Water pumping pipe belt winding equipment for water conservancy project

A water conservancy engineering and pipe belt technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of lack of dust removal device, affecting winding efficiency, inconvenience for next use, etc., and achieves strong flexibility. , Improve winding efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

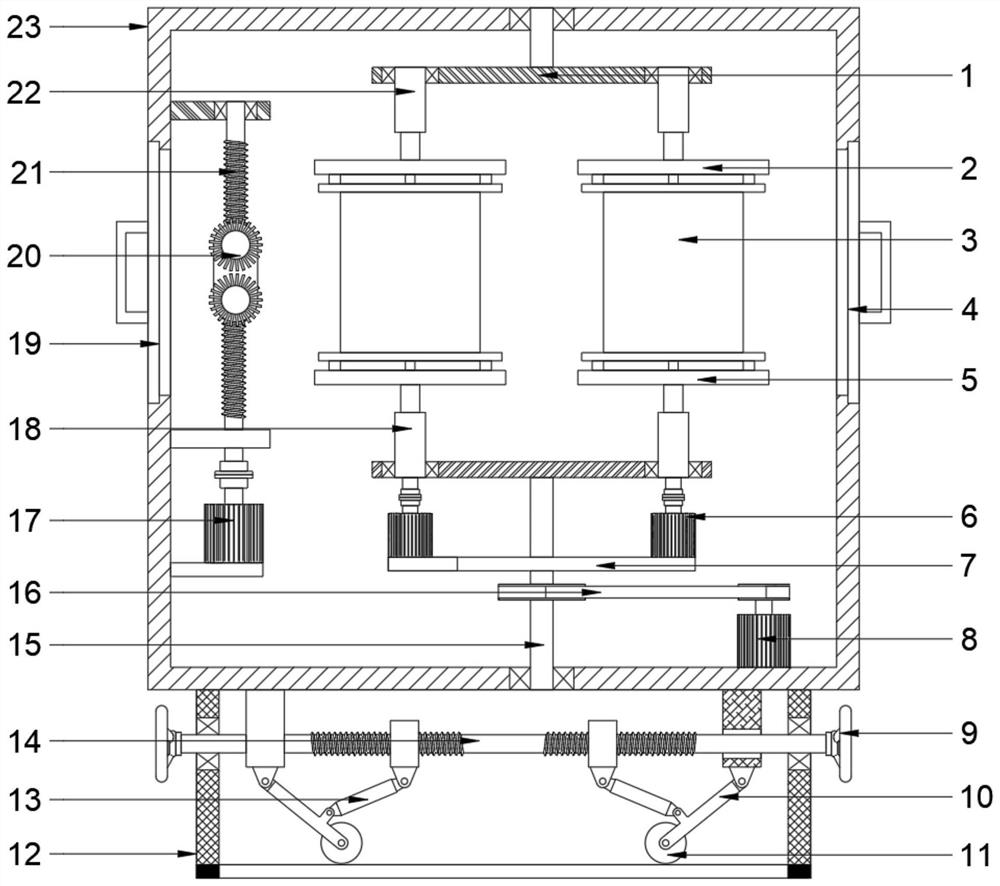

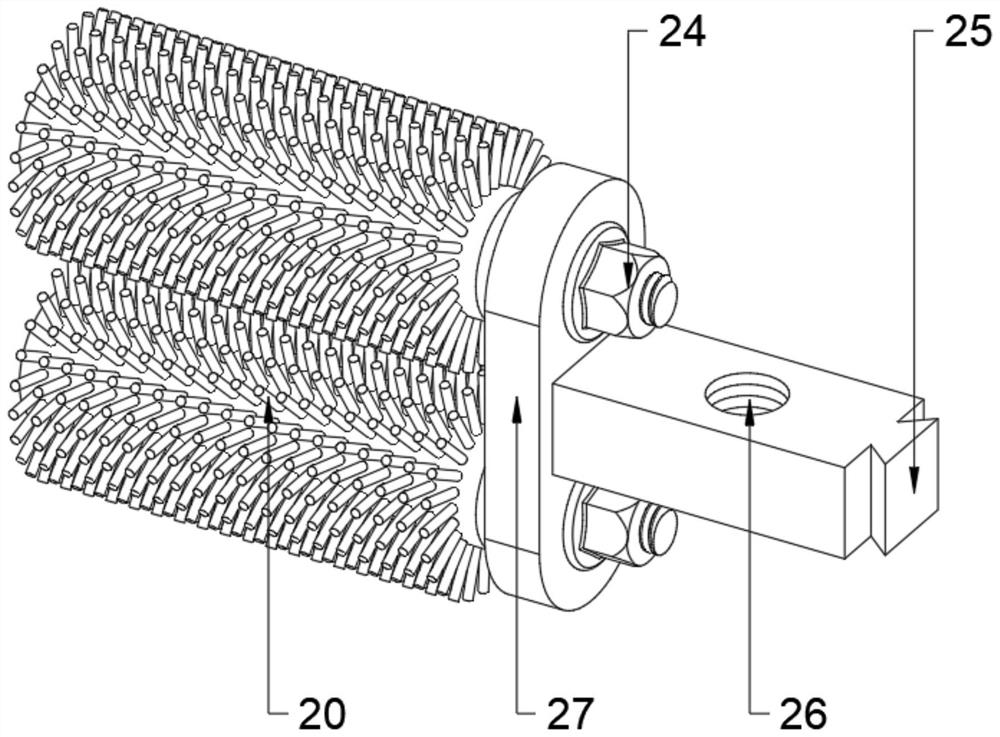

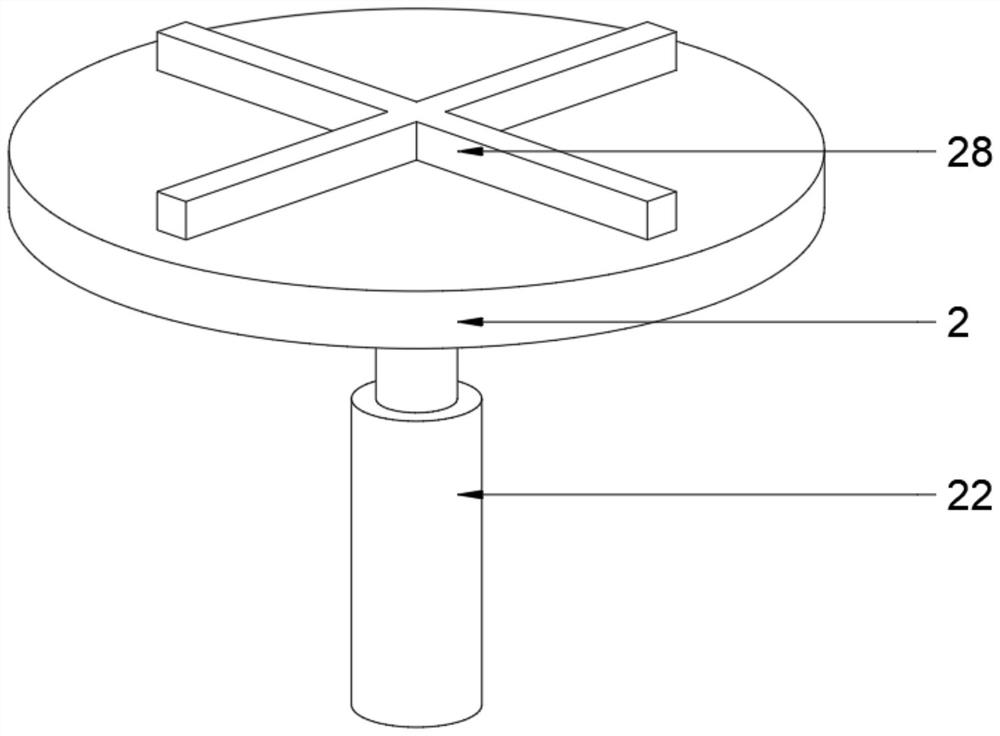

[0026] see Figure 1~4 , in an embodiment of the present invention, a water conservancy engineering pumping pipe belt rewinding device includes a box 23 and a rewinding assembly installed inside the box 23, the rewinding assembly includes a rewinding device and a dust removal device, the The number of winding devices is two groups and arranged side by side in the box body 23; the winding device includes a winding sleeve 3, a clamping mechanism and a driving mechanism, and the clamping mechanism includes an upper clamping mechanism and a lower clamping mechanism. mechanism and the two are respectively stuck on the two ends of the winding sleeve 3, the upper clamping mechanism is installed on the inner top of the box body 23 through the linkage bracket 1, and the lower clamping mechanism is installed on the box body 23 through the transmission bracket 15. In the inner bottom, the drive mechanism includes a first drive mechanism and a second drive mechanism, the first drive mecha...

Embodiment 2

[0035] see figure 1 , in the embodiment of the present invention, a water conservancy project uses a pumping pipe belt rewinding device, in order to enhance the flexibility and stability of the device, on the basis of embodiment 1, the outer bottom of the box 23 is provided with a walking device, Described walking device comprises walking wheel 11, supporting casing 12 and adjusting screw rod 14, and described supporting casing 12 is fixedly installed on the outer bottom of box body 23 and its bottom is provided with non-slip rubber pad, and described adjusting screw rod 14 two ends pass through fixedly respectively. The two sets of fixed blocks installed on the outer bottom of the box body 23 are rotatably mounted on the side wall of the support housing 12 through bearings. The periphery of the adjusting screw 14 is also provided with two sets of threads with opposite rotations and two sets of screw threads are threaded on it. Sliding blocks, the bottom of the two sets of sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com