Silicon-based light emitting diode (LED) chip encapsulating method and LED chip luminous device

A technology of LED chips and packaging methods, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., and can solve the effects of LED light-emitting devices on the luminous effect or effective light output, the effects of light-emitting device service life and work reliability, and increase the production cost of LED chips To achieve flexible and diverse product specifications, improve heat dissipation/heat conduction effect, luminous effect or effective light output improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

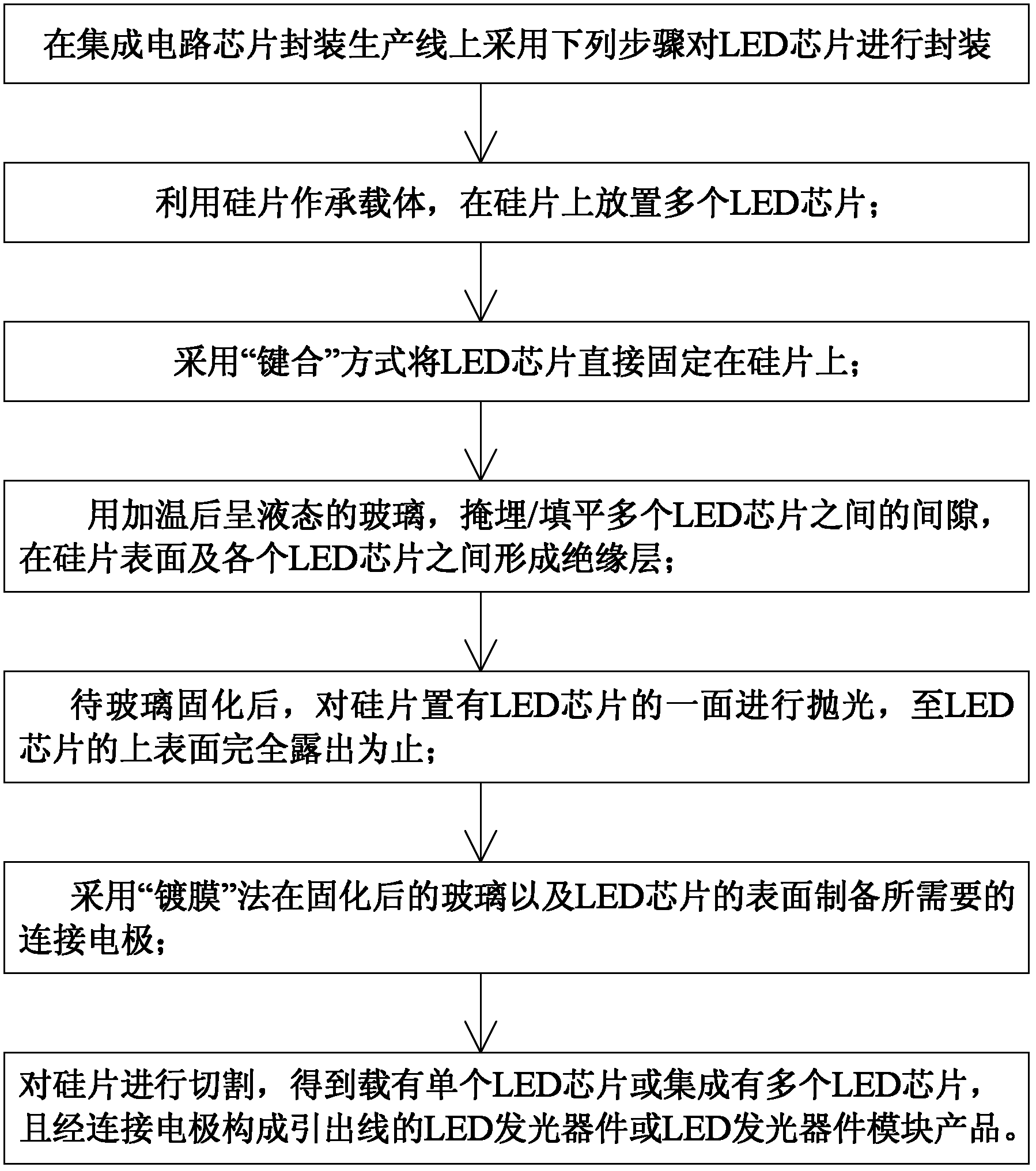

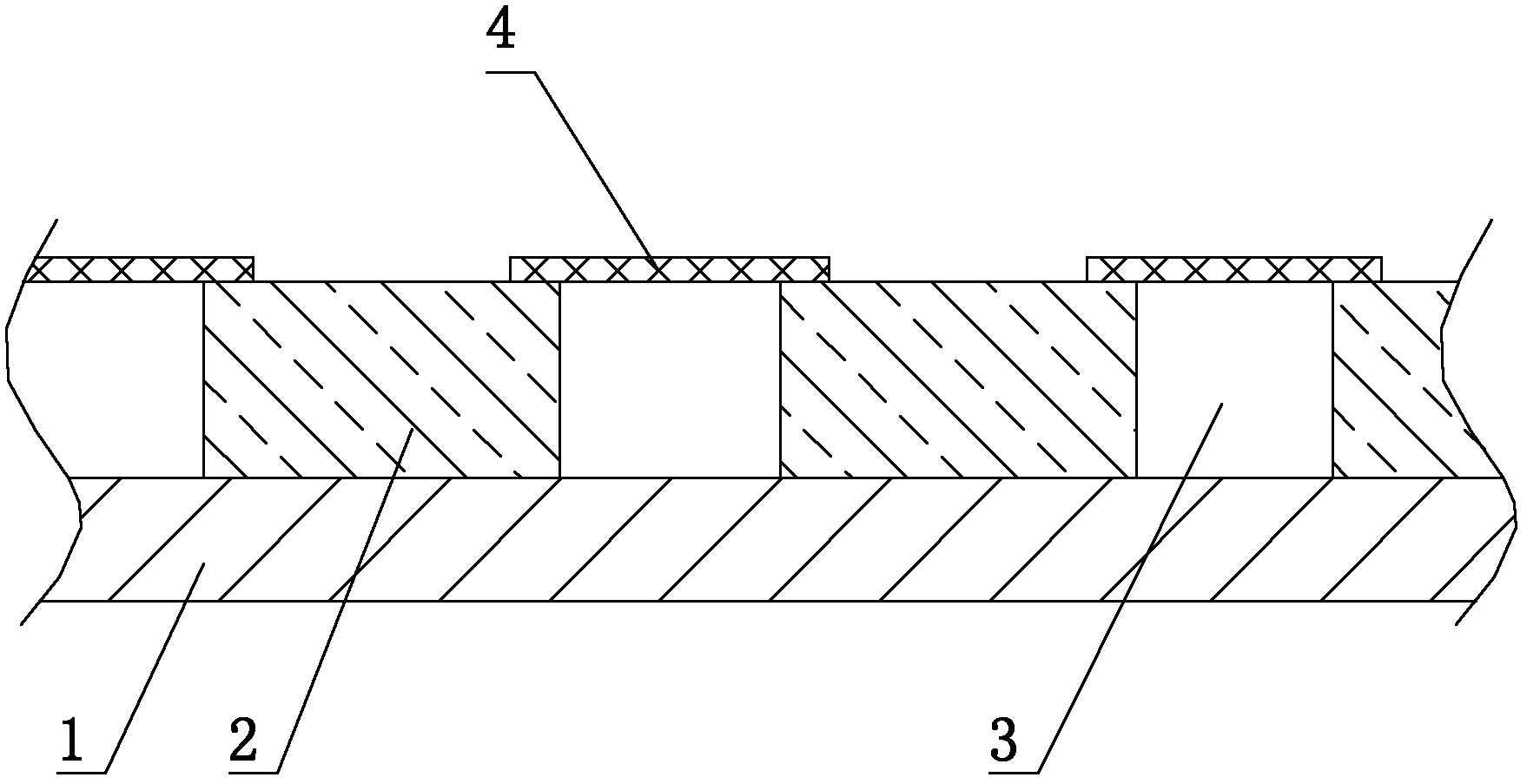

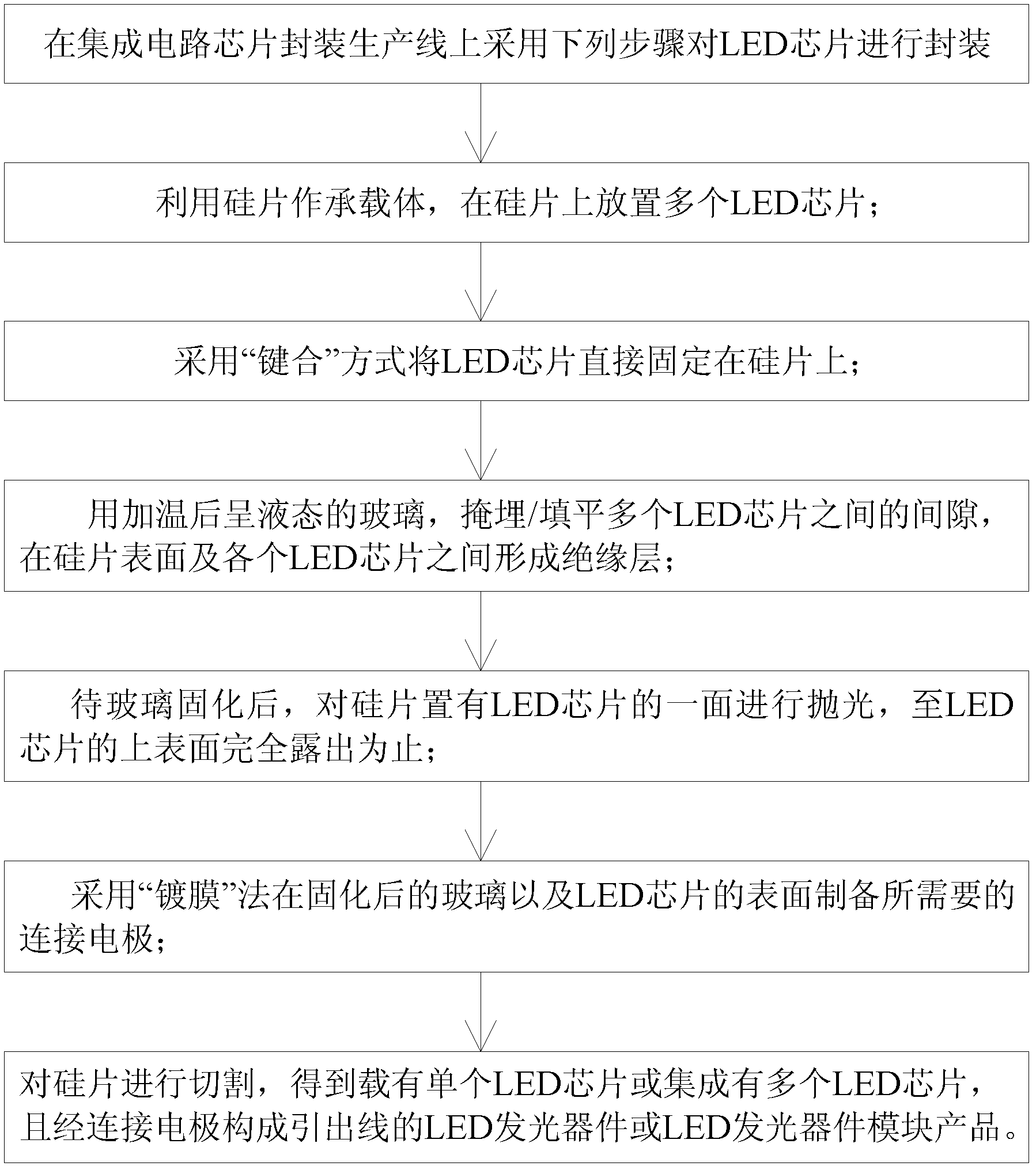

[0045] figure 1 Among them, this technical solution provides a silicon-based LED chip packaging method, which adopts the following steps to package the LED chip on the integrated circuit IC chip packaging production line:

[0046] A. Using a silicon wafer as a carrier, place multiple LED chips on the silicon wafer;

[0047] B. Fix the LED chip directly on the silicon wafer by "bonding" method;

[0048] C. Use liquid glass after heating to bury / fill the gap between each LED chip, and form an insulating layer between the surface of the silicon wafer and each LED chip;

[0049] D. After the glass is solidified, polish the side of the silicon wafer with the LED chip until the LED chip is exposed;

[0050] E. Use the "coating" method to prepare the required connecting electrodes on the surface of the cured glass and the LED chip;

[0051] F. Cutting the silicon wafer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com