Guitar grinding workshop dust removal system

A technology of dust removal system and dust collection system, which is applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, combined devices, etc., and can solve the problem of not being able to provide a complete set of dust removal systems that meet the requirements of dust collection and dust removal in guitar grinding workshops , to reduce the risk factor, reduce the indoor concentration, and contribute to the effect of health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A dust removal system for a guitar grinding workshop in this embodiment includes a dust collection system and a dust removal system,

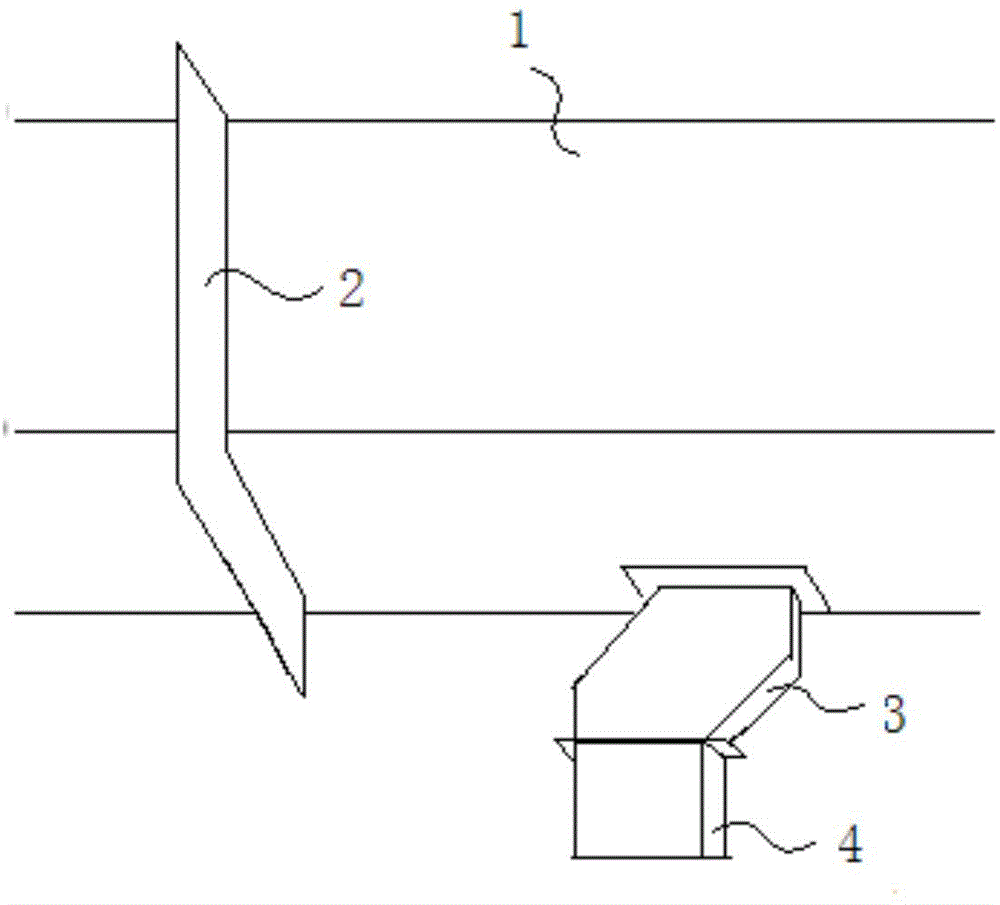

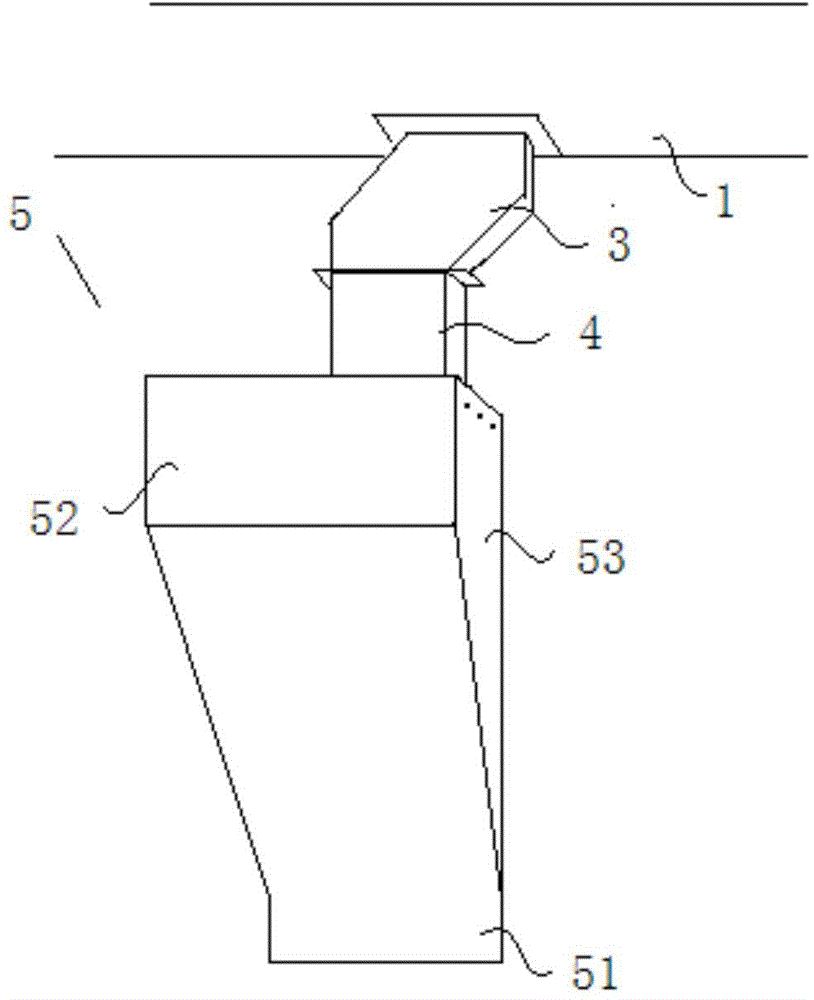

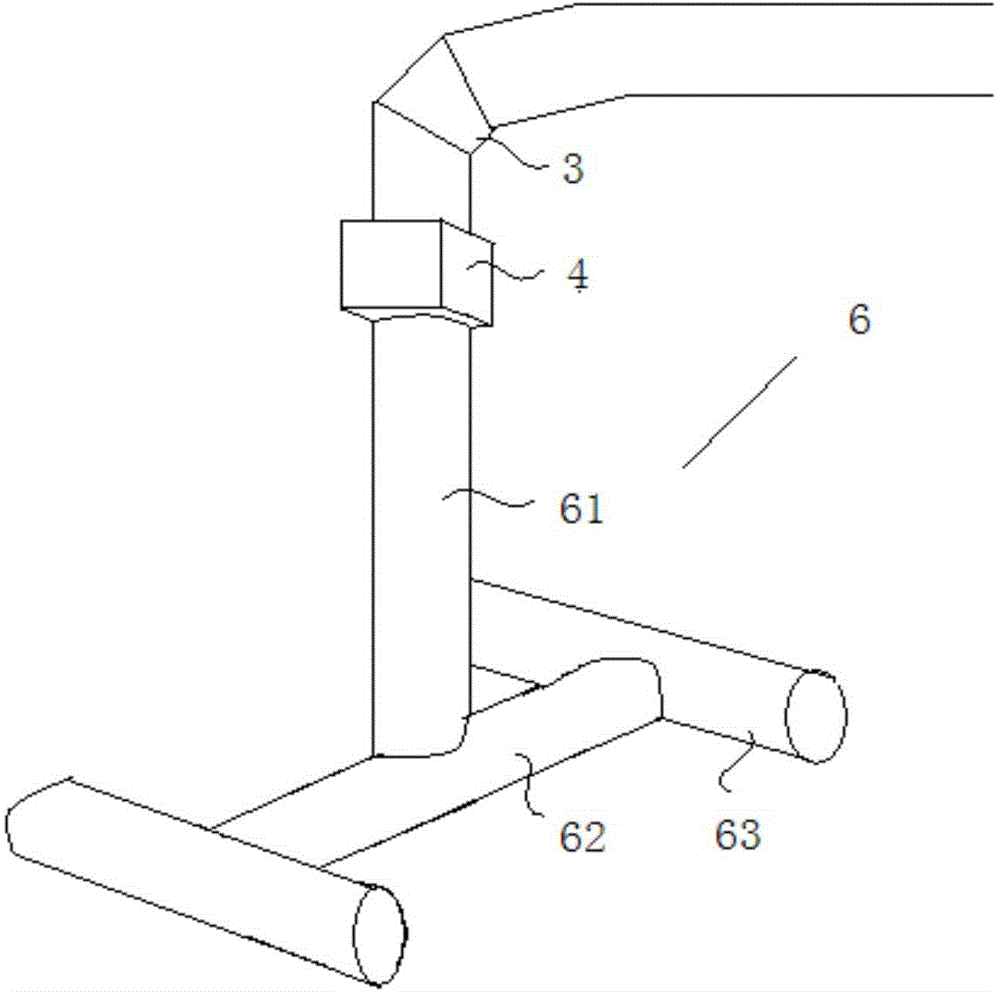

[0048] The dust collection system includes a main dust collection pipe 1 arranged above the grinding workshop, such as figure 1 As shown, the main dust collection pipe 1 is formed by connecting multiple square pipes through flanges 2, and the main dust collection pipe 1 finally converges into a dust outlet channel connected with the fan 9; the main dust collection pipe 1 passes through The connecting pipe 3 is connected with the damper chamber 4, and the lower end of the damper chamber 4 is connected with the dust collection cover. The number and position of the square pipes and the increase or decrease of different types of dust collection covers can be arranged at will, so that the dust collection system can be adapted to the grinding workshop in time. mechanical adjustment. Such as Figure 6 As shown, the inside of the air valve cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com