Corn raw material distribution mechanism of automatic corn popper and production process method of corn raw material distribution mechanism

A popcorn machine and raw material technology, applied in the directions of packaging, loading/unloading, application, etc., can solve the problem of excessive size, achieve the effect of smooth passage, convenient maintenance, and eliminate the problem of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

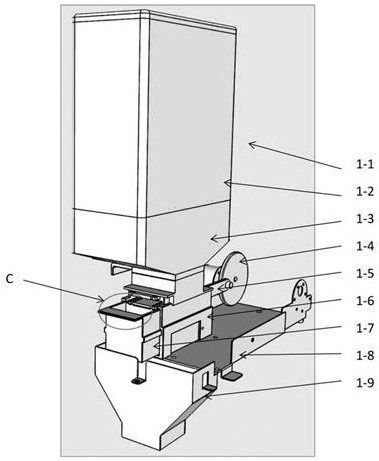

Embodiment 1

[0033]Embodiment 1, with reference to the accompanying drawings, a corn raw material distribution mechanism for an automatic popcorn machine, including: a mounting plate, a transparent material box, a material box base, a material box shutter, an outer cavity seat, an inner cavity, an elastic scraper, Bell crank wheel, plastic connecting rod, geared motor, micro switch, lower hopper, control circuit. Wherein: the inner cavity body is composed of an inner cavity sliding part and a capacity adjustment plate, which can adjust the capacity of the distributed material. The outer chamber seat and the inner chamber body are combined through a guide rail structure and can move longitudinally. The elastic scraper is installed at the entrance of the outer chamber seat. The outer cavity seat and the geared motor are installed on the stainless steel mounting plate. The transparent material box 1-2 is fitted with the material box base 1-3 to form a material box assembly 1-1, and the mate...

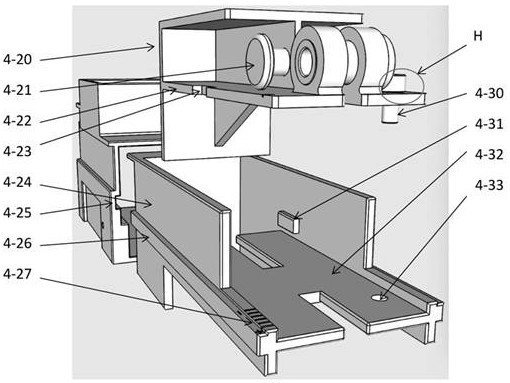

Embodiment 2

[0041] Embodiment 2, a variable amount corn raw material distribution mechanism of an automatic popcorn machine:

[0042] 1. Place the lower hopper in the reserved hole of the machine mounting plate, and insert the lower opening into the feed port of the boiler.

[0043] 2. The raw material distribution mechanism is inserted along the machine installation plate, and the two ear tongues on the bottom plate of the distribution mechanism are snapped into the installation plate.

[0044] 3. One ingot screw net distribution mechanism is fixed on the mounting plate.

[0045] 4. Insert the plug-in wire of the material distribution system and connect the circuit.

[0046] 5. Loosen the inner hexagon socket screw for adjusting the capacity of the dispensing mechanism, adjust the opening size required by the storage bin in the inner cavity (with a scale display), and then fix it, and adjust the capacity according to the exact cup full of popcorn. It can also be fine-tuned during use. ...

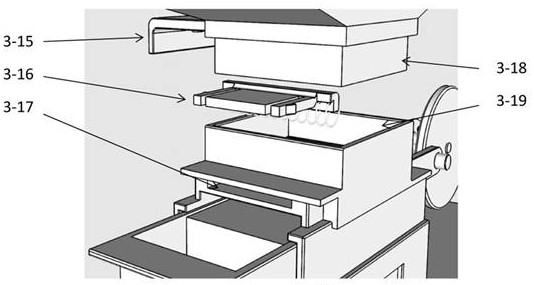

Embodiment 3

[0048] Embodiment 3, with reference to accompanying drawing, with reference to embodiment 1,2, the th The transmission connection mechanism is installed on one side of the base, the The transmission connection mechanism is installed on the other side of the base, and they are connected in parallel as a whole. Among them, the first Transmission connection mechanism: there is a base of the first material box under the first material barrel, a first hopper mouth under the base of the first material box, a first material frame under the first material box, and an inner chamber of the first mechanism under the first material frame , there is a switch gate for the first material box between the first material frame and the mouth of the first material hopper, the base of the first material box is conical, and there is a first supporting plate outside the bottom edge of the base of the first material box, the first material frame is installed on the An outer frame, the first mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com