Smelting device for single-crystal conductive copper rod

A copper rod and single crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of difficult to achieve uniform addition and fusion of additive components, and achieve flexible and diverse production varieties and specifications, and low unit energy consumption. , good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

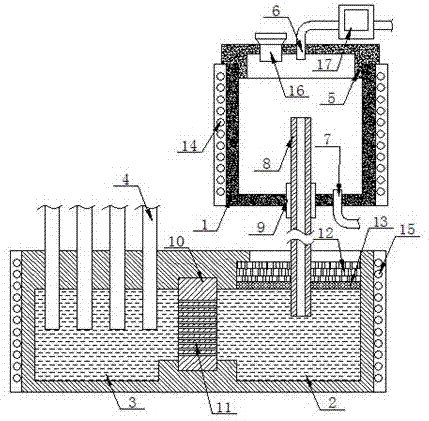

[0016] refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] Such as figure 1 As shown, a single crystal conductive copper rod smelting device includes an upward continuous casting melting furnace and a closed mixed melting furnace 1; the upward continuous casting melting furnace includes a heating and melting feeding chamber 2 and a closed The heating up-leading crystallization chamber 3 provided, the heating and melting feeding chamber 2 and the heating up-leading crystallization chamber 3 are horizontally connected, and several upward-leading crystallizers 4 are vertically arranged in the heating up-leading crystallization chamber 3, and several The lower end of the above-mentioned upward crystallizer 4 is located in the heating upward crystallization chamber 3, and the upper ends of several of the upward crystallizers 4 are connected to the continuous casting head; Above the cavity 2, and the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com