollow shell; heating is carried out; a mandril is inserted into the heated hollow shell, and then the hollow shell is sent into a cross rolling elongating mill for cross rolling, so that the pipe fittings having the wall thickness, the diameter and the length being in accordance with the requirements can be produced; the mandril is removed, and the head and the tail are cut off; finally, the qualified finished pipes can be obtained after sizing, heat treatment for finished product and finishing operation. The technique has short process flow and does not need cross rolling perforation, thus reducing the cost and improving the quality; due to small tapered treatment for the front and the rear ends, 'tail triangle' is avoided when the medium-thick walled pipes are produced, and the performance of secondary gripping is improved, thus improving the quality of the product and the production efficiency.

Owner:北京蓝海科融新技术有限公司

Generating device of program or design documents

ActiveCN101599014BImprove productivityFlexible specificationsSpecific program execution arrangementsProduction rateGame design document

Owner:KK TOSHIBA +1

Continuous roll type cold-bending forming method for S-shaped corner pile

The invention relates to a continuous roll type cold-bending forming method for an S-shaped corner pile. The S-shaped corner pile comprises a straight edge (C), circular arc sections (B) and inclined hook edg (A), wherein the circular arc sections (B) are integrally connected with both sides of the straight edge (C) respectively; the inclined hook edges (A) are connected with the circular arc sections (B); one circular arc section (B) and one inclined hook edge (A) form a fore shaft; two fore shafts are respectively positioned on the upper surface and the lower surface of the straight edge (C); a section formed by the two fore shafts and the straight edge has an S-shaped structure; and an included angle of each inclined hook edge (A) and each straight hook edge (C) is 200 degrees. The forming method for a right-angle buckled angle pile is characterized by comprising the following steps of: preparing materials, carrying out 16 times of continuous roll type cold-bending forming, and cutting. The invention has the advantages of high efficiency, stable quality, changeable length, connection capability with corresponding materials according to the design requirement, wide choice range of raw materials, and the like.

Owner:NANJING WANHUI STEEL SHEET PILING

A production process of single crystal conductive copper rod up-leading continuous casting method

ActiveCN107354507BImprove product qualityImprove continuityPolycrystalline material growthFrom frozen solutionsElectrolysisSingle crystal

The invention discloses a production process of single crystal conductive copper rod up-drawing continuous casting method, comprising the following steps: putting electrolytic copper raw materials into a closed mixed molten material furnace for smelting, putting aluminum-antimony alloy powder into molten copper liquid, For europium oxide powder and beryllium aluminum alloy powder, the mixed gas of nitrogen and carbon monoxide is passed to the closed mixed molten material furnace through the ventilation inlet at the bottom of the closed mixed molten material furnace, and the mixed gas is discharged from the ventilated outlet at the top of the closed mixed molten material furnace; the molten mixture Transfer to the upward continuous casting molten material furnace, the molten mixture enters the upward continuous casting crystallizer through the siphon effect, and the crystallized conductive copper rod in the upward continuous casting crystallizer is drawn from the upward continuous casting crystallizer through the pulling device Lead out from the top of the device, and finally pack the finished conductive copper rods into rolls. Compared with the polycrystalline conductive copper rod produced and processed by the present invention, the elongation rate can be increased by 60% to 80%, and the resistivity can be reduced by 15% to 20%.

Owner:江苏裕铭铜业有限公司

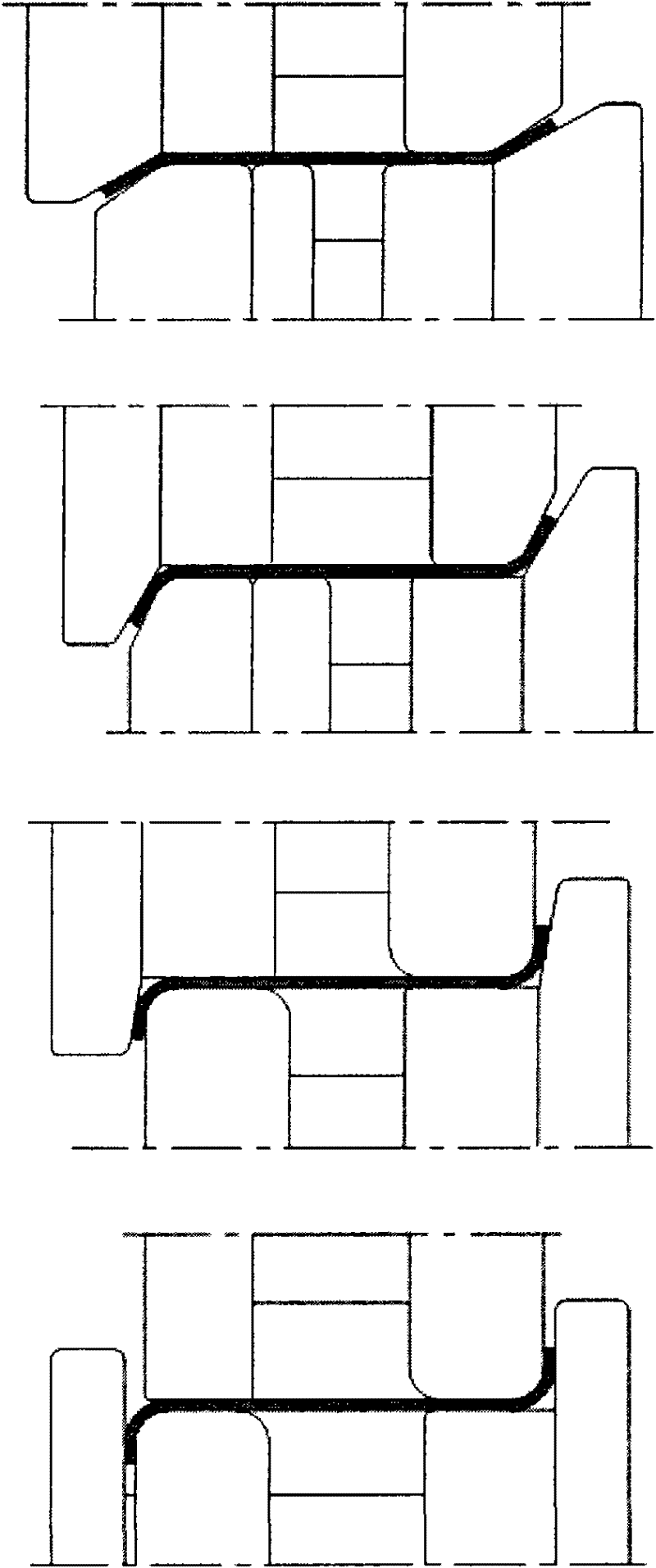

A kind of bimetal layered composite wire drawing forming method

ActiveCN104138923BHigh degree of freedom of combinationHigh bonding strengthWire rodManufactured material

The invention discloses a drawing forming method of a bimetallic layered composite wire, which belongs to the technical field of bimetallic layered composite wire preparation. It is characterized in that high-quality bimetallic layered composite wires are prepared by combining metal tube blanks with dissimilar metal rods, single-pass drawing pre-compounding at room temperature, rapid heating, temperature-controlled drawing metallurgical compounding and room temperature fine drawing . The advantages of the present invention are that the composite interface bonding strength of the bimetallic layered composite wire is high, the diffusion layer is thin, the cladding metal is evenly distributed along the circumferential direction and the longitudinal direction, the cladding ratio is easy to accurately control, no need for drawing and intermediate annealing, and the product specification is flexible , large degree of freedom in combination of raw materials, excellent product quality and performance, and easy preparation of fine bimetallic layered composite wires with a diameter of less than 1mm, etc. Fabrication of Metal Layered Composite Wires.

Owner:UNIV OF SCI & TECH BEIJING

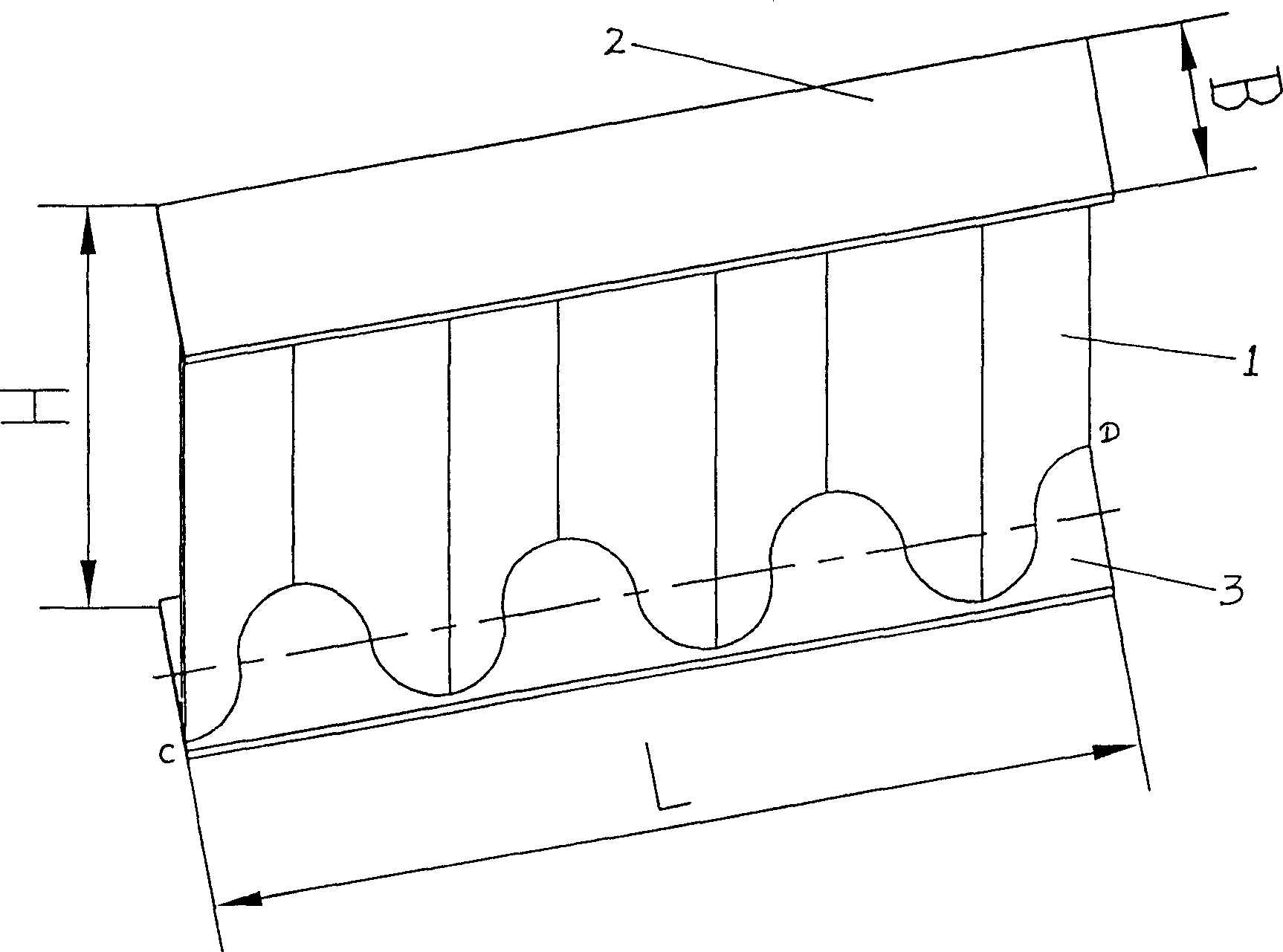

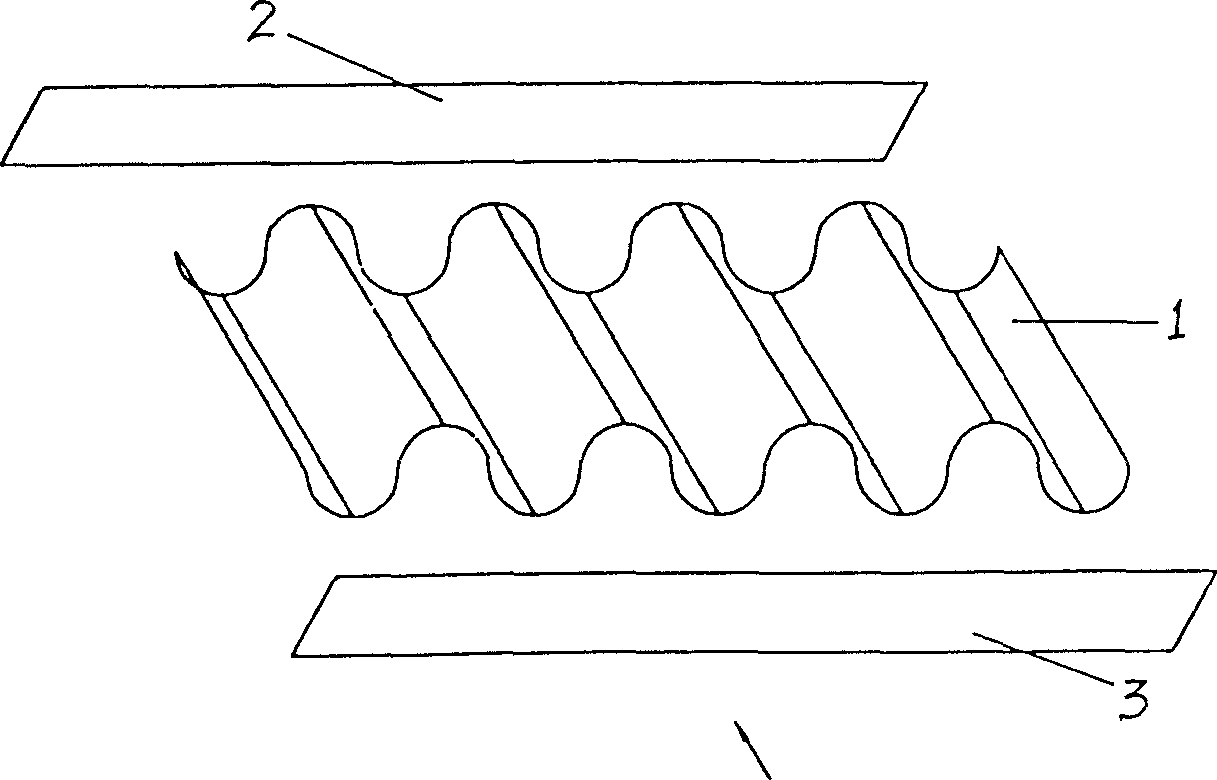

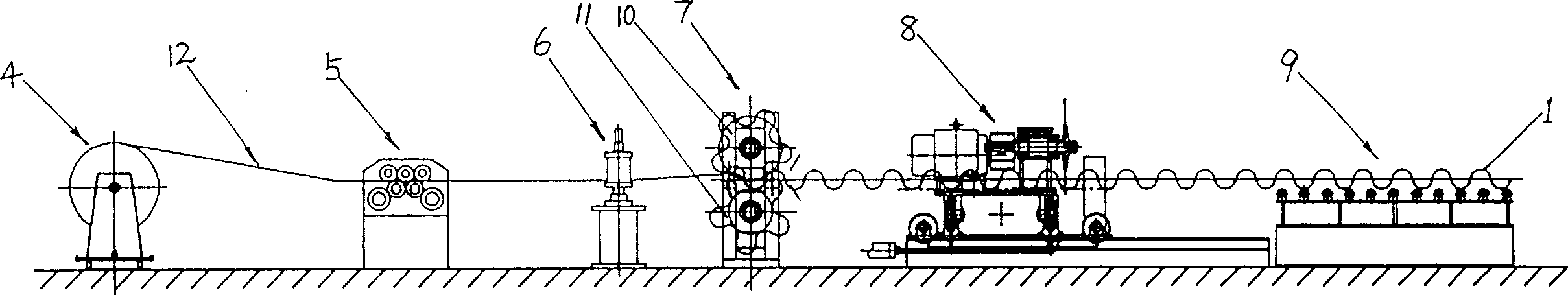

H-shaped section bar having transverse wave form webs, its making process and forming apparatus for transverse wave form webs

InactiveCN1291118CImprove carrying capacityIncrease contact surfaceRailsBridgesWave shapeEngineering

Owner:王银

Composite red mud coiled material used for biogas project and preparation method thereof

ActiveCN101538801BHigh yieldAnti-agingSynthetic resin layered productsLaminationPolyesterEnvironmental resistance

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

A tr component control circuit based on a full bare chip

ActiveCN111123207BImprove reliabilityPower on and load without failureWave based measurement systemsControl signalHemt circuits

The invention discloses a full-bare chip-based TR component control circuit, which includes: a chip group for receiving control signals output by a wave control machine; the chip group includes multi-level chips electrically connected in series, each The bare chips are respectively electrically connected with a multi-function sub-circuit, a power amplifier sub-circuit and a ring amplifier sub-circuit. The invention improves the reliability of TR components.

Owner:BEIJING INST OF RADIO MEASUREMENT

Method for making low-temperature adhesive plate vacuum glass and apparatus thereof

The invention relates to a method for producing vacuum slab glass that has a smooth surface and has no vertebrate tail and sealing plug and an equipment thereof. One piece of glass is cut into two pieces, then a support is arranged between the two pieces of glass, a bonding agent is coated on the four sides of the glass and one notch is left without coating the bonding agent and is used as vacuumpassage of later step, the two pieces of glass are placed into a vacuum box after the bonding process is finished; the inside of the vacuum box is provided with a heating device and a glue-filling machine; also a vacuum pipe is arranged on the vacuum box, then the heating device is started to heat the glass, and a vacuum valve is started to vacuumize, then the glue-filling machine is started to seal the passage, finally the vacuum box is cooled and the pressure is relived to obttain the finished vacuum glass. Compared with the other vacuum glass which has vertebrate tail protuberance on the surface and is sealed by rubber plugs, the vacuum glass production process reduces the production procedure; also the product is more beautiful as the product has no projection or sealing rubber plug; the production line is short, which needs less investment, consumes less energy and reduces the manufacturing cost.

Owner:胡屹博 +2

Silicon-based light emitting diode (LED) chip encapsulating method and LED chip luminous device

InactiveCN102623619BImprove luminous performanceImprove effectivenessSemiconductor devicesProduction lineInsulation layer

The invention relates to a silicon-based light emitting diode (LED) chip encapsulating method and an LED chip luminous diode, and belongs to the field of a semiconductor device. An LED chip is encapsulated on an intelligent card (IC) chip encapsulation production line: a silicon sheet is used as a carrier, and the LED chip is directly and fixedly arranged on the silicon sheet in a bonding manner; insulation layers are respectively formed on the surface of the silicon sheet and among different LED chips by liquid glass; the surface of the silicon sheet which is provided with the LED chip is polished; connection electrodes are respectively prepared on the surfaces of the solidified glass and the LED chips through a film coating method; and the silicon sheet is cut to obtain the LED luminous device or an LED luminous device module product. Due to the adoption of the silicon-based LED chip encapsulating method and the LED chip luminous diode, the encapsulation cost of an LED is reduced, a brand new field is developed for the application and the use of the existing integrated circuit IC chip encapsulation production line, the method is particularly suitable for the production of the LED luminous device with larger power, and larger optical power can be outputted under the same external environmental condition or under the situation with the same power. The method can be widely applied to the production and manufacturing fields of the LED luminous device.

Owner:SHANGHAI RES CENT OF ENG & TECH FOR SOLID STATE LIGHTING

Continuous cold-roll-forming shaping method of straight-hook-shaped corner pile

InactiveCN101954398AIncrease productivityImprove project qualityBulkheads/pilesEngineeringRoll forming

The invention provides a continuous cold-roll-forming shaping method of a straight-hook-shaped corner pile. The straight-hook-shaped corner pile consists of mutually perpendicular straight hook sides (C), an arc section (B) integrally connected with two hook sides and an oblique hook side (A) connected with the arc section (B), wherein the angle between the oblique hook side (A) and the straight hook side (C) is 200 degrees, and the shaping method of the straight-hook-shaped corner pile is characterized by comprising the steps of: preparing materials, performing 16 times of continuous cold-roll-forming shaping and cutting off process. The continuous cold-roll-forming shaping method of straight-hook-shaped corner pile has the advantages of high efficiency, stable quality and random length; besides, corresponding materials can be connected according to design requirements and various raw materials are available.

Owner:NANJING WANHUI STEEL SHEET PILING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com