Vibration ash removal type circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, which is used in fluidized bed combustion equipment, removal of solid residues, and fuel burned in a molten state, etc., can solve the problem of affecting ash removal efficiency, difficult to unify the steps of heating surface tube bundles, and the effect of heating surface tube bundles. Weak strength and other problems, to achieve the effect of increasing the temperature of the endothermic working medium, reducing the temperature of the exhaust gas, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

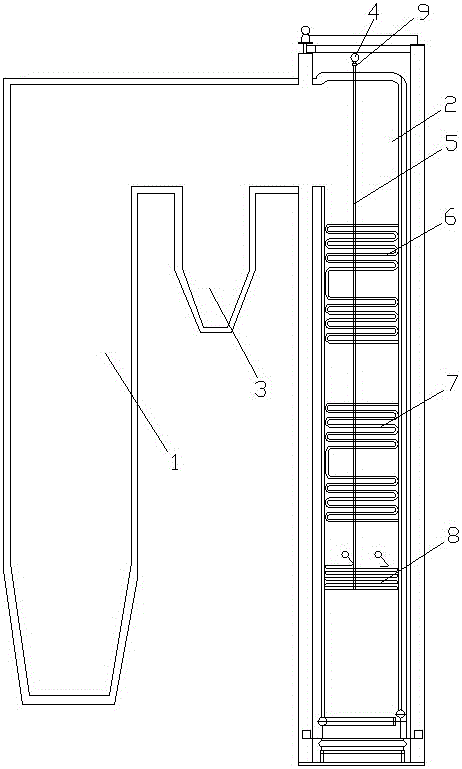

[0044] see figure 1 , a vibrating ash removal circulating fluidized bed boiler, including a furnace 1, a tail flue 2, a separator 3 connecting the furnace 1 and the tail flue 2, and a header 4 located above the tail flue 2, and also includes a penetrating tail The hanging pipe 5 on the top wall of the flue 2, the tail flue 2 is vertically arranged, and the tail flue 2 is provided with a reheater 6, a superheater 7 and an economizer 8 in sequence from top to bottom. The protruding end of the hanging pipe 5 is connected with the header 4, and the protruding end is respectively connected with the reheater 6, the superheater 7 and the economizer 8 in turn, and the header 4 and the tail flue 2 top wall are provided with The pneumatic vibrator 9 is fixed on the hanging pipe 5 through a clamp.

[0045] This embodiment is the most basic implementation mode, with a simple structure, the tail flue is vertically arranged, and a reheater, a superheater and an economizer are arranged ...

Embodiment 2

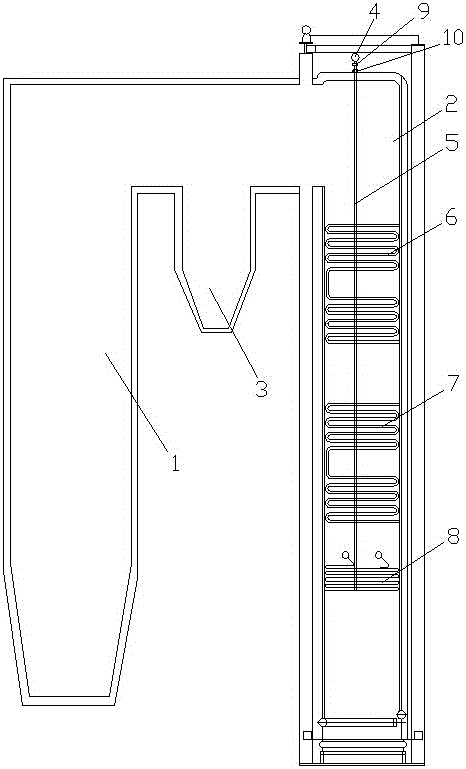

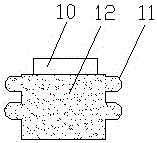

[0047] see figure 2 and image 3 , a vibrating ash removal circulating fluidized bed boiler, including a furnace 1, a tail flue 2, a separator 3 connecting the furnace 1 and the tail flue 2, and a header 4 located above the tail flue 2, and also includes a penetrating tail The hanging pipe 5 on the top wall of the flue 2, the tail flue 2 is vertically arranged, and the tail flue 2 is provided with a reheater 6, a superheater 7 and an economizer 8 in sequence from top to bottom. The protruding end of the hanging pipe 5 is connected with the header 4, and the protruding end is respectively connected with the reheater 6, the superheater 7 and the economizer 8 in turn, and the header 4 and the tail flue 2 top wall are provided with The pneumatic vibrator 9 is fixed on the hanging pipe 5 through a clamp.

[0048] A corrugated sealing box 10 is provided at the joint between the top wall of the tail flue 2 and the hanging pipe 5, and the corrugated sealing box 10 is composed of a ...

Embodiment 3

[0051] see image 3 and Figure 4 , a vibrating ash removal circulating fluidized bed boiler, including a furnace 1, a tail flue 2, a separator 3 connecting the furnace 1 and the tail flue 2, and a header 4 located above the tail flue 2, and also includes a penetrating tail The hanging pipe 5 on the top wall of the flue 2, the tail flue 2 is vertically arranged, and the tail flue 2 is provided with a reheater 6, a superheater 7 and an economizer 8 in sequence from top to bottom. The protruding end of the hanging pipe 5 is connected with the header 4, and the protruding end is respectively connected with the reheater 6, the superheater 7 and the economizer 8 in turn, and the header 4 and the tail flue 2 top wall are provided with The pneumatic vibrator 9 is fixed on the hanging pipe 5 through a clamp.

[0052] A corrugated sealing box 10 is provided at the joint between the top wall of the tail flue 2 and the hanging pipe 5, and the corrugated sealing box 10 is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com