Photovoltaic array module automatic cleaning and dust removal system

A photovoltaic array and automatic cleaning technology, applied in photovoltaic power generation, photovoltaic modules, electrical components and other directions, can solve the problems of unsatisfactory cleaning effect, low mop cleaning efficiency, high water cost, and achieve automatic cleaning and dust removal, convenient automatic cleaning and dust removal , the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the device and do not limit the scope of the present invention.

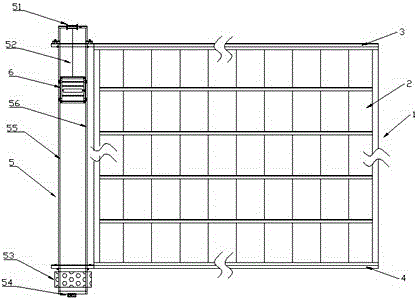

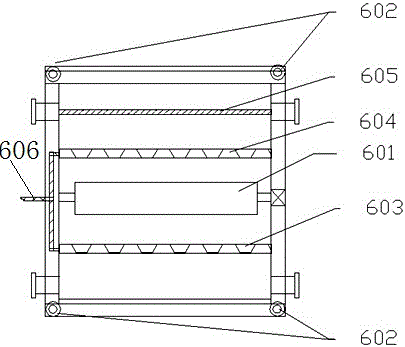

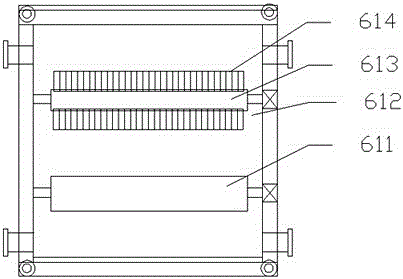

[0014] Such as Figure 1 to Figure 6 As shown, the automatic cleaning and dust removal system for photovoltaic array components includes upper rail 3, lower rail 4, mobile frame 5, cleaning trolley 6, cleaning and dust removal device, sensor 602, photovoltaic battery panel 53, battery and controller 54, wherein upper rail 3 and The lower track 4 is installed on the upper edge and the lower edge of the photovoltaic array 1, and is parallel to the upper edge and the lower edge of the photovoltaic array 1, and the moving frame 5 is installed on the upper track 3 and the lower track 4, and the inclined surface higher than the photovoltaic array 1 must be Keep the distance parallel to the inclined surface of the photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com