Semi-continuous casting device and method for a three-layer clad ingot

A semi-continuous casting and ingot casting technology, applied in the field of layered composite material preparation, can solve problems such as interface damage, interface instability, insufficient cooling capacity, etc., and achieve high alloy composition freedom, good composite interface quality, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

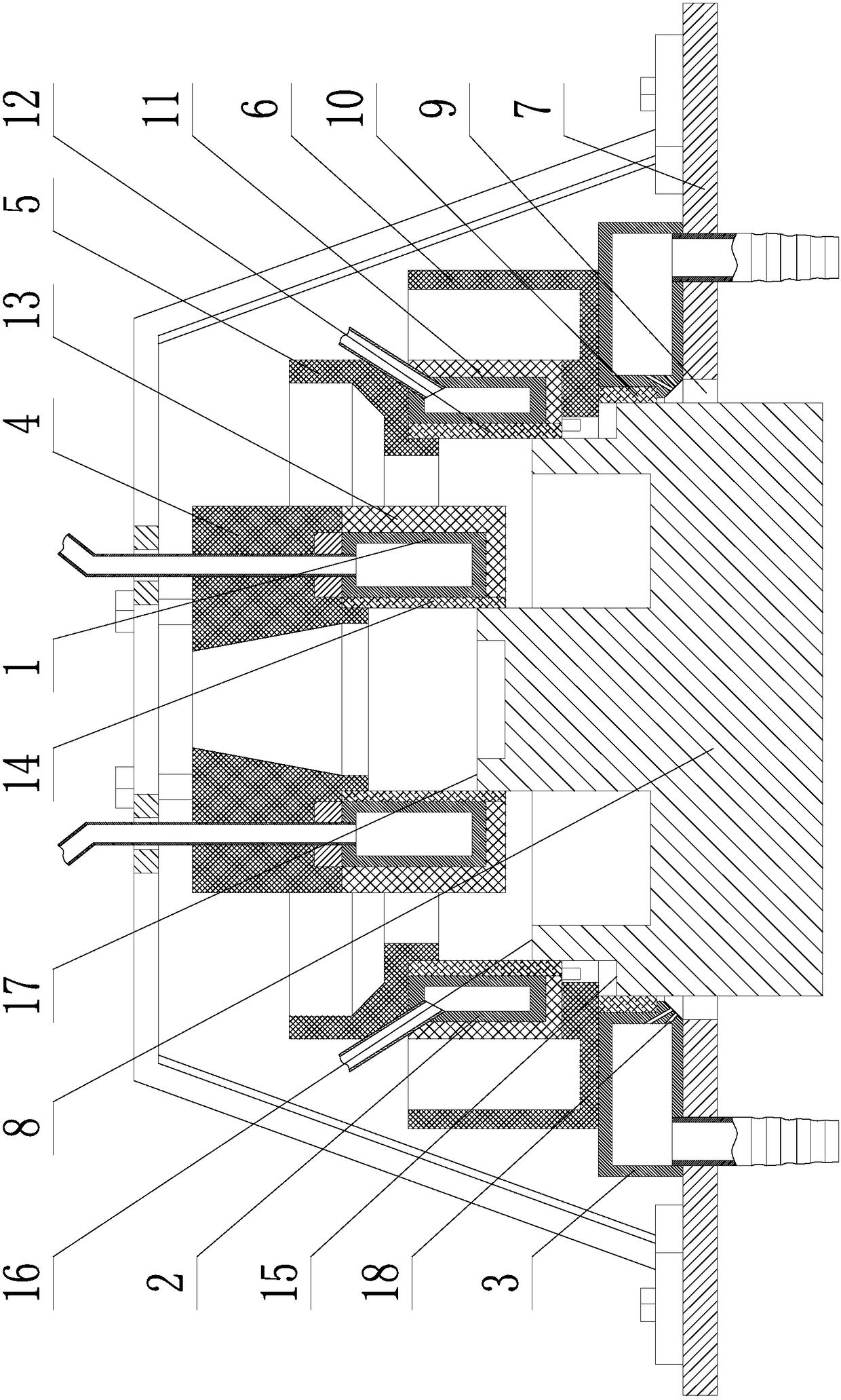

[0061] In this embodiment, the material of the core material melt 34 is 3003 aluminum alloy (the liquidus temperature is 658° C., and the solidus temperature is 646° C.), and the material of the intermediate layer melt 35 is 6069 aluminum alloy (the liquidus temperature is 646° C.). is 647°C, solidus temperature is 511°C), the material of the outer layer melt 36 is 4045 aluminum alloy (liquidus temperature is 595°C, solidus temperature is 577°C), each of the three-layer clad ingot Layer design size is φ164mm / φ152mm / φ80mm.

[0062] Before casting, the core material melt 34 , the middle layer melt 35 and the outer layer melt 36 are respectively melted in three independent electric resistance furnaces, refined and degassed, then kept warm for later use.

[0063] During casting, the pouring temperature of the outer layer melt 36 is controlled at 750°C, the pouring temperature of the middle layer melt 35 is controlled at 740°C, and the pouring temperature of the outer layer melt 36...

Embodiment 2

[0067] In this embodiment, the material of the core material melt 34 is 7004 aluminum alloy (the liquidus temperature is 645° C., and the solidus temperature is 482° C.), and the material of the intermediate layer melt 35 is 3003 aluminum alloy (the liquidus temperature is 482° C.). is 658°C, and the solidus temperature is 646°C), the material of the outer layer melt 36 is 4045 aluminum alloy (the liquidus temperature is 595°C, the solidus temperature is 577°C), each of the three-layer clad ingots Layer design size is φ164mm / φ152mm / φ100mm.

[0068] Before casting, the core material melt 34 , the middle layer melt 35 and the outer layer melt 36 are respectively melted in three independent electric resistance furnaces, refined and degassed, then kept warm for later use.

[0069] During casting, the pouring temperature of the outer layer melt 36 is controlled at 750°C, the pouring temperature of the middle layer melt 35 is controlled at 730°C, and the pouring temperature of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com