Plate rejecting and supplementing system used after zinc stripping, zinc stripping washing system and zinc stripping washing method

A technology of stripping zinc and patching plates, which is applied in photography technology, instruments, photography auxiliary technology, etc., can solve the problems of high labor intensity, poor working environment and high labor cost, save workshop space, reduce transfer time, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

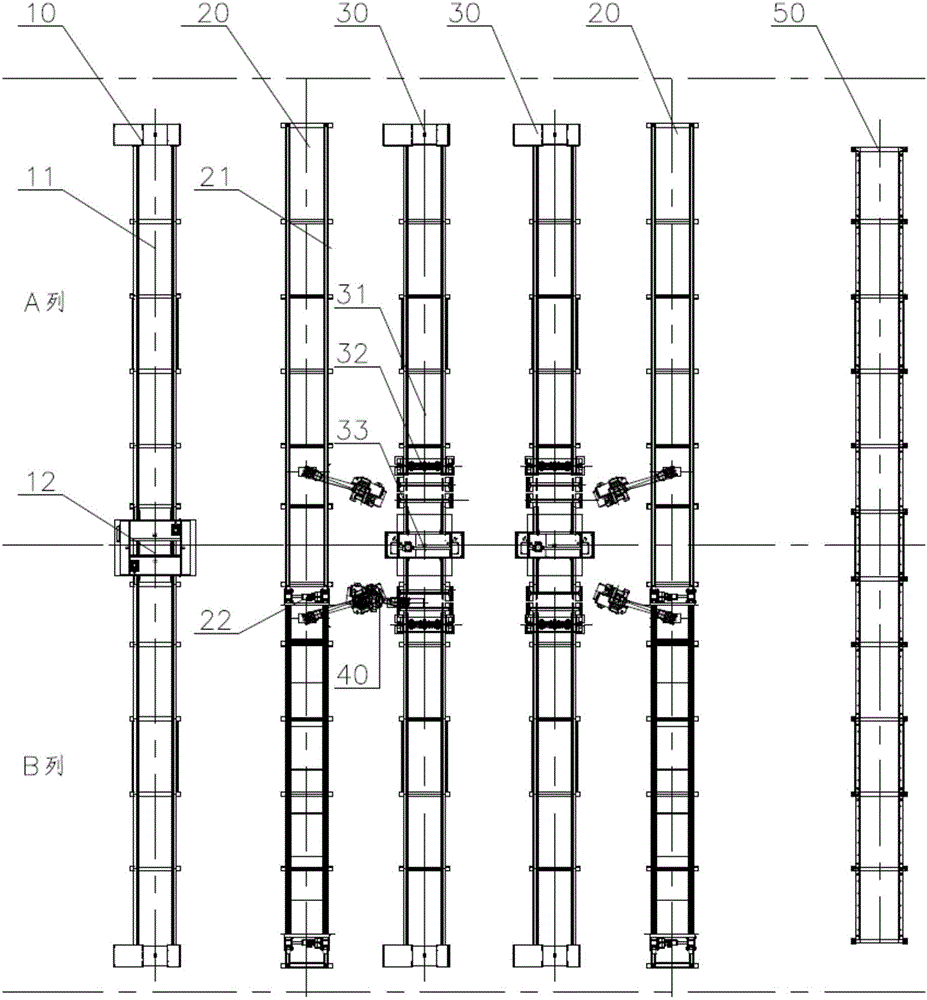

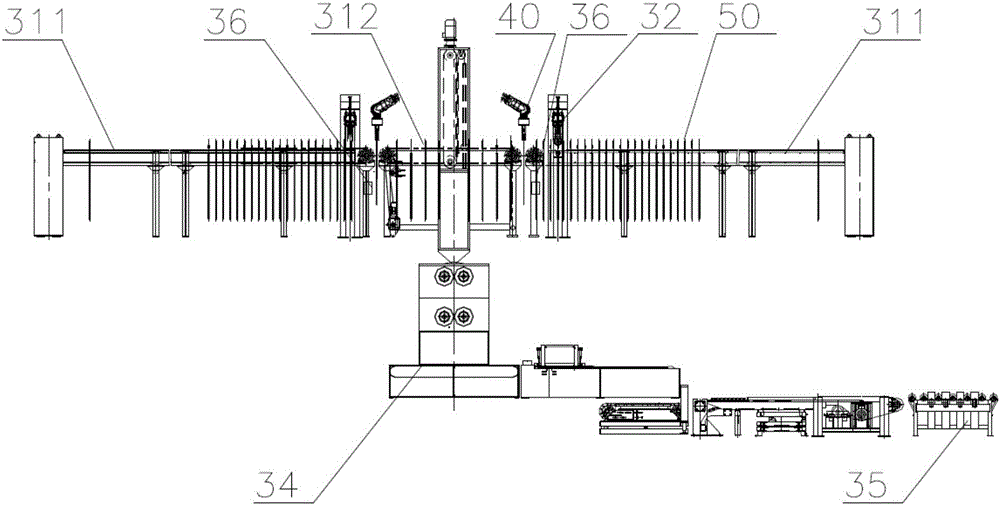

[0042] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

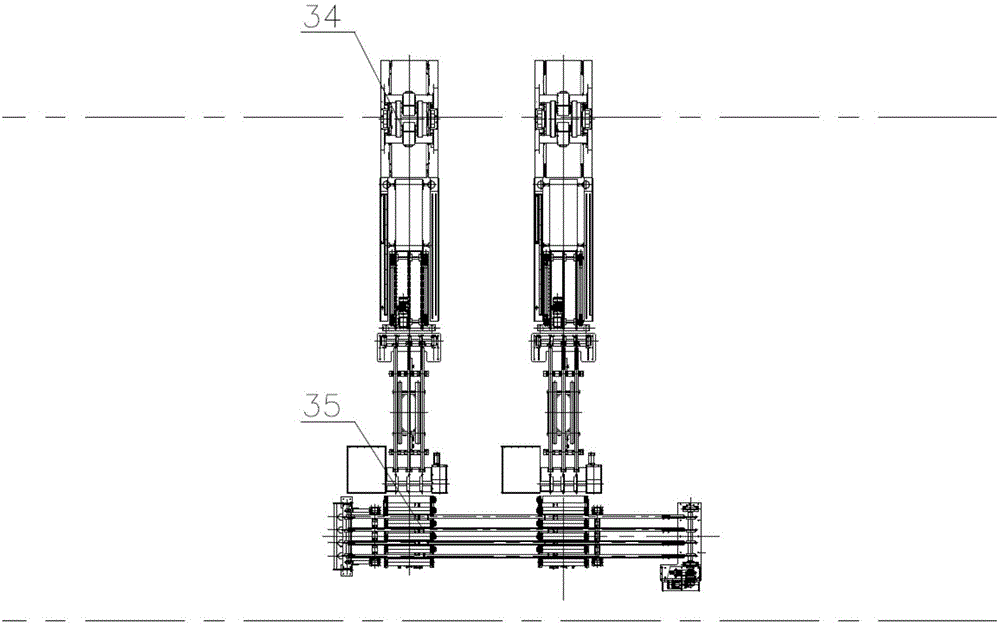

[0043] A zinc stripping scrubbing system, its main process can be found in figure 1 and 2 As shown, according to the current configuration of the workshop, the workshop building is divided into two columns, A and B, and the stripping unit 30 can accept pole plates from column A or column B. A and B columns are separately equipped with independent cranes responsible for transferring cranes.

[0044] Assuming that the 1 / 2 tank cathode plate transferred f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com