Composite red mud coiled material used for biogas project and preparation method thereof

A composite roll and red mud technology, applied in the field of chemical industry, can solve problems such as insufficient lamination fastness, non-compliance with environmental protection requirements, soil pollution, etc., to facilitate commercial production and industrial promotion, increase biogas generation, The effect of increasing the activity of anaerobic bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

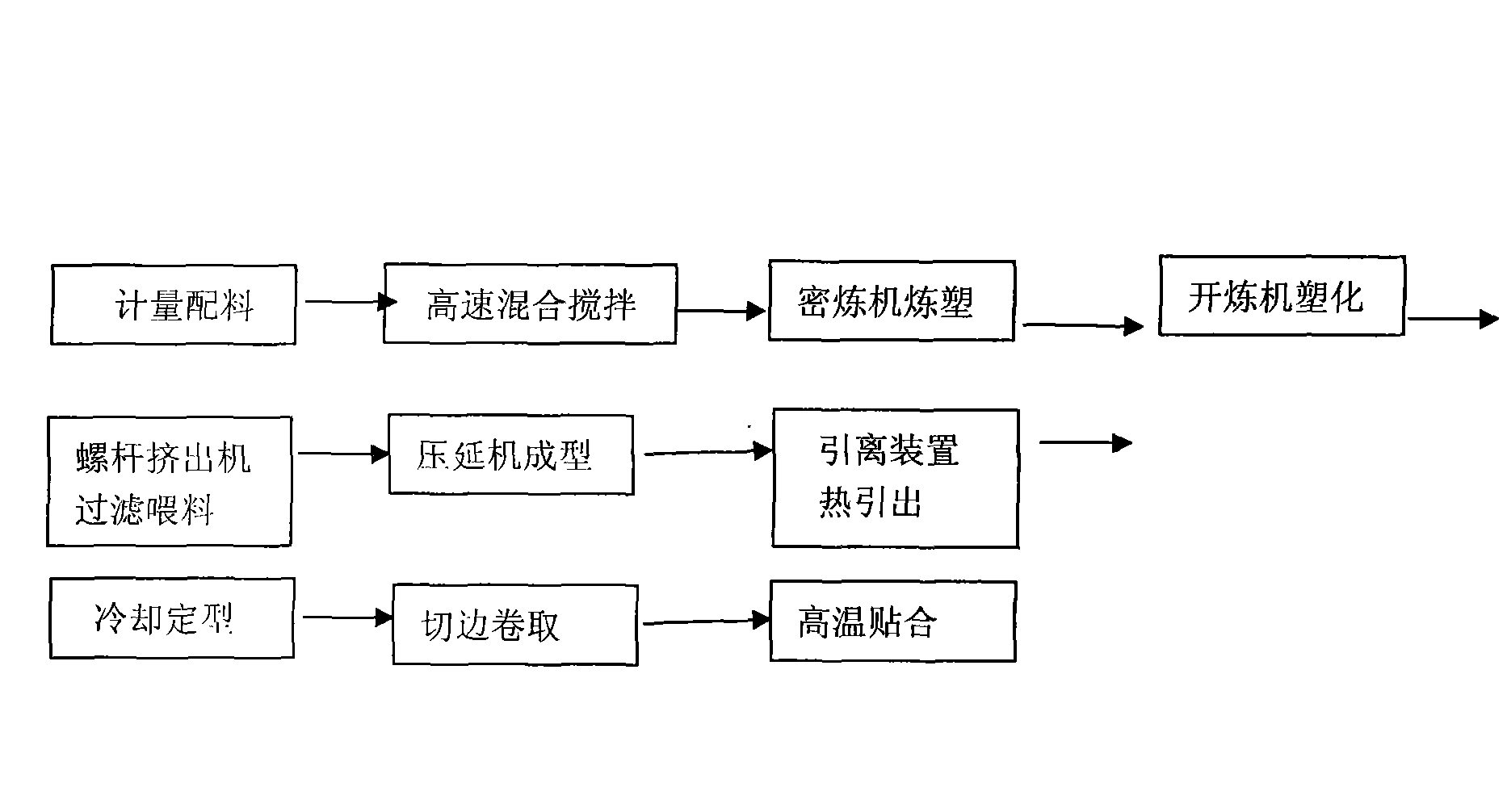

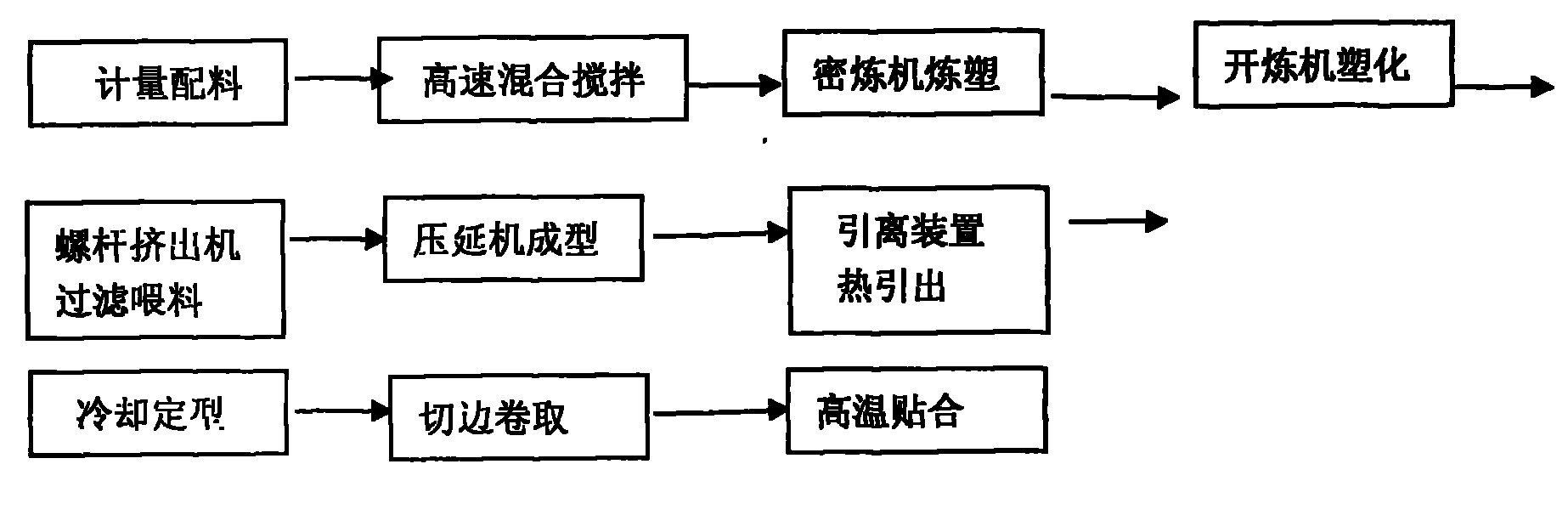

Method used

Image

Examples

Embodiment 1

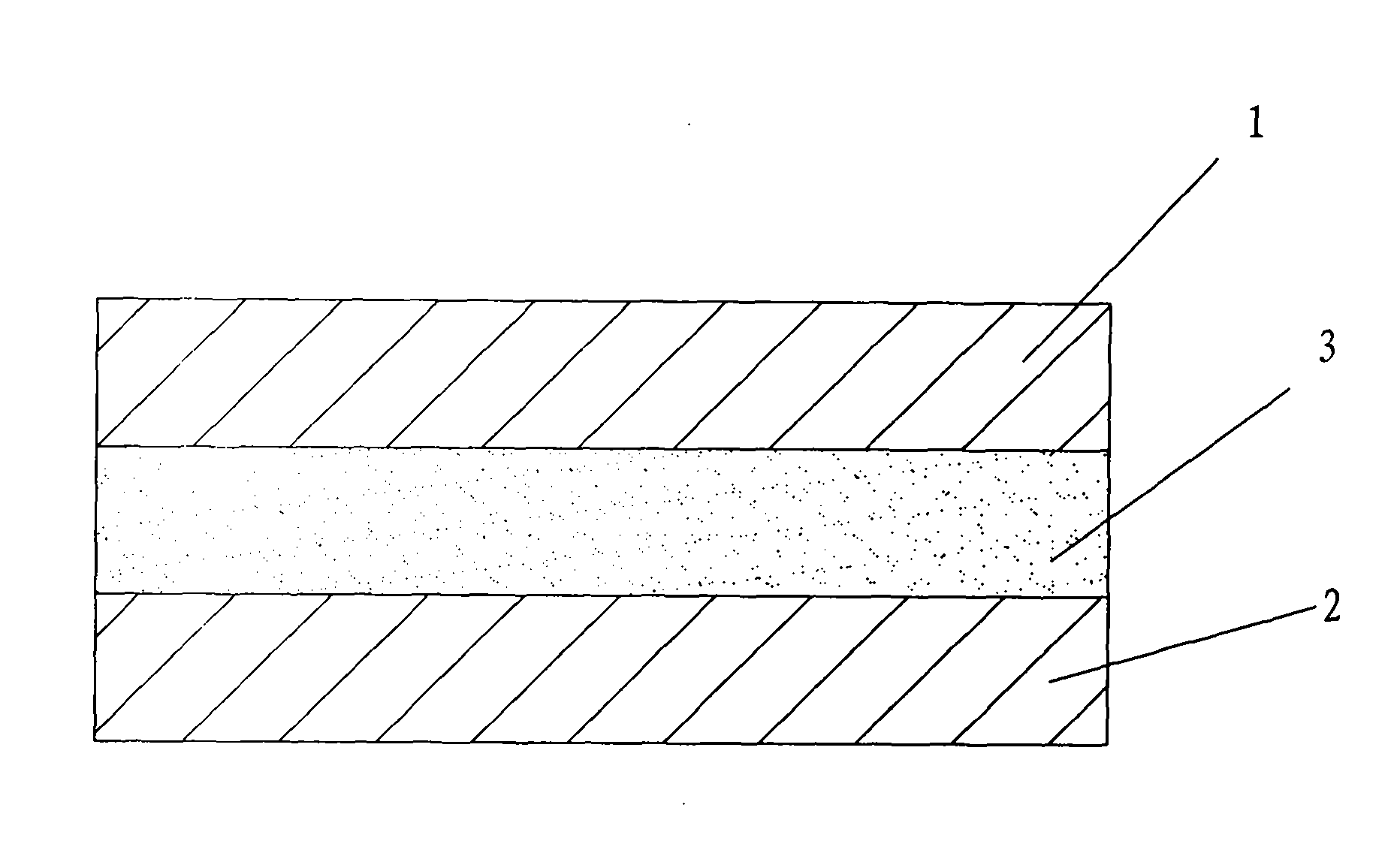

[0046] see figure 2 , a red mud composite coil material for biogas engineering, consisting of two layers of red mud modified plastic embryo film, and a layer of high-strength polyester mesh cloth 3 compounded between the two layers of red mud modified plastic embryo film, the The red mud modified plastic embryo film is divided into base film 2 and facial film 1, and anti-slip embossing is printed on the described facial film, wherein the red mud modified plastic embryo film is made of the following raw materials in parts by weight:

[0047] PVC resin 100

[0048] DOP plasticizer 50

[0049] DOA plasticizer 10

[0050] Other modified additives 10

[0051] Red mud modified additive fineness > 350 mesh 13

[0052] Photooxygen stabilizer 0.4

[0053] Composite environmental heat stabilizer 3;

[0054] In addition, coloring materials, such as red coloring materials, can also be added according to specific requirements.

[0055] Other modifying additives consist of the follo...

Embodiment 2

[0066] A red mud composite coil material for biogas engineering, which is composed of two layers of red mud modified plastic embryo film, and a layer of high-strength polyester grid cloth compounded between the two layers of red mud modified plastic embryo film, wherein the red mud The modified plastic embryo film is made from the following raw materials in parts by weight:

[0067] PVC resin 100

[0068]DOP plasticizer 35

[0069] DOA low temperature plasticizer 5

[0070] Other modified additives 5

[0071] Red mud modified additive fineness > 350 mesh 10

[0072] Photooxygen stabilizer 0.3

[0073] Composite environmental heat stabilizer 2.5.

[0074] The raw materials also include suitable colorants.

[0075] Described other modifying additives are made up of the raw material of following weight part:

[0076] Chlorinated polyethylene resin 4

[0077] Acrylate Processing Modifier 2

[0078] Flame retardant antimony trioxide 5.

[0079] Described photo-oxygen stab...

Embodiment 3

[0086] A red mud composite coil material for biogas engineering, which is composed of two layers of red mud modified plastic embryo film, and a layer of high-strength polyester grid cloth compounded between the two layers of red mud modified plastic embryo film, wherein the red mud The modified plastic embryo film is made from the following raw materials in parts by weight:

[0087] PVC resin 100

[0088] DOP plasticizer 40

[0089] DOA low temperature plasticizer 7

[0090] Other modified additives 15

[0091] Red mud modified additive fineness > 350 mesh 15

[0092] Photooxygen stabilizer 0.5

[0093] Composite environmental heat stabilizer 4.

[0094] The raw materials also include suitable colorants.

[0095] Described other modifying additives are made up of the raw material of following weight part:

[0096] Chlorinated polyethylene resin 8

[0097] Acrylate Processing Modifier 5

[0098] Flame retardant antimony trioxide 5.

[0099] Described photo-oxygen stab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com