Pulse cloth bag dust remover capable of easily collecting ash

A technology of pulse cloth bag and dust collector, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of high power of air compressor, aggravated energy consumption, time-consuming, etc., to reduce consumption and remove dust Good effect, avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

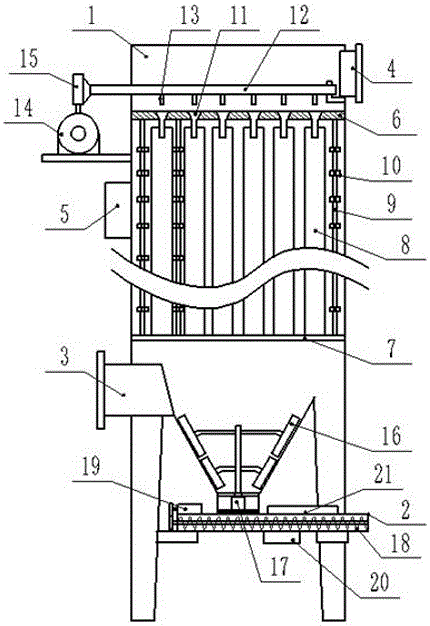

[0015] see figure 1 , a pulse bag filter that is easy to collect dust, including a box body 1 and an ash outlet pipe 2, the lower end of the left side of the box body 1 is connected with an air inlet pipe 3, and the upper right side of the box body 1 is connected with an air outlet pipe 4, and the box body 1. The left side wall is also fixedly connected with a control device 5. The control device 5 is an S7-300 programmable controller 5, which is convenient for controlling the opening and closing of the following electrical components and has completed automatic control. This is a conventional pulse dust collector. structure, the box 1 is fixedly connected with a flower plate 6 and a cage frame 7, a number of filter bags 8 are fixedly connected between the flower plate 6 and the cage frame 7, and there are two filter bags 8 between the flower plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com