Stepping type air suction and ash removal dust collector

A step-by-step dust collector technology, which is applied in the field of environmental protection and resource reuse, can solve the problems of inconvenient cleaning of bag dust collectors, etc., achieve the effect of fast, convenient and powerful dust removal process, and ensure the effect of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

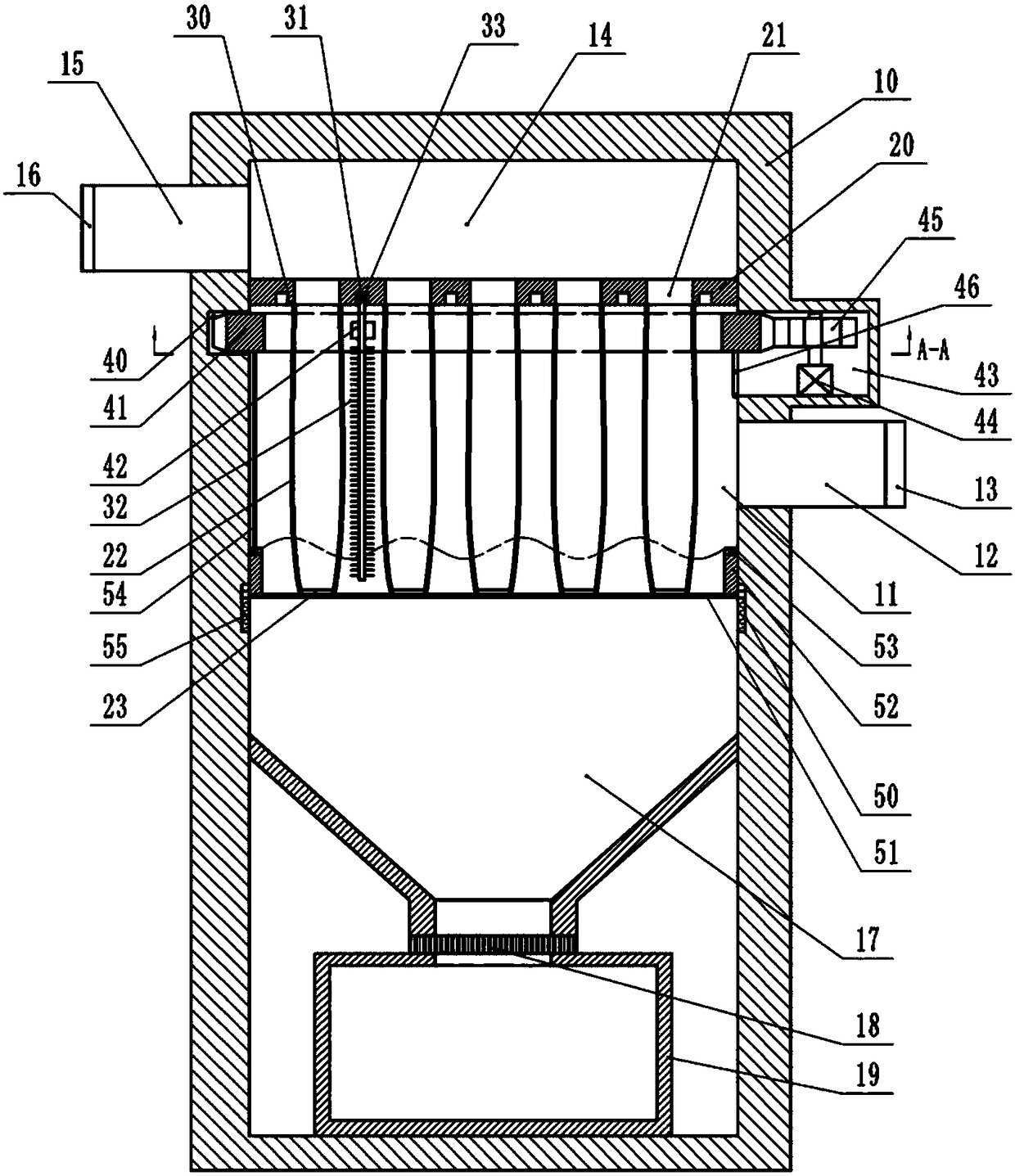

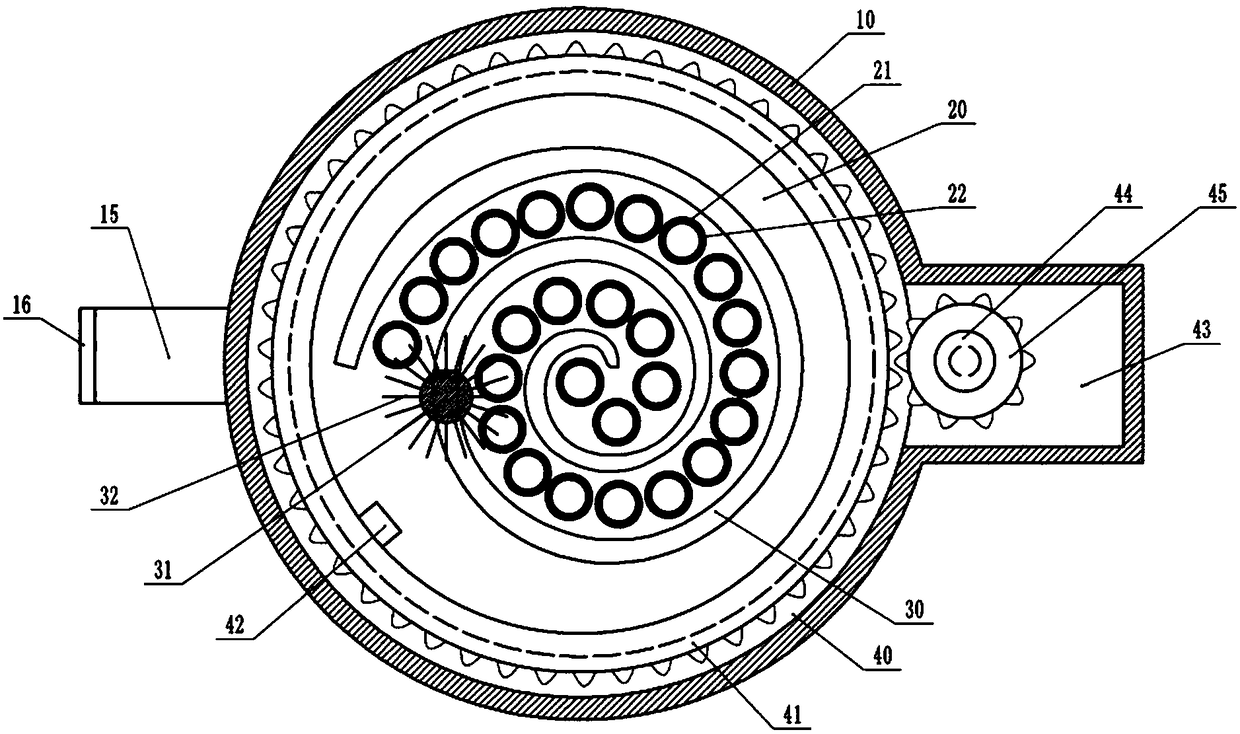

[0029] The reference signs in the drawings of the description include: box body 10, air inlet chamber 11, air inlet pipe 12, air inlet cover 13, air outlet chamber 14, air outlet pipe 15, air outlet cover 16, collection chamber 17, sealing plate 18. Dust collection box 19, partition 20, through hole 21, cloth bag 22, circular plate 23, spiral groove 30, slider 31, brush 32, magnetic block 33, annular cavity 40, ring gear 41, electromagnet 42, Cavity 43, stepper motor 44, gear 45, cover plate 46, chute 50, fixed net 51, ring block 52, annular groove 53, pole 54, elastic member 55.

[0030] Such as figure 1 , figure 2 As shown, the step-by-step suction dust removal device includes a casing 10, the casing 10 is cylindrical, and both sides of the upper end of the casing 10 are provided with an air outlet pipe 15 and an air inlet pipe 12; the air inlet pipe 12 is far away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com