Coke oven ascending pipe cleaning interconnected control method and system

A technology of interlocking control and rising pipes, which is applied in general control systems, control/regulation systems, coke ovens, etc., can solve problems such as difficulties in popularizing technology for waste heat utilization of rising pipes, improve the ability of automatic information collection, reduce safety costs, The effect of protecting the safety of personnel and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

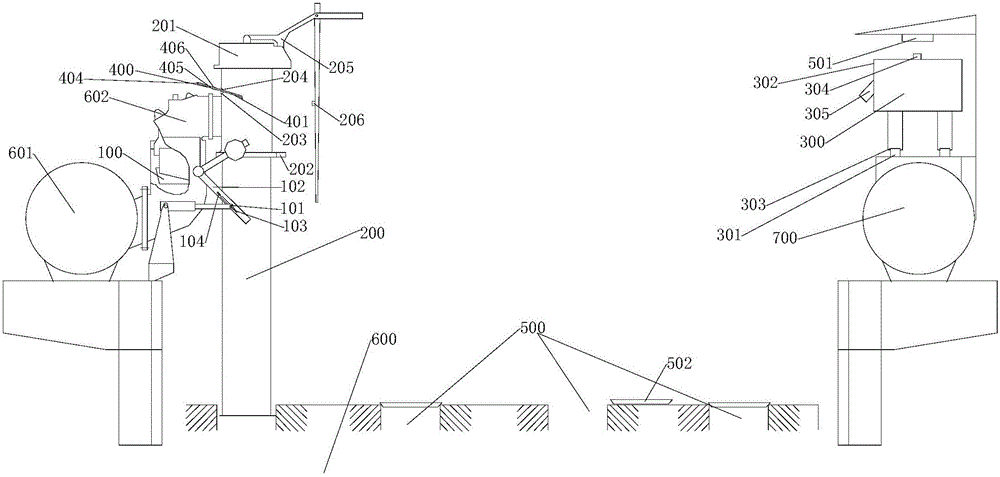

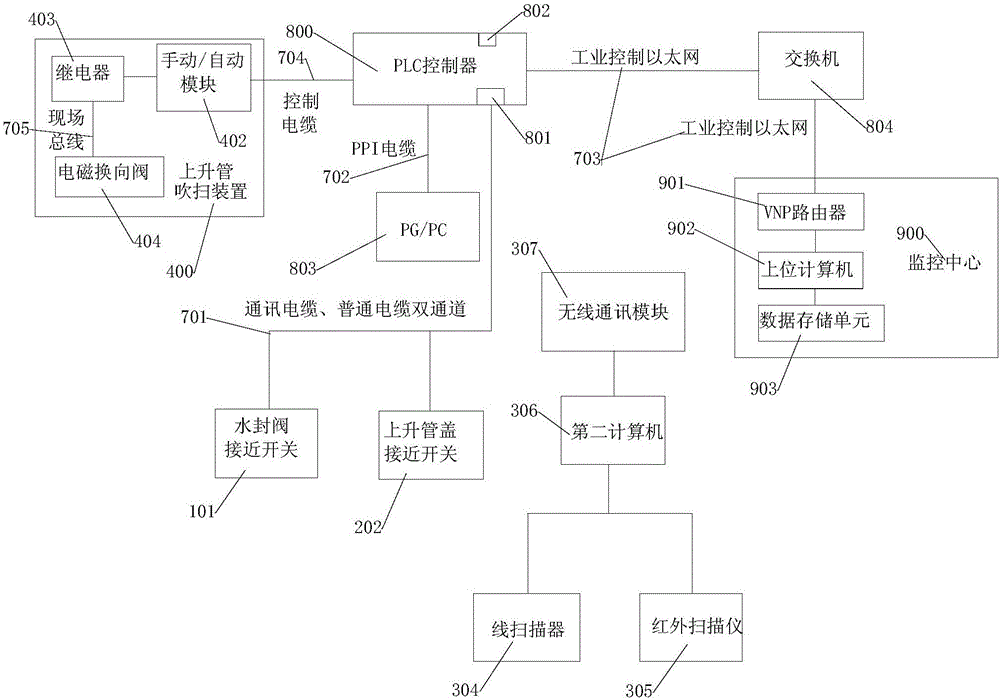

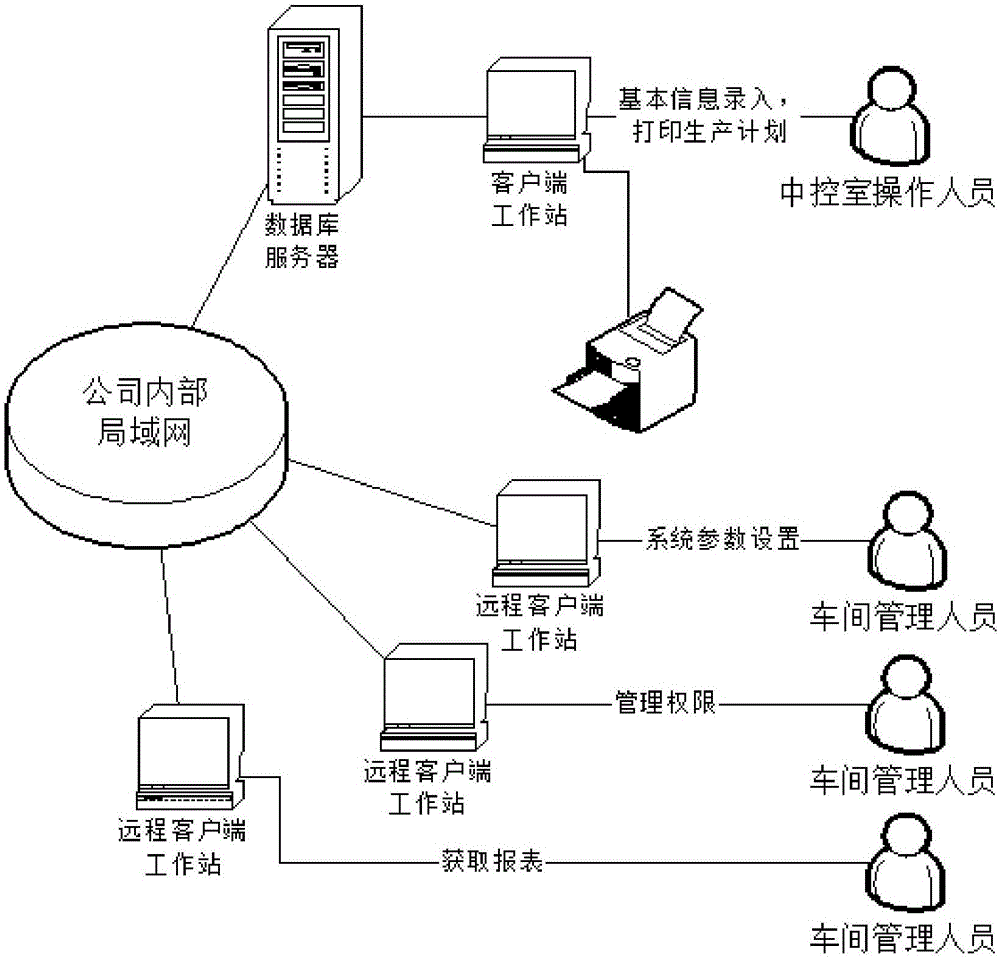

[0043] Embodiment 1: as figure 1 figure 2 As shown, a coke oven riser cleaning interlock control system includes: water seal valve 100 proximity switch 101, riser cover proximity switch 202, moving device 300, riser purge device 400; water seal valve proximity switch 101 detects The end is arranged at the position 104 facing when the water seal valve opening and closing control device 102 is opened or the position 103 facing when it is closed. The detection end of the ascending pipe cover proximity switch 202 is set at the position 206 facing when the opening and closing control device 205 of the ascending pipe cover 201 is opened. The water seal valve 100 is installed on the air collecting pipe 601, the bridge pipe 602 is installed on the water seal valve 100, the bridge pipe 602 is connected to the riser pipe 200, the water seal valve proximity switch 101, the riser pipe cover proximity switch 202 communicate with the The PLC controller 800 of the data collector 801 is co...

Embodiment 2

[0054] Embodiment 2: as Figure 4 As shown, a coke oven riser cleaning interlocking control method includes the following steps:

[0055] S01, monitor the switching value input event A triggered by the complete closure of the water seal valve 100 located between the 1# coke oven 02# rising pipe 200 and the gas collecting pipe 601 through the water seal valve proximity switch 101;

[0056] S02. Monitor the switching value input event B triggered by the opening of the 1# coke oven 02# ascending pipe cover 201 through the ascending pipe cover proximity switch 202;

[0057] S03. Judging whether the 1# coke oven 02# ascending pipe 200 is in the state of isolating explosive gas according to the switching value input event in the steps S01 and S02, including: the PLC controller 800 acquires the 1# coke that generated the input event Furnace 02# water seal valve 100 IP address data C and 1# coke oven 02# ascending pipe cover 201 IP address data D, the host computer 902 judges the 1# ...

Embodiment 3

[0062] S07. The planned coke pushing time of the 02# carbonization chamber of the 1# coke oven mentioned in the step S06 is shown in Table 3. Time

[0063] table 3

[0064]

[0065]The upper computer 902 judges the coke pushing plan time of 1# coke oven 02# carbonization chamber 600 described in the step S06 and the difference F of the current time "2016-10-03 4:40", that is, "-70 minutes". Whether the 1# coke oven 02# riser 200 is in a cleanable state includes: judging whether the currently extracted time difference F is greater than or equal to the first threshold value of 60 minutes, the preset time, or less than or equal to 0 Minutes is the third threshold of the preset time. At this time, the F value is less than 0 minutes, indicating that the coke in the 02# carbonization chamber 600 of the 1# coke oven has already been released. At this time, the 1# coke oven 02# carbonization chamber 600 may be just installed Coal state, 1# coke oven 02# ascending pipe 200 is fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com