Short-process efficient production method for metal-layered composite board strips

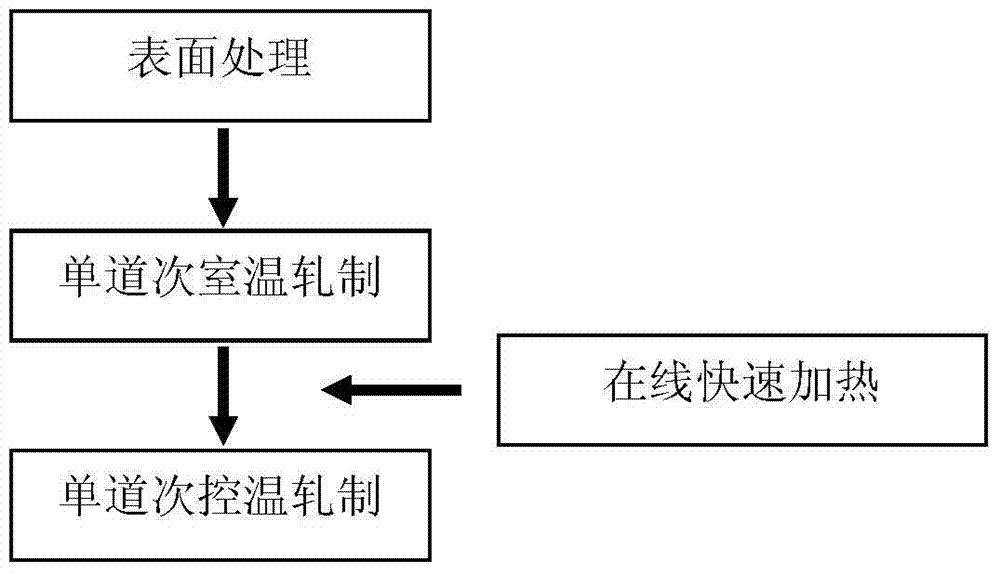

A composite strip and metal layer technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problem of low degree of automation and continuity, low material utilization rate and production efficiency, and inability to use active metals Compounding and other issues, to achieve the effect of flexible specifications, large degrees of freedom, and no potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] At room temperature, the surface of the pure titanium plate (thickness 1.1 mm) and carbon steel plate (thickness 4.4 mm) to be compounded was ground with an online grinding wheel; then the surface of the pure titanium plate and carbon steel plate after grinding Superimposed, and continuously bitten into the first rolling mill, the online single-pass room temperature rolling is carried out to achieve pre-compounding, the rolling reduction rate is 30%, and the pre-compounded titanium / steel layered composite slab is obtained; then the pre-compounded The composite titanium / steel layered composite slab is directly transported into the current heating device, and the pre-composited titanium / steel layered composite slab is heated online rapidly in the current heating device, so that the pre-composited titanium / steel layered composite slab heats up rapidly To the required rolling temperature of 750 °C, the heating time is 10 s; then the heated pre-clad titanium / steel layered com...

Embodiment 2

[0028] At room temperature, the surface of the cleaned pure titanium strip (thickness 0.1 mm) and carbon steel strip (thickness 0.6 mm) to be composited was polished with an online high-speed rotating steel brush; then the pure titanium strip and carbon steel strip The polished surfaces of the materials are superimposed, and continuously bitten into the first rolling mill, and the online single-pass room temperature rolling is carried out to achieve pre-compounding. The rolling reduction rate is 30%, and the pre-compounded titanium / steel layered Composite strip; then the pre-composite titanium / steel layered composite strip is directly transported into the induction heating device, and the pre-compound titanium / steel layered composite strip is rapidly heated online in the induction heating device, so that the pre-compound titanium / steel The layered composite strip was heated rapidly to the required rolling temperature of 650 °C, and the heating time was 5 s; then the heated pre-...

Embodiment 3

[0030] The surface to be compounded (one side of aluminum, two sides of titanium) of pure aluminum plate (thickness 3 mm), pure titanium plate (thickness 1 mm) and carbon steel plate (thickness 5 mm) after surface cleaning at room temperature surface and one side surface of carbon steel) for online high-speed rotary steel brush grinding; then, according to the three-layer composite method of pure aluminum sheet / pure titanium sheet / carbon steel sheet, the pure aluminum sheet, pure titanium sheet and carbon steel sheet are polished The treated surfaces are superimposed and continuously bitten into the first rolling mill for on-line single-pass room temperature rolling to achieve pre-compounding. The rolling reduction rate is 50%, and the pre-compounded aluminum / titanium / carbon steel layered Composite slab; then the pre-composite aluminum / titanium / carbon steel layered composite slab is directly transported into the induction heating device, and the pre-compounded aluminum / titanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com