Rear shelf for motor vehicle equipped with a folding roof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

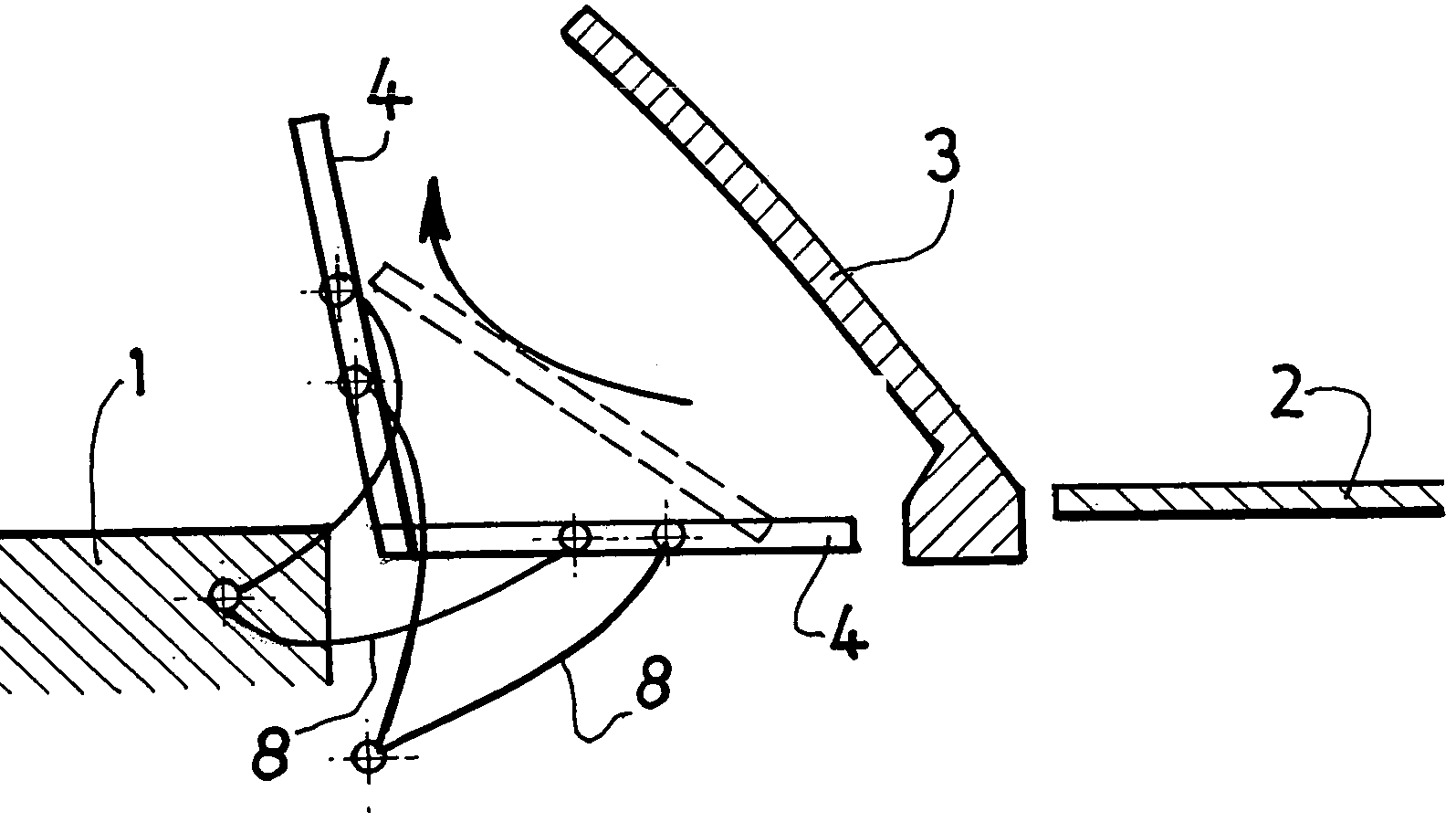

[0033] illustrated by FIGS. 1 to 3, the lateral elements 6 are retracted towards the bottom of the vehicle, so that it is not necessary to withdraw the roof before the panel 4 is moved.

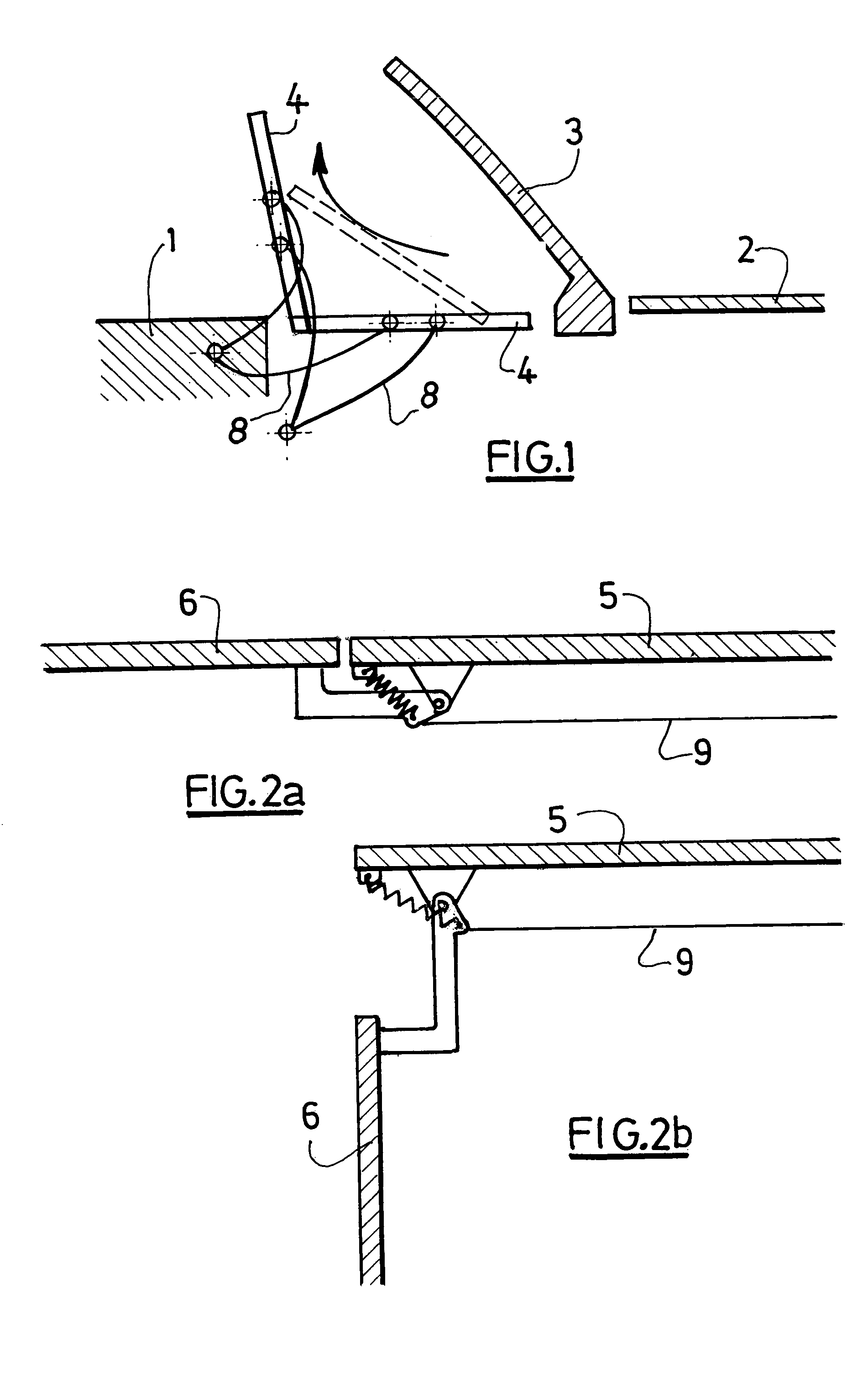

[0034]To this end, according to a first variant, illustrated by FIGS. 1 and 2, articulated arms 8 are provided, fixed by one end to the panel 4 and by the other end to the chassis 1. A linkage 9 directly mounted on these arms 8 (FIG. 2) makes it possible, by means of a system of connecting rods (not shown), to make the lateral elements 6 pivot downwards.

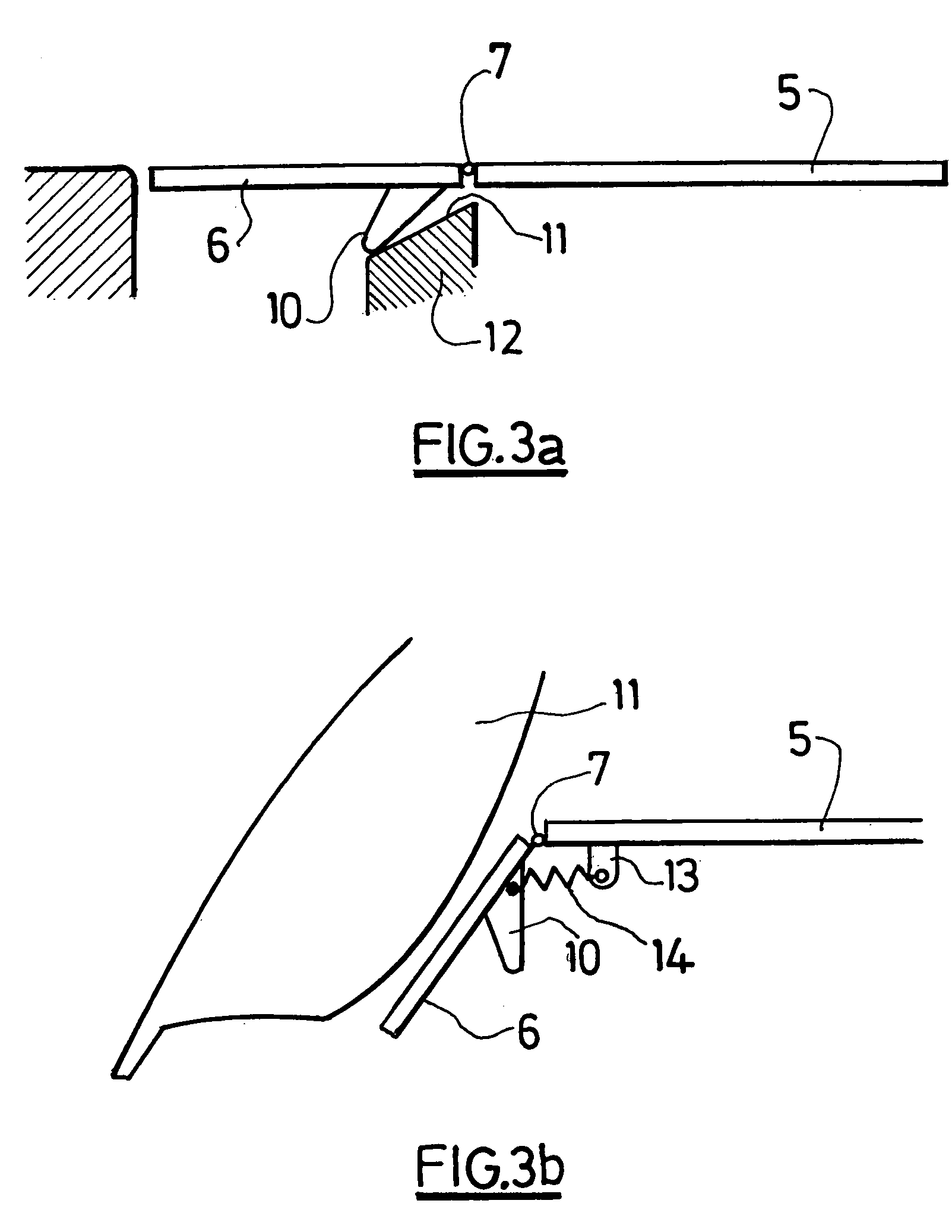

[0035]According to a second variant of the first embodiment (FIG. 3), the downward pivoting of the lateral elements 6 is achieved by means of a lug 10 fixed to the lateral elements 6. This lug 10 constitutes a cam follower able to cooperate with a cam track 11 situated on a support 12 fixed to the chassis 1.

[0036]A spring 14 disposed between the lug 10 and a lug 13 situated on the central element 5 of the panel is arranged so as to cause such a pivotin...

second embodiment

[0037] illustrated by FIGS. 4a and 4b, the lateral elements 6 are retracted towards the top of the vehicle, so that it is necessary to withdraw the roof by any suitable means prior to the movement of the panel 4.

[0038]To this end, the lateral elements 6 are provided with a cam follower 15 in the form of a swan neck, the end of which is mounted so as to pivot rotationally on the central element 5 of the panel 4. This cam follower 15 is arranged so as to cooperate with a cam track 17 situated on the support 12 fixed to the chassis 1.

[0039]A return spring 18 is fixed on the one hand to the nose 19 of the cam follower 15 and on the other hand to a lug 20 situated on the panel. This spring 18 makes it possible to apply the nose 19 of the cam follower 15 to the cam track 17, when the panel 4 is in a position of use (FIG. 4a). Then, when the panel 4 is raised, the spring 18 drives the nose 19 of the cam follower 15 upwards, this movement causing the lifting of the lateral element 6 and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com