Ash removing agent, preparation method and application thereof, and ash removing method for silicon-aluminum alloy

A silicon-aluminum alloy and deashing agent technology, which is applied in the field of aluminum alloy surface treatment, can solve problems such as poor ash removal performance and affecting the electroplating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

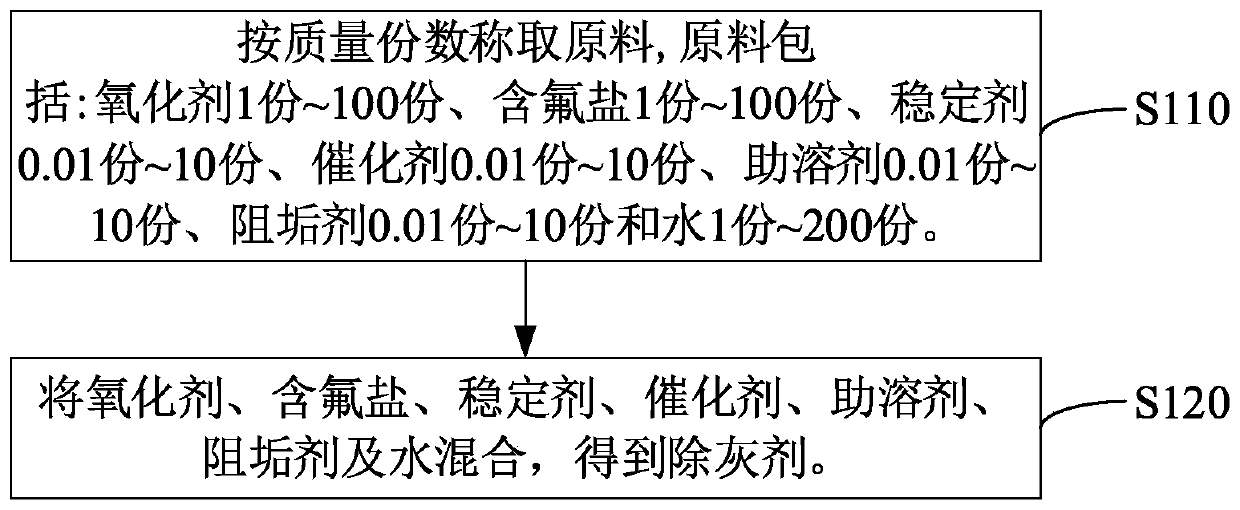

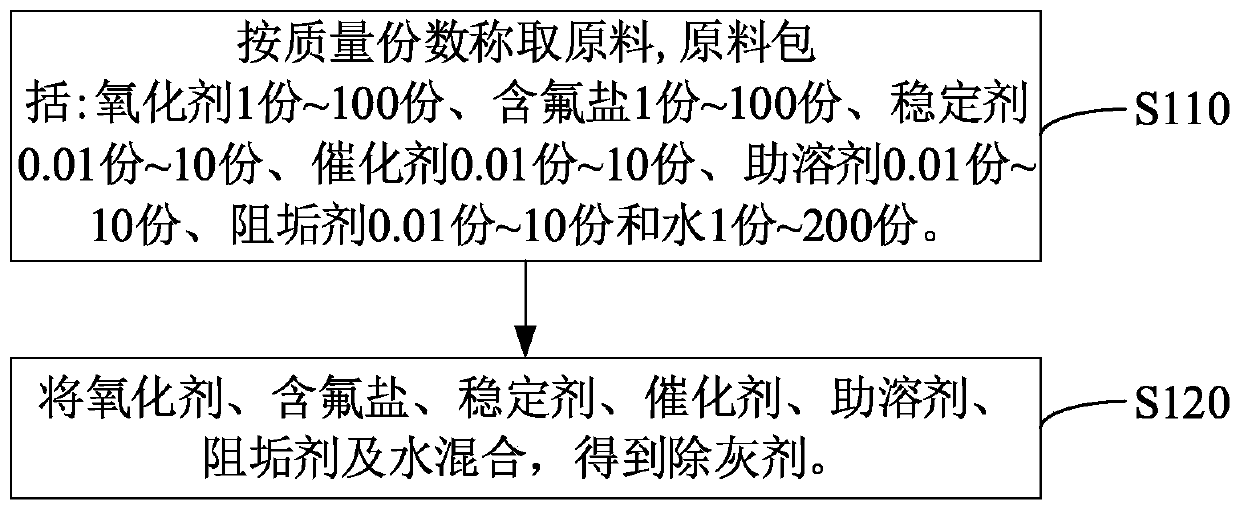

[0040] see figure 1 , the preparation method of the deashing agent of one embodiment, comprises the steps:

[0041]Step S110: Weigh raw materials by mass parts, raw materials include: 1-100 parts of oxidizing agent, 1-100 parts of fluorine-containing salt, 0.01-10 parts of stabilizer, 0.01-10 parts of catalyst, 0.01-10 parts of cosolvent 10 parts, 0.01 to 10 parts of antiscalant and 1 to 200 parts of water.

[0042] Step S120: Mix the oxidant, fluorine-containing salt, stabilizer, catalyst, co-solvent, scale inhibitor and water to obtain the deashing agent.

[0043] Wherein, the time for mixing the oxidizing agent, fluorine-containing salt, stabilizer, catalyst, co-solvent, scale inhibitor and water is 10 minutes to 240 minutes.

[0044] Specifically, step S120 includes:

[0045] Under the condition of stirring, add fluorine-containing salt and oxidizing agent to the water successively, stir until completely dissolved, and obtain the first stirred liquid;

[0046] Add scal...

Embodiment 1

[0070] The preparation process of the deashing agent of this embodiment is as follows: in parts by mass, add 100 parts of water into the stirring tank, and in the state of stirring, add 20 parts of potassium fluoride and 30 parts of hydrogen peroxide successively, stir until completely dissolved and then add 5 parts of sodium hydroxyethylidene diphosphonate, 1 part of ethylene glycol butyl ether, 10 parts of ethylene glycol, and 2 parts of ferric trichloride were stirred evenly to obtain the deashing agent. Wherein, the mass content of hydrogen peroxide in the hydrogen peroxide is 50%.

[0071] The silicon-aluminum alloy used in this embodiment is a silicon-aluminum alloy sheet obtained by die-casting the aluminum alloy AC-44300. The size of the silicon aluminum alloy sheet is 70mm×50mm×2.5mm.

[0072] The ash removal process of the silicon-aluminum alloy in this example is as follows: After ultrasonic degreasing, pickling and alkali etching, the silicon-aluminum alloy sheet ...

Embodiment 2

[0074] The preparation process of the deashing agent of this embodiment is as follows: in parts by mass, add 200 parts of water in the stirring tank, and in the stirring state, add 50 parts of ammonium fluoride and 30 parts of hydrogen peroxide successively and stir until completely dissolved, then add 2 1 part of hydroxyethylidene diphosphonic acid, 2 parts of ethylene glycol ethyl ether, 4 parts of propylene glycol, and 1 part of nickel sulfate hexahydrate were stirred evenly to obtain the deashing agent. Wherein, the mass content of hydrogen peroxide in the hydrogen peroxide is 50%.

[0075] The silicon-aluminum alloy used in this embodiment is a silicon-aluminum alloy filter cavity obtained by die-casting the aluminum alloy AC-44300. The size of the silicon aluminum alloy filter cavity is 450mm×300mm×70mm.

[0076] The ash removal process of the silicon-aluminum alloy in this embodiment is as follows: after ultrasonic degreasing, pickling and alkali etching, the silicon-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com