Patents

Literature

71results about How to "Avoid affecting the dust removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

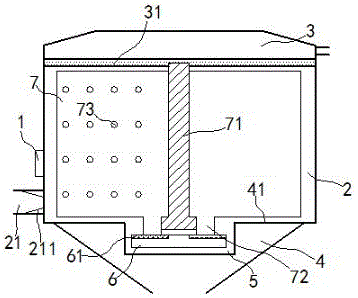

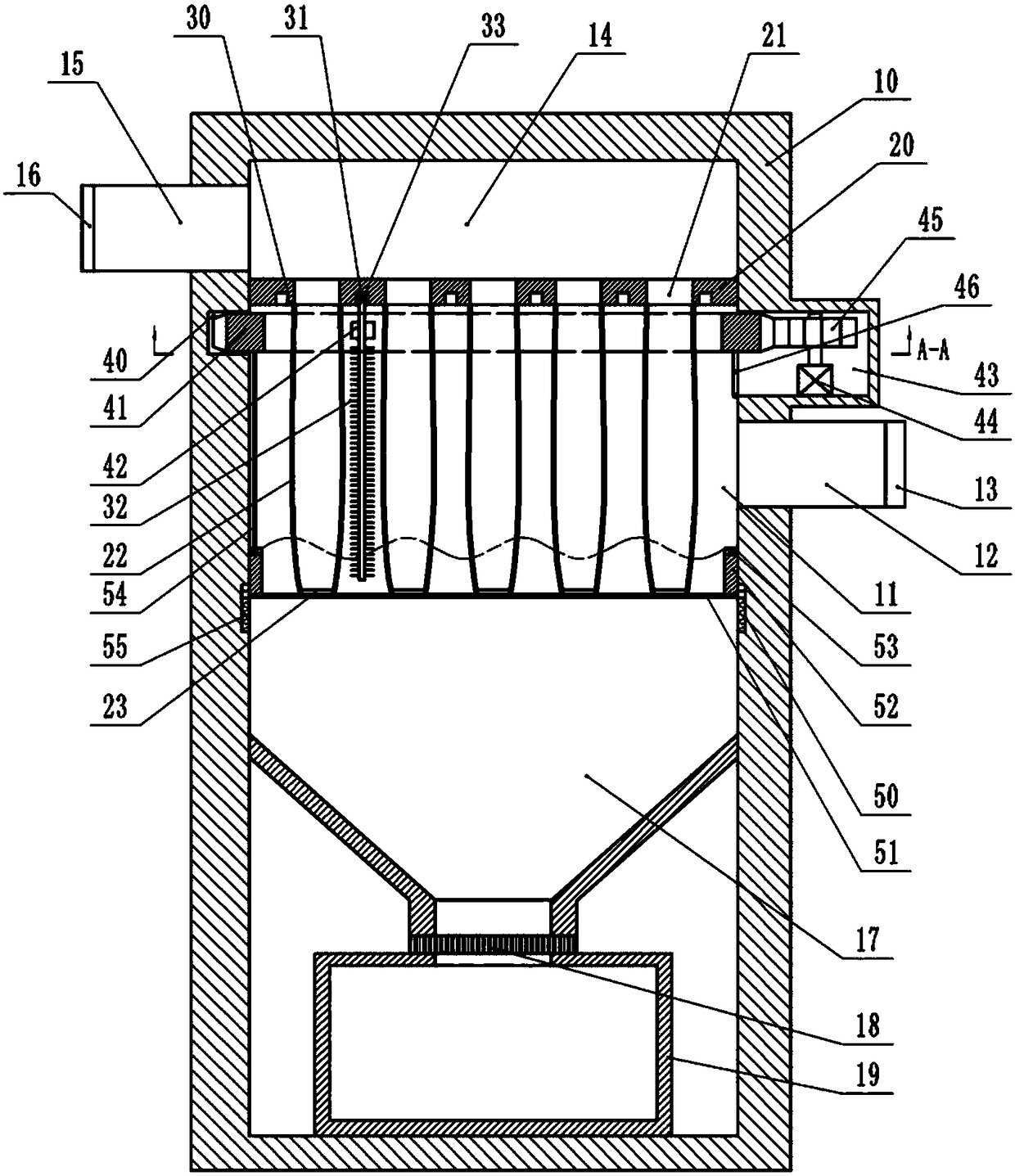

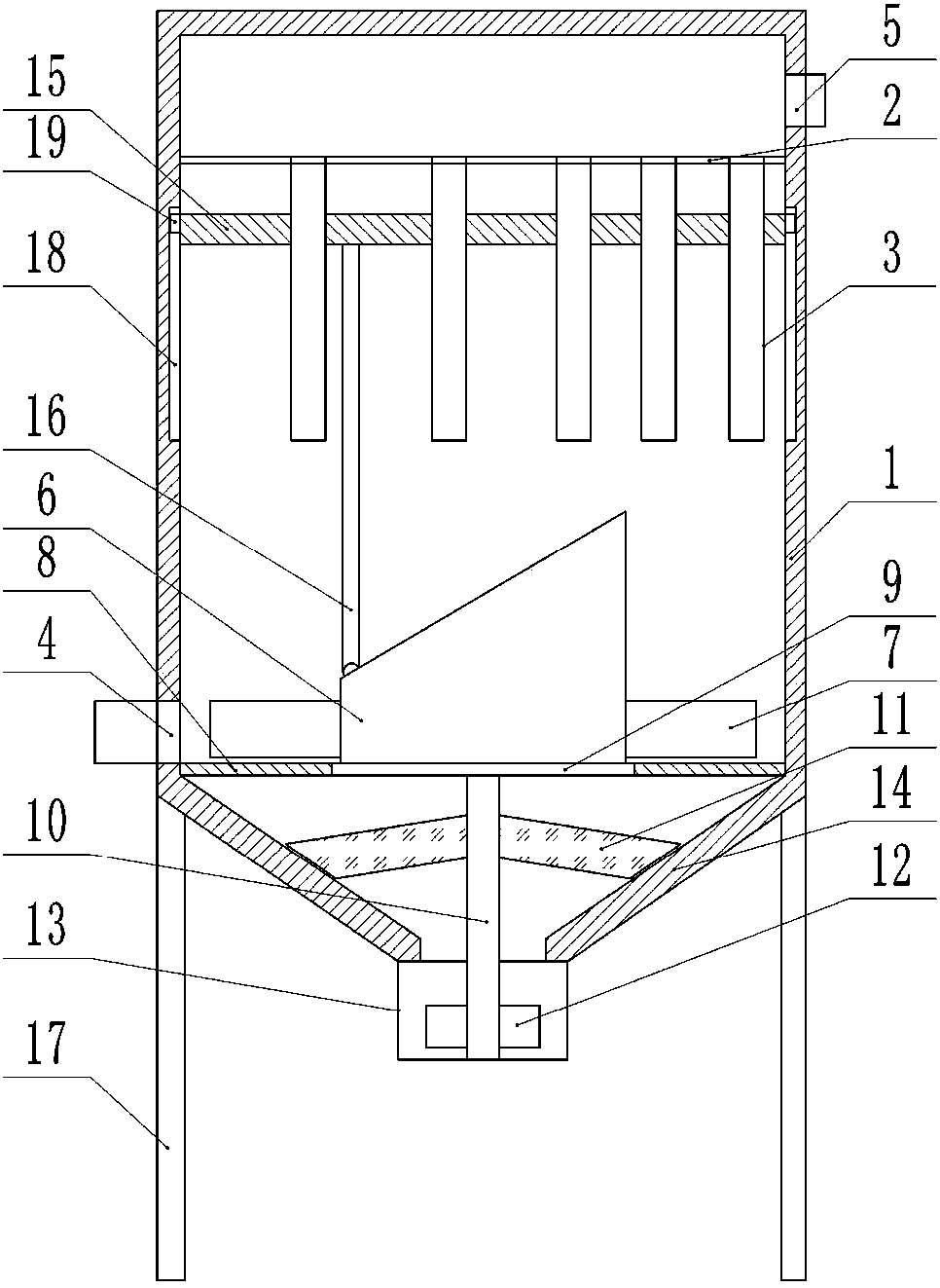

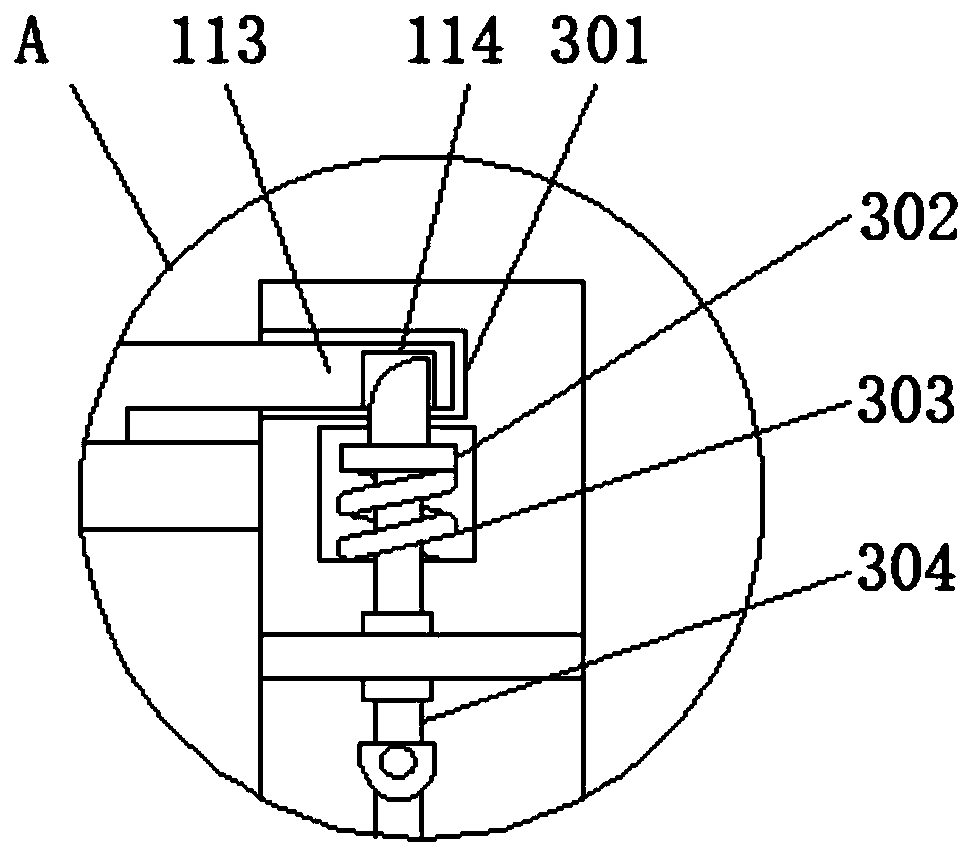

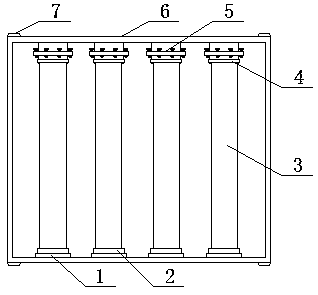

Pulse cloth bag dust remover capable of easily collecting ash

InactiveCN106377952AImprove ash removal effectBetter and faster dust removalDispersed particle filtrationSpiral bladeBaghouse

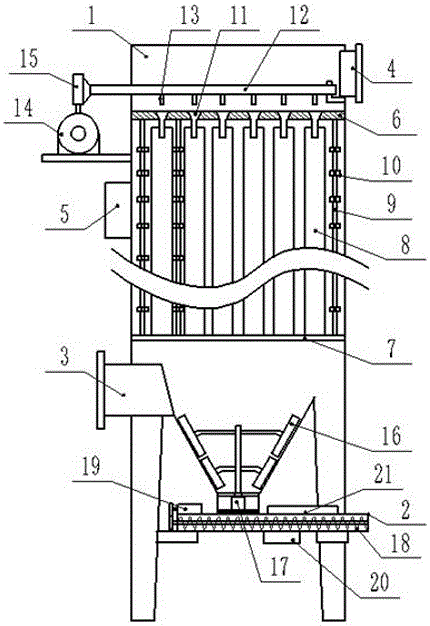

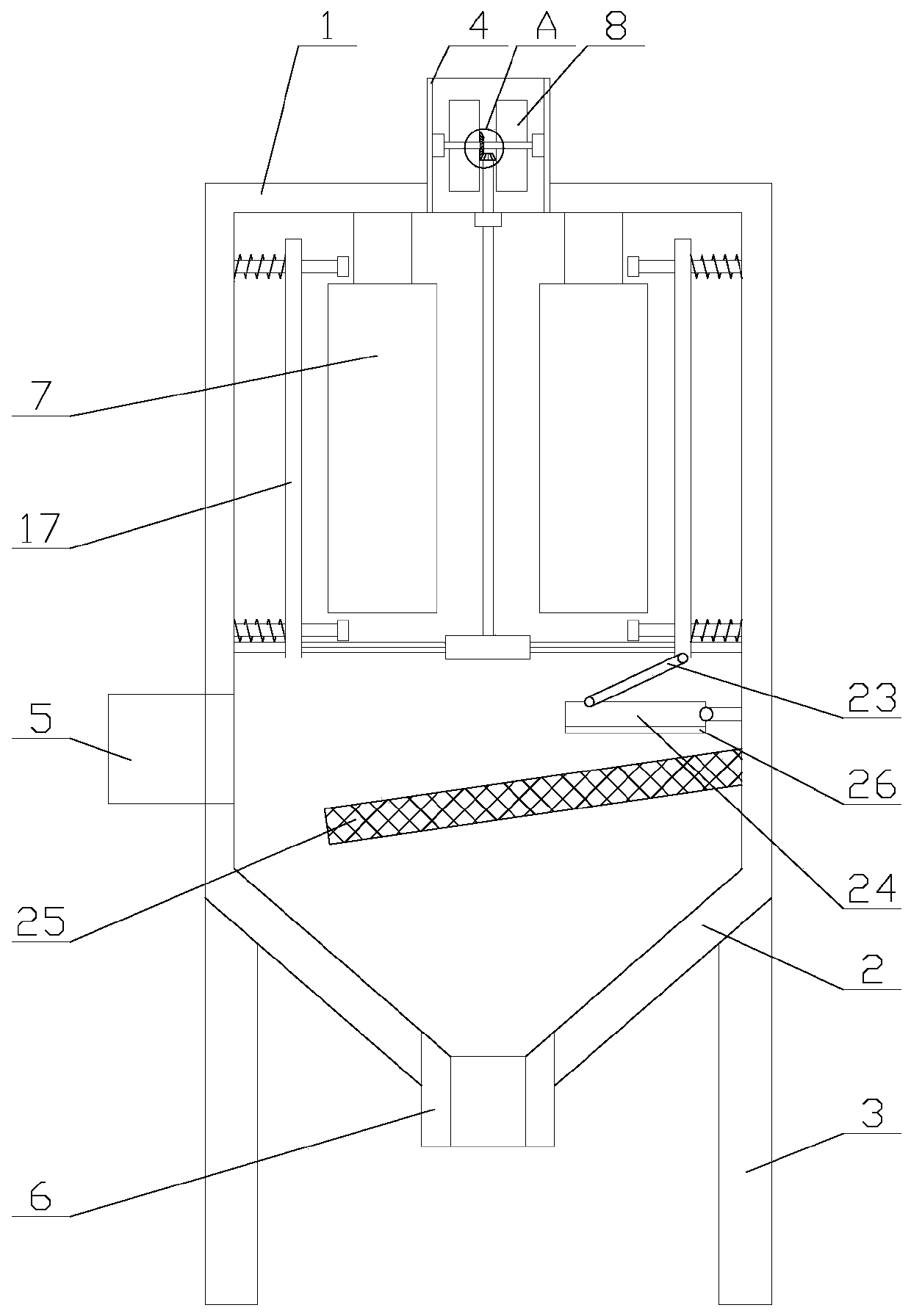

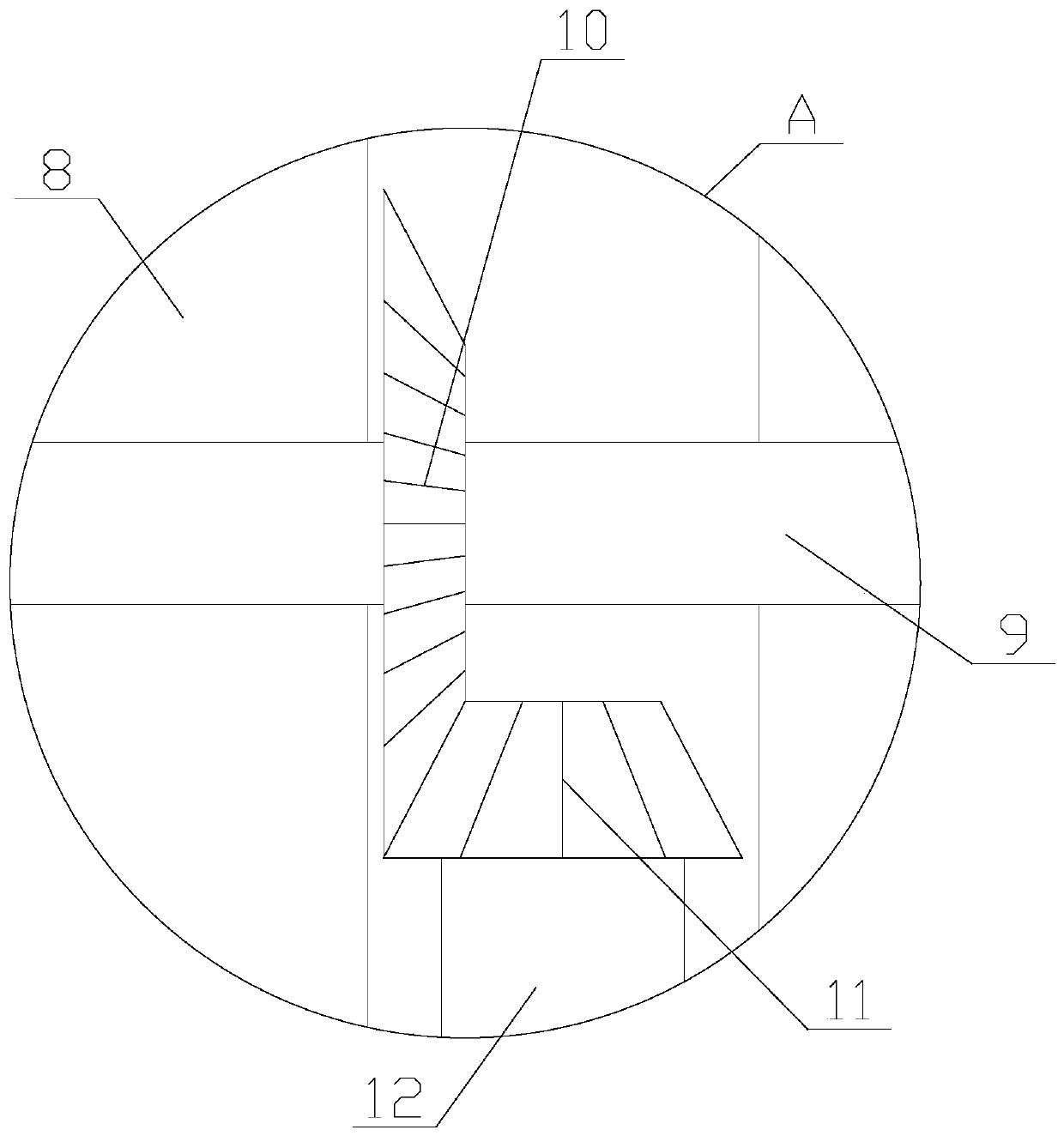

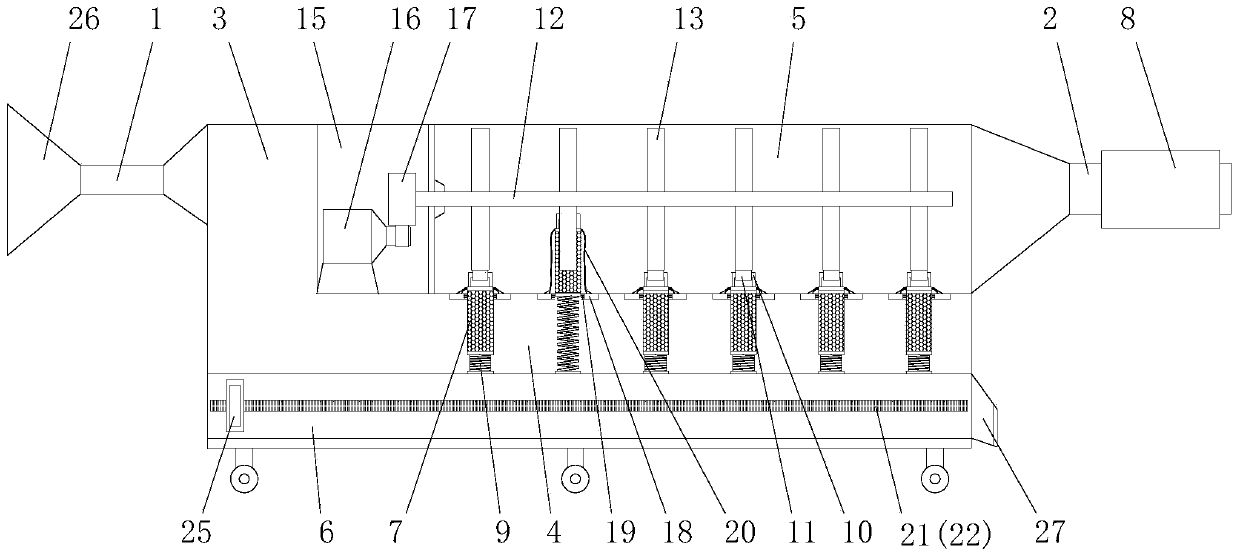

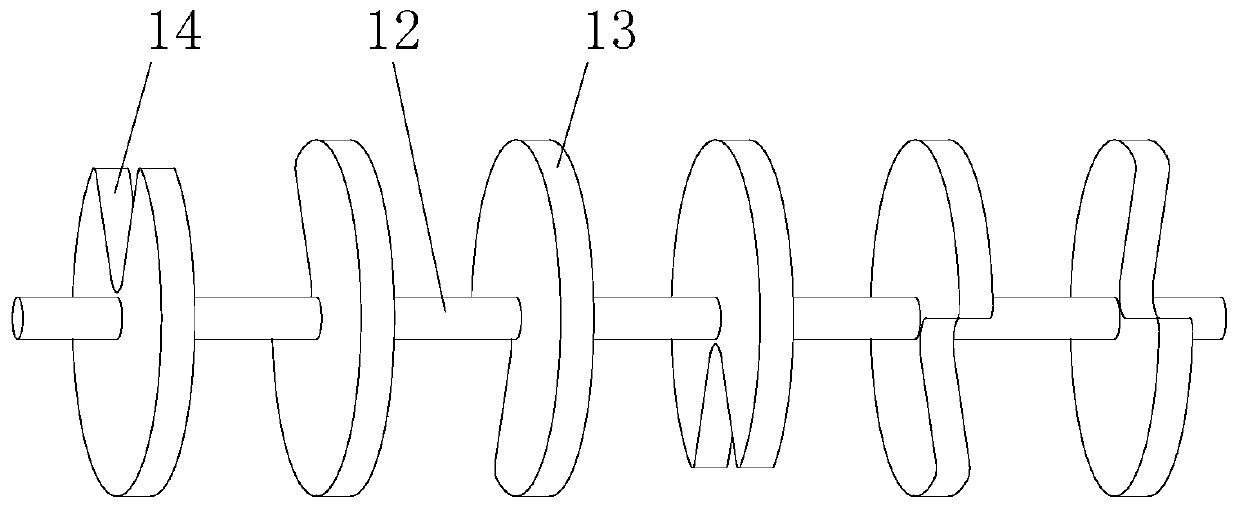

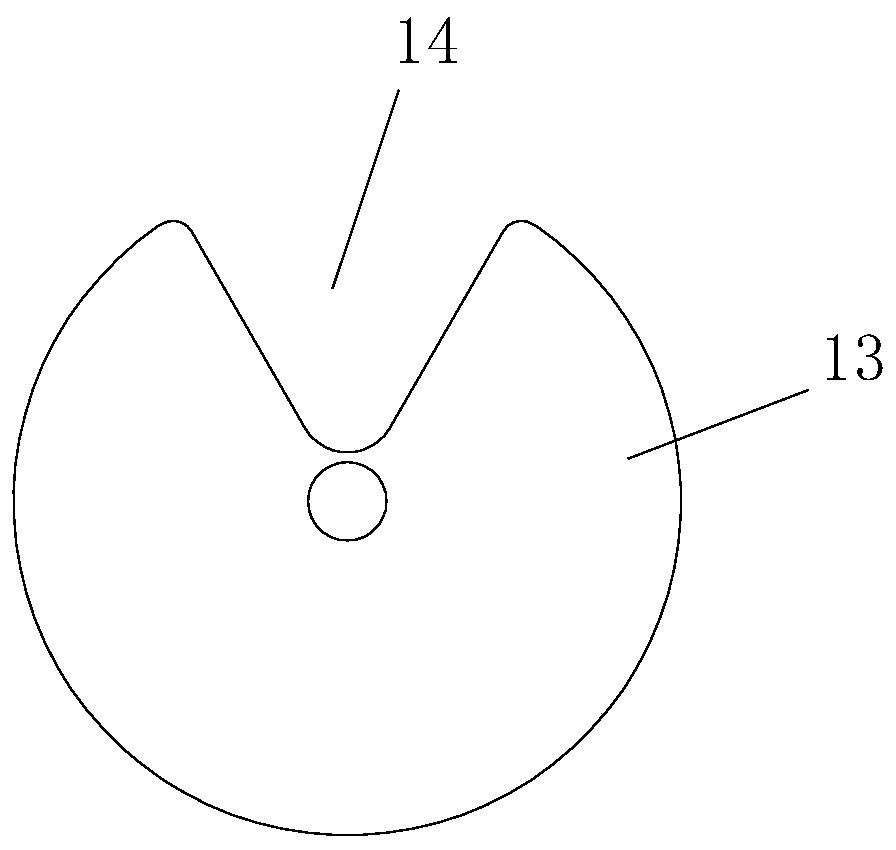

The invention discloses a pulse cloth bag dust remover capable of easily collecting ash. The pulse cloth bag dust remover comprises a box body and an ash outlet pipe, wherein a ceiling and a cage framework are fixedly connected in the box body; a plurality of filter bags are fixedly connected between the ceiling and the cage framework; beating blades are connected between the ceiling and the cage framework and at two sides of the filter bags in a rotary manner; upper ends of the filter bags are connected with a venturi tube penetrating through the ceiling; a blowing pipe is further fixedly connected with a position, located above the ceiling, in the box body; the lower part of the box body is connected with a brushing shaft in the rotary manner; the brushing shaft is fixedly connected with a plurality of brushing plates; an opening formed in the lower end of the box body is communicated with the upper end of the ash outlet pipe; the ash outlet pipe is fixedly connected below the box body; the ash outlet pipe is internally connected with a spiral blade in the rotary manner; an atomizer is further fixedly connected with the lower end of the ash outlet pipe; an outlet of the atomizer is communicated with a flow spitting box; the lower end of the flow spitting box is communicated with a plurality of humidifying nozzles introduced into the ash outlet pipe. The pulse cloth bag dust remover capable of easily collecting the ash is high in reverse blowing and ash falling efficiency, dust is not stuck and remained and does not cause secondary pollution after being discharged; energy saving and high efficiency are realized.

Owner:广西金邦泰科技有限公司

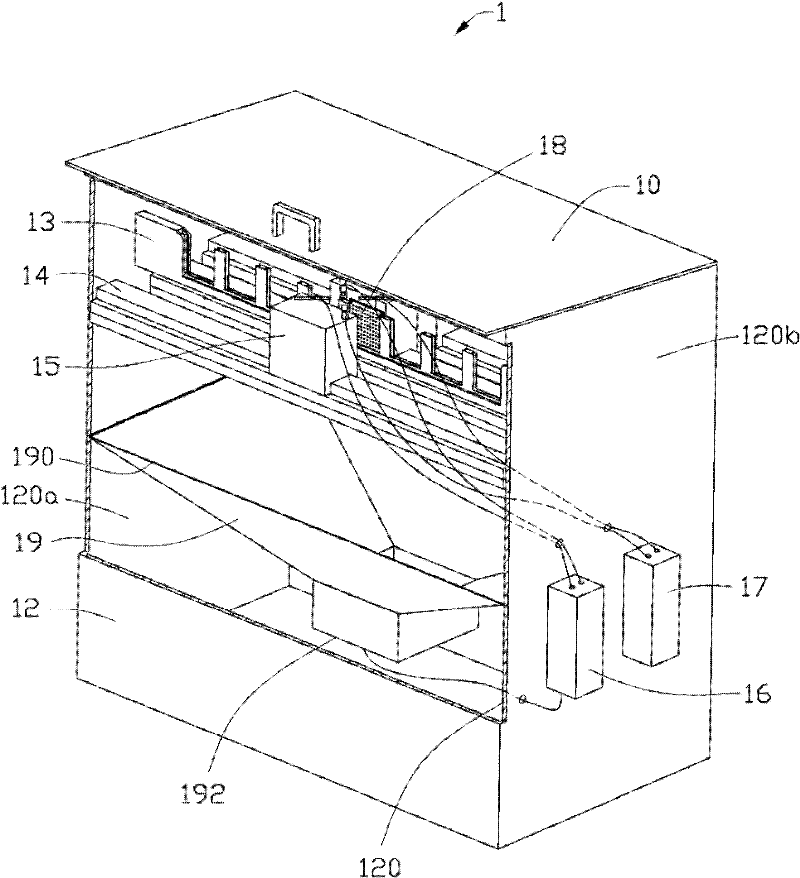

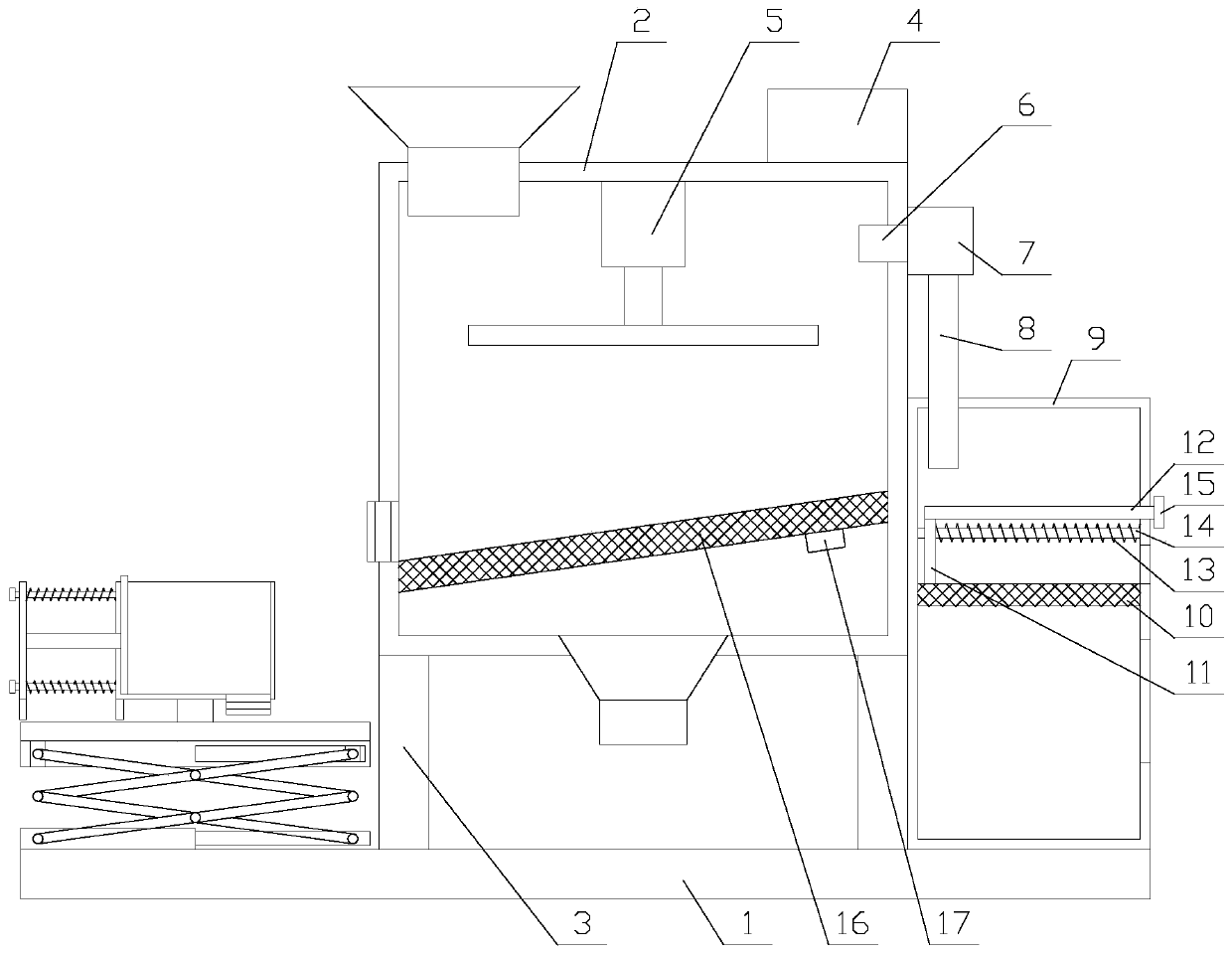

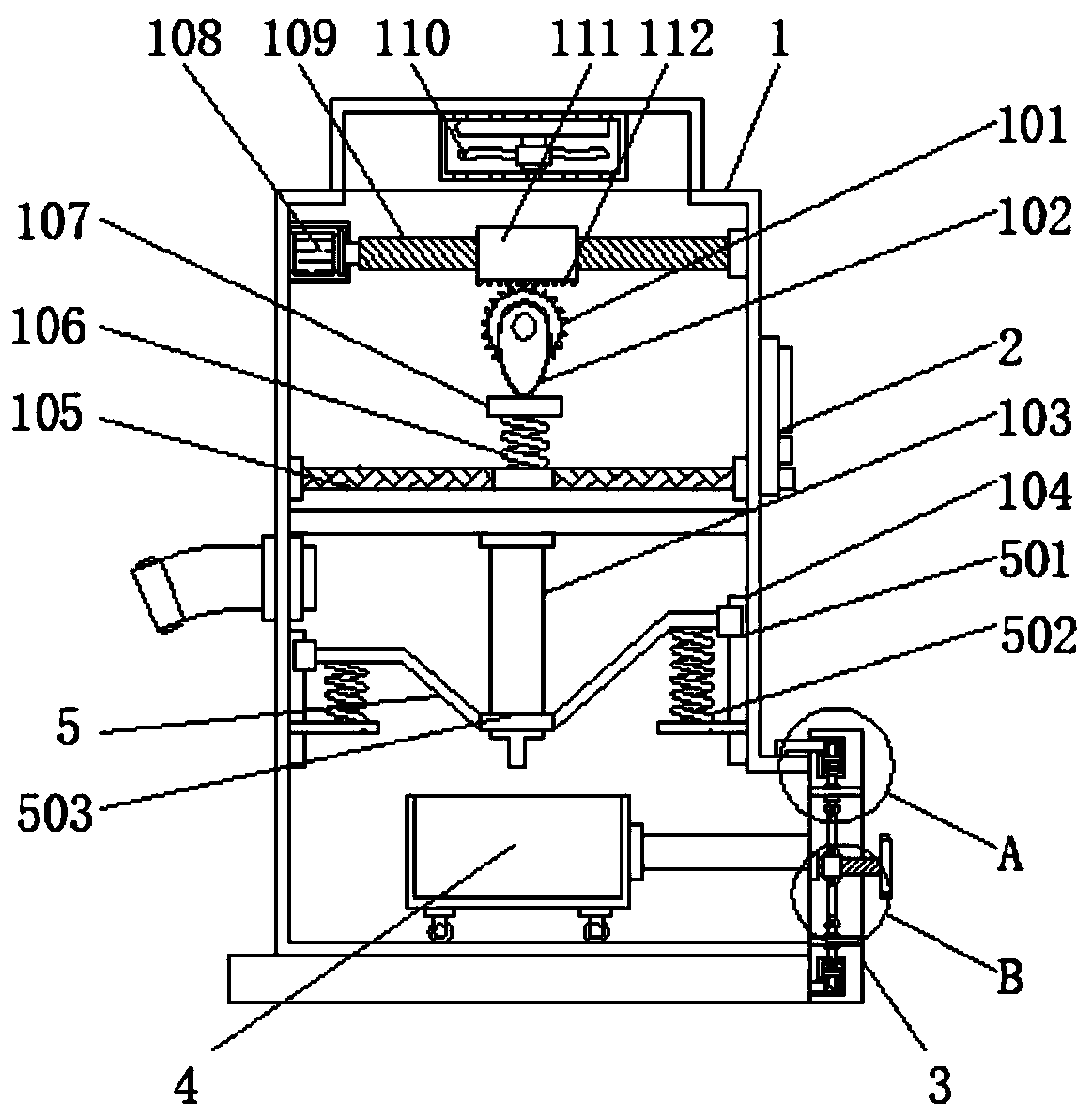

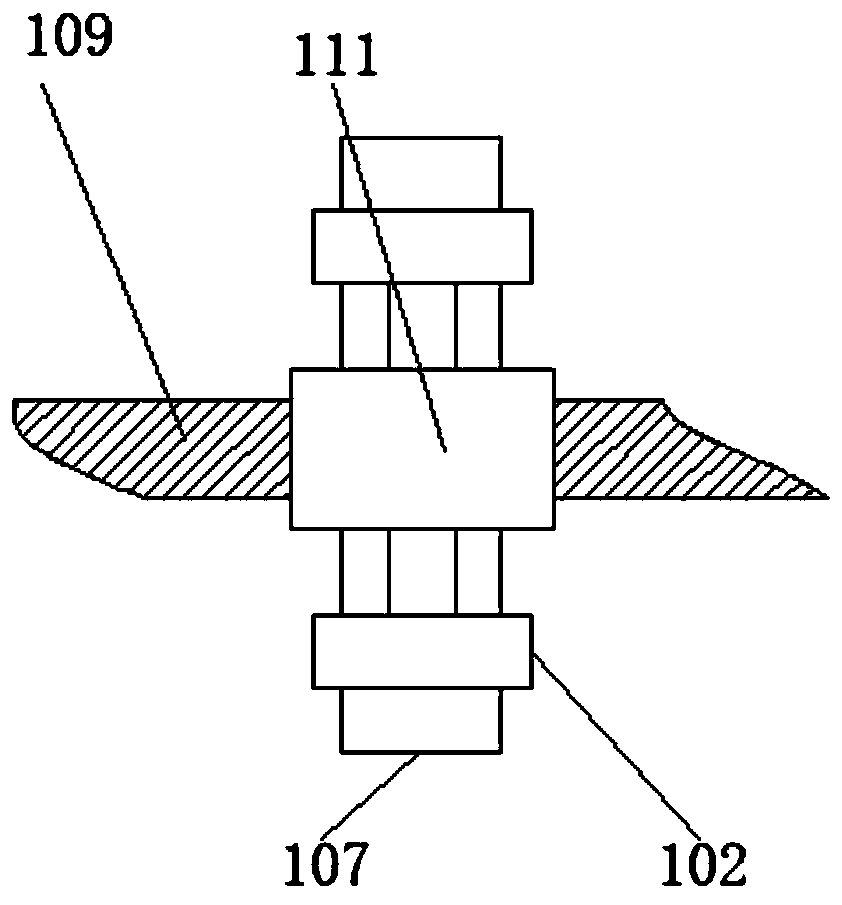

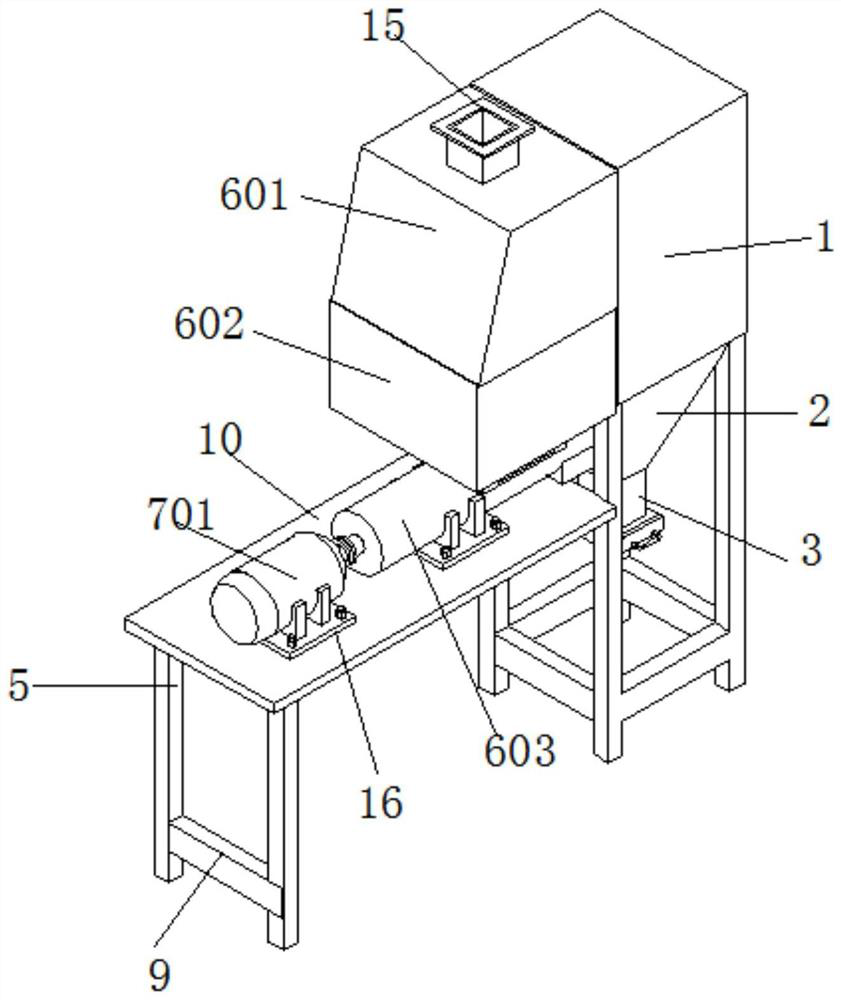

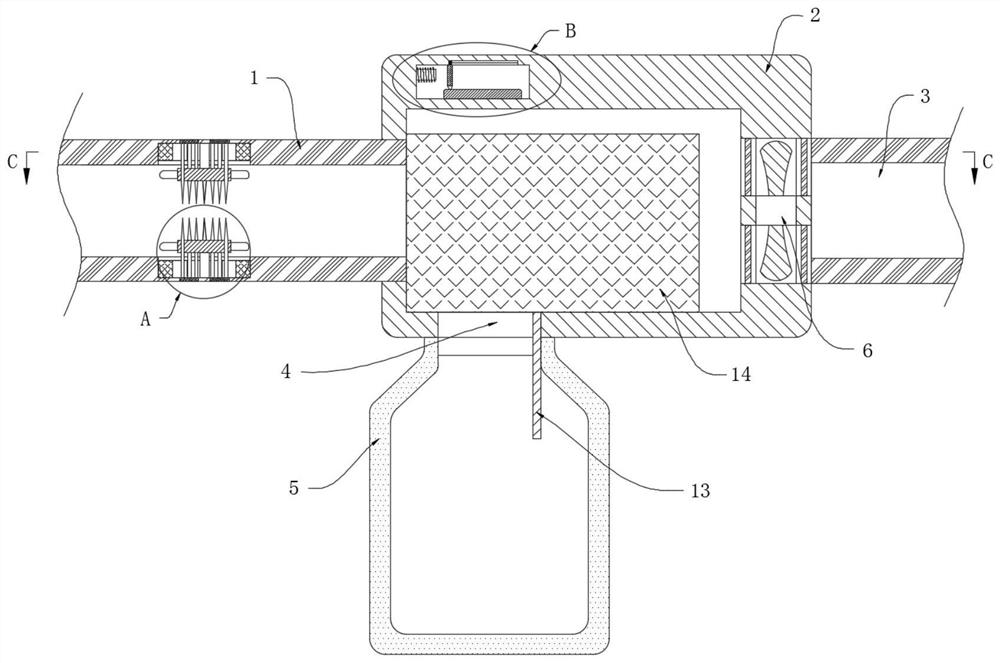

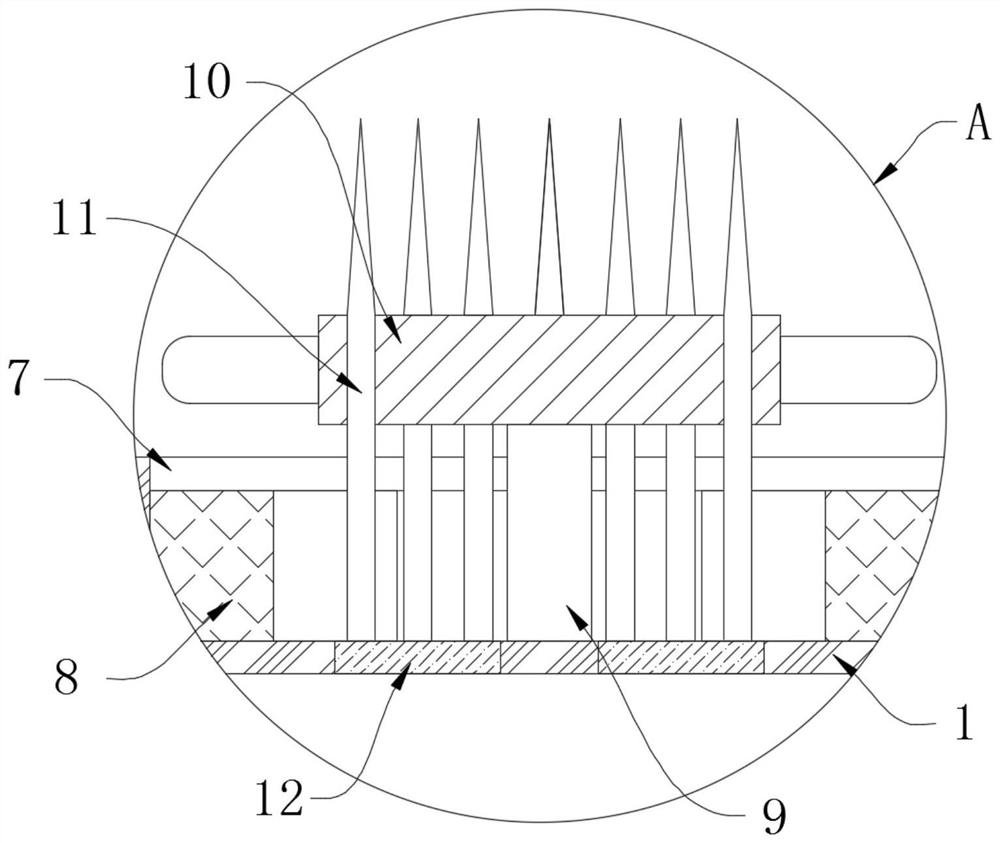

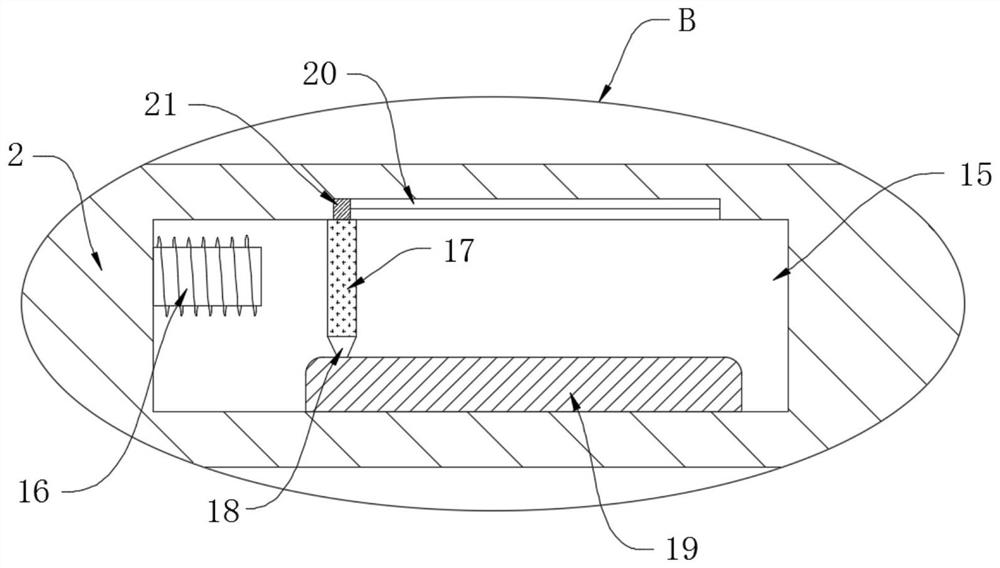

Efficient dust removal device for workshop mechanical part finish machining

InactiveCN112169484AAchieve cleaning effectAvoid affecting the dust removal effectDispersed particle filtrationTransportation and packagingStructural engineeringManufacturing engineering

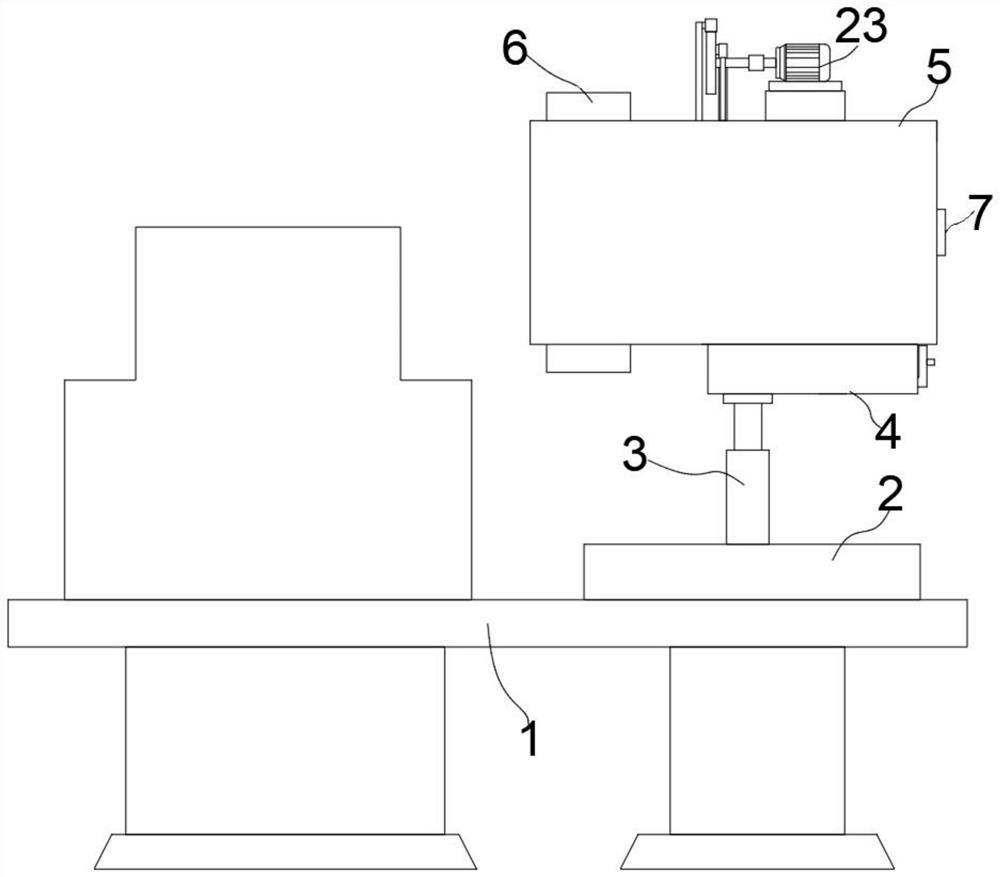

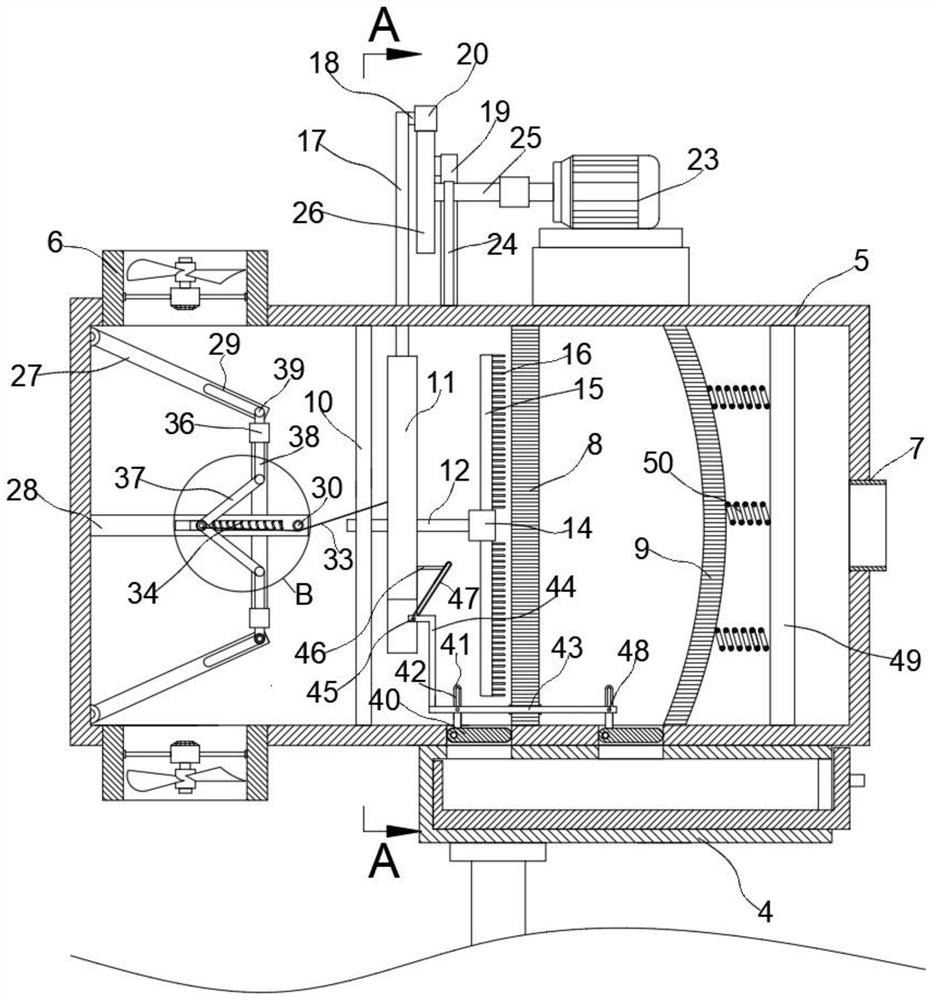

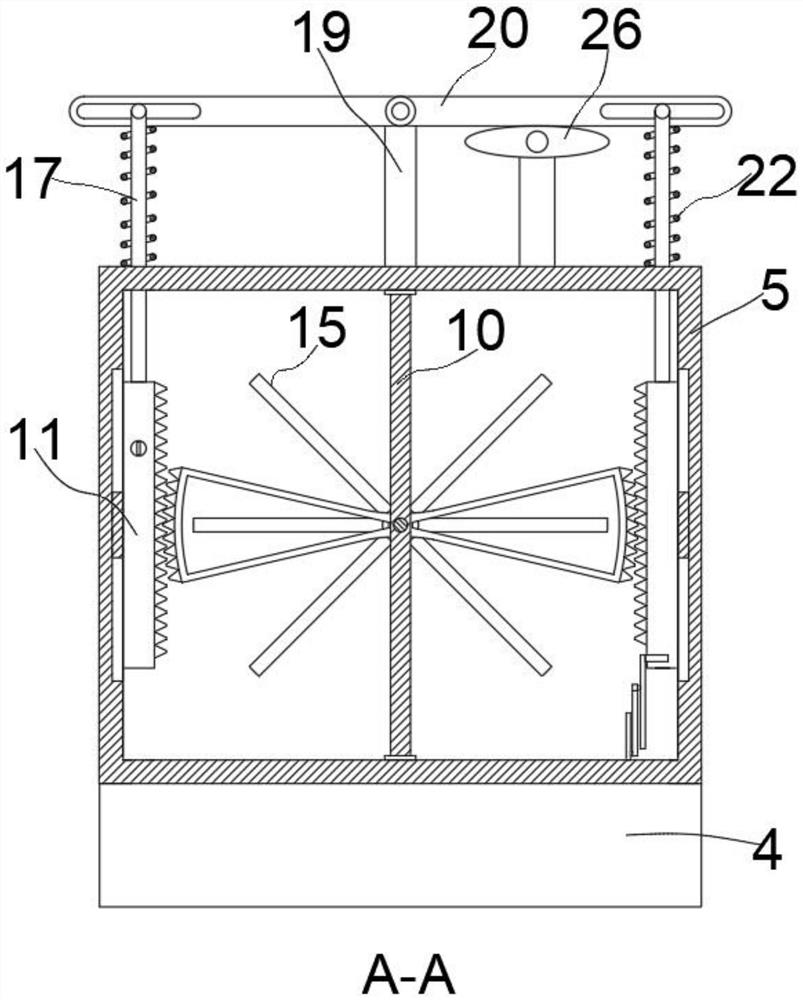

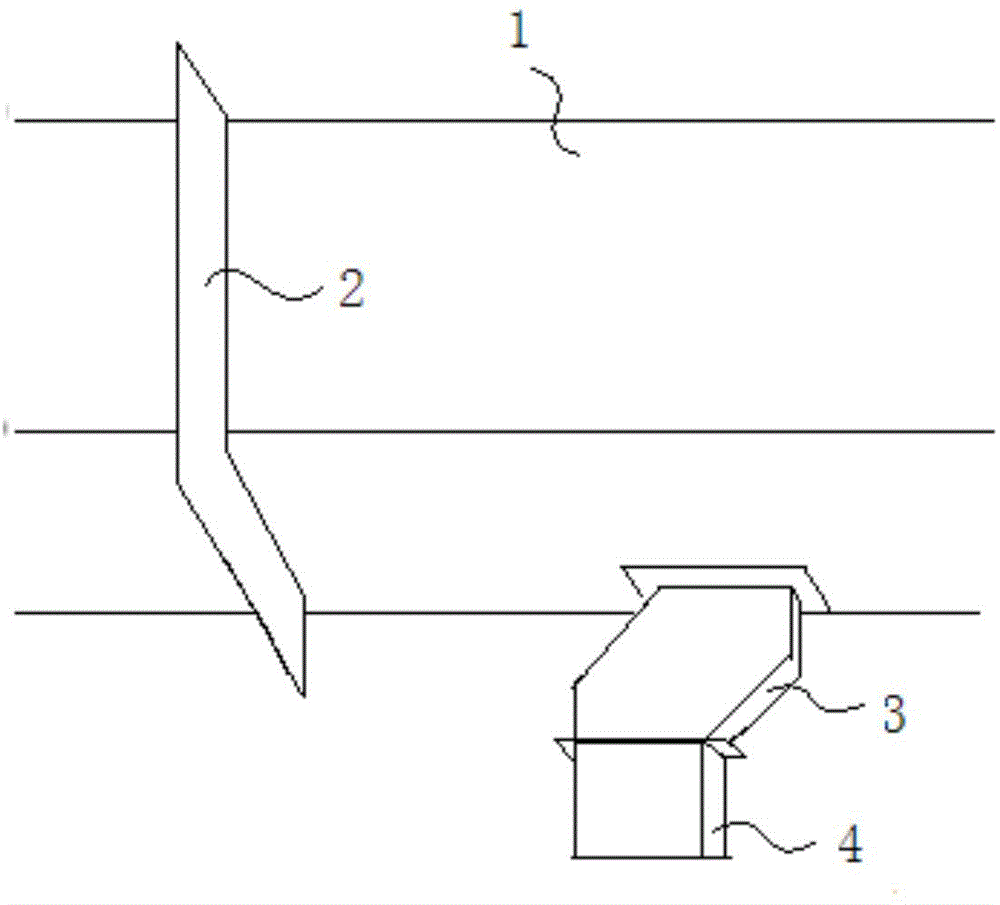

The present invention discloses an efficient dust removal device for workshop mechanical part finish machining, which comprises a machine tool; a base is fixed to the top of one side of the machine tool, a lifting air cylinder is fixed to the top of the base, a dust collection box is fixed to the top of the lifting air cylinder, and a dust removal box is fixed to the top of the dust collection box; air inlet holes are formed in the outer walls, close to the machine tool, of the upper side and the lower side of the dust removal box, air suction fans are fixed to the inner walls of the air inletholes, air outlet holes are formed in the outer wall of the side, away from the machine tool, of the dust removal box, a filtering mechanism, a cleaning mechanism and a switching mechanism are arranged in the dust removal box, and the dust removal box communicates with the dust collection box. By arranging the filtering mechanism, the cleaning mechanism and the switch mechanism, the effect of collecting brushed dust and impurities while cleaning the filtering plate is achieved, and the situation that the filtering plate is blocked, and consequently the dust removal effect is low is prevented.

Owner:福州鑫启美机械设备有限公司

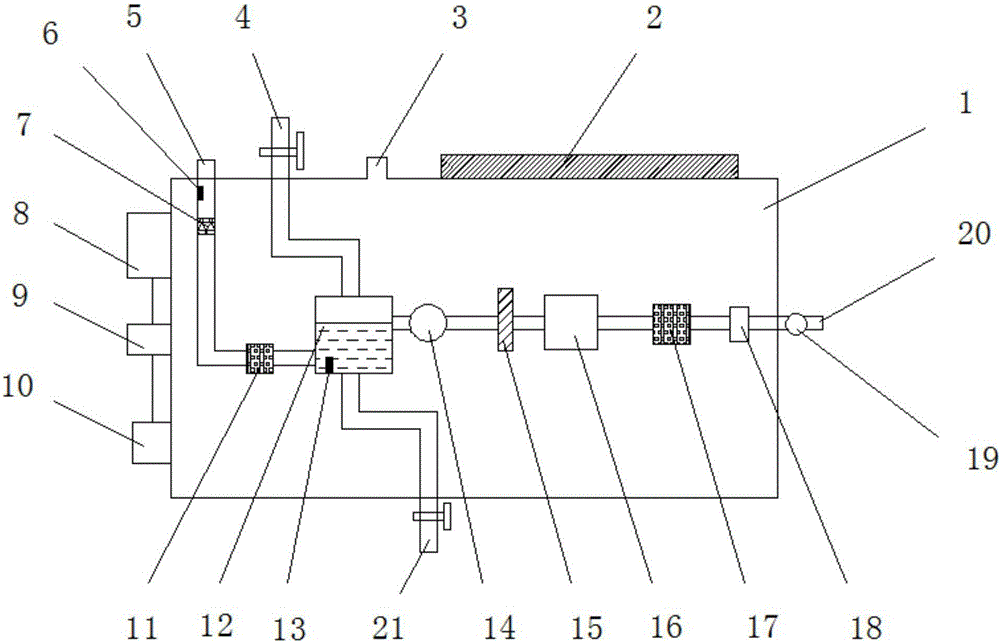

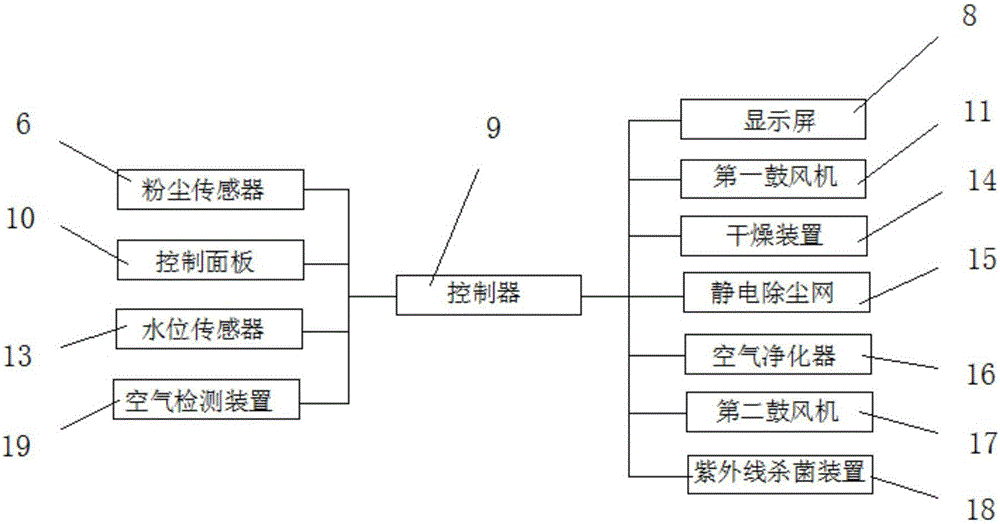

Electrical automation dust removal device

InactiveCN106268151AReasonable designAffect the effect of dust removalCombination devicesRadiationAir purifiersEngineering

The invention discloses an electrical automation dust removal device. The electrical automation dust removal device comprises a shell, an air inlet and an air outlet. The air inlet is formed in the top end of the shell, provided with a dust concentration sensor and a filter screen and connected with a first air blower, a water tank, a drying device, an electrostatic dust removal screen, an air purifier, a second air blower, an ultraviolet sterilization device and the air outlet in sequence through pipelines. The top end of the water tank is communicated with a water inlet through a water pipe, and the bottom end of the water tank is communicated with a water outlet through a water pipe. A display screen, a controller and a control panel are installed on the outer side of the shell. The display screen, the control panel, the dust concentration sensor, the first air blower, the drying device, the electrostatic dust removal screen, the air purifier, the second air blower and the ultraviolet sterilization device are electrically connected with the controller through wires. The electrical automation dust removal device is reasonable in design, high in automation degree and good in dust removal effect and can be widely used and popularized.

Owner:GUANGZHOU OUSHU ENVIRONMENTAL PROTECTION TECH CO LTD

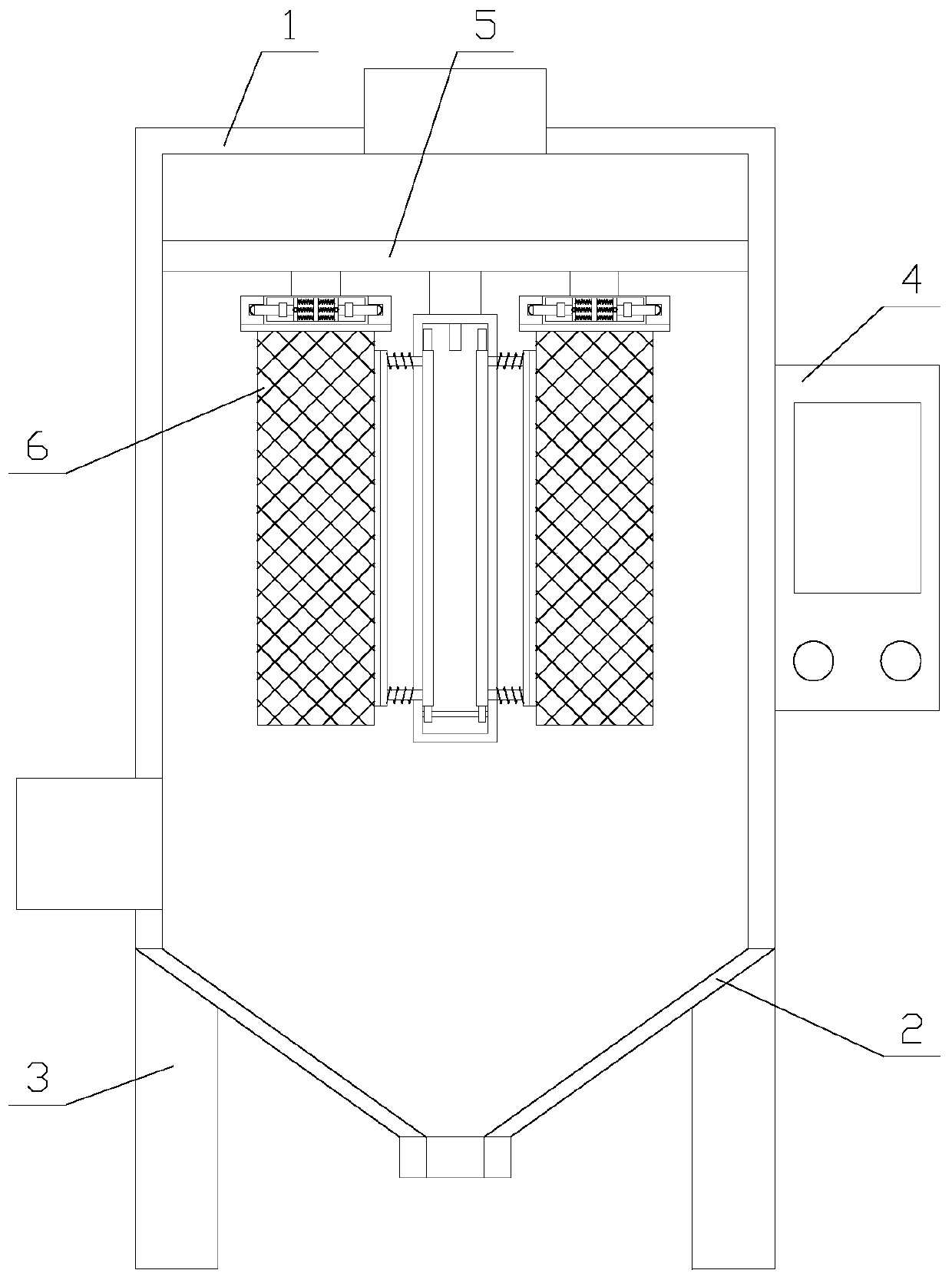

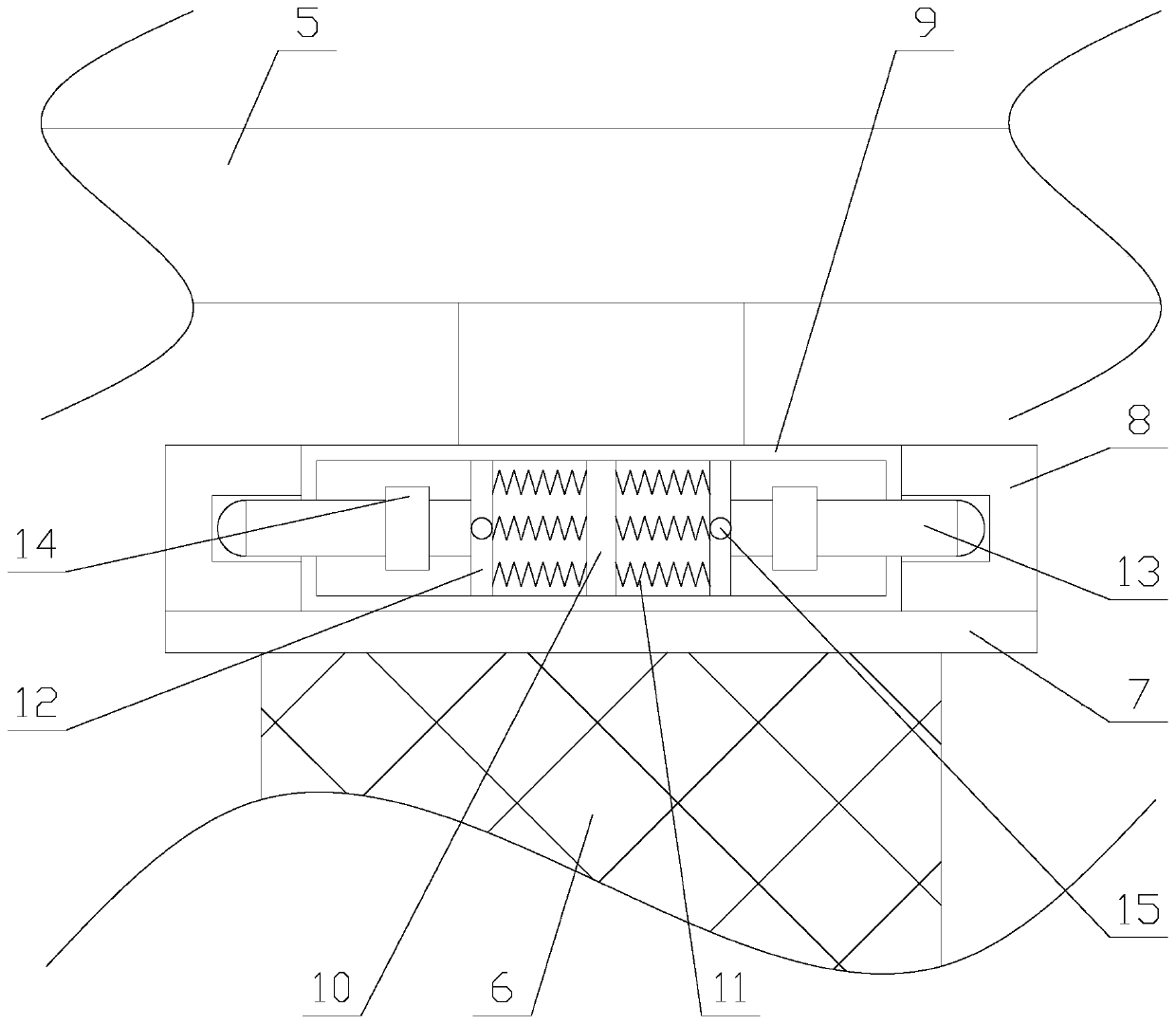

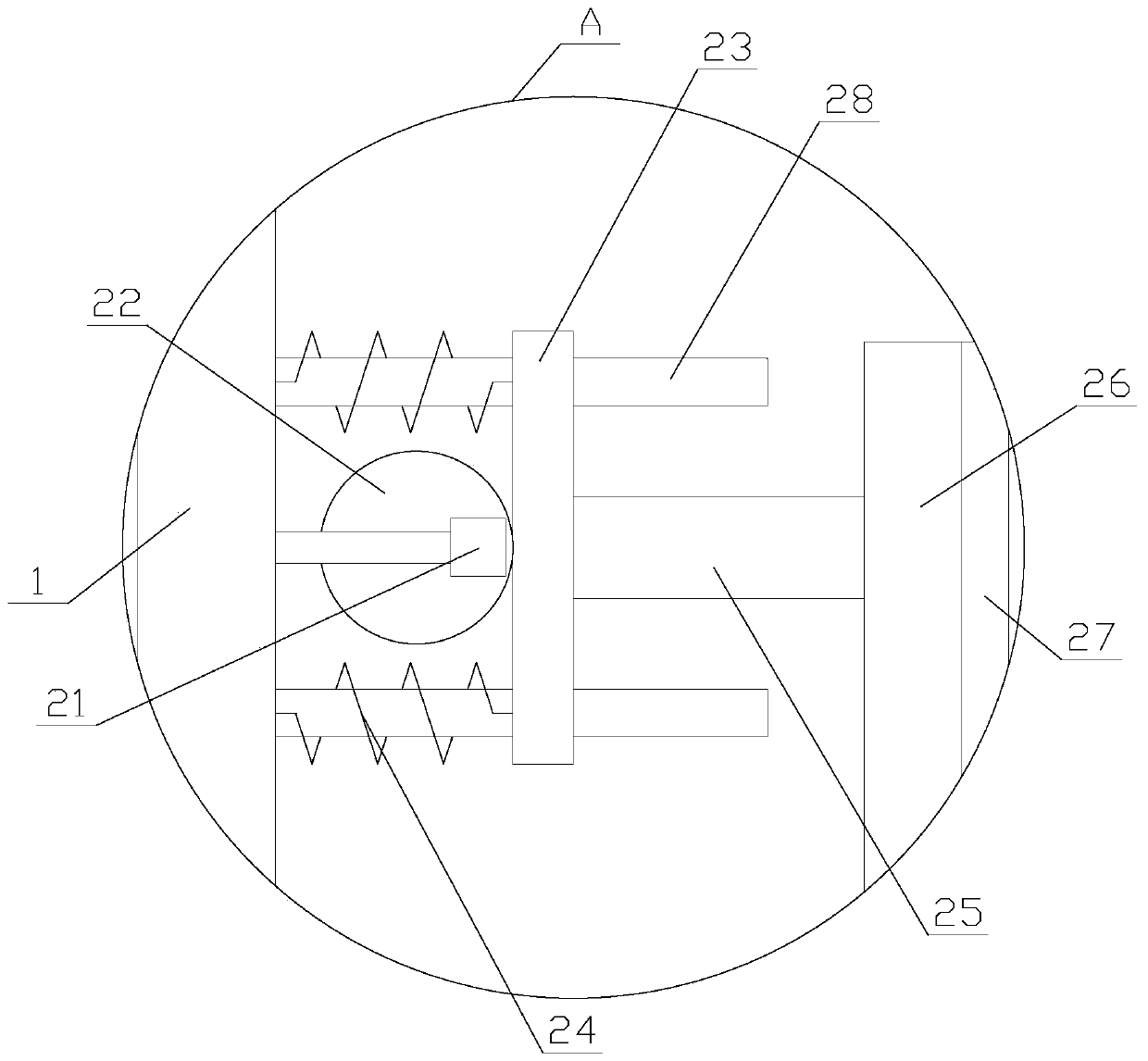

Convenient cloth bag dust removing device used for chemical processing of coal and having anti-clogging function

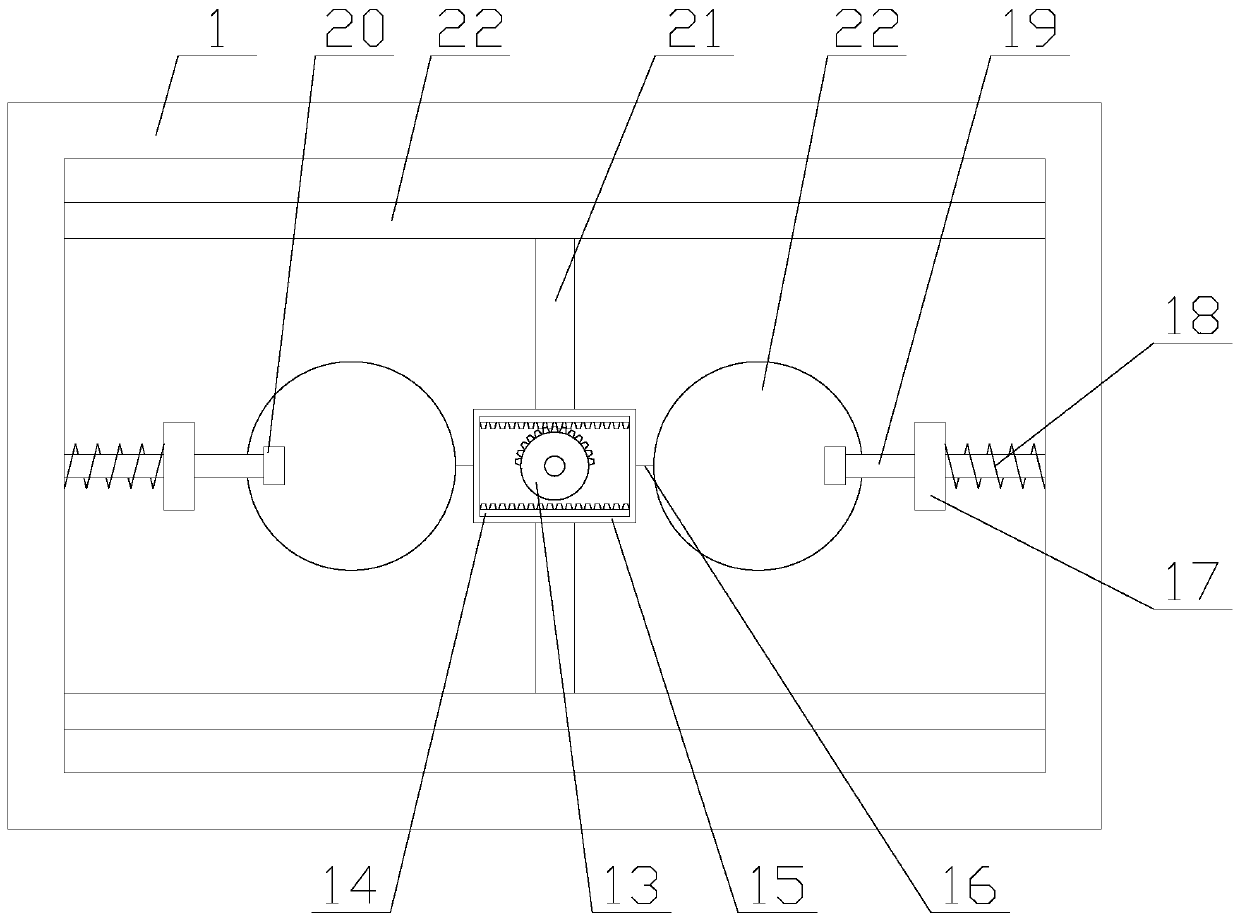

The invention relates to a convenient cloth bag dust removing device used for chemical processing of coal and having anti-clogging function. The convenient cloth bag dust removing device comprises a main body, an ash hopper, two support columns and two dust removing devices, wherein a disassembly-assembly mechanism and a shaking mechanism are arranged inside the main body, the disassembly-assemblymechanism comprises a support rod and two disassembly-assembly assemblies, the disassembly-assembly assembly comprises a supporting rod and a fixing box, a supporting plate and two fixing units are arranged inside the fixing box, the fixing unit comprises a moving plate, a fixing rod and a plurality of first springs, the shaking mechanism comprises a support block and a shaking box, a driving assembly and two shaking assemblies are arranged inside the shaking box, and the shaking assembly comprises a shaking plate, a connecting plate, two connecting rods and two second springs. According to the present invention, the convenient cloth bag dust removing device can improve the convenience of dust removing bag disassembly and assembly through the disassembly-assembly mechanism; and through the shaking mechanism, the dust adhered to the dust removing bag can be shaken off, such that the condition that the dust clogs the dust removing bag to affect the dust removing effect can be avoided.

Owner:SHENZHEN JIUPIN AIR PURIFICATION TECH CO LTD

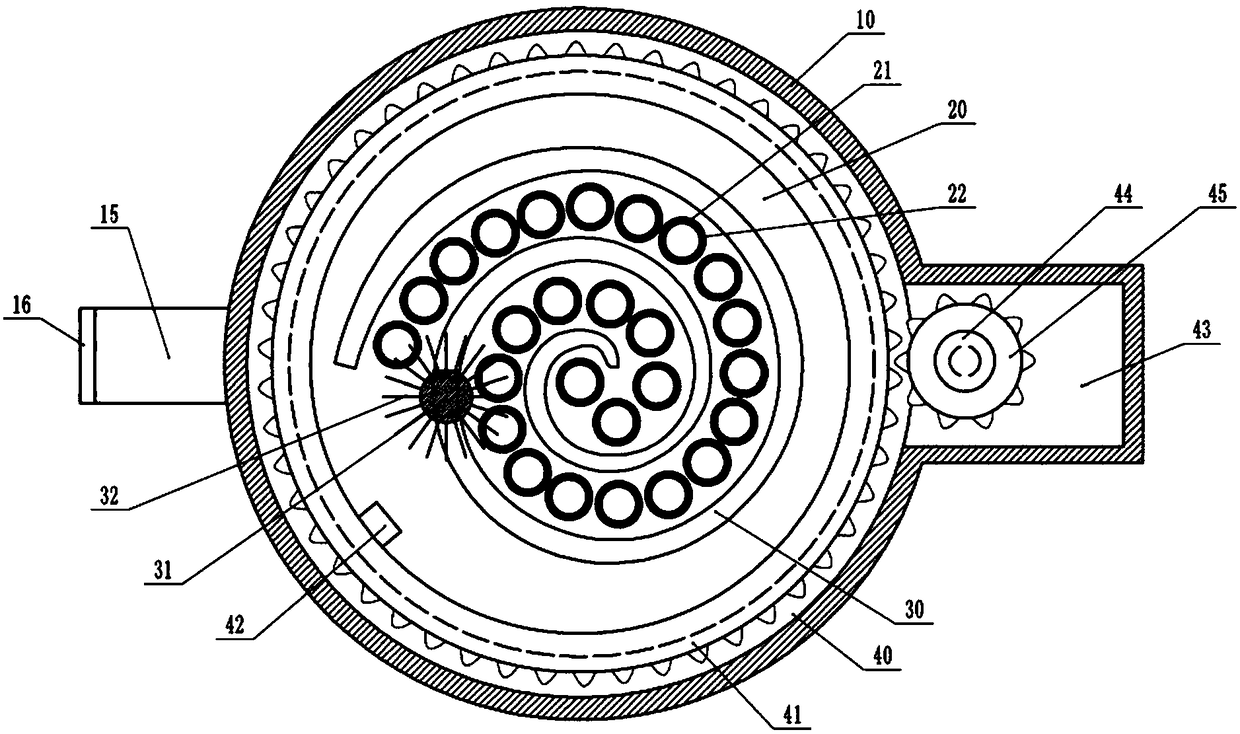

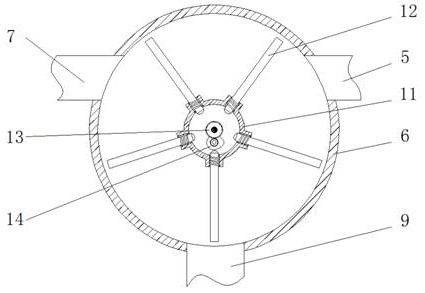

Fan type electrostatic dust remover

InactiveCN105665138ARealize periodic adsorptionAchieve settlementExternal electric electrostatic seperatorElectrostatic separation detailsEngineeringElectrostatic generator

The invention relates to a fan type electrostatic dust remover. The fan type electrostatic dust remover comprises an electrostatic generator, a dust removal cavity, a purification cavity and a dust hopper. A discharging piece is electrically connected to an air inlet. The discharging piece is electrically connected with the negative electrode of the electrostatic generator. The dust removal cavity is spaced from the dust hopper through a dust collection screen plate. A driving box is fixedly installed in the center of the dust collection screen plate. A power disc is installed in the driving box. Conducting strips are embedded in the disc surface of the power disc in the circumferential direction. All the conducting strips are insulated from one another and electrically connected with a ground wire or a positive electrode wire of the electrostatic generator. A dust removal fan is installed above the power disc and can rotate freely around a fixing rotary shaft. Conducting brushes extend out downwards from all fan surfaces of the dust removal fan. All the conducting brushes are closely attached to the disc surface of the power disc. The fan type electrostatic dust remover is novel in structure, dust accumulation and dust residues can be effectively prevented while efficient dust removal is conducted, and the dust removal continuity is effectively improved.

Owner:宣城市锦绣超细重质碳酸钙厂(普通合伙)

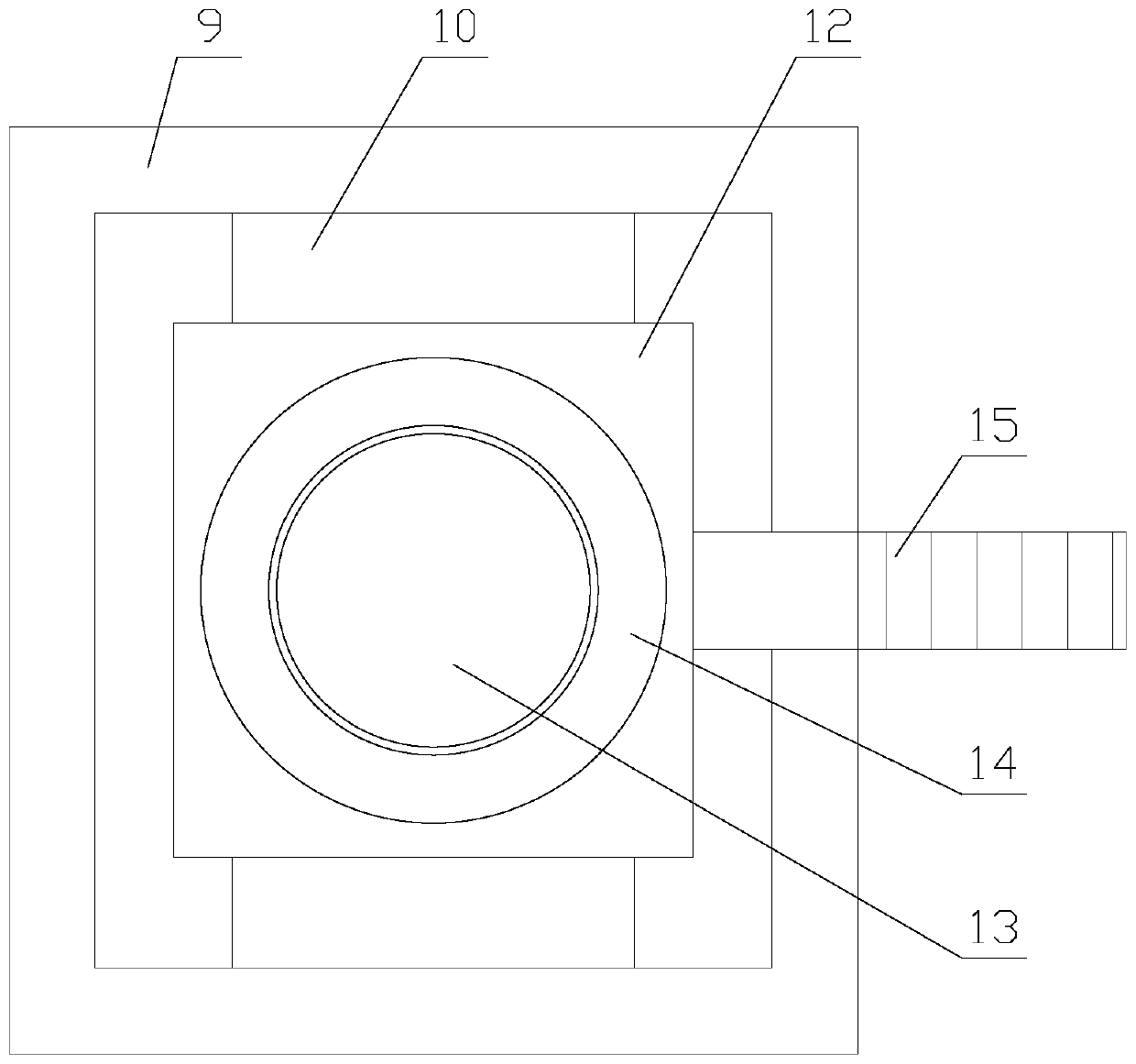

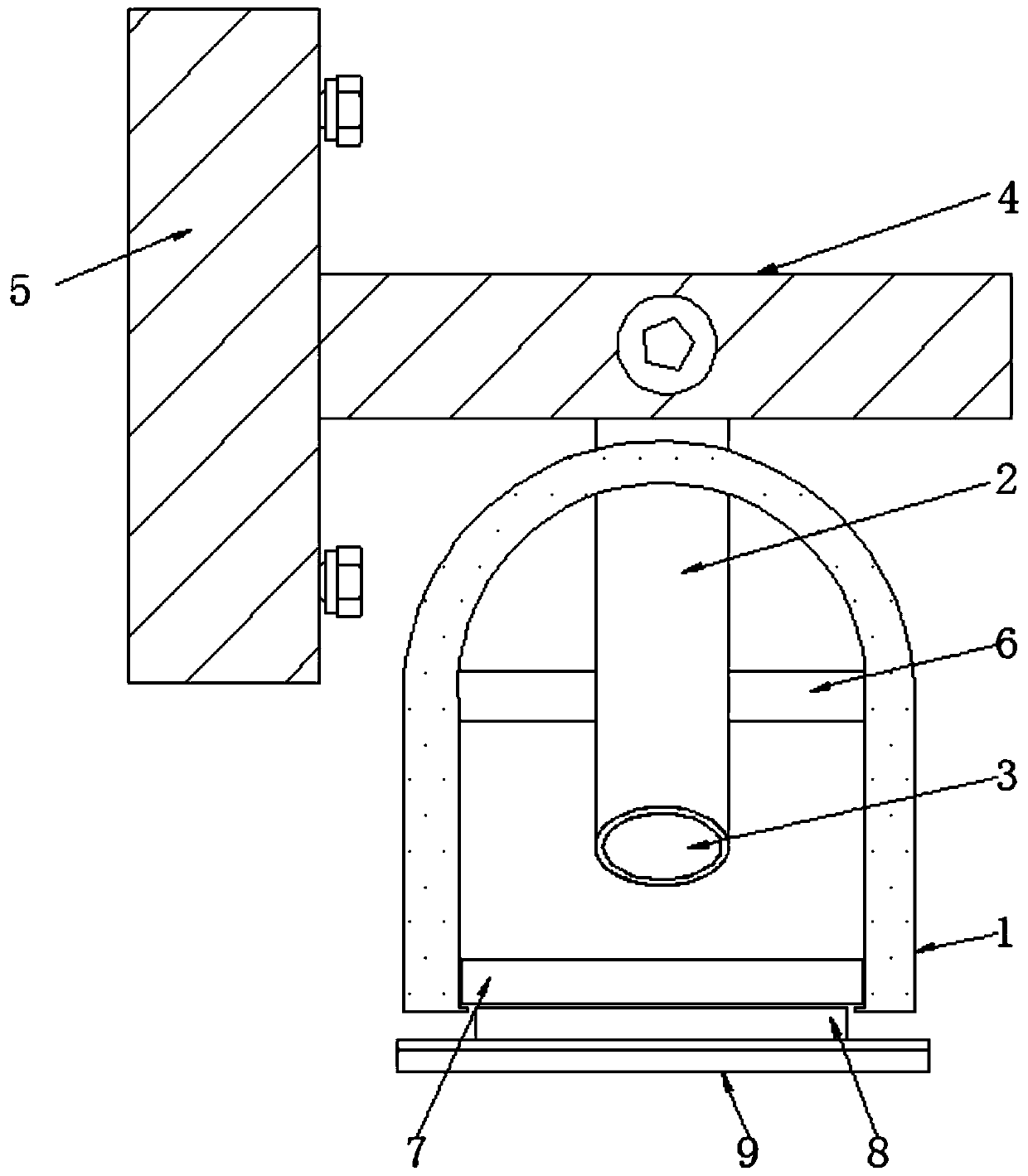

Dedusting device

InactiveCN102233341ASuck away in timeAvoid affecting the dust removal effectCleaning using gasesMechanical engineeringAir blower

The invention provides a dedusting device. The dedusting device comprises a top cover, an accommodation cavity, a bracket, a sliding rail, a dedusting sliding seat, an air extractor, an air blower and a lens bearing disk, wherein the accommodation cavity is provided with an opening; the top cover is used for sealing the opening of the accommodation cavity so as to form a closed accommodation space; two ends of the bracket are respectively fixed in the accommodation cavity; at least one side of the bracket is equipped with the sliding rail parallel to the bracket; the lens bearing disk is fixed on the bracket and used for bearing a lens to be dedusted; the air extractor and the air blower are arranged outside the accommodation cavity; and the dedusting sliding seat is respectively connected with the air extractor and the air blower and slides along the sliding rail so as to blow and suck air for the lens bearing disk fixed on the bracket at the same time, thereby blowing off and sucking out ash on the lens.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Efficient bag type dust removal equipment with impurity removal function for coal chemical engineering

InactiveCN109876563AImprove practicalityAvoid damageDispersed particle filtrationImpurityWaste material

The invention relates to efficient bag type dust removal equipment with an impurity removal function for coal chemical engineering. The efficient bag type dust removal equipment comprises a main body,an air inlet pipe, an air outlet pipe, a dust removal bag, an ash hopper, an ash discharge pipe, two support frames, an impurity removal mechanism and two cleaning mechanisms, wherein the impurity removal mechanism comprises an impurity removal plate, a communication pipe, a waste material box and a drainage assembly; the drainage assembly comprises a driving unit, a connecting plate and a plurality of dredge rods; the cleaning mechanism comprises a vibration plate and two power assemblies; each power assembly comprises a fixing rod, a first motor, an eccentric wheel, a moving plate, a connecting rod and two springs. The efficient bag type dust removal equipment with the impurity removal function for coal chemical engineering can be used for performing impurity removal work on waste gas through the impurity removal mechanism; the dust removal bag damage due to entering of large particle impurities in the waste gas into the main body is avoided; the influence on the service life of thedust removal bag is avoided; through the cleaning mechanisms, the cleaning work can be performed on the dust removal bag; the dust removal bag blockage by the dust can be avoided; the influence on the dust removal effect is avoided.

Owner:GUANGZHOU LINDIAN TECH CO LTD

High-production-quality dust proof type powder grinding machine for mineral separation

InactiveCN110124840AImprove practicalityAvoid cloggingDispersed particle filtrationTransportation and packagingEngineeringImpurity

The invention relates to a high-production-quality dust proof type powder grinding machine for mineral separation. The high-production-quality dust proof type powder grinding machine comprises a mainbody, a powder grinding device, an operating panel, a base seat and two supports and further comprises a recycling mechanism and a dust proof mechanism, wherein the dust proof mechanism comprises an air suction component, a fixed box, a filter net and a cleaning component, the cleaning component comprises a scraping plate, a pulling rod and a first spring, the recycling mechanism comprises a screen net, a lifting component, a recycling box and two moving components, the side, away from the main body, of the recycling box is provided with a material pushing component, and the material pushing component comprises a moving plate, a connection rod, a pushing plate, an electromagnet, an iron block and two second springs. According to the high-production-quality dust proof type powder grinding machine for the mineral separation, by means of the recycling mechanism, mineral materials which do not meet powder grinding requirements can be collected to be guided into the main body again to perform the powder grinding work, and the production quality of the high-production-quality dust proof type powder grinding machine is improved; and by means of the dust proof mechanism, impurity removal work can be performed on air inside the main body, and the situation that dust is directly discharged into the atmosphere to affect the air quality is avoided.

Owner:王玉玲

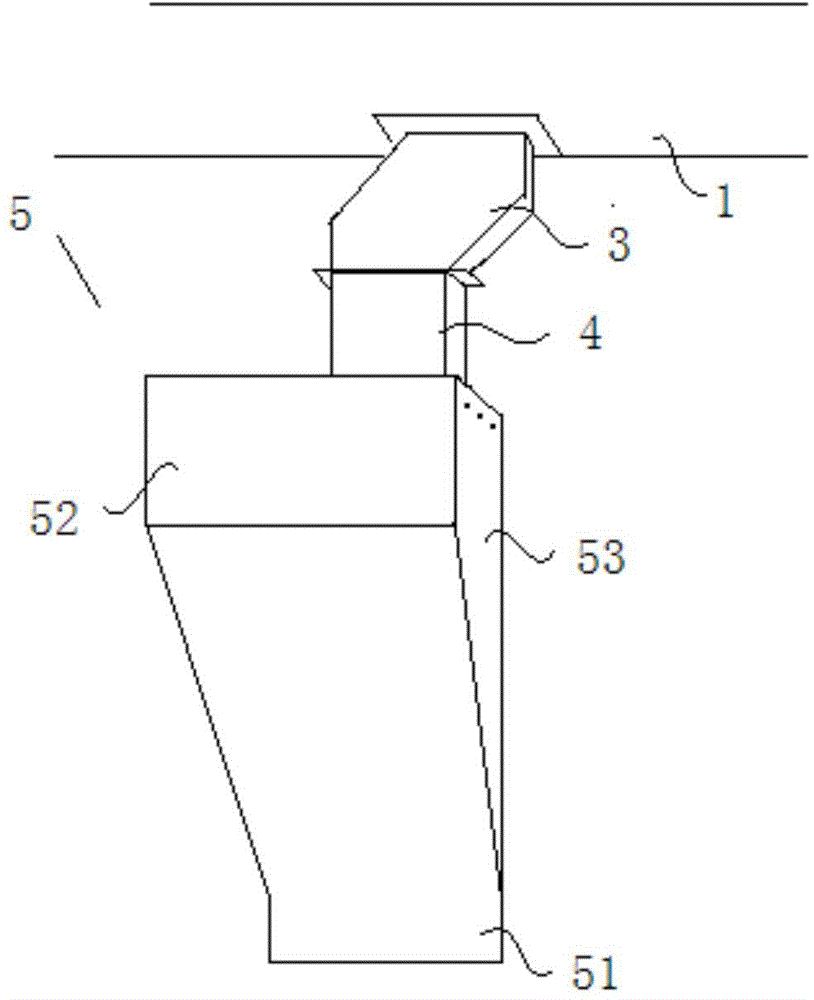

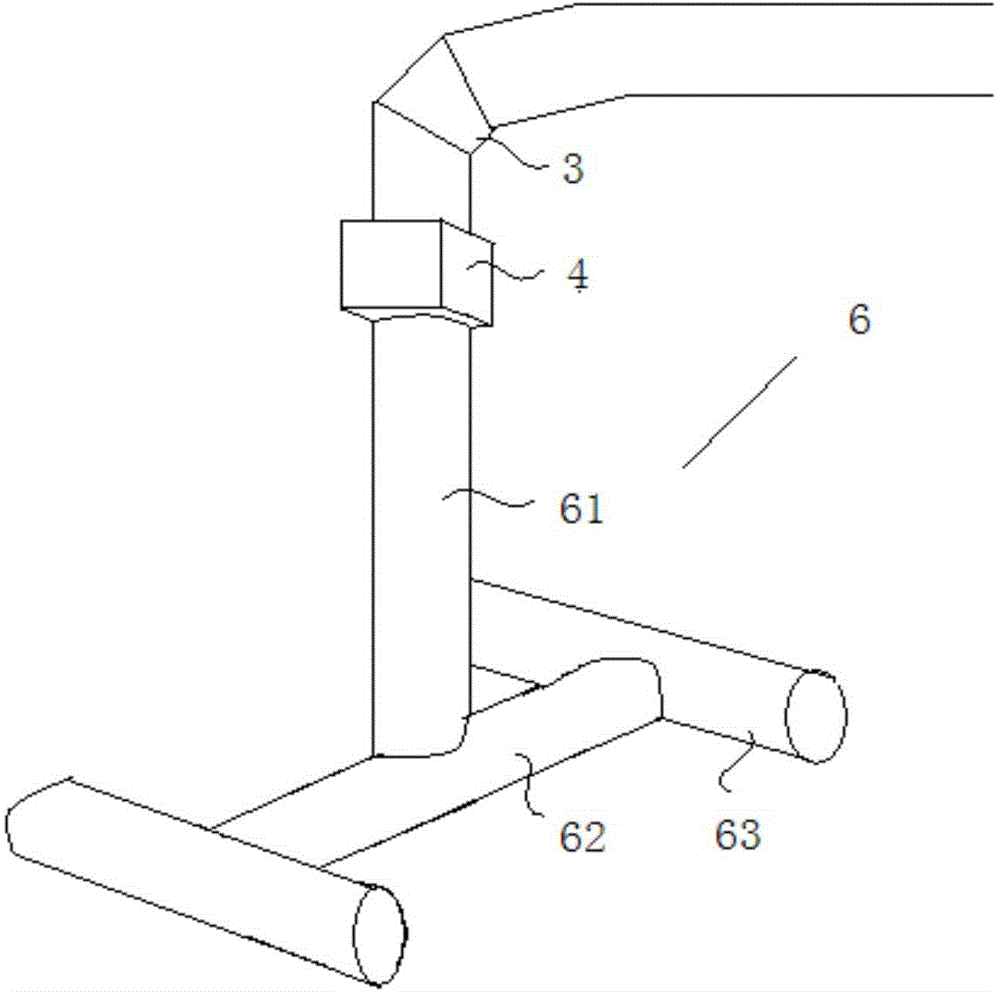

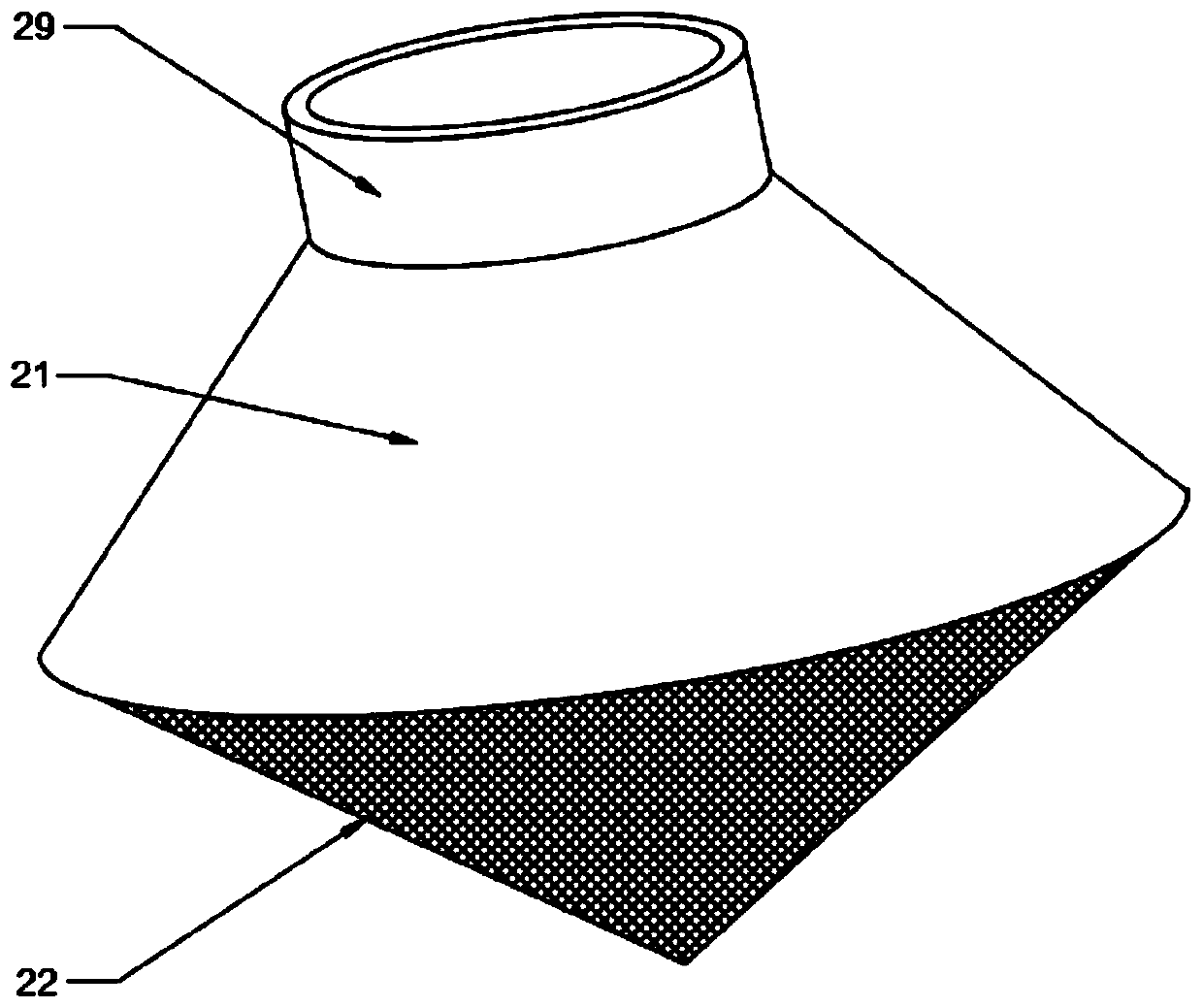

Adjustable telescopic dust collecting hood

InactiveCN106345784AAvoid affecting the dust removal effectDirt cleaningElectric machineryLiving environment

The invention provides an adjustable telescopic dust collecting hood. A dust suction hood is installed on a fixed base, a dust collecting hood body is installed below the dust suction hood, and the dust collecting hood body comprises a fixed portion on the upper portion and a telescopic portion on the lower portion. The adjustable telescopic dust collecting hood has the advantages of being adjustable in folding, unfolding and telescopic motion, small in size, high in efficiency and low cost, integrating gas, smoke, dust and noise collecting and discharging and the like, especially, by means of the adjustable telescopic dust collecting hood, the gas, smoke, dust and noise collecting effect is enhanced, under the same motor suction, the dust removal effect is remarkable, power consumption is greatly reduced, pollutants can be adjustably collected or removed to purify living environments, and the adjustable telescopic dust collecting hood is especially suitable for working occasions with smoke, dust, smell and noise collecting and discharging. By means of up-and-down telescopic motion of dust collecting hood cord fabric, the purpose of adjustably collecting or discharging the pollutants is achieved. The adjustable telescopic dust collecting hood is an ideal device special for being matched with the dust suction hood and suitable for various dust removal occasions.

Owner:HONGDA PLASTIC RUBBER CORP QINGDAO

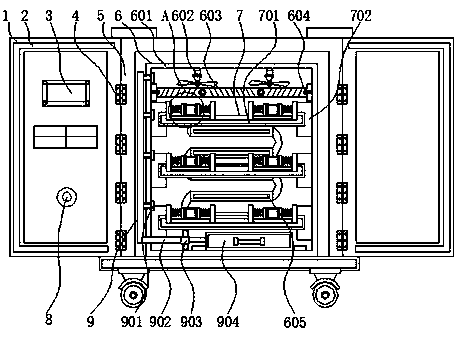

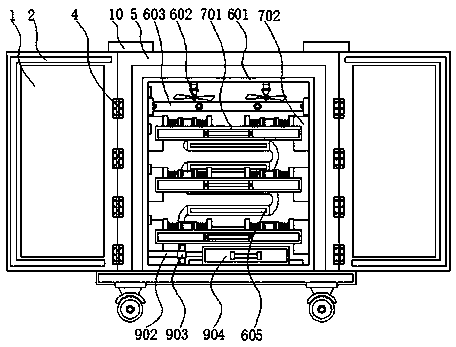

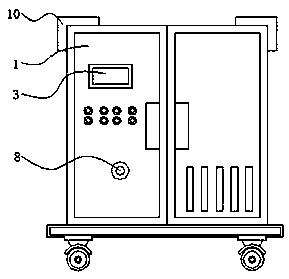

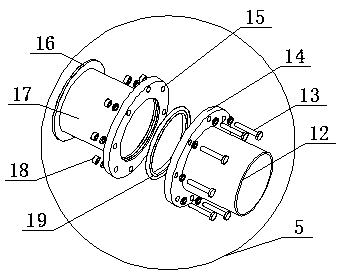

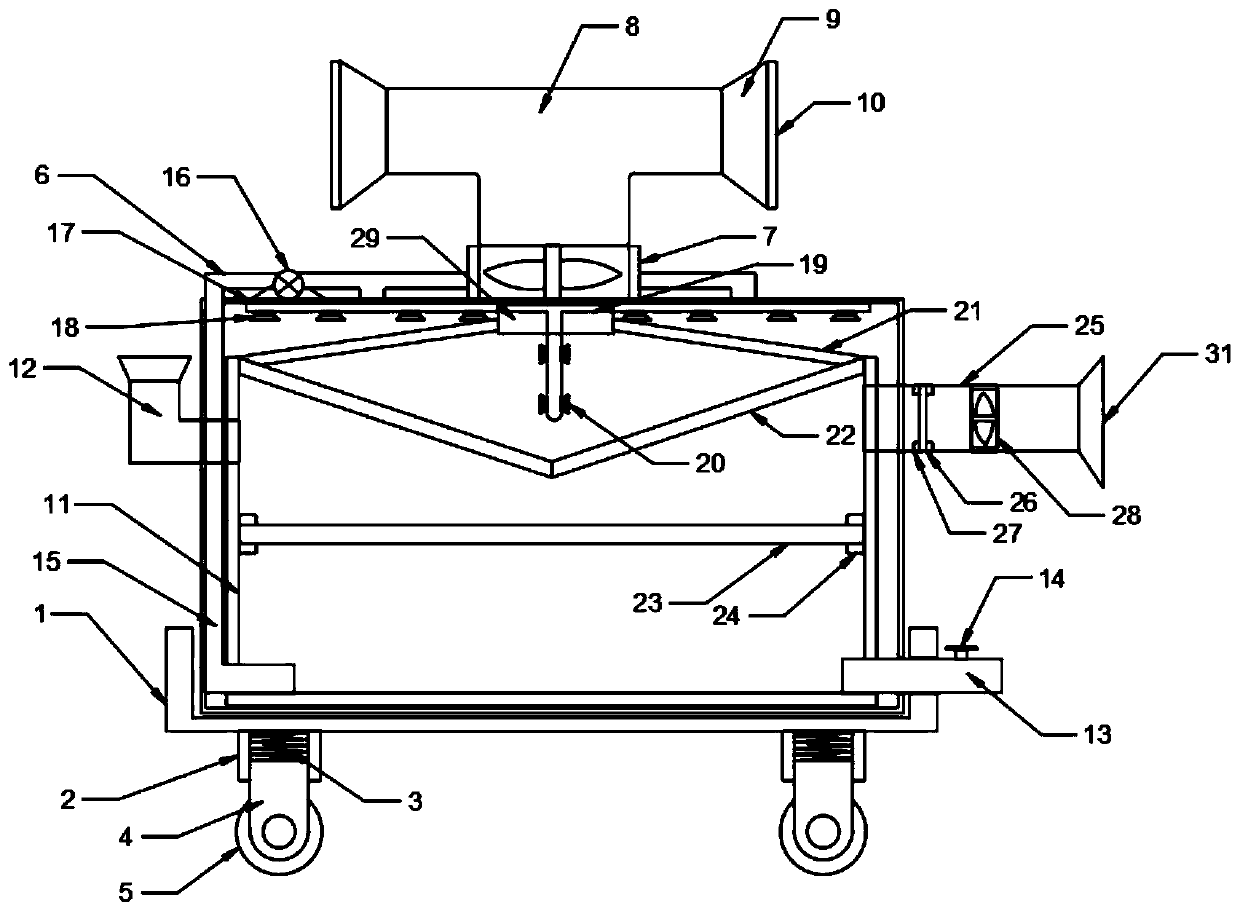

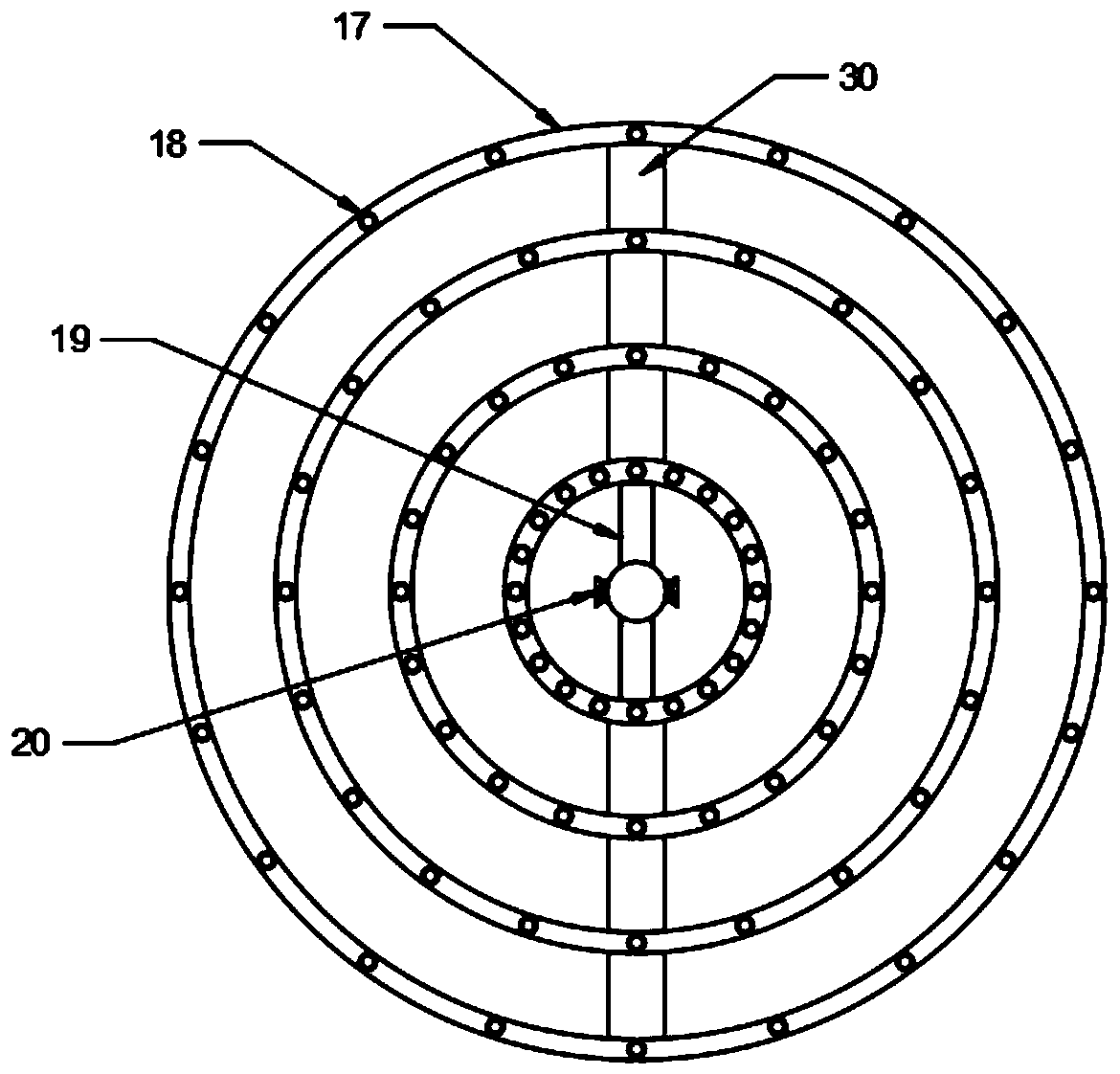

Stepping type air suction and ash removal dust collector

ActiveCN108479216AAvoid affecting the dust removal effectEasy to moveDispersed particle filtrationEngineeringDust collector

The invention belongs to the technical field of environmental protection and resource reuse, and particularly discloses a stepping type air suction and ash removal dust collector. The stepping type air suction and ash removal dust collector comprises a tank body, wherein an air discharging pipe and an air feeding pipe are arranged at the upper end of the tank body; a cloth bag is arranged in the tank body; a partition plate is arranged inside the tank body; the upper end of the partition plate and the inside of the tank body define an air discharging cavity communicated with the air discharging pipe; the lower end of the partition plate and the inner wall of the tank body define an air feeding cavity communicated with the air feeding pipe; the lower end of the air feeding cavity is a collection cavity; a dust collection box is arranged at the lower end of the collection cavity; multiple through holes are formed in the partition plate; the cloth bag is located at the lower end of the partition plate; an opening of the cloth bag is fixedly connected with the lower ends of the through holes; the inside of the cloth bag is communicated with the air discharging cavity; a fixed mesh is arranged between the air feeding cavity and the collection cavity; the lower end of the cloth bag is fixed on the fixed mesh. Compared with the prior art, the dust collector disclosed by the inventioncan quickly and conveniently clean dust during dust removal of the cloth bag, and the ash removal process can be completed in the tank body without a person, so that the environment cannot be polluted; the dust is greatly cleaned, and the device cannot be damaged.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

Bag type dust removal equipment capable of preventing flying dust

InactiveCN111298532AReduce cloggingEasy to collectDispersed particle filtrationEnvironmental engineeringMechanical engineering

The invention relates to bag type dust removal equipment capable of preventing flying dust. The bag type dust removal equipment comprises a main body, an air inlet pipe, an air outlet pipe, an ash discharging hopper, an ash discharging pipe, two dust removing bags and two supporting rods and further comprises a dust raising prevention mechanism and an anti-blocking mechanism. The anti-blocking mechanism comprises a rotating assembly, a transmission assembly and two knocking assemblies. Each knocking assembly comprises a knocking plate, a pull wire and two springs; the dust raising prevention mechanism comprises a filter screen, a supporting shaft, a shaking plate and a hinge rod. According to the bag type dust removal equipment capable of preventing flying dust, the dust removal bags can be knocked off through the anti-blocking mechanism, dust adhering to the dust removal bags is shaken off, the blocking probability of the dust removal bags is reduced, the dust raising prevention function is achieved through the dust raising prevention mechanism, and the situation that the dust removal effect is affected due to secondary blowing of the dust is avoided.

Owner:南京昕知环保科技有限公司

Guitar grinding workshop dust removal system

InactiveCN104669121ASimple designReduce distanceCombination devicesGrinding/polishing safety devicesWater sprayLarge particle

The invention discloses a guitar grinding workshop dust removal system, and belongs to the field of the guitar grinding. The dust collection system comprises a main dust collection pipe which is arranged above a grinding workshop, wherein the main dust collection pipe is connected with a fan, the other end of the main dust collection pipe is connected with a dust collection cover through a connecting pipe and an air valve chamber, the dust collection cover is arranged at a dust source of a grinding machine or a polishing machine; the dust removal system comprises a gravity settling chamber connected to the fan and a dust filter device connected to the gravity settling chamber, a first filter layer, a water spray layer which is arranged above the first filter layer and a second filter layer which is arranged above the water spraying layer are arranged inside the dust filter device, the first filter layer is filled with a dust removal filter matter, the dust removal filter matter is obtained by pyrolysing large-particle saw dust collected in the gravity settling chamber in a high temperature anaerobic environment, the second filter layer is filled with a water removal filter matter, and the water removal filter matter is large-particle saw dust collected in the gravity settling chamber. By adopting the dust collection system and the dust removal system, the dust removal requirement of the guitar grinding workshop can be met.

Owner:淮南市乐森黑马乐器有限公司

Negative pressure internal filter dust-removing equipment

InactiveCN108434882AReduce impactImprove dust removal effectDispersed particle filtrationEngineeringOblique plane

The invention belongs to the technical field of dust removal equipment, and specifically discloses negative pressure internal filter dust-removing equipment. The equipment comprises a box body and anannular supporting frame, the box body is provided with an air inlet and an ash bucket, the upper part of the box body is provided with a perforated plate and an air outlet, the perforated plate is provided with venturi tubes, bag cages are arranged on the venturi tubes, the outer sides of the bag cages are wrapped with bags, a push plate slidably connected with the box body is arranged at the position, located below the perforated plate, of the box body, slide holes for the bags to pass through are formed in the push plate, and a downward ejector rod is arranged on the push plate; a pluralityof supporting rods are arranged in the circumferential direction at the position, located below the air outlet, of the box body, the supporting rods are connected with the supporting frame, the supporting frame is provided with a cylinder rotatably connected with the supporting frame, the upper end face of the cylinder is an oblique plane, the cylinder is circumferentially provided with a plurality of fan blades fixedly connected with the cylinder, and the ejector rod is slidably connected with the oblique plane. The equipment is mainly used for industrial dust removal, and the problem that the production progress is affected when the dust-removing equipment is overhauled is solved.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

Dust removal equipment

InactiveCN108889463AEasy to disassembleEasy to replaceReversed direction vortexCopper wireEngineering

The invention discloses dust removal equipment. The dust removal equipment comprises a dust removal equipment shell, wherein an air inlet pipe is fixedly mounted at a position, close to the top end, of an outer surface of the dust removal equipment shell; an upper end cover is arranged on an outer surface of the top end of the dust removal equipment shell; and an air outlet pipe is fixedly mountedat the center of the outer surface of the top of the upper end cover. The dust removal equipment disclosed by the invention is provided with a No. 1 airbag, a copper wire net and a washing ring, so that the cyclone dust removal equipment can be more conveniently detached and replaced; meanwhile, the cyclone dust removal equipment can be sealed very well and a condition that dust flies out from agap to influence a dust removal effect is prevented; the integrality in the dust removal equipment shell can be more conveniently and rapidly detected, and certain potential safety hazards caused by the fact that the dust is caused and is not found in time are avoided; and the inner part of the cyclone dust removal equipment can be more conveniently washed, a condition that time and efforts are wasted, caused by manual washing, is avoided, and a better application prospect is brought.

Owner:江西柏立松科技环保设备制造有限公司

Multifunctional electric sweeper capable of preventing flying dust in winter

The invention relates to the technical field of multifunctional electric sweepers, and discloses a multifunctional electric sweeper capable of preventing flying dust in winter. The sweeper comprises asweeping shell, a roller is movably mounted in the sweeping shell, and a sweeping brush is fixedly mounted on the outer side of the roller and located in the sweeping shell. The left side of the sweeping shell is fixedly connected with a dust suction hood, the left side of the dust suction hood is fixedly connected with a dust suction pipe, the left side of the dust suction pipe is fixedly connected with a dust removal box, the left side of the dust removal box is fixedly connected with an air suction pipe, and the left side of the air suction pipe is fixedly connected with a draught fan. Through cooperative use of the sweeping brush, the dust suction pipe and the dust removal box, after dust on a road is swept and raised by the sweeping brush, the dust is sucked into the dust suction pipe through the dust suction hood, the raised dust is prevented from polluting the environment, the dust enters the dust removal box and is filtered by the filter plate, and the filtered air is exhausted; and therefore, the effect of cleaning dust on the road is achieved.

Owner:HUNAN UNIV OF TECH

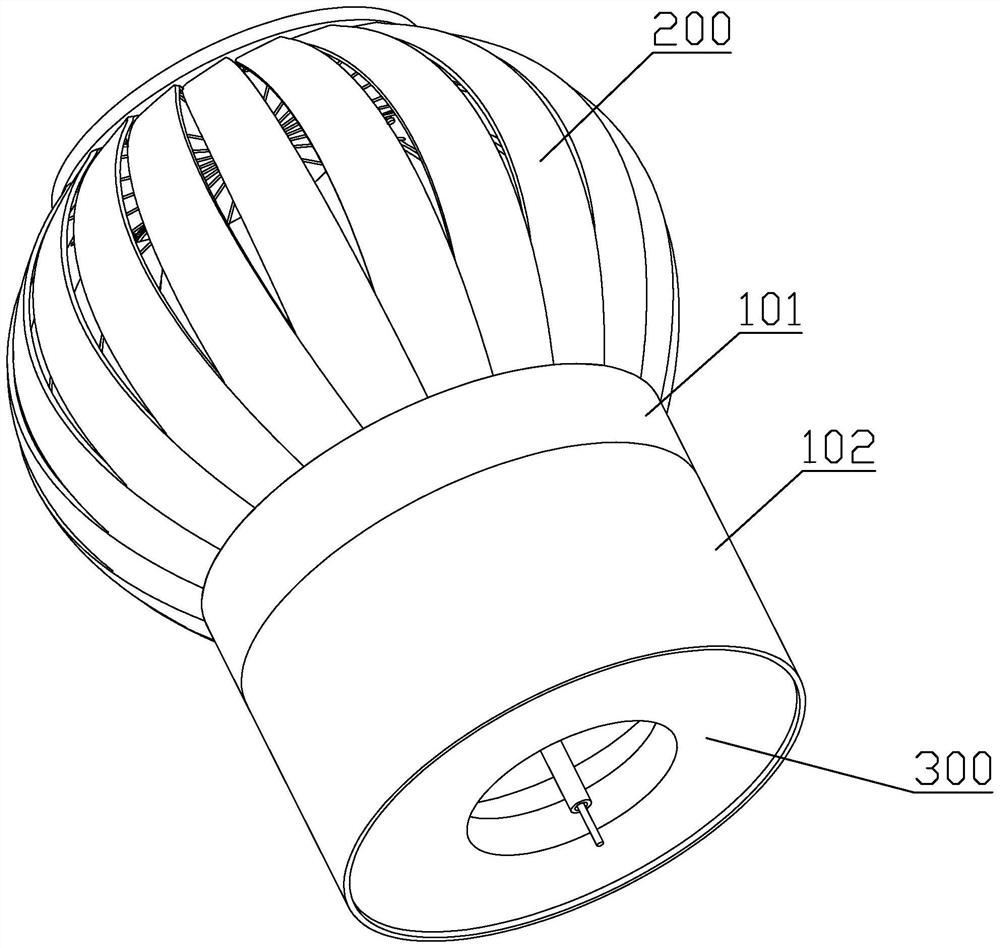

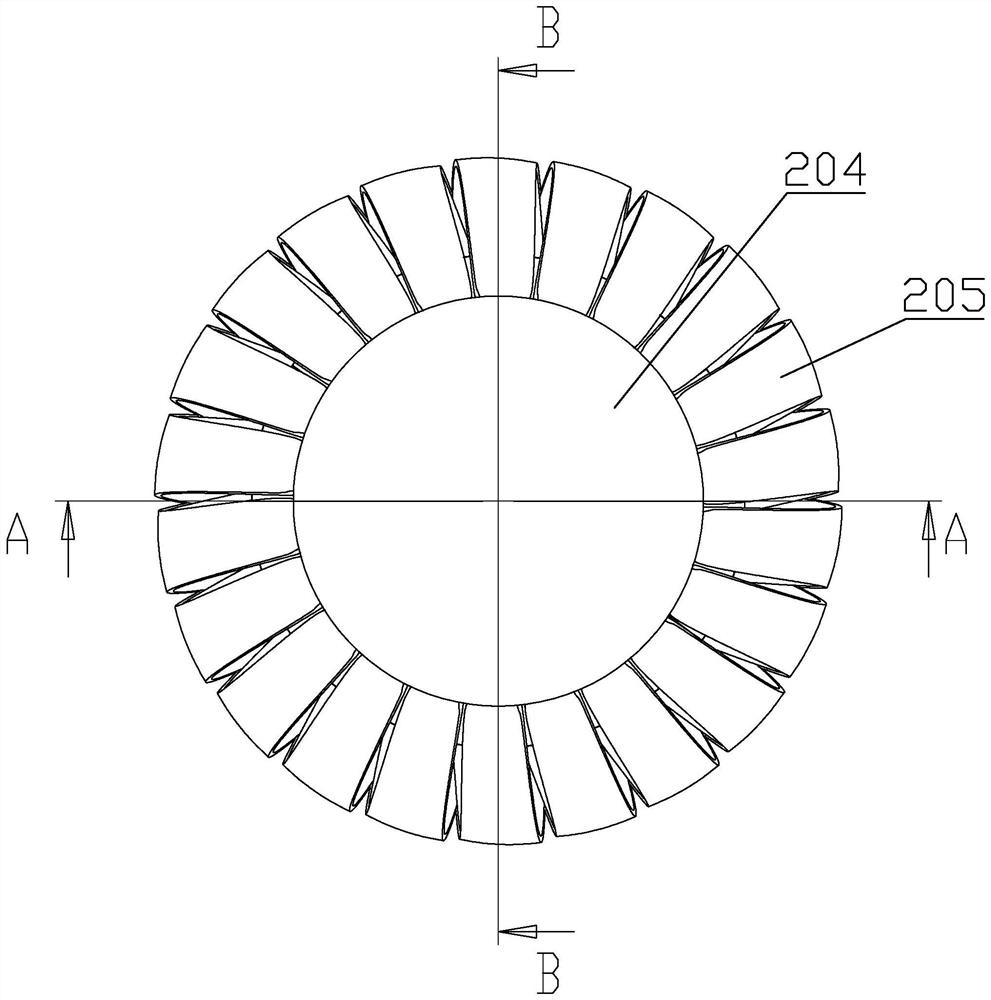

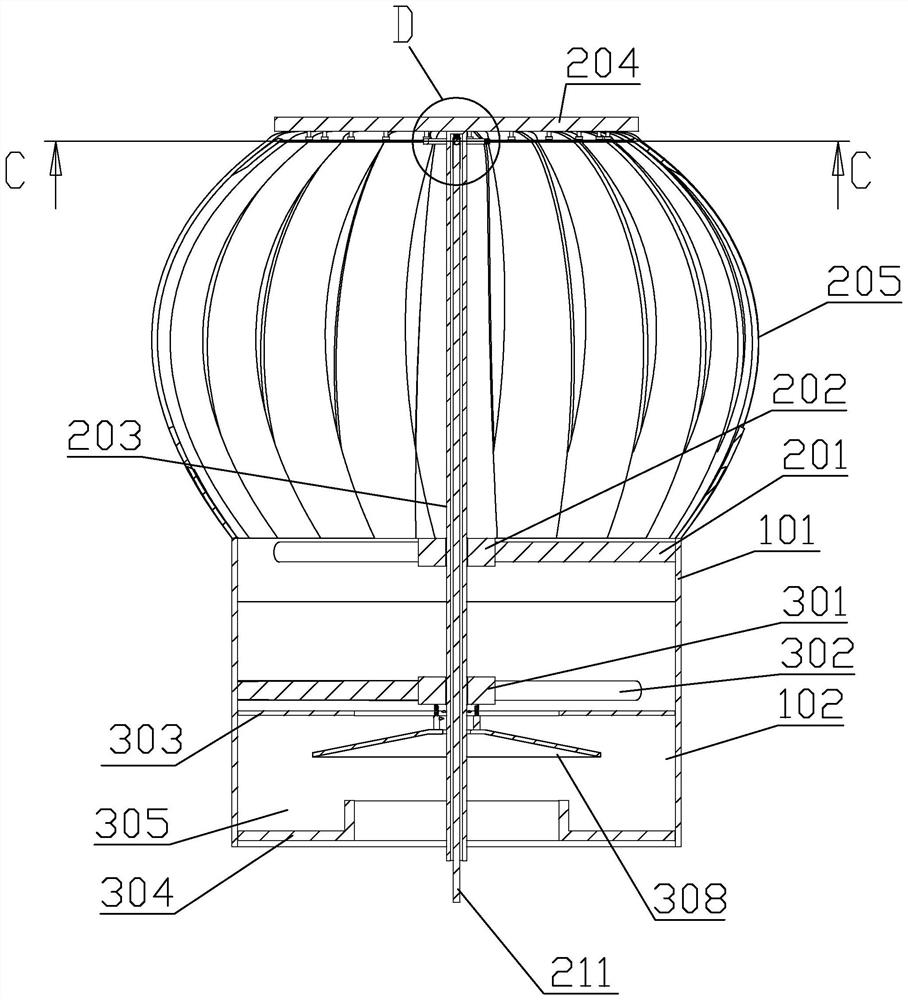

Controllable dedusting environment-friendly unpowered air 1cap

ActiveCN113089942AExtended service lifeAvoid affecting the dust removal effectLighting and heating apparatusDispersed particle separationClassical mechanicsDust control

The invention belongs to the field of ventilation equipment, and discloses a controllable dedusting environment-friendly unpowered air cap. The cap comprises a cylindrical rotating cylinder, the lower end of the rotating cylinder is rotationally connected with an equal-diameter fixed cylinder, a control device for opening and closing the air cap is arranged on the upper side of the rotating cylinder, and a dust removal device for dust removal during ventilation is arranged in the fixed cylinder. A lifting ring and a sliding pin are arranged, so that when the interior of a plant does not need to be ventilated, a pull rod is pulled downwards through external force, the pull rod pulls the lifting ring to move downwards through a lifting rod, the lifting ring pulls the fan blades through a pull rope to drive the sliding pin to slide in an arc-shaped sliding groove, the fan blades rotate, the gap between the adjacent fan blades is closed, the purpose of stopping rotating for ventilation is achieved, and the service life of a bearing is prolonged.

Owner:府谷县昊田煤电冶化有限公司

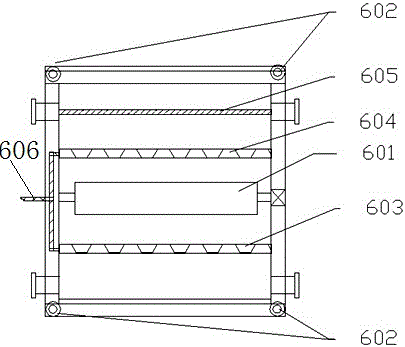

Storing device used for super heat conductivity high polymer materials and capable of reducing water vapor

ActiveCN109775109ASpeed up the flowShorten cooling timeDomestic cooling apparatusLighting and heating apparatusMagnetEngineering

The invention discloses a storing device used for super heat conductivity high polymer materials and capable of reducing water vapor. The device specifically comprises sealing covers, a shell, an adjusting mechanism and a layered fixing mechanism. The shell and the adjusting mechanism are in screw connection. The inner wall surface of one sealing cover is connected with a magnet in a bonding mode.A temperature control port is mounted below a control panel. The outer surfaces of the left and right ends of the shell are in screw connection with hinges correspondingly. The hinges and the corresponding sealing covers are in screw connection. A rear cover is arranged at the rear end of the adjusting mechanism. A dedusting mechanism is arranged below the layered fixing mechanism. The bottom endof the dedusting mechanism and the bottom end of the shell are in screw connection. According to the storing device used for the super heat conductivity high polymer materials and capable of reducingwater vapor, through condensing pipes, the interior of the device is cooled, the super heat conductivity high polymer materials inside the device can be stored easily, the water vapor produced in thematerial storing process is reduced, and the super heat conductivity high polymer materials can be stored in the device easily.

Owner:深圳市旭友科技有限公司

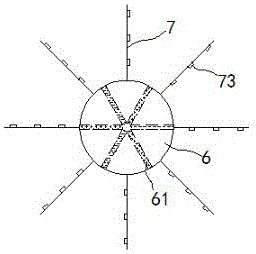

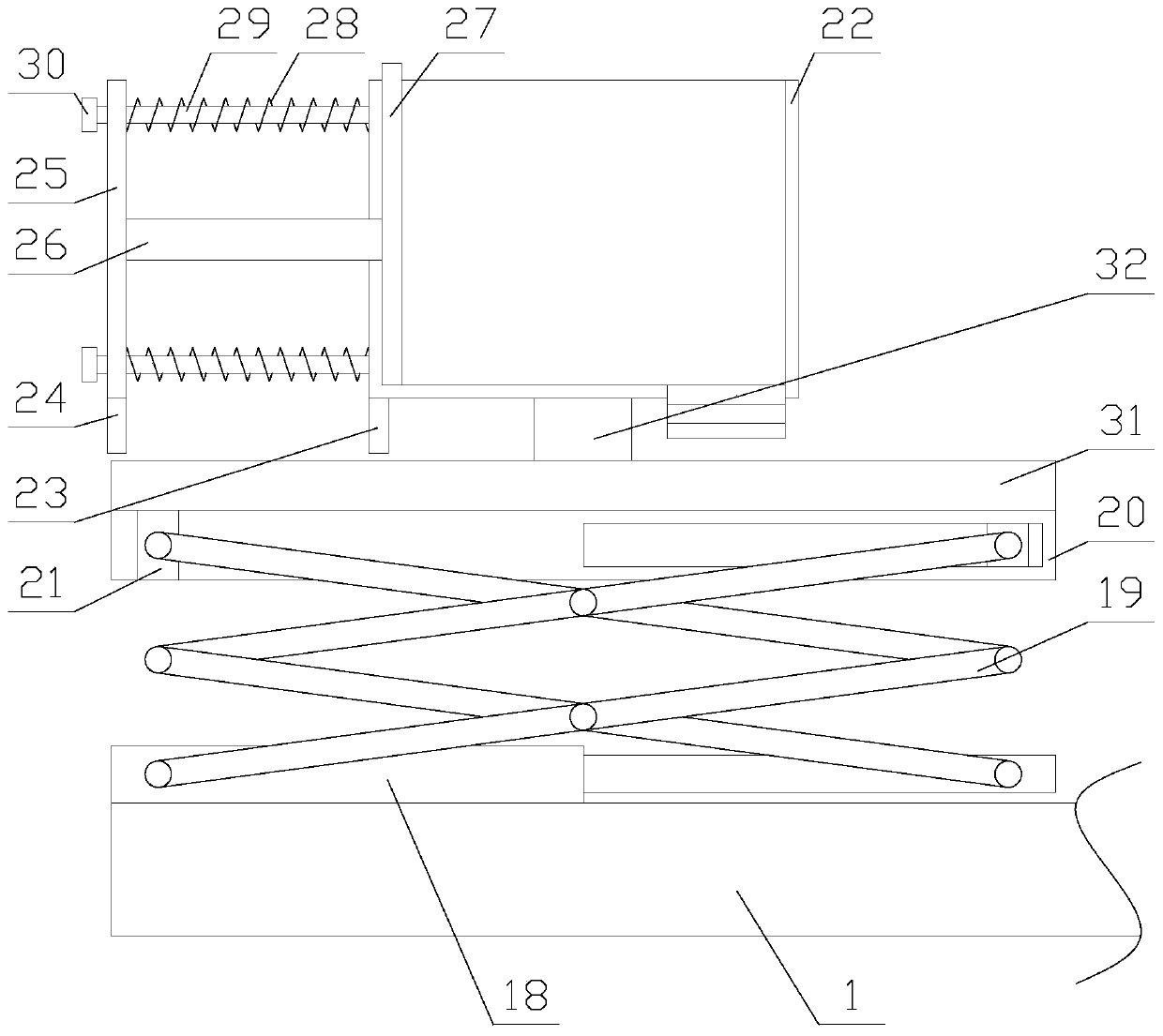

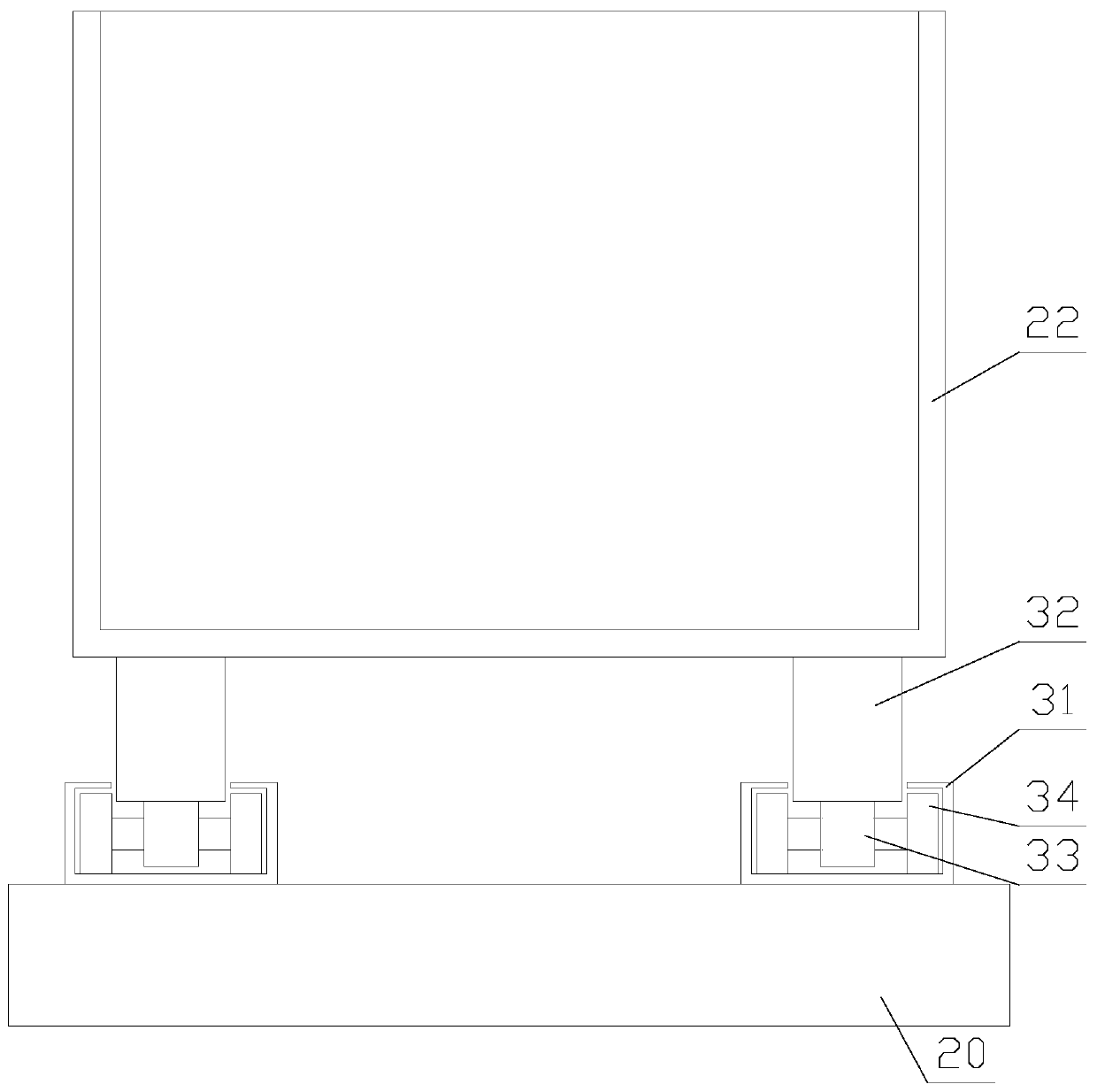

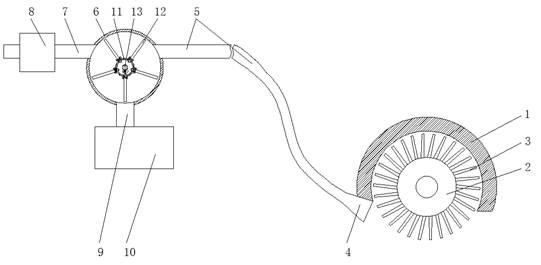

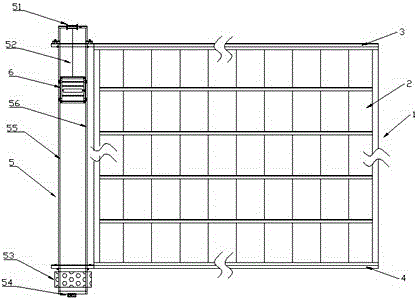

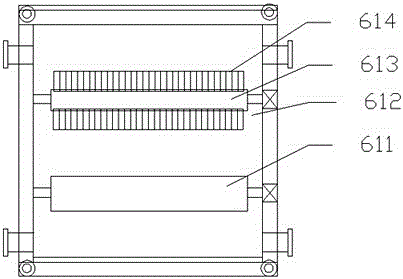

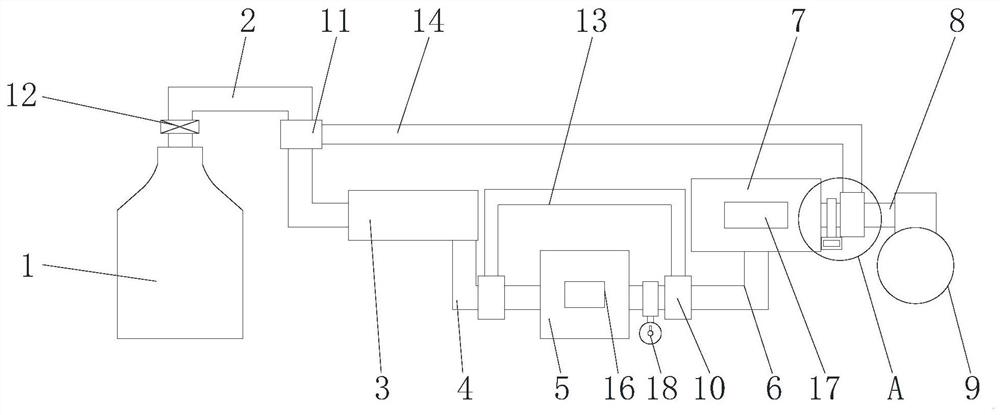

Photovoltaic array module automatic cleaning and dust removal system

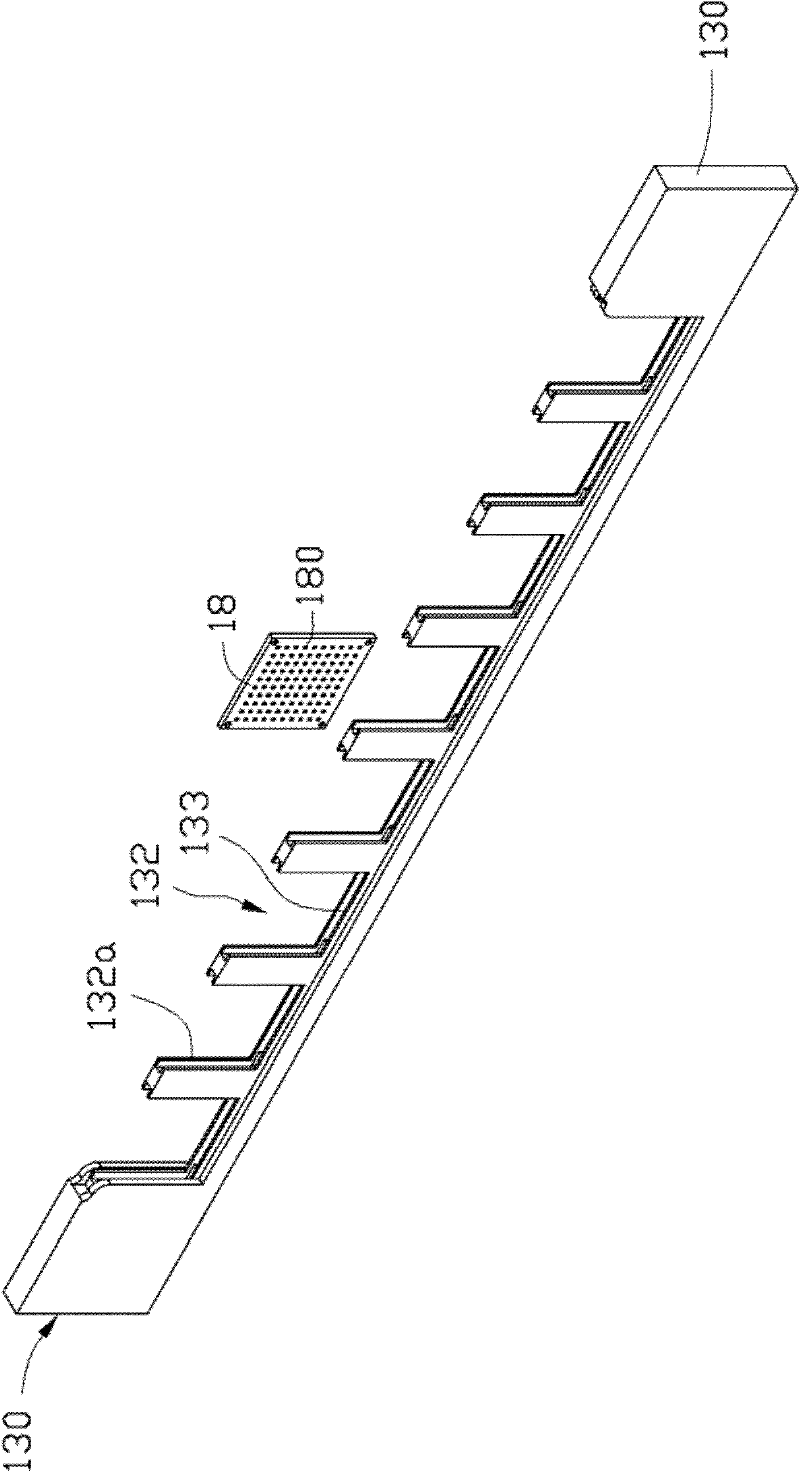

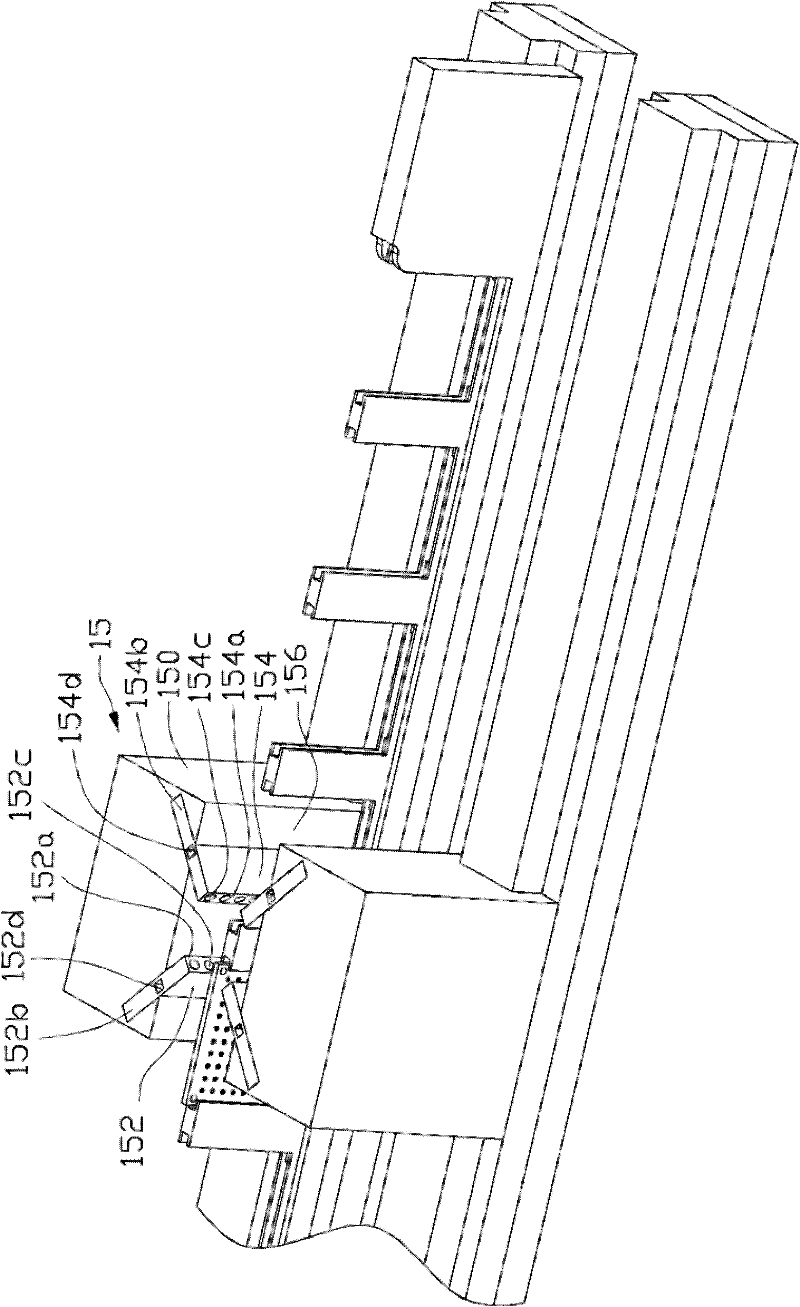

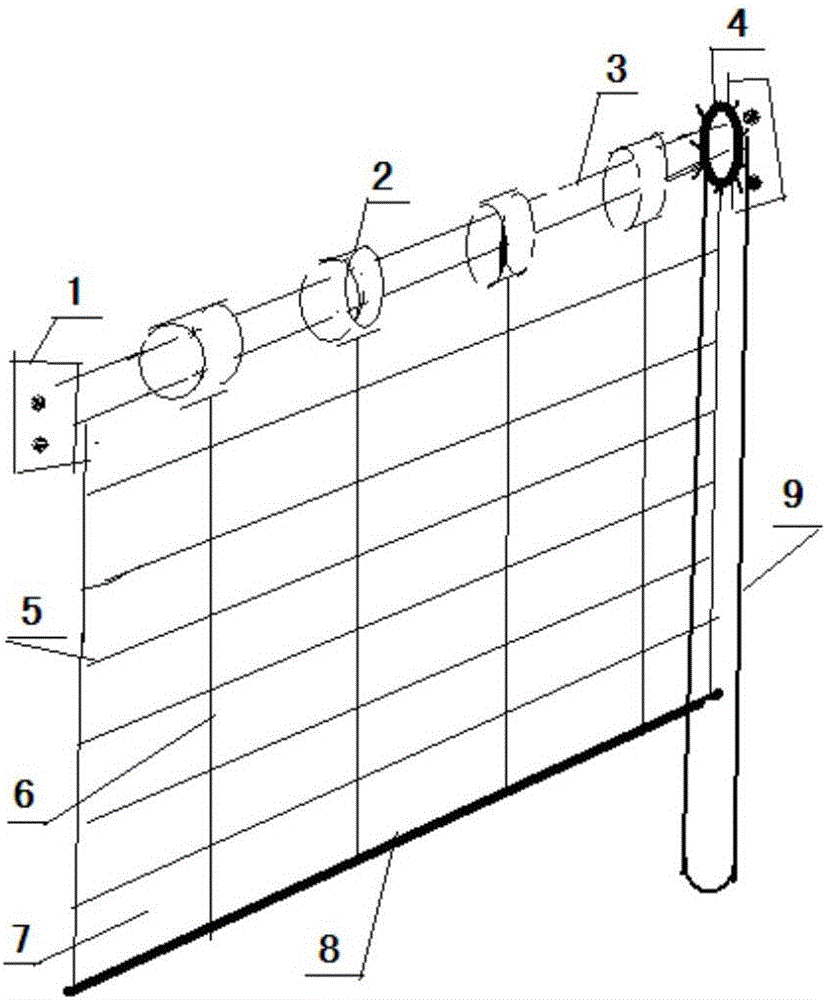

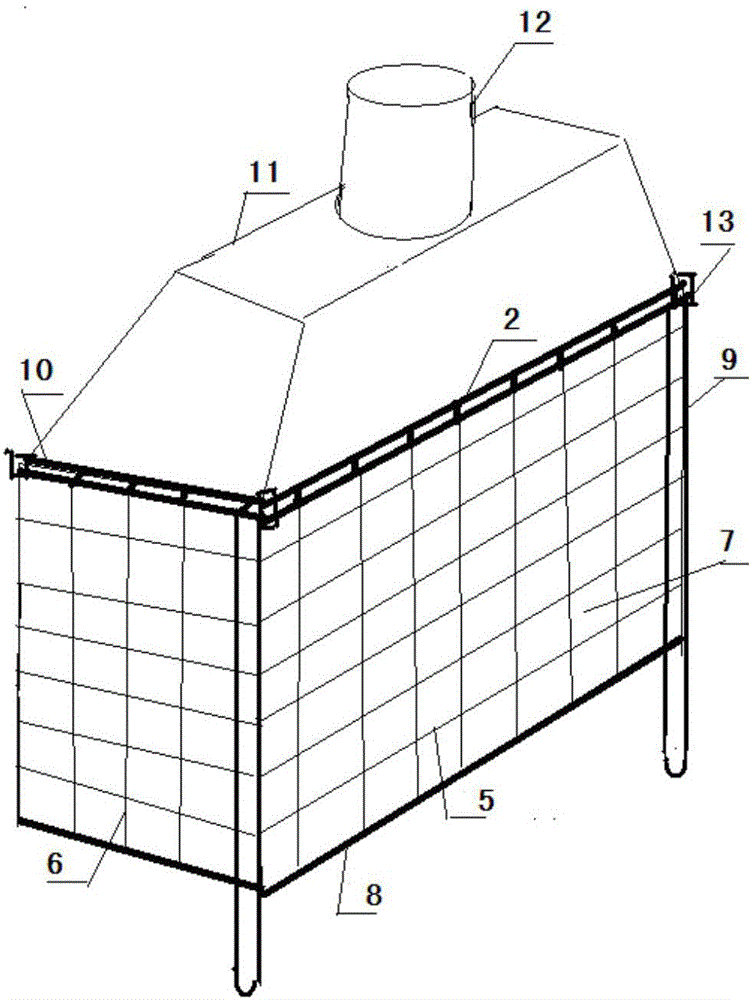

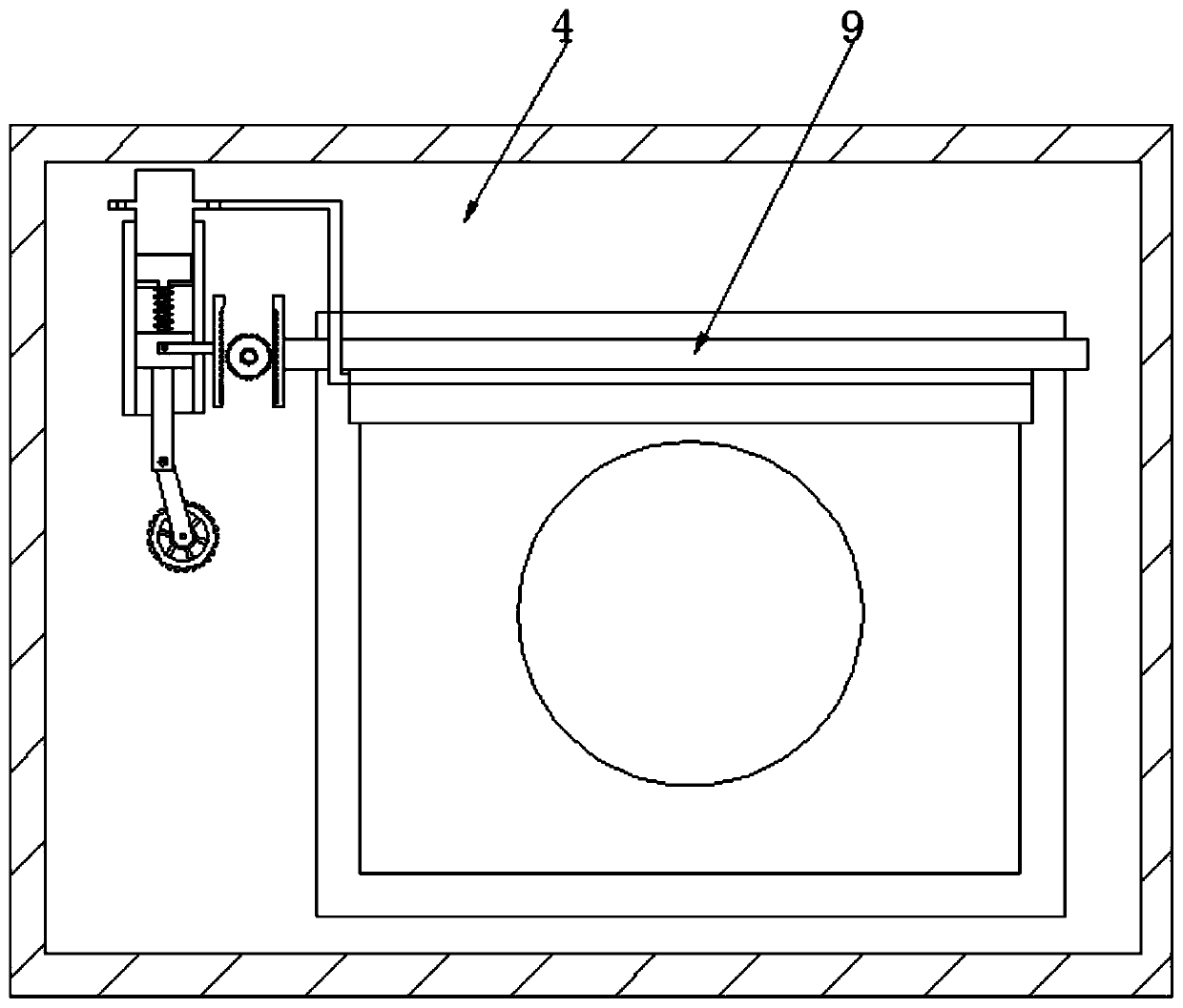

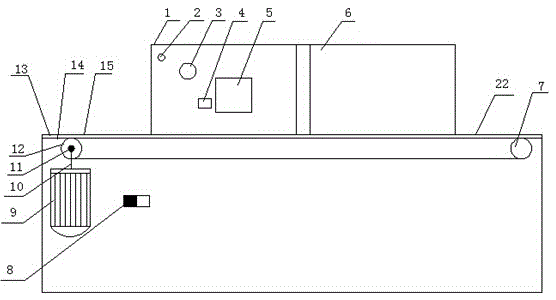

ActiveCN104539233BRealize automatic cleaning and dust removalEasy to replacePhotovoltaicsPhotovoltaic energy generationElectric machineryDrive motor

The invention discloses an automatic cleaning dust removal system for a photovoltaic array component, and belongs to the technical field of photovoltaic power generation. The system is arranged on a photovoltaic array and comprises an upper rail and a lower rail which are arranged at the top part of the photovoltaic array respectively, wherein a moving frame is supported on the upper rail and the lower rail; a power supply cable or a photovoltaic cell plate, a storage battery and a controller are arranged on the moving frame; a driving motor moving leftwards and rightwards is also arranged on the moving frame; a winding wheel is arranged at the upper end of the moving frame and is controlled by a deploying and retracting motor; a tensile cable is wound on the winding wheel, and an end part of the tensile cable is connected with a cleaning walking trolley; a cleaning dust removal device is arranged on the cleaning walking trolley; and a sensor is arranged on the cleaning walking trolley, a sensor is arranged on the moving frame, and the sensors are in signal connection with the controller. The automatic cleaning dust removal system disclosed by the invention can be used for conveniently realizing automatic cleaning dust removal of the photovoltaic array.

Owner:ANYANG HIGH NEW DISTRICT PRODIVITY PROMOTION CENT

Vortex negative-pressure dust removal device for down-the-hole drill

PendingCN110841413AAvoid affecting the dust removal effectAchieve fixationCombination devicesConstructionsStructural engineeringDust abatement

The invention discloses a vortex negative-pressure dust removal device for a down-the-hole drill. The vortex negative-pressure dust removal device comprises a device main body, a control panel and a concave plate, wherein a dust receiving box is slidably arranged at the bottom end of the interior of the device main body; the concave plate is arranged in the middle position of the interior of the device main body; two sides of the concave plate are respectively and slidably connected with a sliding block; a second screw rod is movably connected with and arranged at the middle position of the interior of a cover plate; a second screw sleeve is movably connected with and arranged at the exterior of the second screw rod; two sides of the second screw sleeve are respectively and movably connected with a connecting rod; and a pull rod is fixedly connected with and arranged at one side of each connecting rod. According to the invention, the concave plate is arranged in the middle position ofthe interior of the device main body; dust and gravels sucked into the device main body by a fan fall onto the concave plate due to gravity; when the gravity reaches a certain value, the concave plateslides downwards on sliding grooves through the sliding blocks; a through hole located at the bottom end of the concave plate is not in contact with a connecting column; the dust and the gravels thenenter the dust receiving box; and the concave plate then returns to an original position under the elastic force of third springs.

Owner:THE SUNS WORLD JIANGSU OIL & GAS ENG & TECH

Dust-removal system cleaning device

InactiveCN107511373AAvoid affecting the dust removal effectGuaranteed working environmentHollow article cleaningPush pullEngineering

The present invention is mainly used in the field of dust removal system cleaning and modification, and particularly relates to a dust removal system cleaning device, which includes a dust removal pipe, a dust removal fan is arranged on the top of the dust removal pipe, a cleaning window is arranged on the dust removal pipe, and the bottom of the cleaning window is connected to the dust removal pipe through a hinge for corresponding cleaning. The top of the window is provided with an external baffle on the dust removal pipe, a magnet is provided between the external baffle and the cleaning window, a push-pull hole is provided on the cleaning window, a cleaning rod is installed on one side of the dust removal pipe, the cleaning rod is installed on a bracket, and the bracket is installed on the dust removal pipe on the outer wall. After using this equipment, the agglomeration of the dust collector pipeline is prevented from affecting the dust removal effect, and the working environment is guaranteed. Improved cleaning efficiency.

Owner:SHANDONG HUALIAN MINING

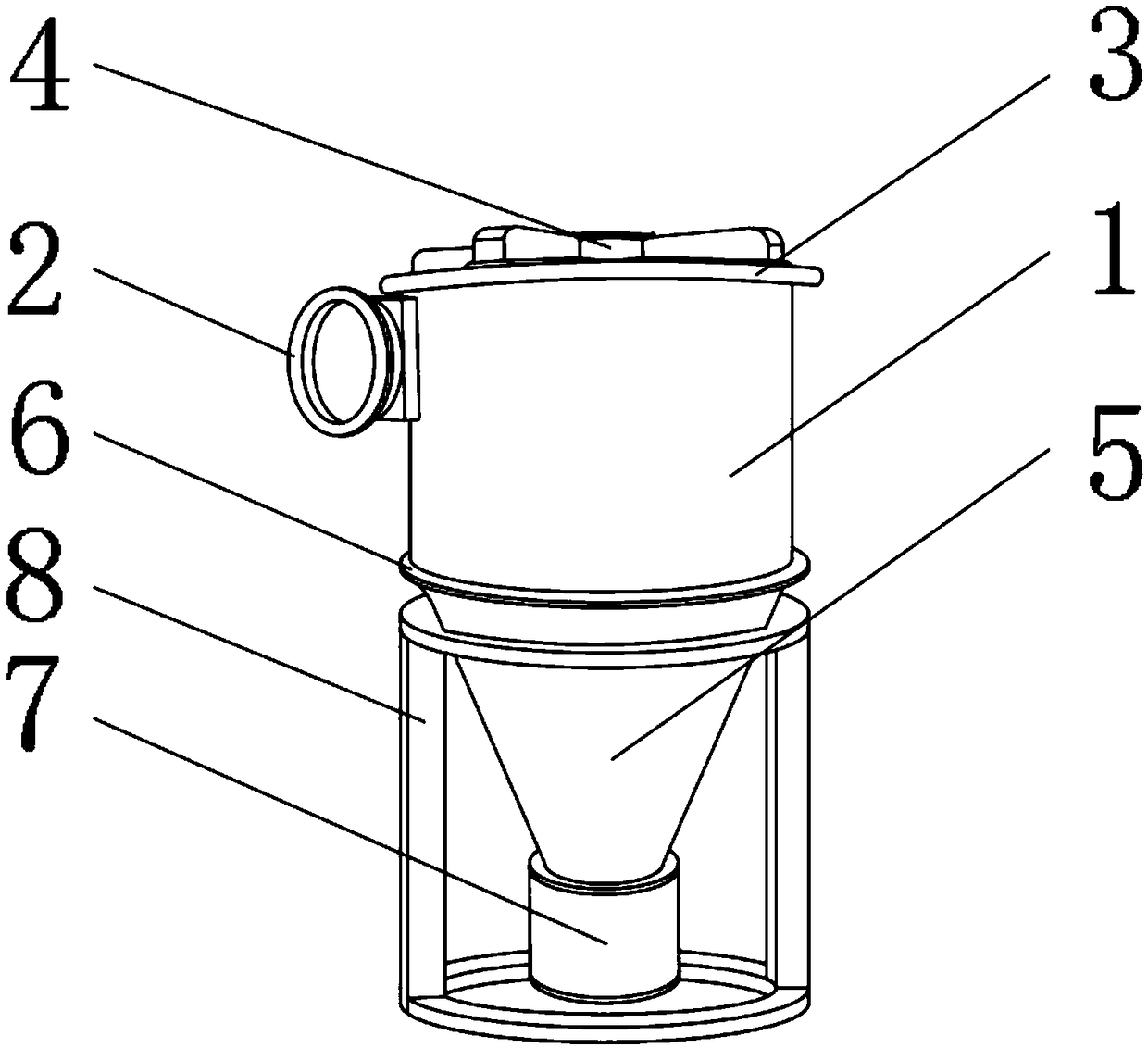

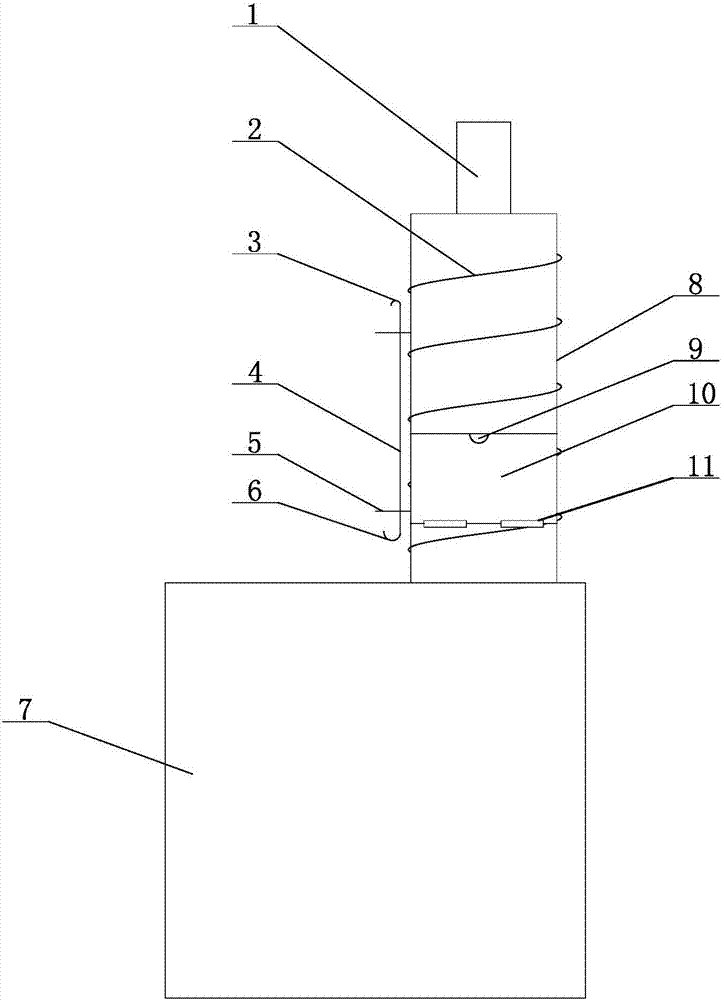

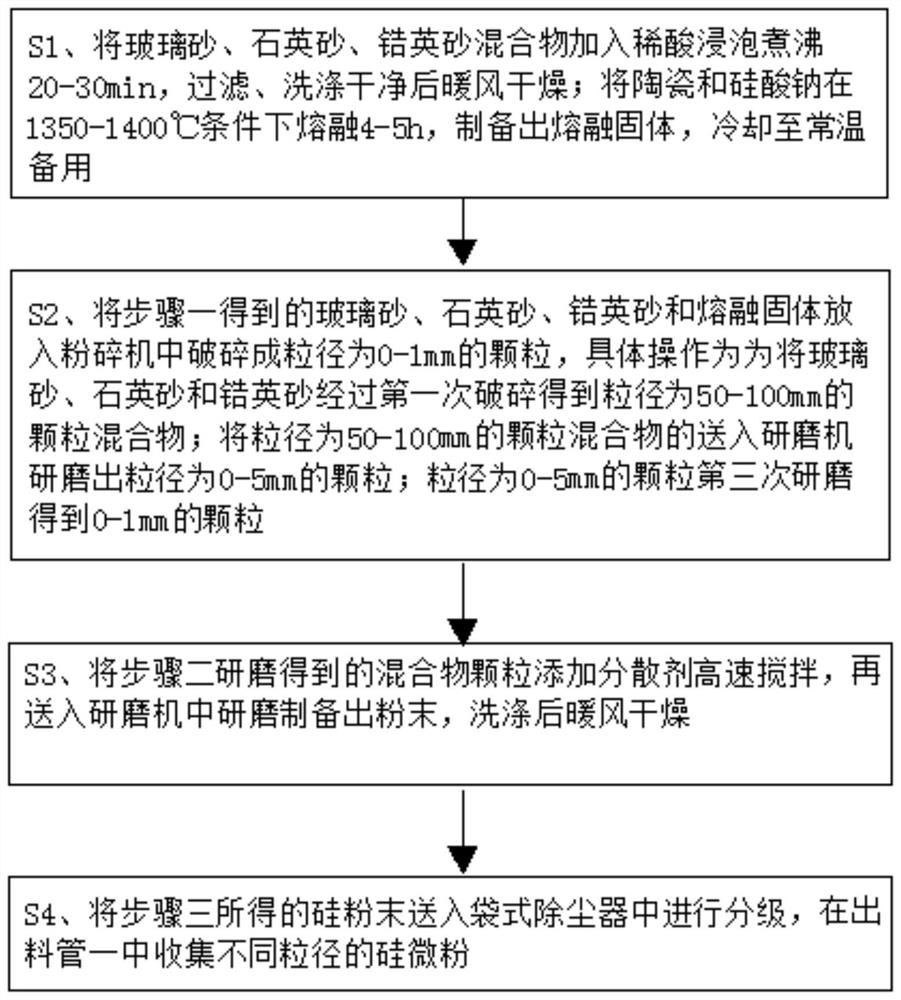

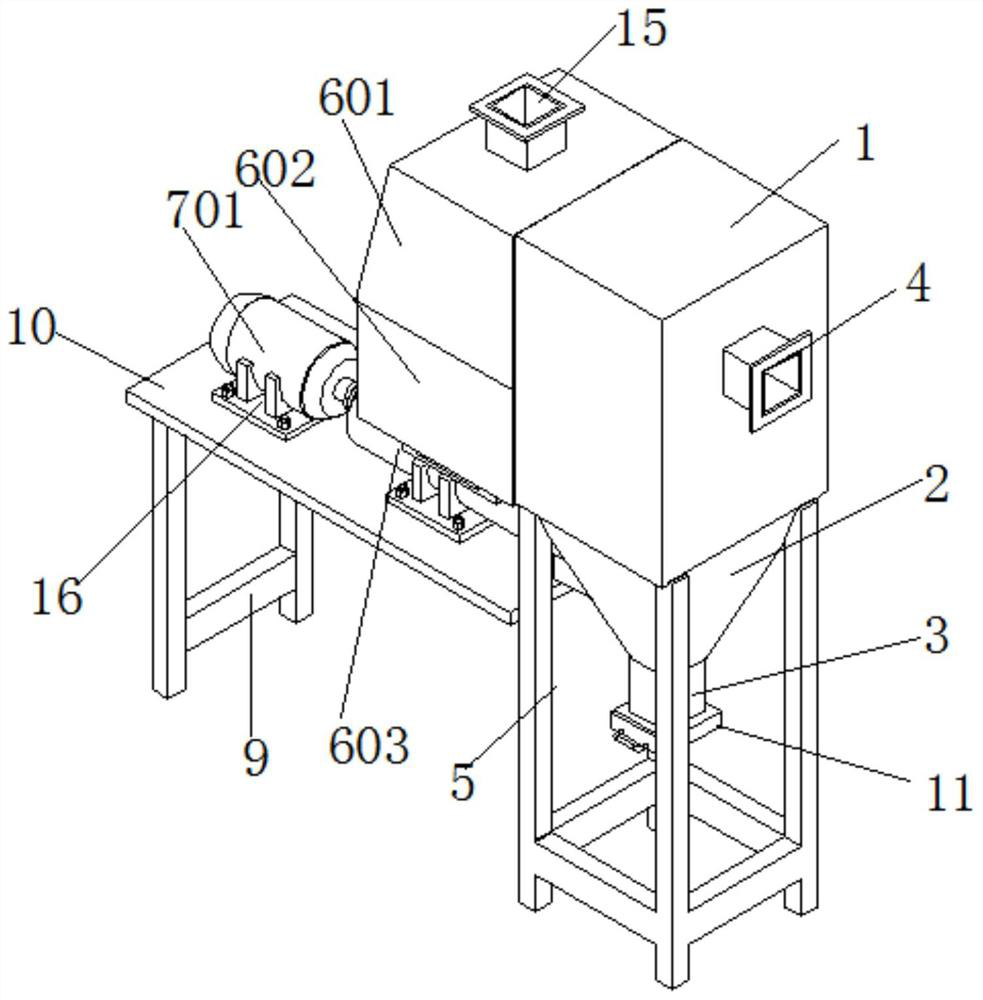

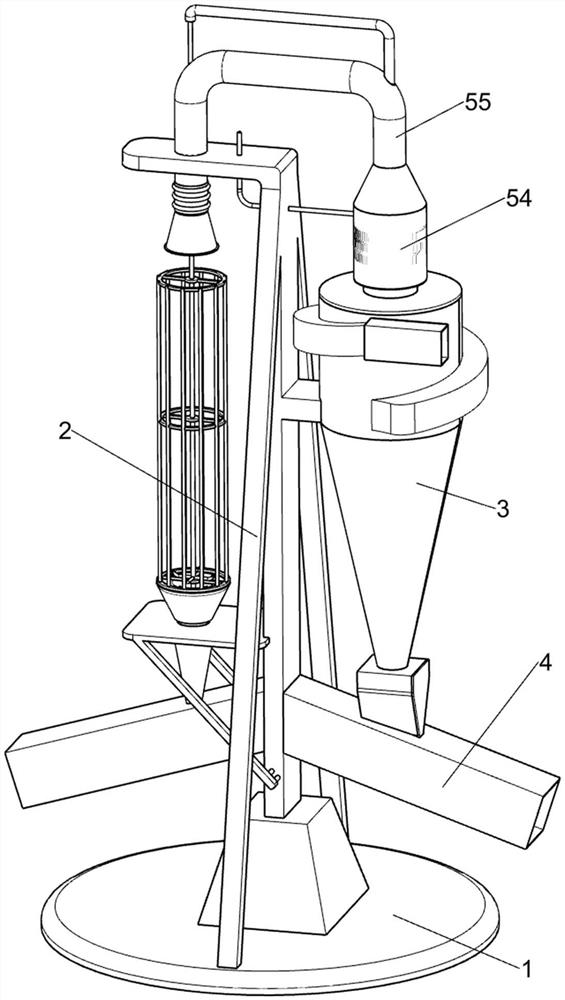

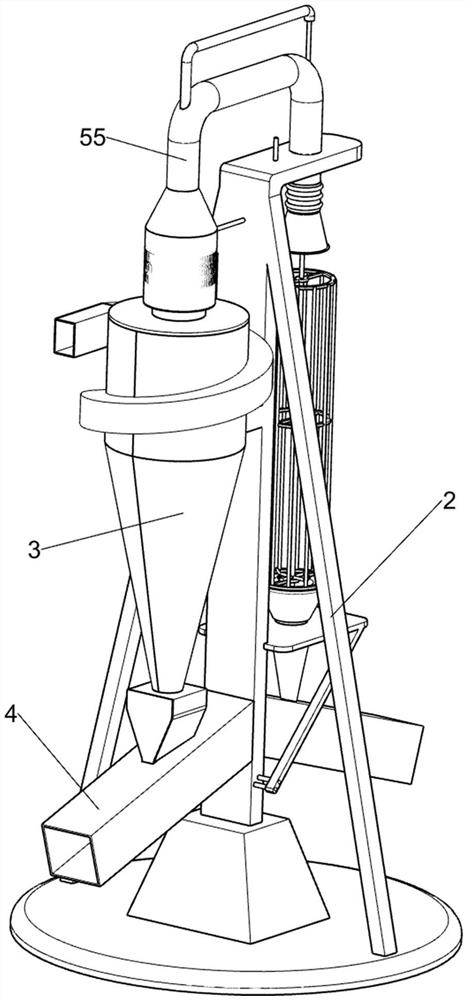

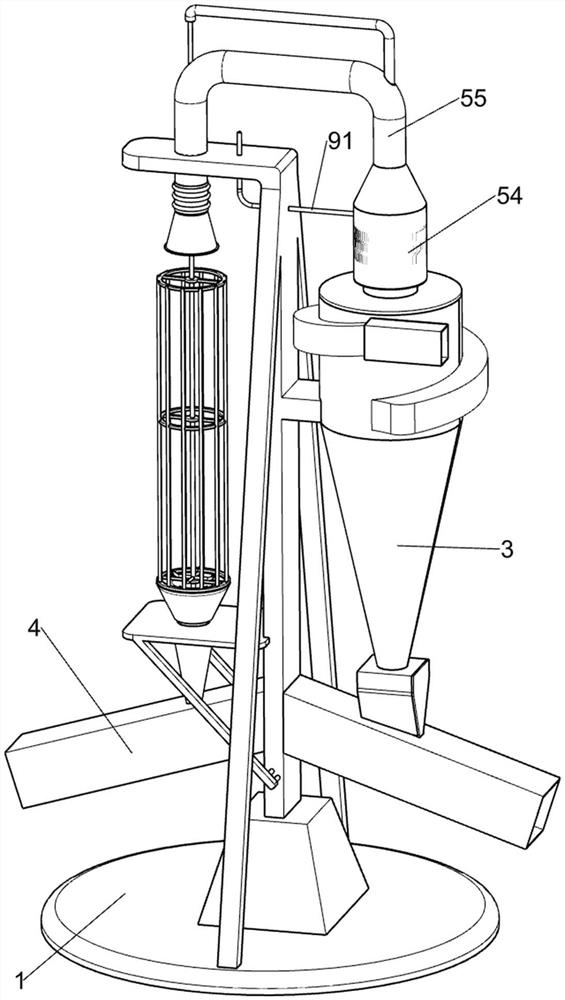

Preparation method of soft composite silica powder

ActiveCN112624727AEasy to disassembleEasy maintenanceVortex flow apparatusDispersed particle separationPhysical chemistrySodium silicate

The invention provides soft composite silica powder which is prepared from the following components in parts by mass: 25-30 parts of glass sand, 15-20 parts of quartz sand, 10-15 parts of zircon sand, 12-18 parts of ceramic and 5-10 parts of sodium silicate. The preparation method of the soft composite silica powder is characterized by comprising the following steps: adding a mixture of glass sand, quartz sand and zircon sand into dilute acid, soaking and boiling for 20-30 minutes, filtering, washing, and drying with warm air; melting ceramic and sodium silicate at 1350-1400 DEG C for 4-5 hours to prepare a molten solid, and cooling to the room temperature for later use.

Owner:LIANYUNGANG MIAOJING SILICON MATERIAL

Bag type dust removal device for flue gas treatment

PendingCN113908637APlay a role in separationEfficient separationCombination devicesDispersed particle filtrationFlue gasDust control

The invention relates to the field of flue gas treatment, in particular to a bag type dust removal device for flue gas treatment. The bag type dust removal device comprises a chassis, a fixed support, a preliminary filter cartridge, blanking frames, a preliminary filter assembly and the like, wherein the fixed support is fixedly mounted on the top surface of the chassis, the preliminary filter cartridge is fixedly mounted on the right side of the middle of the fixed support, the blanking frames are symmetrically arranged below the fixed support, and the preliminary filter assembly is arranged on the preliminary filter cartridge. Under the action of the preliminary filter cartridge, airflow generated by flue gas can do variable circular motion in the preliminary filter cartridge, so the flue gas can generate centrifugal force during rotation to throw solid particles to the inner wall of the preliminary filter cartridge; and the thrown solid particles can slide down along the inner wall of the preliminary filter cartridge, so the effect of separating the flue gas from the solid particles is achieved.

Owner:徐阁阁

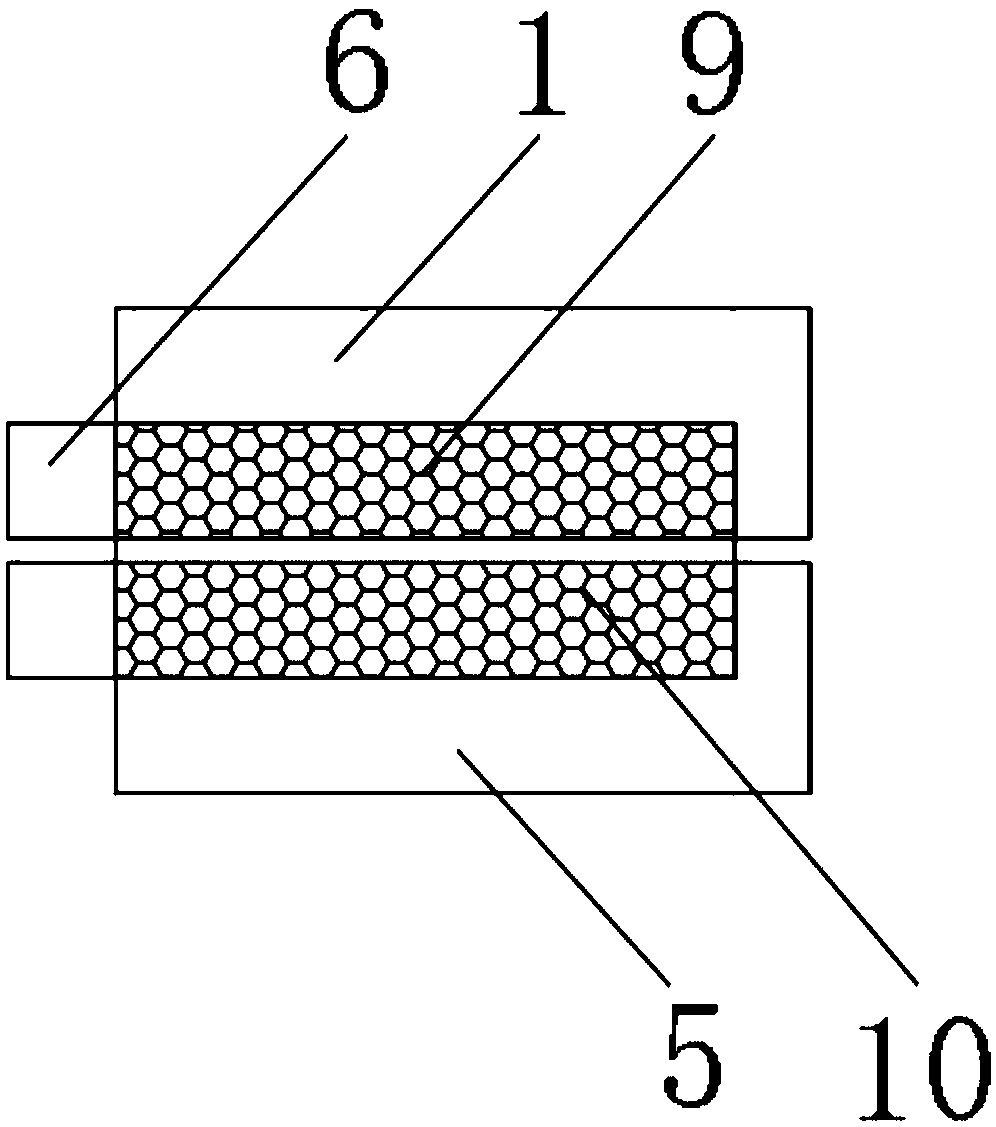

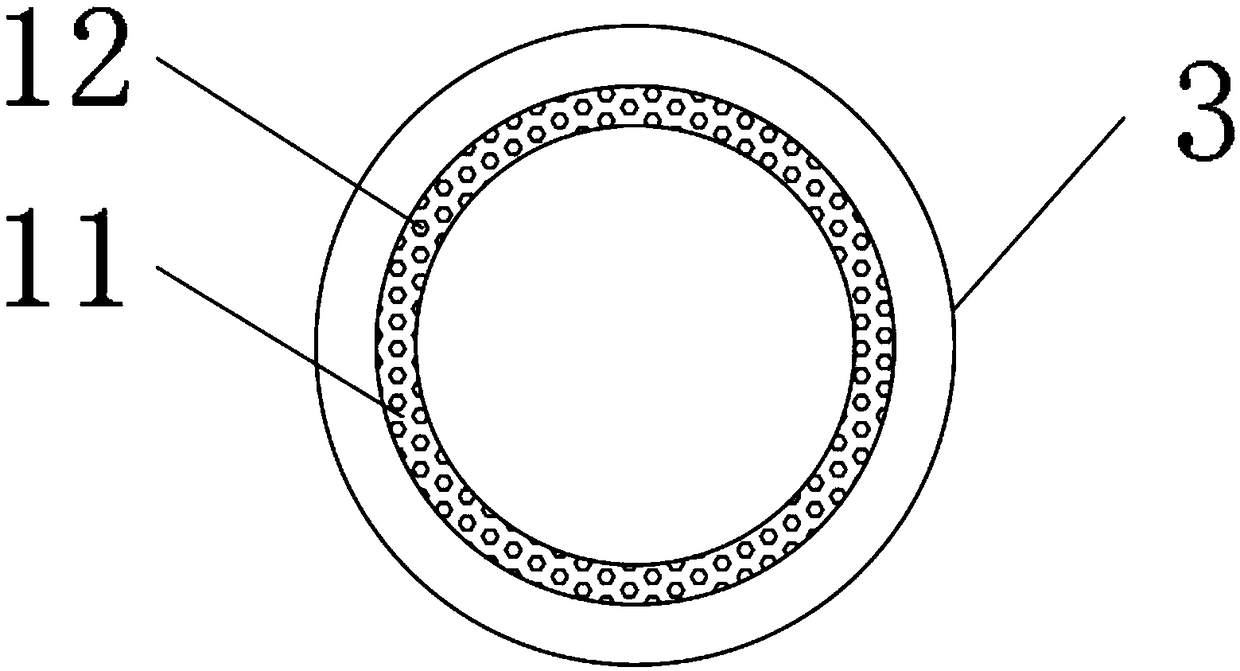

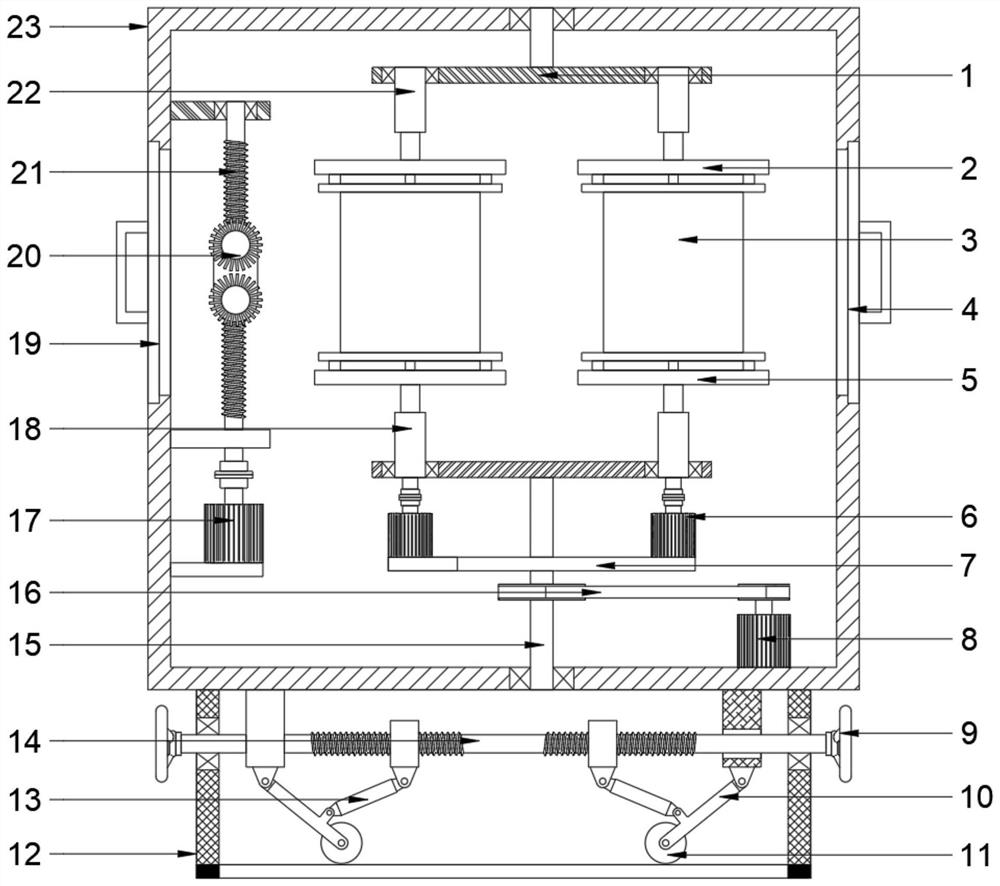

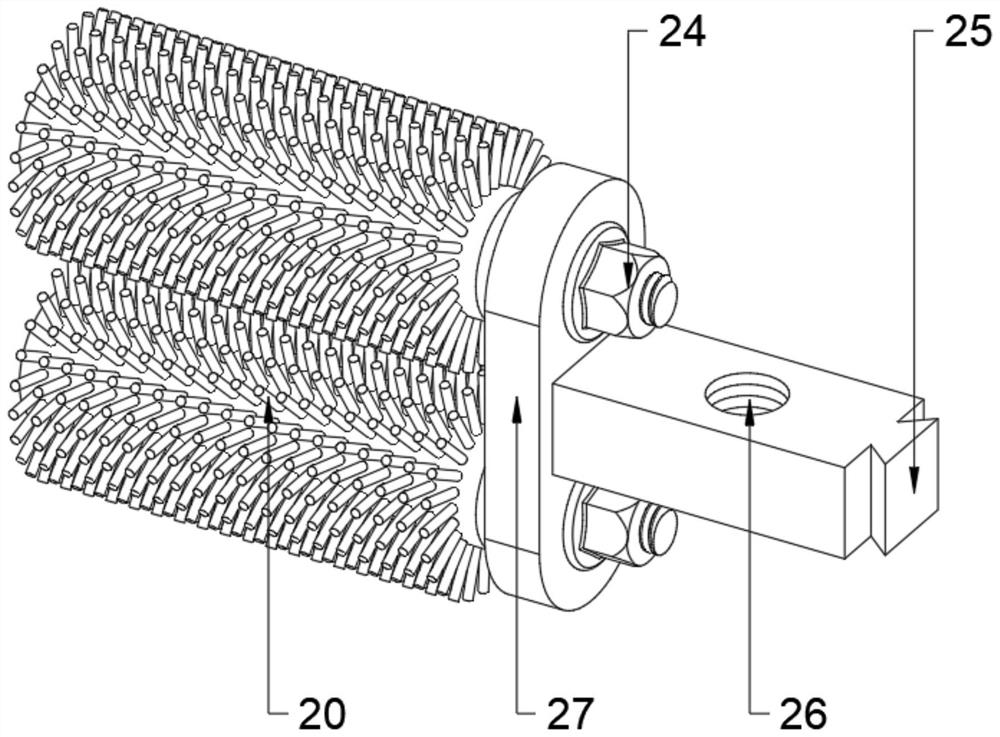

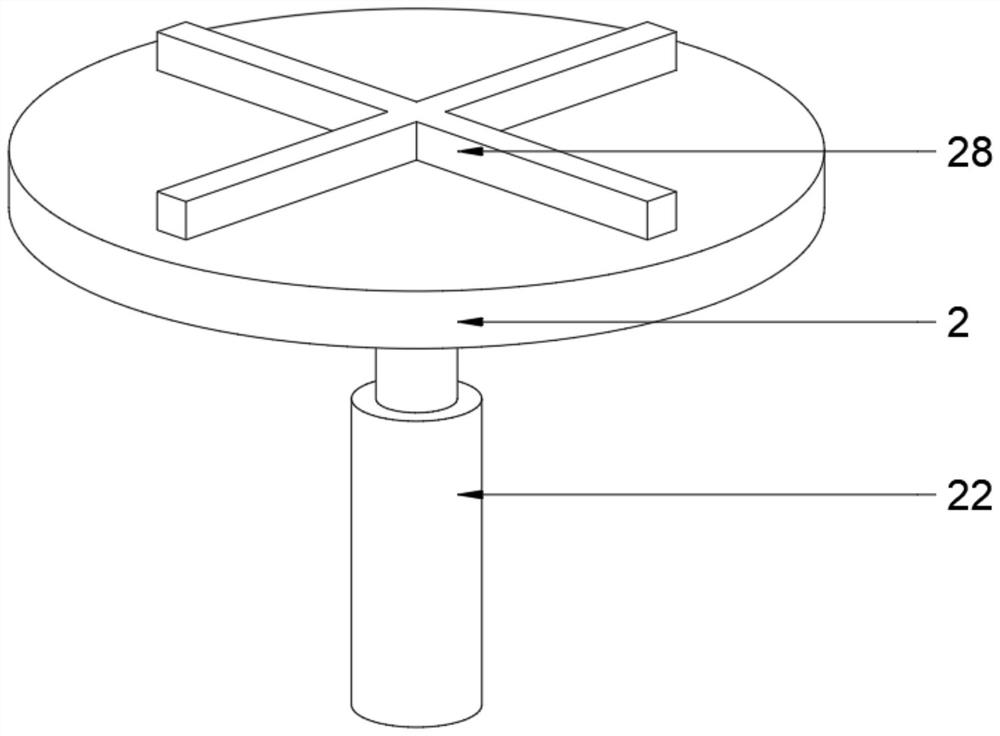

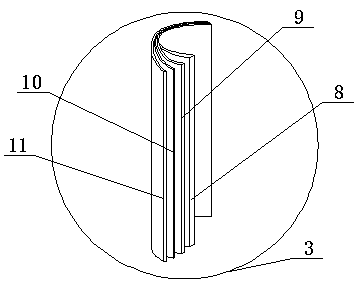

Water pumping pipe belt winding equipment for water conservancy project

InactiveCN112158662AAvoid deflectionAvoid affecting the dust removal effectFilament handlingDust controlElectric machinery

The invention discloses water pumping pipe belt winding equipment for a water conservancy project. The equipment comprises a box body and a winding assembly installed in the box body, the winding assembly comprises a winding device and a dust removal device, and the winding device comprises a winding sleeve, a clamping mechanism and a driving mechanism; the clamping mechanism comprises an upper clamping mechanism and a lower clamping mechanism which are rotationally mounted in the box body through a linkage bracket and a transmission bracket respectively; and the dust removal device comprisesdust removal roller brushes, a dust removal mounting plate and a moving mechanism. According to the equipment, the dust removal roller brushes are adopted and matched with a dust removal lead screw and a dust removal motor, so that a water pumping pipe belt located between the two sets of dust removal roller brushes is cleanly and tidily arranged on the winding sleeve, and the winding efficiency is improved; a limiting sliding block is matched with a limiting sliding groove to prevent the dust removal roller brushes from swinging left and right to influence the dust removal effect; and an upper clamping plate and a lower clamping plate with clamping blocks are adopted and matched with an upper telescopic rod, a lower telescopic rod and the winding sleeve with clamping grooves, and clampingand fixing of the winding sleeve are achieved.

Owner:苏蒲燕

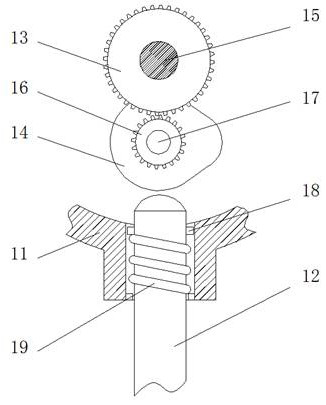

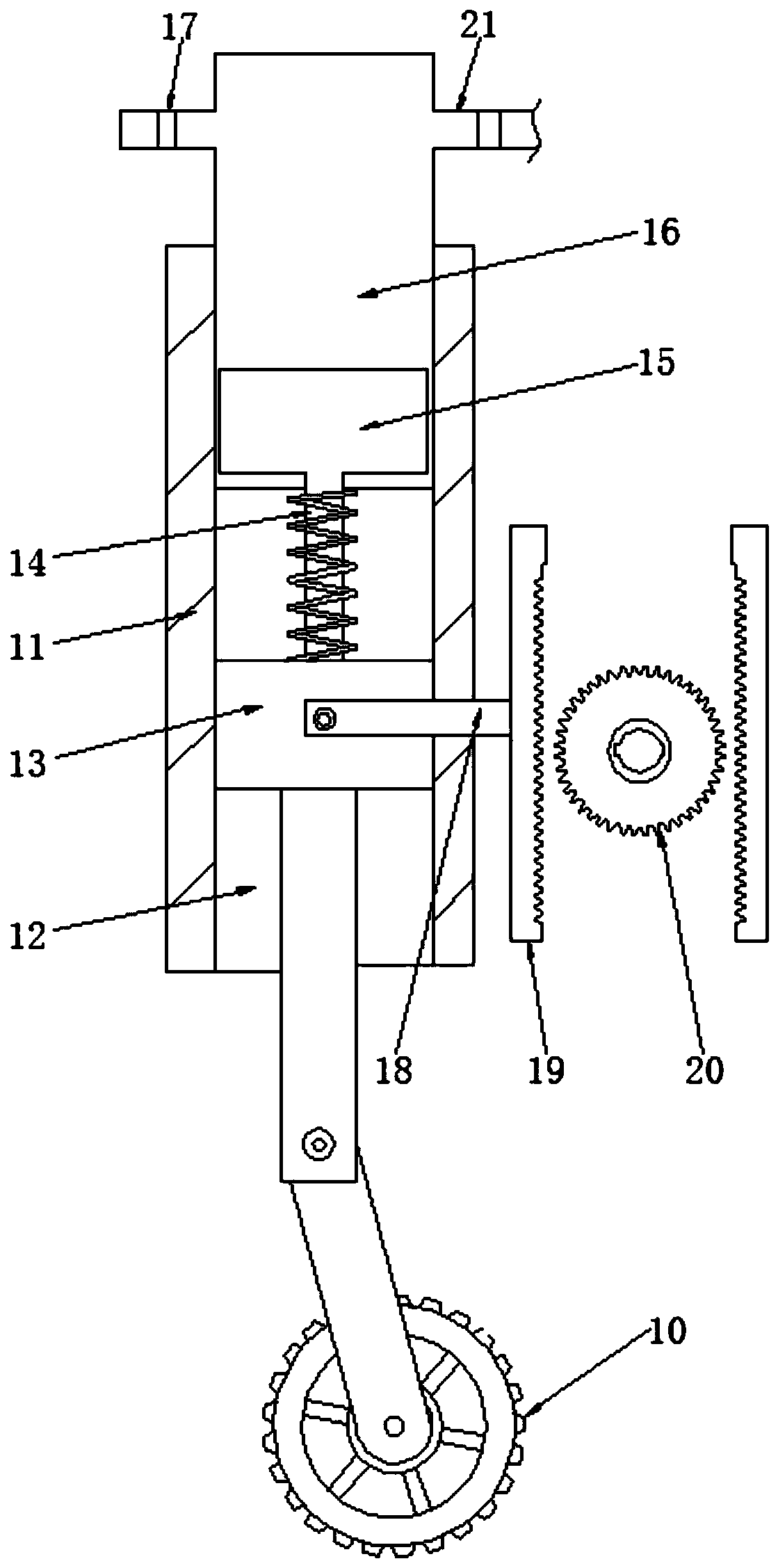

Monitoring camera dust removal device

InactiveCN110899164AAffect clarityAvoid affecting the dust removal effectDirt cleaningCleaning using toolsReciprocating motionGear wheel

The invention relates to the technical field of monitoring, and further discloses a monitoring camera dust removal device that includes a dust cover; a connecting column is fixedly connected to the interior of the dust cover; the bottom of the connecting column is movably connected with a camera; an output shaft of a motor is movably connected with a first gear; the first gear rotates, and a sliding block reciprocates up and down in a sliding groove to drive a connecting strip to reciprocate up and down; synchronous movement of racks are realized, two racks are arranged, the rack on the rightside also moves to enable a connecting plate to synchronously move; therefore, a dedusting scraper is driven to reciprocate up and down to remove dusts attached to a transparent glass; a sucker pipe is arranged above the dedusting scraper, and movably connected with a suction layer port; the sliding block moves to drive a piston to move in a cavity and when the piston moves downwards, the dust outlet is closed, the suction layer port is opened, and dust is sucked out; and similarly, when the piston moves upwards, the dust is discharged, and the situation that the dust removal effect is affected due to the fact that the dust layers on sponge is large is avoided.

Owner:余兰兰

Flange opening dust removal cloth bag capable of being conveniently and fast installed

PendingCN109316857AEasy to installImprove work efficiencyDispersed particle filtrationExhaust gasDuctility

The invention discloses a flange opening dust removal cloth bag capable of being conveniently and fast installed. The flange opening dust removal cloth bag comprises a fixing frame and fixing blocks,wherein the fixing blocks are arranged in the four corners of the fixing frame; the flange opening dust removal cloth bag capable of being conveniently and fast installed uses the flange connection mode to fix the cloth bag; a fixing clamp seat and a clamp connection head are installed; through the fixing clamp seat arranged on the fixing frame and the clamp connection head arranged at the tail end of the bag body, the bag body is firmly clamped and connected onto the fixing frame; the flange connection mode is used for connecting the bag body, so that the installation of the bag body is convenient and fast; when the equipment is used for purifying tail gas with high moisture content, heating treatment is performed on high-pressure reverse air flow required to be used for ash cleaning inside the equipment. The bag body consisting of a high-temperature-resistant base layer, an adsorption layer, a reinforcing layer and an elastic outer layer can endure the high-temperature air flow without damage; in addition, the bag body has good ductility, so that the ash cleaning efficiency and practicability of the equipment can be improved.

Owner:江苏华泽环保集团有限公司

Environment-friendly dust removal device for atmospheric control

InactiveCN111544997AEasy to settleEasy to moveCombination devicesStationary filtering element filtersDust controlStructural engineering

The invention discloses an environment-friendly dust removal device for atmospheric control. The environment-friendly dust removal device comprises a base, a dust removal box and a water tank; the dust removal box is arranged at the upper end of the base, a first fan is arranged in the middle of the top end of the dust removal box, and a first ventilation pipe is arranged at the top end of the first fan; a water tank is arranged at the inner bottom of the dust removal box, a first spraying pipe is arranged at the top end of the inner side of the dust removal box, and first nozzles are arrangedat the bottom end of the first spraying pipe; a limiting pipe is mounted at the bottom of the first fan; a second spraying pipe is mounted on the inner side of the limiting pipe; second nozzles are mounted on the outer side of the bottom end of the second spraying pipe; dustproof cloth is arranged between the outer side of the bottom of the limiting pipe and the inner side of the upper end of thewater tank; a first filter screen is arranged on the inner side of the top end of the water tank, a second filter screen is arranged in the middle of the inner side of the water tank, a second ventilation pipe is arranged on the right side of the upper end of the water tank, and a third filter screen and a second fan are arranged on the inner side of the second ventilation pipe. The dust removaldevice is reasonable in structure, dust in air can be conveniently precipitated, dust of different sizes can be conveniently coped with, and the dust removal efficiency is effectively improved.

Owner:GUANGZHOU BAOYUAN ECONOMY ENVIRONMENTAL POLLUTION SCI & TECH CO LTD

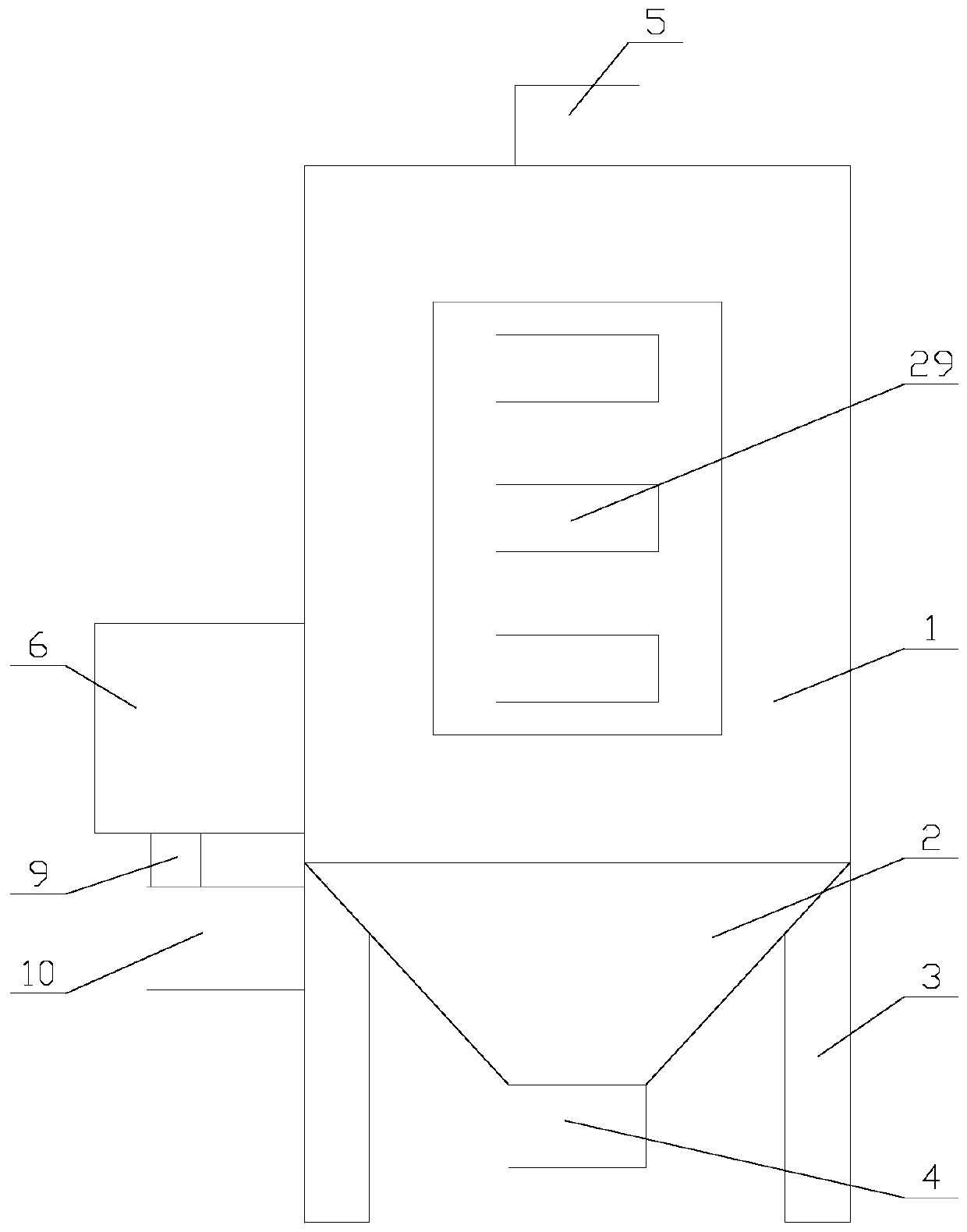

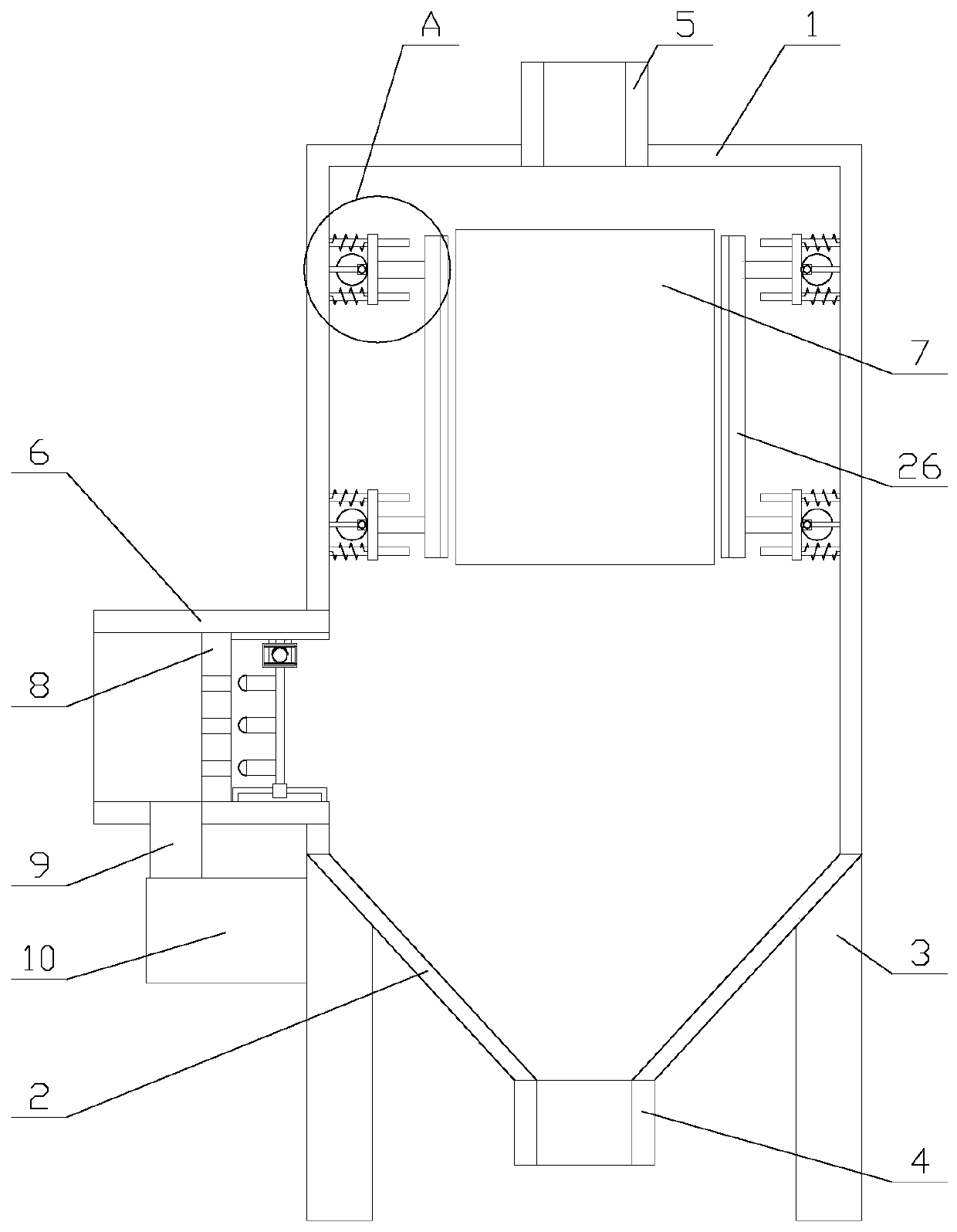

A mine dry dust collector

ActiveCN110306982BAvoid affecting the dust removal effectReduce energy consumptionSlitting machinesThermodynamicsEngineering

Owner:PINGAN KAICHENG INTELLIGENT SAFETY EQUIP

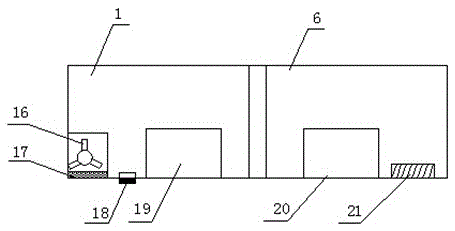

Continuous film laminating machine used for processing of packing boxes

InactiveCN106696419AEasy to removeEasy to detectLamination ancillary operationsControlling laminationDrive wheelConveyor belt

The invention provides a continuous film laminating machine used for processing of packing boxes, and relates to the technical field of packing box processing devices. The continuous film laminating machine comprises a first film laminating chamber, a second film laminating chamber and an operating chamber, the second film laminating chamber is arranged at one side of the first film laminating chamber, the first film laminating chamber is fixedly connected with the second film laminating chamber, an operating chamber is arranged at one side of the first film laminating chamber and the second film laminating chamber, the operating chamber is provided with a transmission switch, the transmission switch is electrically connected with a motor, a rotating shaft is arranged at one side of the motor, a rotator is arranged at one side of the rotating shaft, a driving wheel is arranged at one side of the rotator, a driven wheel is arranged at one side of the driving wheel, a conveyor belt is arranged between the driving wheel and the driven wheel, a feeding bench is arranged at one side of the operating chamber, a discharging bench is arranged at the other side of the operating chamber, and the first film laminating chamber is provided with a power supply switch and a running indicating lamp which is arranged at one side of the power supply switch. Packing boxes are continuously laminated with a film through the first film laminating chamber, the second film laminating chamber and a conveying device.

Owner:HENGYANG MINGZHU PACKAGING

Waste gas treatment system for zinc alloy production

ActiveCN112246057AGuaranteed dust removal performanceWill not polluteHuman health protectionCombination devicesExhaust fumesDust control

The invention relates to the technical field of waste gas treatment, and particularly discloses a waste gas treatment system for zinc alloy production. The waste gas treatment system comprises a casting furnace, wherein the top of the casting furnace is communicated with a first smoke exhaust pipe, and a first-stage dust removal device is arranged at one end, away from the casting furnace, of thesmoke exhaust pipe. Through cooperation of the first-stage dust removal device, the cooling device, the second-stage dust removal device and the cloth bag, secondary dust removal is conducted on wastegas through the first-stage dust removal device and the second-stage dust removal device, large-particle pollutants in the waste gas can be treated before cloth bag dust removal, and therefore the work load capacity of cloth bag dust removal is greatly reduced; therefore, the bag-type dust collector ensures the bag-type dust collection effect, further ensures that waste gas exhausted into air does not pollute the air and meets the requirement of environmental protection, thereby improving the dust collection effect and solving the problem of poor dust collection effect of the existing device.

Owner:苏州墁道金属材料科技有限公司

Electrostatic dust collector for factory workshop

InactiveCN112371680AAvoid affecting the dust removal effectIncrease operating powerDirt cleaningParticle charging/ionising stationsElectric machineryDust control

The invention discloses an electrostatic dust collector for a factory workshop. The collector comprises a hollow dust collection chamber. A mounting chamber is formed in the top wall of the dust collection chamber. An air inlet pipe is fixedly connected to the side wall of the dust collection chamber in a penetrating manner. An air outlet pipe is fixedly connected to the side wall of the side, away from the air inlet pipe, of the dust collection chamber in a penetrating manner. A fan is arranged in the side wall, located at the air outlet pipe, of the dust collection chamber. A through hole isformed in the bottom wall of the dust collection chamber. A dust collection box is fixedly connected to the lower surface of the dust collection chamber through a flange. The through hole communicates with the dust collection chamber and the dust collection box. Permanent magnet plates are embedded in the two opposite inner side walls of the dust collection chamber. Charge generation devices arearranged in the top wall and the bottom wall of the air inlet pipe. A fan rotating speed adjusting device is arranged in the mounting chamber. The electrostatic dust collector for the factory workshophas the advantages that a filter screen is not needed for dust collection, it is avoided that the dust collection effect is affected due to blockage of the filter screen after the filter screen is used for dust collection for a long time in the prior art, meanwhile, the motor power can be changed according to the amount of dust in the workshop, and more energy is saved.

Owner:德清之家纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com