Backlight module and display device

A backlight module and light source technology, which is applied in the direction of lighting devices, fixed lighting devices, lighting device components, etc., can solve the problems of reducing the effective lighting area, side-entry backlight modules are difficult to be round or irregular in shape, etc. , to achieve the effect of increasing the effective lighting area, diversifying the shape, and emitting light evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

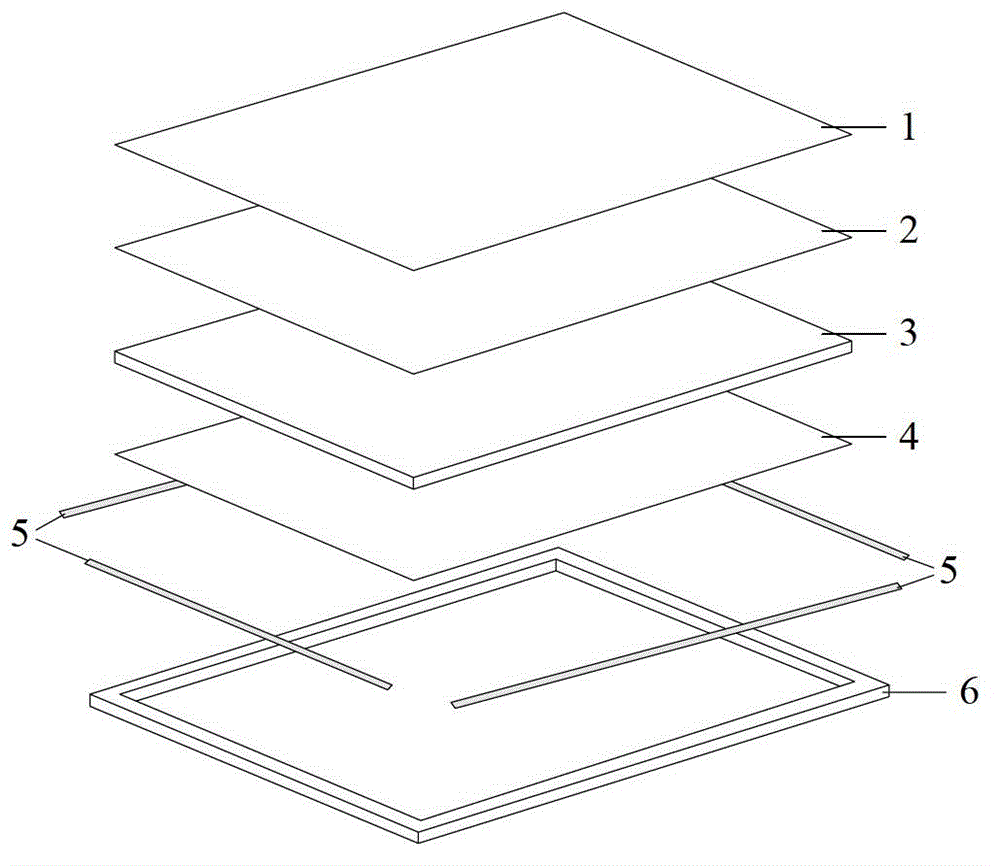

[0035] This embodiment provides a backlight module, including a light guide plate, a light source, and a reflector;

[0036] The reflective sheet includes a first reflective sheet and a second reflective sheet.

[0037] The first reflective sheet is arranged on the side of the light guide plate, the second reflective sheet is arranged on the bottom of the light guide plate, the light source is arranged below the first reflective sheet, and the first reflective sheet It is used to reflect the light emitted by the light source to the inside of the light guide plate, and the light is emitted from the top of the light guide plate after being scattered by the light guide plate and reflected by the second reflection sheet.

[0038] This embodiment also provides a display device including the above-mentioned backlight module.

[0039] It can be seen that the light emitted by the light source in the backlight module described in this embodiment is reflected by the first reflection sh...

Embodiment 2

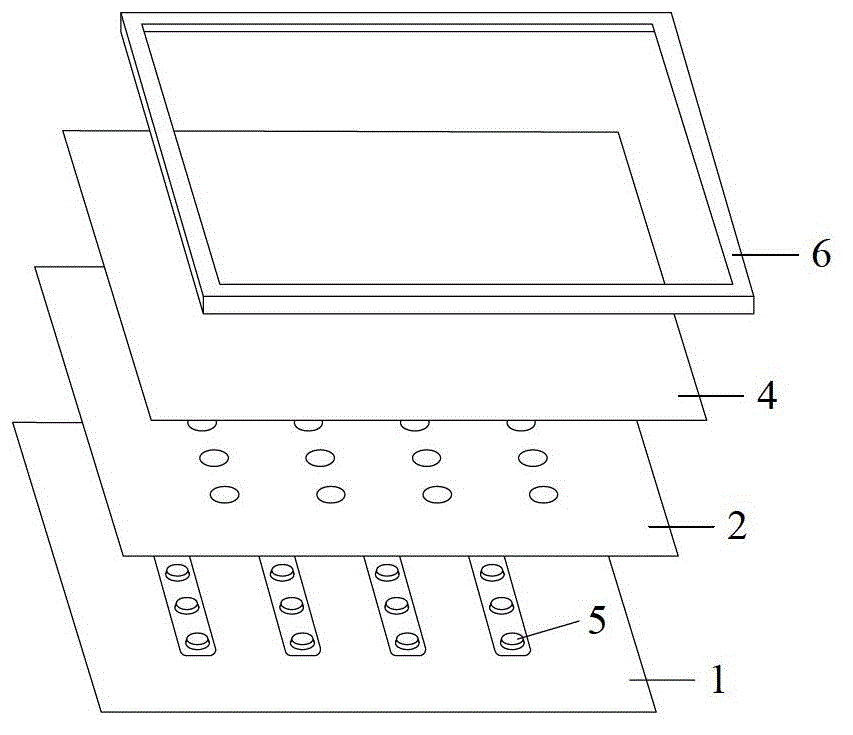

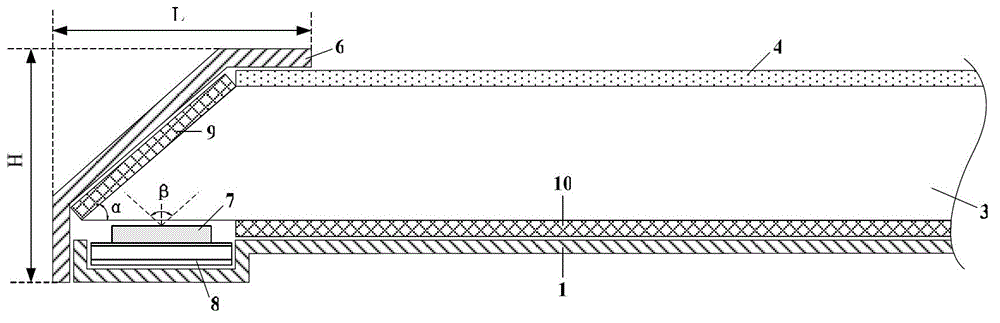

[0041] like image 3 As shown, this embodiment provides a backlight module, including a light guide plate 3, a light source 7, a PCB board (printed circuit board) 8, an optical film material 4, a first reflection sheet 9, a second reflection sheet 10, a backplane 1 and the outer frame 6. The optical film material 4 includes a diffuser.

[0042] Wherein, the first reflection sheet 9 is arranged on the side of the light guide plate 3, specifically, it can be arranged on any one or more sides of all the sides of the light guide plate, and of course it can also be arranged on all sides around the light guide plate; The second reflection sheet 10 is arranged at the bottom of the light guide plate 3; the light source 7 is arranged below the first reflection sheet 9 and on the PCB board 8. It should be noted that the light source 7 is also arranged below the light guide plate 3, and in order to prevent the light source 7 from heating and causing the light guide plate 3 to be heated...

Embodiment 3

[0055] like Figure 4 As shown, the difference between the backlight module described in this embodiment and Embodiment 3 is:

[0056] The light guide plate 3 in the backlight module also includes a protrusion 3a disposed on its bottom edge, the protrusion 3a extends into the concave portion of the back plate 1, and the light source 7 is disposed on the protrusion 3a (the light source 7 is not in contact with the protrusion 3a), so as to avoid that the light emitted from the part of the light source close to the first reflector 9 cannot be transmitted to the optical film material 4 due to the limitation of the light emitting angle of the light source As a result, the resulting light loss improves the utilization rate of the reflected light after the light emitted by the light source is reflected by the first reflective sheet 9 .

[0057] Preferably, the relationship between the thickness B of the protrusion 3a, the width D of the protrusion 3a, and the light emitting angle β ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com