Technique and structure for transversal heating circuit of hot pressing plate of plate continuous press

A technology of heating circuit and hot pressing plate, which is applied in the technical and structural fields of heating circuit and sealing plate welding, can solve the problem of inability to guarantee the quality of slab pressing, the inability to guarantee the heat conduction efficiency of slab pressing, the uniformity of heat conduction, and the temperature of the plate surface. Unbalanced left and right, etc., to achieve the effect of smooth passage, normal operation and firm welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

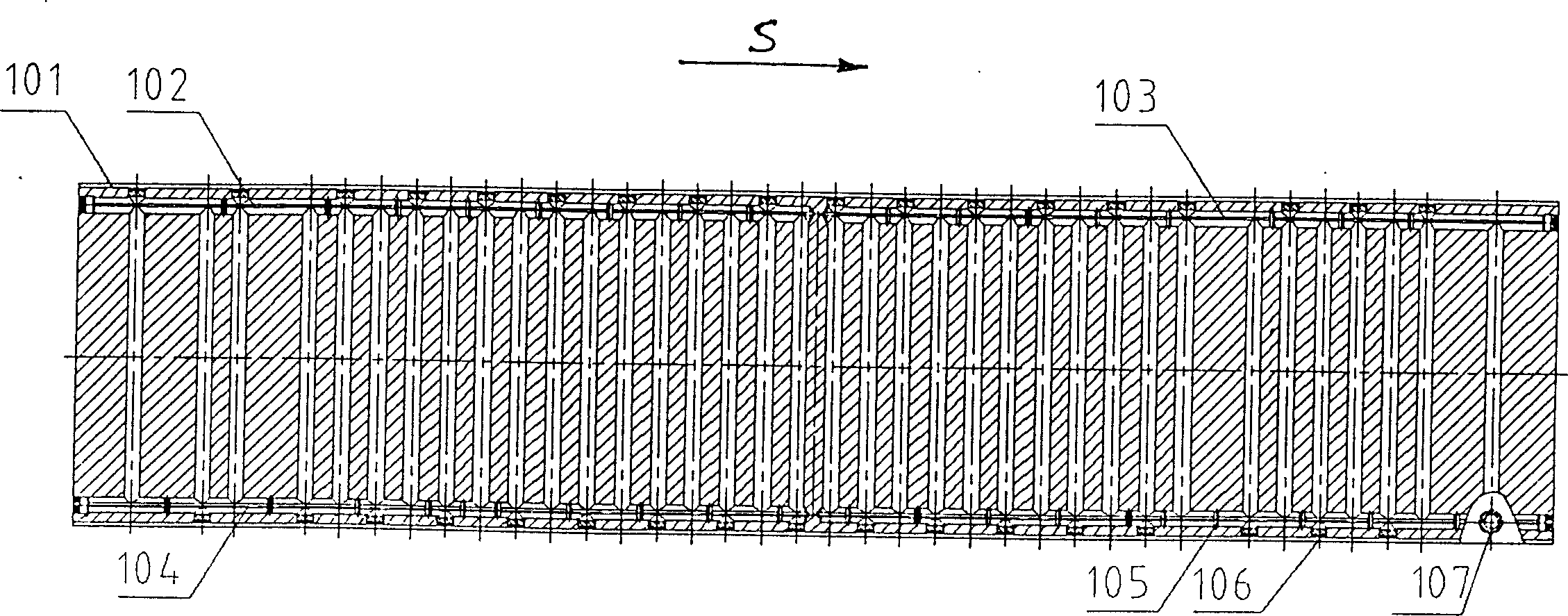

[0012] An embodiment of the present invention is as figure 1 The shown structure is a hot-pressing plate used in a flat-press continuous press, mainly consisting of a hot-pressing plate 101, a guide rod a 102, a guide rod b 103, a guide rod c 104, a guide rod d 105, a sealing plate 106, joint 107 etc. other parts are formed.

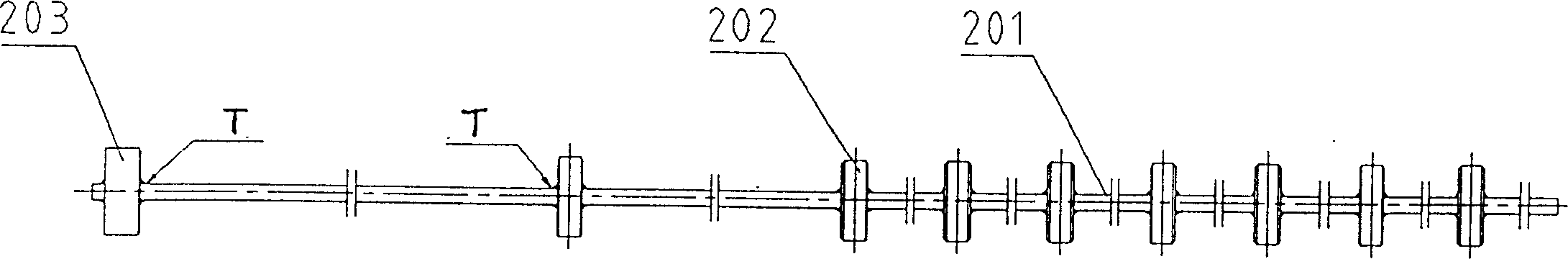

[0013] Guide rod a 102, guide rod b 103, guide rod c 104, guide rod d 105, as attached figure 2 The structure shown is composed of connecting rod 201, partition plate 202, and plug plate 203. The material of connecting rod 201 is No. 20 steel wire with a diameter of φ6mm. The 101 heating circuit requires that it be welded on the connecting rod 201 at a certain distance, and the separator 202 is welded on the end of the connecting rod 201 .

[0014] The hot pressing plate 101 is made of special steel. According to the design requirements, four holes with a diameter of φ32mm are drilled in the longitudinal direction, and a certain number of holes with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com