Preparation method of beta molecular sieve

A technology of β molecular sieve and crystal seed, which is applied in the field of catalytic chemistry, can solve the problems of stable reaction system, difficult control of reaction conditions, and difficult control of reaction conditions, so as to improve yield and crystallinity, shorten synthesis time, Realize the effect of rapid crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A kind of preparation method of β molecular sieve provided by the present invention, this preparation method comprises:

[0044] (1) Synthesis of initial gel: mix silicon source, aluminum source, alkaline metal source, and water, stir evenly, and synthesize initial gel; silicon source is SiO 2 In terms of aluminum source as Al 2 o 3 In terms of alkaline metal sources as Na 2 In terms of O, the molar ratio of raw materials for synthesizing the initial gel is: SiO 2 / Al 2 o 3 =30~150,Na 2 O / SiO 2 =0.03~0.35,H 2 O / SiO 2 =3.0~50.0; preferably: SiO 2 / Al 2 o 3 =30~95:1, Na 2 O / SiO 2 =0.07~0.30:1,H 2 O / SiO 2 =3.5~22:1;

[0045] (2) Microwave treatment of the initial gel: add β molecular sieve seed crystals to the initial gel prepared in step (1), the seed crystal silicon aluminum ratio SiO 2 / Al 2 o 3 =20~100, the amount added is SiO in the silicon source by mass 2 3% to 25% of the effective mass, mixed evenly and then heated by microwave at a temperature ...

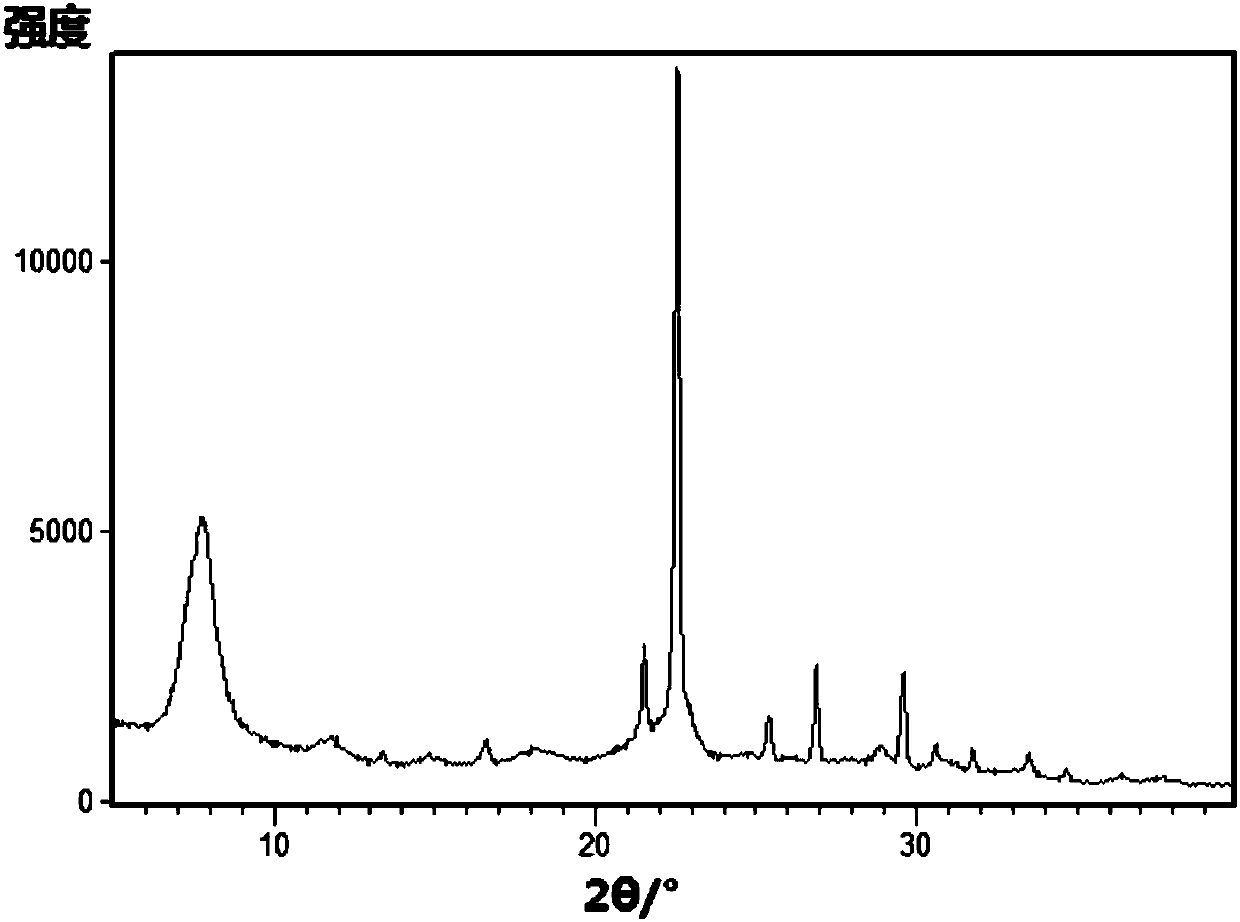

Embodiment 1

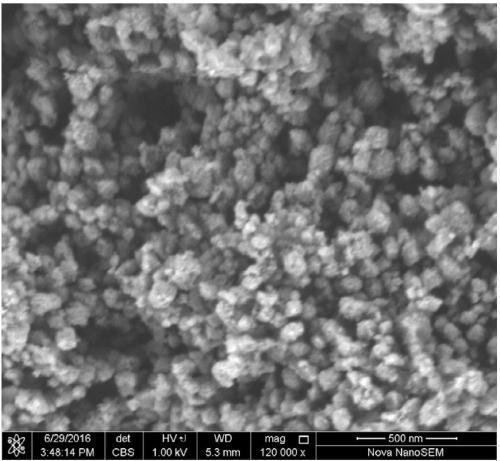

[0064] Add 28.43 g of deionized water and 0.42 g of sodium hydroxide into a container in a water bath at 70° C., and stir to dissolve. Add 1.65g of sodium metaaluminate and stir to dissolve. Add 15.00g of coarse-porous silica gel and stir evenly. Add 1.80 g of β molecular sieve seed crystals and stir evenly to obtain an initial gel. Microwave treatment was performed on the initial gel at a controlled temperature of 120°C for 4 hours to obtain a crystallized precursor gel. Then microwave heating was carried out to carry out the crystallization reaction, the temperature was controlled at 170° C., and the reaction time was 10 h. After the reaction was completed, the product was washed and dried, and characterized by X-ray diffraction. The crystallinity of the product is shown in Table 1. SEM and BET analysis were carried out, and the results are shown in Table 2.

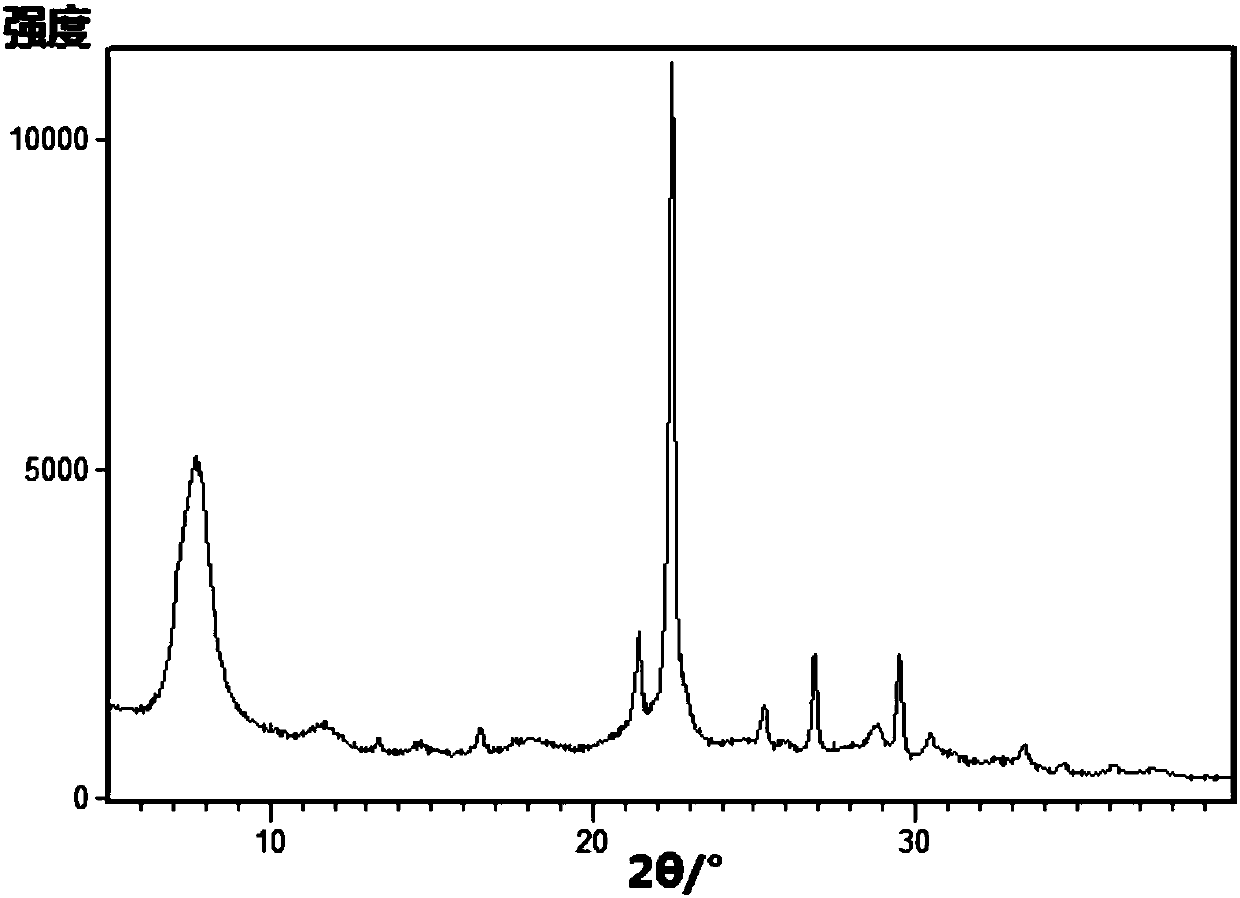

Embodiment 2

[0066] Add 28.43 g of deionized water and 0.42 g of sodium hydroxide into a container in a water bath at 70° C., and stir to dissolve. Add 1.65g of sodium metaaluminate and stir to dissolve. Add 15.00g of coarse-porous silica gel and stir evenly. Add 0.75 g of β molecular sieve seed crystals and stir evenly to obtain an initial gel. Microwave treatment was performed on the initial gel at a controlled temperature of 120°C for 4 hours to obtain a crystallized precursor gel. Then microwave heating was carried out to carry out the crystallization reaction, the temperature was controlled at 170° C., and the reaction time was 10 h. After the reaction was completed, the product was washed and dried, and characterized by X-ray diffraction. The crystallinity of the product is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com