Low-temperature denitration and heat storage integrated catalytic type honeycomb ceramic material

A technology of honeycomb ceramics and low-temperature denitrification, which is applied in the direction of physical/chemical process catalysts, ceramic products, catalyst activation/preparation, etc. It can solve the problems of increasing the electricity cost of induced draft fans, narrow activation temperature window, and no heat storage function. Achieve the effects of improving energy utilization efficiency, improving anti-sintering ability, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

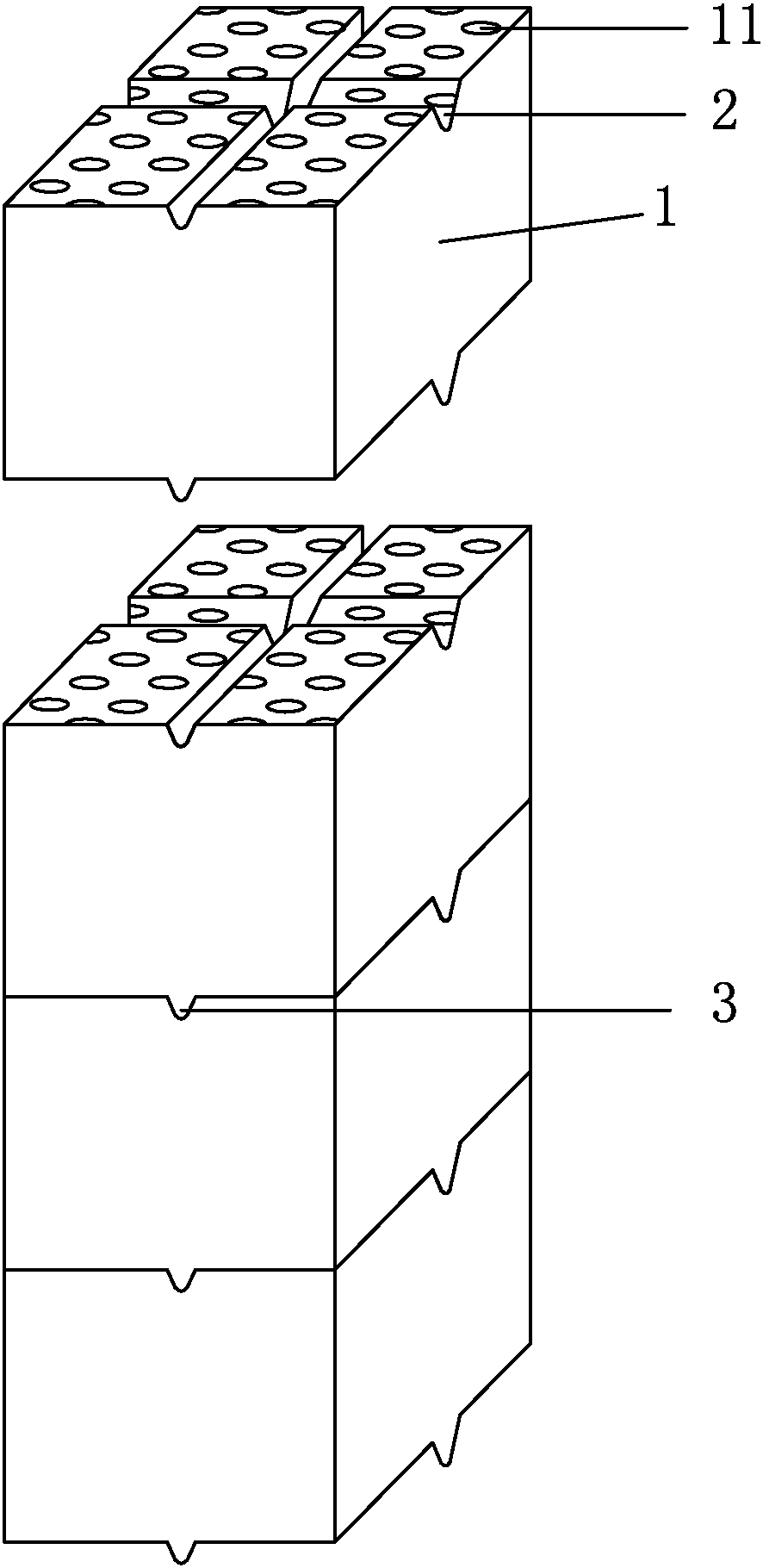

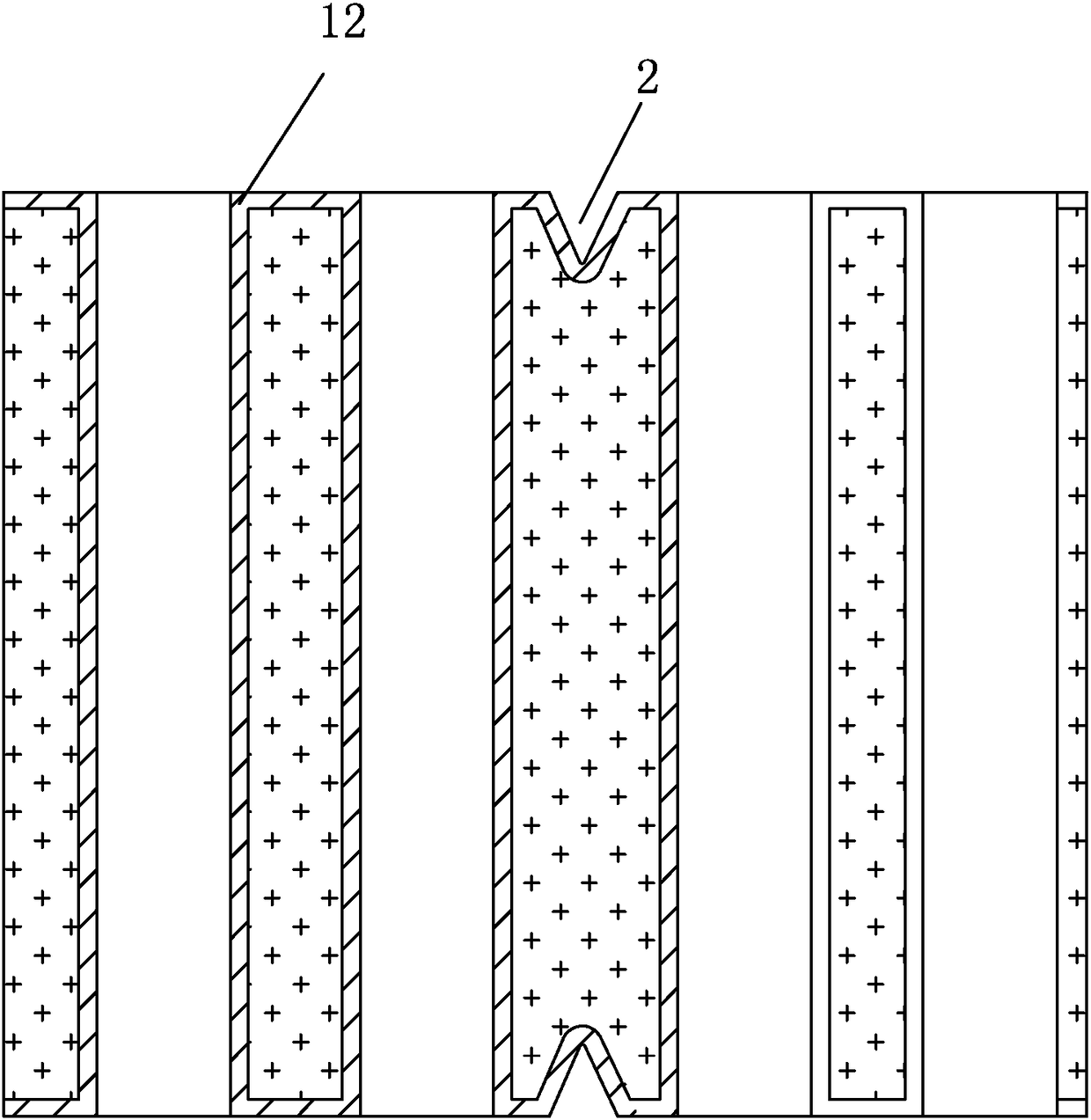

[0034] The low-temperature denitrification and heat storage integrated catalytic honeycomb ceramic material mainly consists of the following components: 70 parts of nano-scale alumina, 40 parts of nano-magnesia, 35 parts of nano-titanium dioxide, 1 part of boron nitride, 50 parts of silicon dioxide powder, methyl 10 parts of methyl acrylate-butadiene-styrene terpolymer, 8 parts of glass fiber, 0.8 part of stearic acid, 0.8 part of high molecular polymer fiber, and 1 part of amino cellulose are kneaded with mud, aged and extruded Prepared by forming, drying and calcining, impregnating the catalytic slurry, drying and calcining again;

[0035] The catalytic slurry is mainly composed of the following components: weigh 5 parts of nano-scale alumina, 5 parts of ferric nitrate, 15 parts of manganese nitrate, 10 parts of mullite, 5 parts of ammonium dihydrogen phosphate, polydimethylsiloxane 2 parts of alkane, 6 parts of aluminum stearate, 3 parts of nano-neodymium oxide, 8 parts of ...

Embodiment 2

[0049] The low-temperature denitrification and heat storage integrated catalytic honeycomb ceramic material mainly consists of the following components: 75 parts of nano-scale alumina, 38 parts of nano-magnesia, 32 parts of nano-titanium dioxide, 2 parts of boron nitride, 55 parts of silicon dioxide powder, methyl 8 parts of methyl acrylate-butadiene-styrene terpolymer, 5 parts of glass fiber, 0.9 part of stearic acid, 0.9 part of high molecular polymer fiber, and 0.9 part of amino cellulose are kneaded with mud, aged and extruded Prepared by forming, drying and calcining, impregnating the catalytic slurry, drying and calcining again;

[0050] The catalytic slurry is mainly composed of the following components: 6 parts of nano-scale alumina, 8 parts of iron nitrate, 10 parts of manganese nitrate, 8 parts of mullite, 7 parts of ammonium dihydrogen phosphate, polydimethylsiloxane 1.2 parts of alkane, 8 parts of aluminum stearate, 4 parts of nano-neodymium oxide, 6 parts of ammon...

Embodiment 3

[0064] The low-temperature denitrification and heat storage integrated catalytic honeycomb ceramic material mainly consists of the following components: 80 parts of nano-scale alumina, 35 parts of nano-magnesia, 30 parts of nano-titanium dioxide, 3 parts of boron nitride, 60 parts of silicon dioxide powder, methyl 4 parts of methyl acrylate-butadiene-styrene terpolymer, 3 parts of glass fiber, 1 part of stearic acid, 1 part of polymer fiber, 0.8 part of amino cellulose, kneaded with mud, aged and extruded Prepared by forming, drying and calcining, impregnating the catalytic slurry, drying and calcining again;

[0065] The catalytic slurry is mainly composed of the following components: 8 parts of nano-scale alumina, 10 parts of iron nitrate, 5 parts of manganese nitrate, 5 parts of mullite, 10 parts of ammonium dihydrogen phosphate, polydimethylsiloxane 0.5 parts of alkane, 10 parts of aluminum stearate, 5 parts of nano-neodymium oxide, 5 parts of ammonium metatungstate, 4 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com