A kind of bimetal layered composite wire drawing forming method

A bimetallic layered and composite wire technology, applied in the field of bimetallic layered composite wire drawing and forming, can solve the problems of unstable quality and performance of composite wires, coordinated large plastic deformation between bimetals, and difficulty in precise control of cladding ratio, etc. problem, to achieve the effect of easy and precise control of cladding ratio, no need for drawing and intermediate annealing, and flexible specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

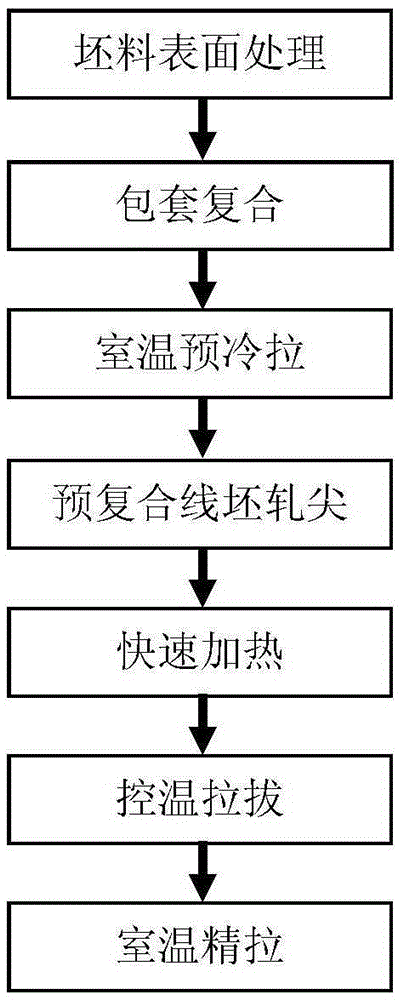

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of copper-clad nickel-nickel layered composite wire with a diameter of Φ4.0mm and a cladding ratio of 35%

[0025] Grinding the inner surface of the annealed double-layer T2 pure copper tube billet (size Φ8×1mm) and the surface of the annealed core CuNi44Mn1 nickel-nickel rod (diameter Φ6mm) at room temperature; at room temperature The core CuNi44Mn1 cupronickel rod is covered by the clad T2 pure copper tube billet to obtain the clad composite billet; the clad clad billet is sharpened, and then the single-pass casing composite pre-cooling is carried out to achieve pre-compounding and drawing deformation The pre-composite wire billet was obtained at a rate of 12%; the pre-composite wire billet was tipped; then the pre-composite wire billet was placed in an off-line resistance furnace with a temperature of 400 °C for heating and kept for 5 minutes, so that the temperature quickly reached the drawing temperature. The drawing temperature is 400°C, a...

Embodiment 2

[0026] Example 2: Preparation of copper-clad nickel-copper layered composite wire with a diameter of Φ0.3mm and a cladding ratio of 29%

[0027] Grinding the inner surface of the annealed double-layer T2 pure copper tube billet (size Φ8×1mm) and the surface of the annealed core CuNi44Mn1 nickel-nickel rod (diameter Φ6mm) at room temperature; at room temperature The core CuNi44Mn1 cupronickel rod is covered by the clad T2 pure copper tube billet to obtain the clad composite billet; the clad clad billet is sharpened, and then the single-pass casing composite pre-cooling is carried out to achieve pre-compounding and drawing deformation The pre-composite wire billet was obtained at a rate of 12%; the pre-composite wire billet was tipped; then the pre-composite wire billet was placed in an off-line resistance furnace with a temperature of 300 °C for heating and kept for 3 minutes, so that the temperature quickly reached the drawing temperature. The drawing temperature is 300°C. At ...

Embodiment 3

[0028] Example 3: Preparation of Copper-clad Cupronickel Laminated Composite Wire with a Diameter of Φ0.05mm and a Covering Ratio of 30%

[0029] At room temperature, the inner surface of the annealed double-layer T2 pure copper tube billet (size Φ8×1mm) and the surface of the annealed core CuNi44Mn1 nickel-nickel rod (diameter Φ6mm) were polished with a high-speed rotating steel brush at room temperature; At room temperature, the clad T2 pure copper tube billet is used to wrap the core CuNi44Mn1 cupronickel rod to obtain the clad composite billet; the clad clad billet is rolled to a point, and then the single-pass casing composite pre-cooling is carried out to achieve pre-compounding. The drawing deformation rate was 12%, and the pre-composite wire billet was obtained; the pre-composite wire billet was rolled to the tip; then the pre-compound wire billet was rapidly heated to the drawing temperature of 600 °C within 5 seconds by an online induction heating device, and the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com