Environment-friendly ash removal agent

A kind of deashing agent, environmental protection technology, applied in the field of environmental protection deashing agent, can solve the problems of large environmental pollution, etc., achieve the effect of reducing pollution, preventing corrosion, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

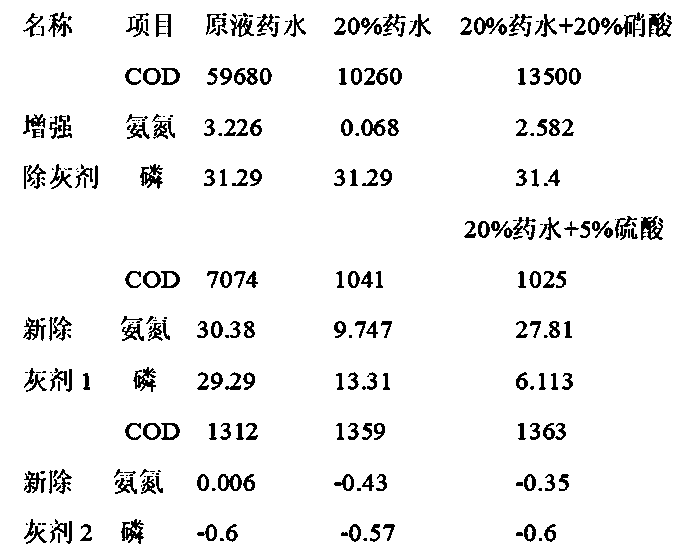

Image

Examples

Embodiment 1

[0021] The present invention provides an environmentally friendly ash remover, which is composed of the following components in parts by weight ratio: 1% sulfuric acid, 20% oxidant, surfactant, polycarboxylic acid compound, and the balance is water.

[0022] Specifically, the surfactant includes sodium dodecylbenzene sulfonate.

[0023] Specifically, the oxidizing agent includes hydrogen peroxide.

[0024] A preparation method of an environmentally friendly ash remover includes the following steps:

[0025] S1. First prepare a suitable container and add a certain amount of water in the container;

[0026] S2. Add 1.5% sulfuric acid to the water and stir for 10 minutes to dissolve and mix to obtain a solvent;

[0027] S3. Then, in the solvent obtained in S2, add an oxidant and a surfactant in sequence, and stir for 20 minutes to dissolve and mix uniformly;

[0028] S4. Finally, add the polycarboxylic acid compound and stir for 5 minutes to make it evenly mixed. After standing for 10 minute...

Embodiment 2

[0033] The present invention provides an environmentally friendly ash remover, which is made up of the following components in parts by weight ratio: sulfuric acid 1.5%, oxidant 23%, surfactant, polycarboxylic acid compound, and the balance is water.

[0034] Specifically, the surfactant includes sodium dodecylbenzene sulfonate.

[0035] Specifically, the oxidizing agent includes hydrogen peroxide.

[0036] A preparation method of an environmentally friendly ash remover includes the following steps:

[0037] S1. First prepare a suitable container and add a certain amount of water in the container;

[0038] S2. Add 1.5% sulfuric acid to the water, stir for 13 minutes to dissolve and mix to obtain a solvent;

[0039] S3. In the solvent obtained in S2, add an oxidant and a surfactant in sequence, and stir for 25 minutes to dissolve and mix uniformly;

[0040] S4. Finally, add the polycarboxylic acid compound and stir for 10 minutes to make it evenly mixed. After standing for 10 minutes, stir...

Embodiment 3

[0045] The invention provides an environmentally friendly ash remover, which is made up of the following components in parts by weight: 2% sulfuric acid, 25% oxidant, surfactant, polycarboxylic acid compound, and the balance is water.

[0046] Specifically, the surfactant includes sodium dodecylbenzene sulfonate.

[0047] Specifically, the oxidizing agent includes hydrogen peroxide.

[0048] A preparation method of an environmentally friendly ash remover includes the following steps:

[0049] S1. First prepare a suitable container and add a certain amount of water in the container;

[0050] S2. Add 1.5% sulfuric acid to the water, stir for 15 minutes to dissolve and mix to obtain a solvent;

[0051] S3. In the solvent obtained in S2, add an oxidant and a surfactant in sequence, and stir for 30 minutes to dissolve and mix uniformly;

[0052] S4. Finally, add the polycarboxylic acid compound and stir for 15 minutes to make it evenly mixed. After standing for 10 minutes, stir for another 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com