Continuous roll type cold-bending forming method for S-shaped corner pile

A corner pile and cold-bending technology, which is applied in the field of continuous roll-type cold-bending forming of S-shaped corner piles, can solve problems affecting project quality, achieve the effects of improving project quality, reducing production costs, and solving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

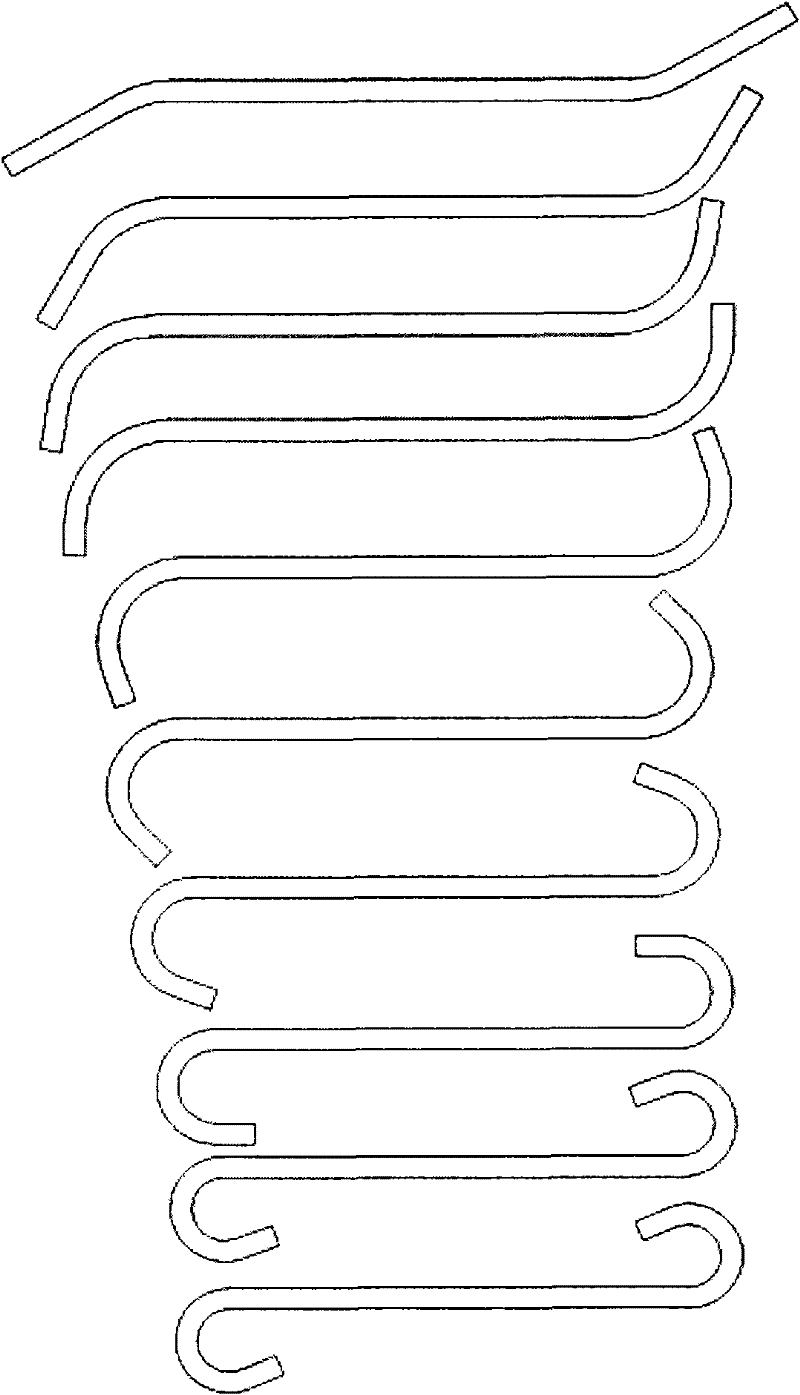

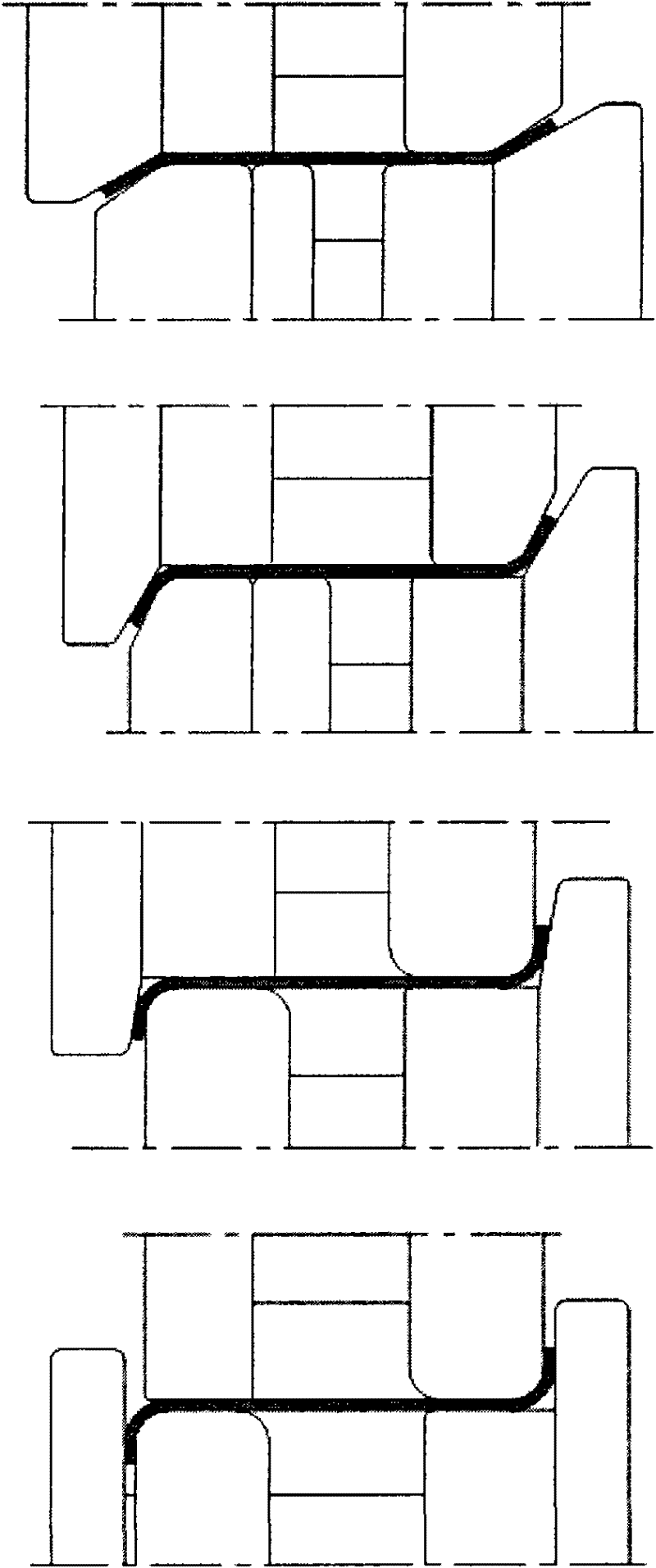

[0038] Such as Figure 1-5 shown.

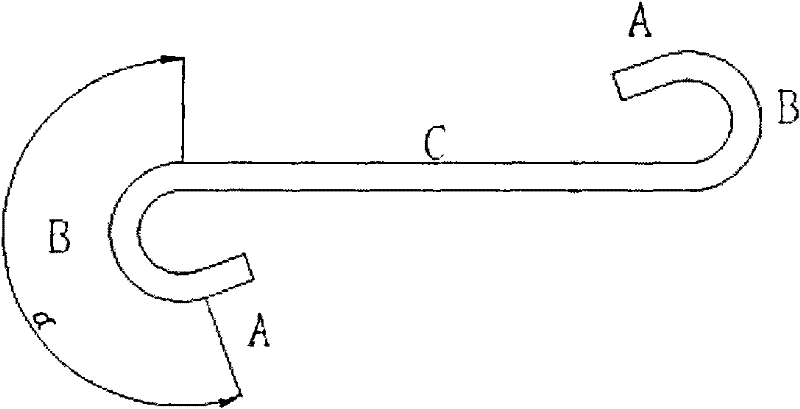

[0039] An S-shaped corner pile, which is composed of a straight side C, an arc segment B integrally connected with both sides of the straight side C, and an oblique hook side A connected with the arc segment B, an arc segment B and an oblique hook side A constitutes a lock on one side, and the two locks are respectively located on the upper and lower surfaces of the straight side C. From any cross-section, the lock and the straight side form an approximate S-shaped structure. The steel used for cold bending The thickness of the belt can be selected according to the needs, generally 5-16 mm, such as figure 1 As shown, the angle α between the oblique hook side A and the straight hook side C is 200 degrees.

[0040] The present invention adopts the method of continuous roll-type cold-bending forming to directly obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com