Continuous film laminating machine used for processing of packing boxes

A technology of laminating machine and packaging box, which is applied in the directions of lamination device, lamination auxiliary operation, chemical instrument and method, etc., can solve the problems of automatic lamination and poor lamination effect, etc. Good effect, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

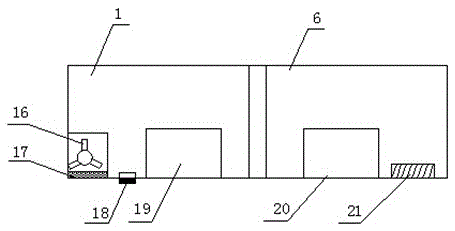

[0022] Such as figure 2 As shown, a fan 16 is provided on one side of the first laminating device 19, and a blower port 17 is provided on one side of the fan 16.

[0023] In the present invention, through the fan 16 on the side of the first laminating device 19 and the blower port 17 arranged on the side of the fan 16, it is convenient to remove the dust on the surface of the article to be processed, avoiding the influence of dust on the dust removal effect, and greatly improving the efficiency of the device.

Embodiment 2

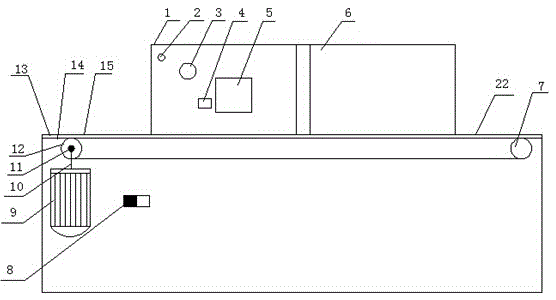

[0025] Such as figure 1 and figure 2 As shown, the first laminating chamber 1 is provided with a display screen 5 , and the first laminating device 19 is provided with a quantity detector 18 , and the quantity detector 18 is connected to the display screen 5 .

[0026] In the present invention, through the quantity detector 18 in the first lamination chamber 1, it is convenient to accurately detect the quantity of processed products, and at the same time connect the display screen 5 through the quantity detector 18, so as to facilitate better display of the detected quantity information, Quantitative information can be understood more clearly.

Embodiment 3

[0028] Such as figure 1 As shown, a reset button 4 is provided on one side of the display screen 5 .

[0029] In the present invention, through the reset key 4 on one side of the display screen 5, it is convenient to reset the quantity information, which is beneficial to the next re-counting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com