Dedusting and heat-radiating integrated cabinet

A cabinet, integrated technology, applied in the field of cabinets with integrated dust removal and heat dissipation, can solve problems such as low working efficiency of cabinets, and achieve the effects of ensuring heat dissipation effect and efficiency, reducing temperature, and facilitating removal, cleaning and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

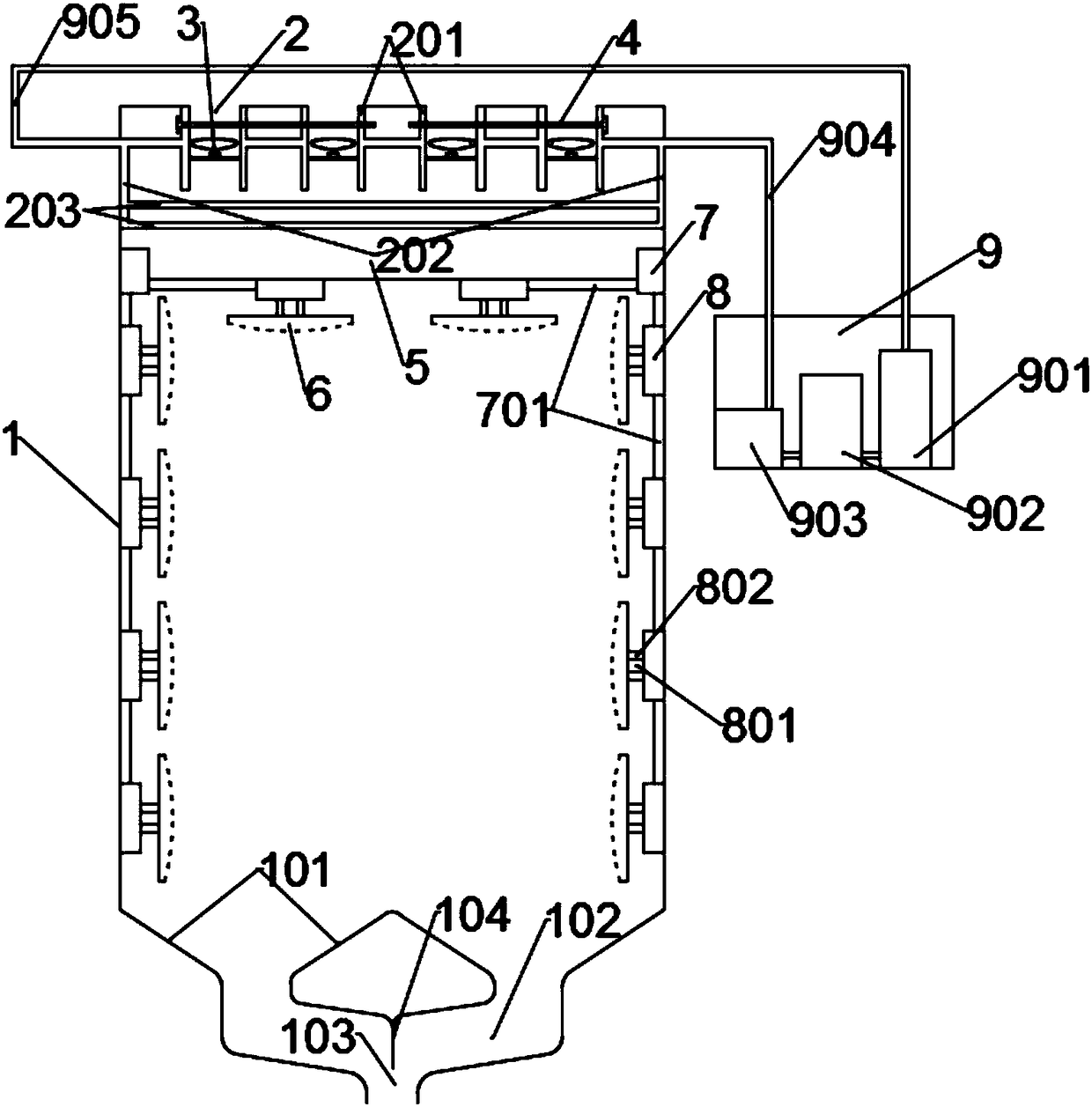

[0036]A cabinet with integrated dust removal and heat dissipation, including a cabinet body 1, an air inlet passage 2 is arranged above the cabinet body 1, and an inlet fan 3 is installed in the air inlet passage 2, and it is characterized in that the air inlet passage 2 A filter layer 4 is provided above the internal air intake fan 3, and the filter layer 4 is connected to the cabinet body 1 through a chute, and a first cooling wall 201 is provided around the air intake passage 2, and the intake A cooling chamber 5 is provided below the air passage 2, and a second cooling wall 202 is arranged around the cooling chamber 5, and the first cooling wall 201 and the second cooling wall 202 are connected to the water inlet pipe 904 and the water outlet pipe 905, The water outlet pipe 905 communicates with the water tank 901 in the refrigeration chamber 9, the water inlet pipe 904 communicates with the water pump 903 in the refrigeration chamber 9, and a refrigerator 902 is connected ...

Embodiment 2

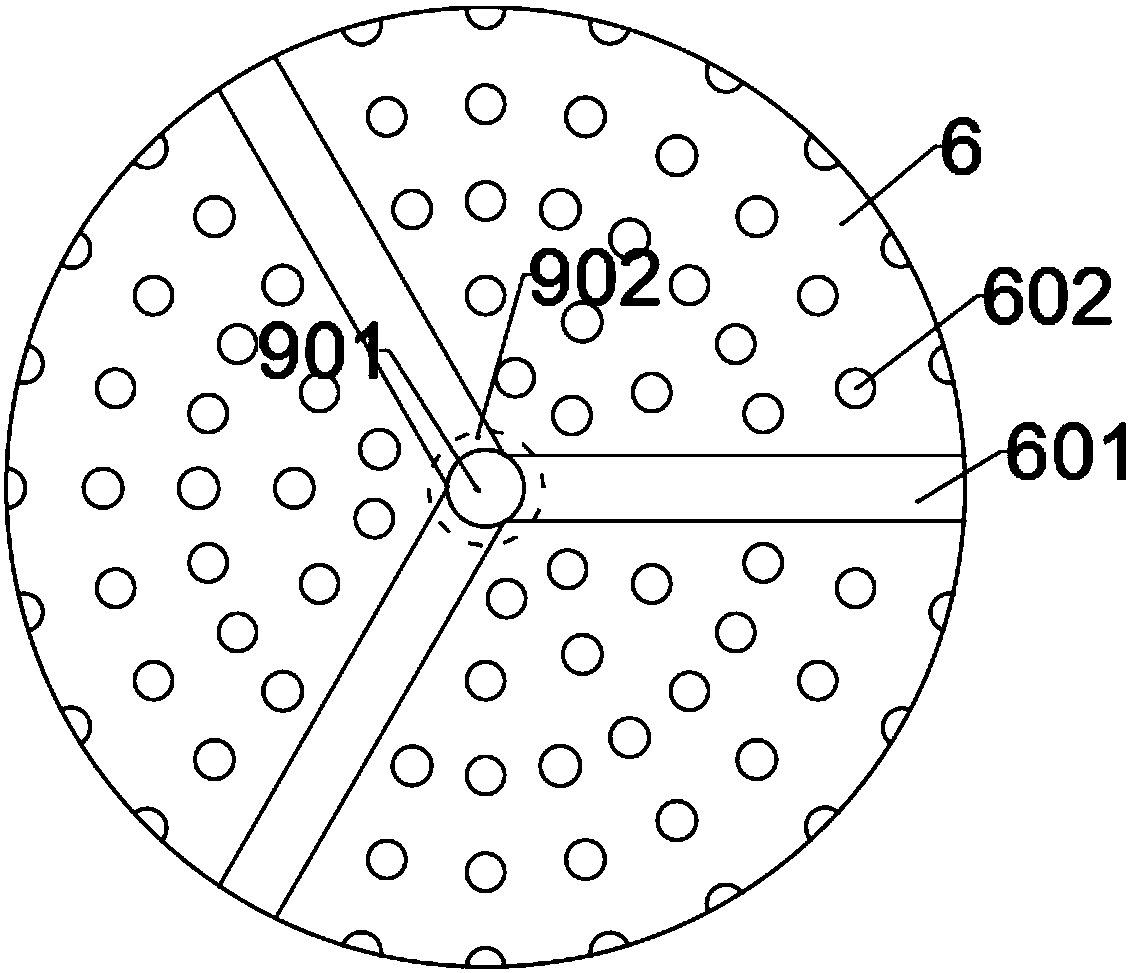

[0040] This embodiment is further optimized on the basis of Embodiment 1. Specifically, a booster pump 7 is provided between the cooling chamber 5 and the first air duct 701, and the first air duct 701 and the second air duct The air pipes 802 all adopt high-pressure air pipes, and the lower end of the cooling chamber 5 is provided with a mounting platform 8 on the outside, and the rotating disk 6 is connected to the mounting table 8 through a rotating shaft 801. And the number of said ash diverting slopes 101 is set to 4, the lower end of said ash diverting slope 101 is connected with ash collection road 102, and said ash collection road 102 is set at least 2, said ash collection road 102 and ash discharge road 103 The ash-collecting channels 102 are provided with ash-blocking boards 104 above the ash-discharging channels 103, and the corners of the ash-collecting channels 102 and the ash-discharging channels 103 are arranged in arc shapes.

[0041] Furthermore, by adjusting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com