Preparation method of soft composite silica powder

A kind of silicon micropowder, soft technology, applied in the field of silicon micropowder, can solve the problems of incurring transportation cost, affecting the effect of dust removal, and consuming transportation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

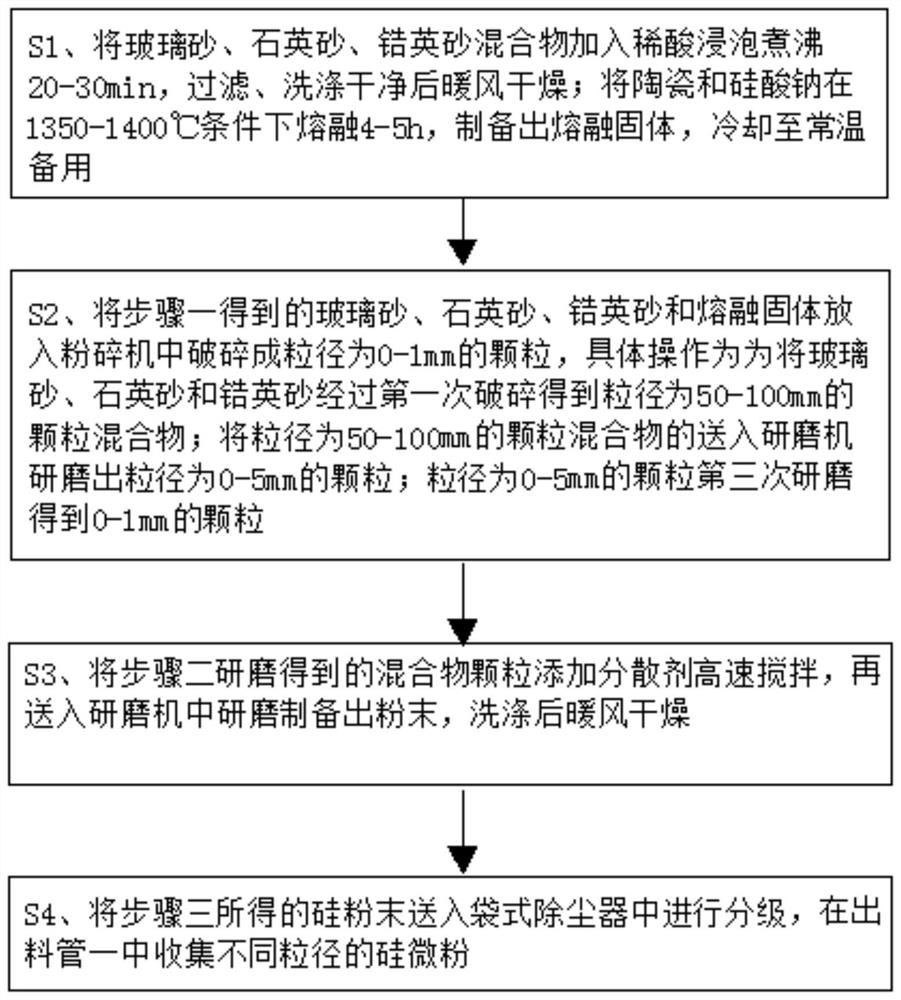

[0050] Such as figure 1 As shown, embodiment 1 provides a kind of preparation method of soft composite silica powder, and preparation method comprises the following steps:

[0051] Step 1. Add the mixture of glass sand, quartz sand and zircon sand to dilute acid, soak and boil for 20 minutes, filter, wash and dry with warm air; melt ceramics and sodium silicate at 1350°C for 4 hours to prepare a molten solid, and cool to room temperature for later use;

[0052] Step 2. Put the glass sand, quartz sand, zircon sand and molten solid obtained in step 1 into a pulverizer and crush them into particles with a particle size of 0-1mm. The specific operation is to mix the glass sand, quartz sand and zircon sand After the first crushing, a particle mixture with a particle size of 50-100mm is obtained; the particle mixture with a particle size of 50-100mm is sent to a grinder to grind particles with a particle size of 0-5mm; particles with a particle size of 0-5mm The third grinding to ...

Embodiment 2

[0064] Such as figure 1 As shown, embodiment 2 provides a kind of preparation method of soft composite silica powder, and preparation method comprises the following steps:

[0065] Step 1. Add the mixture of glass sand, quartz sand and zircon sand to dilute acid, soak and boil for 25 minutes, filter, wash and dry with warm air; melt ceramics and sodium silicate at 1400°C for 5 hours to prepare a molten solid, and cool to room temperature for later use;

[0066] Step 2. Put the glass sand, quartz sand, zircon sand and molten solid obtained in step 1 into a pulverizer and crush them into particles with a particle size of 0-1mm. The specific operation is to mix the glass sand, quartz sand and zircon sand After the first crushing, a particle mixture with a particle size of 50-100mm is obtained; the particle mixture with a particle size of 50-100mm is sent to a grinder to grind particles with a particle size of 0-5mm; particles with a particle size of 0-5mm The third grinding to ...

Embodiment 3

[0073] Such as figure 1 As shown, embodiment 3 provides a kind of preparation method of soft composite silica powder, and preparation method comprises the following steps:

[0074] Step 1. Add the mixture of glass sand, quartz sand and zircon sand to dilute acid, soak and boil for 30 minutes, filter, wash and dry with warm air; melt ceramics and sodium silicate at 1375°C for 4 hours to prepare a molten solid, and cool to room temperature for later use;

[0075] Step 2. Put the glass sand, quartz sand, zircon sand and molten solid obtained in step 1 into a pulverizer and crush them into particles with a particle size of 0-1mm. The specific operation is to mix the glass sand, quartz sand and zircon sand After the first crushing, a particle mixture with a particle size of 50-100mm is obtained; the particle mixture with a particle size of 50-100mm is sent to a grinder to grind particles with a particle size of 0-5mm; particles with a particle size of 0-5mm The third grinding to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com