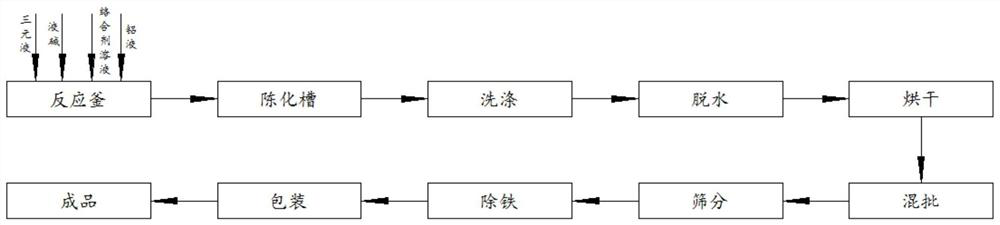

Preparation method of nickel-cobalt-aluminum ternary positive electrode material precursor

A cathode material and precursor technology, which is applied in the field of new energy battery material precursor synthesis, can solve the problems of irregularity, affecting the electrochemical performance of cathode materials, and less pore distribution, so as to reduce microcracks, improve cycle performance and safety performance. , the effect of reducing stress expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) prepare respectively the binary solution of concentration 60g / L, nickel-cobalt molar ratio is 5.0:5.0, aluminum content is the sodium metaaluminate solution of 0.5g / L, and concentration is the liquid caustic soda solution of 9.0%, and concentration is 2.0mol The complexing agent solution of / L, wherein complexing agent is ammonium sulfate;

[0021] (2) to 6.0m 3 Add 3.0m 3 Pure water, 20L concentration is 2.0mol / L complexing agent solution (i.e. ammonium sulfate solution), 12L concentration is 9.0% liquid caustic soda solution, is made into the base liquid that pH is 9.0, and ammonia concentration is 2.5g / L, passes into Nitrogen flow 0.1m 3 / h, heat up to 30°C;

[0022] (3) Add the prepared nickel-cobalt binary solution, sodium metaaluminate solution, liquid caustic soda and complexing agent solution in parallel at 200L / h, 10L / h, 40L / h and 20L / h through a mass flow meter. React in the reactor, control the stirring rate at 105rpm, and the temperature at 30°C, and...

Embodiment 2

[0026] (1) prepare concentration 140g / L respectively, the binary solution that nickel-cobalt mol ratio is 9.9:0.1, aluminum content is the sodium metaaluminate solution of 50.0g / L, and concentration is the liquid caustic soda solution of 60%, and concentration is 20mol / The complexing agent solution of L, wherein the complexing agent is ammonium sulfate, ammonium thiosulfate, and the ratio of the amount of substances is 1:1;

[0027] (2) to 15.0m 3 Add 8.0m to the reaction kettle 3 Pure water, 400L of complexing agent solution with a concentration of 20mol / L, 100L of 60% liquid caustic soda, made into a bottom solution with a pH of 12.0 and an ammonia concentration of 11.9g / L, and a nitrogen flow rate of 10.0m 3 / h, heat up to 80°C;

[0028] (3) Add the prepared nickel-cobalt binary solution, sodium metaaluminate solution, liquid caustic soda and complexing agent solution in parallel at 500L / h, 125L / h, 162L / h and 43L / h through a mass flow meter Reactor, stirring rate 400rpm...

Embodiment 3

[0032] (1) Prepare respectively a binary solution with a concentration of 80g / L and a nickel-cobalt molar ratio of 7.0:3.0, a sodium metaaluminate solution with an aluminum content of 6.2g / L, and a 25% liquid alkali solution with a concentration of 8.0mol / L complexing agent solution, wherein the complexing agent is ammonium sulfate, ammonium thiosulfate, ammonium sulfide, the ratio of the amount of substances is 1:0.5:1;

[0033] (2) to 8.0m 3 Add 4.0m to the reaction kettle 3 Pure water, 200L of complexing agent solution with a concentration of 8.0mol / L, 30L of 25% liquid caustic soda, made into a bottom solution with a pH of 11.8 and an ammonia concentration of 7.6g / L, and a nitrogen gas flow rate of 2.5m 3 / h, heat up to 45°C;

[0034] (3) Add the prepared nickel-cobalt binary solution, sodium metaaluminate solution, liquid caustic soda and complexing agent solution in parallel at 300L / h, 80L / h, 120L / h and 30L / h through a mass flow meter Reactor, stirring rate 145rpm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com