Positive electrode material for lithium ion battery, preparation method of positive electrode material and lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in the field of cathode materials for lithium-ion batteries and its preparation, can solve the problems of lack of mutual support and inability to effectively inhibit the growth of internal cracks, and achieve improved cycle performance and increased radial distribution ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

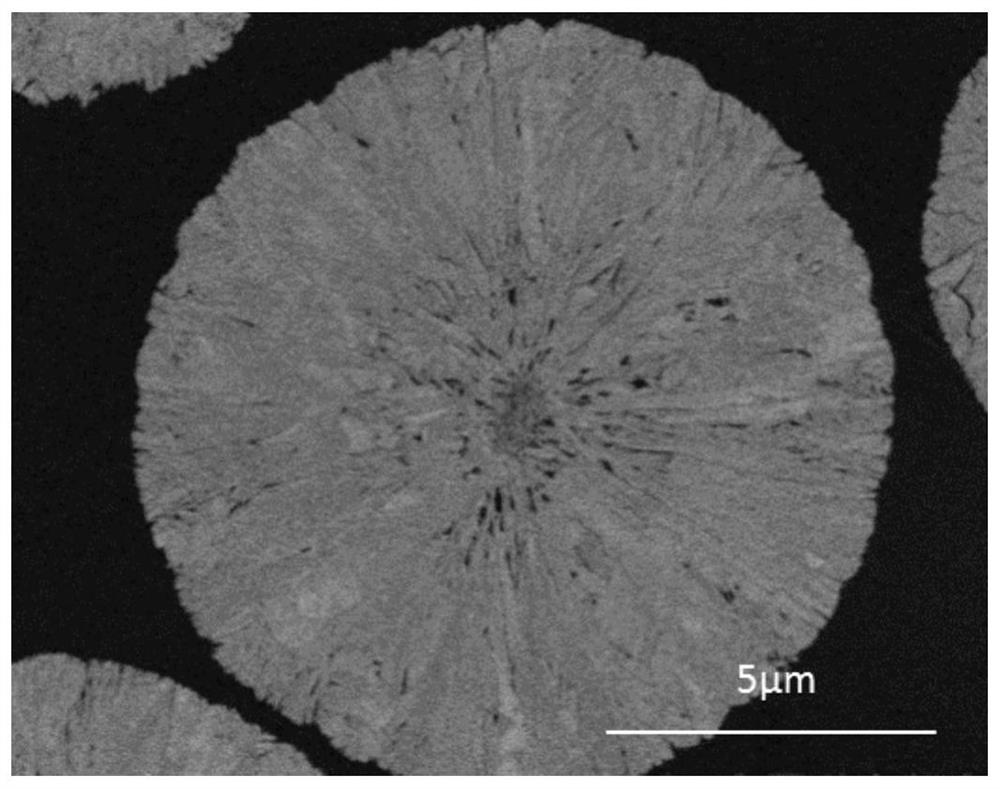

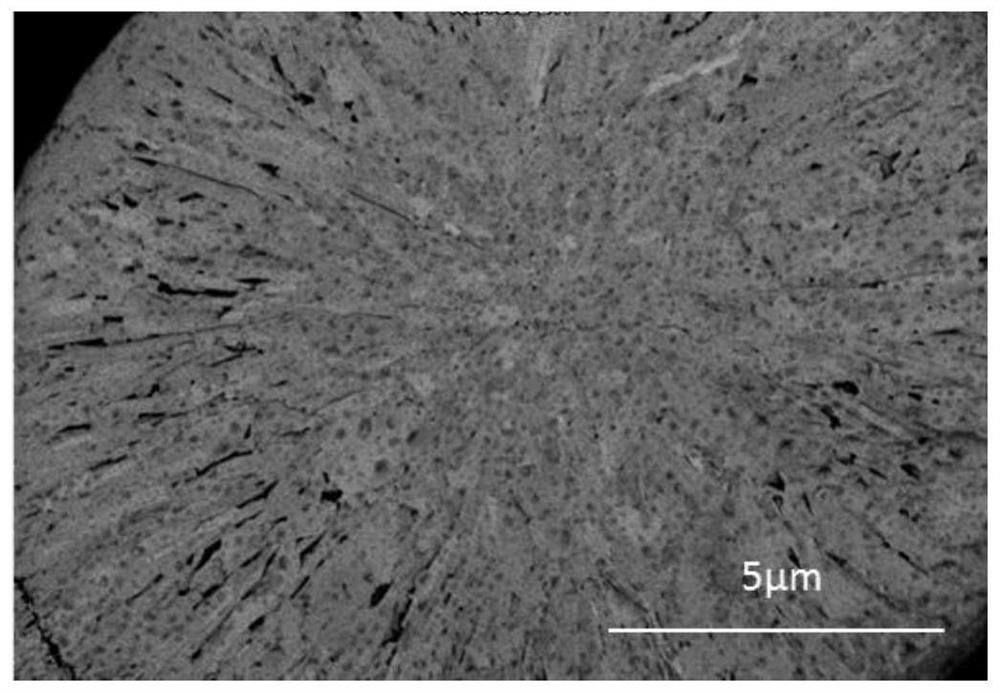

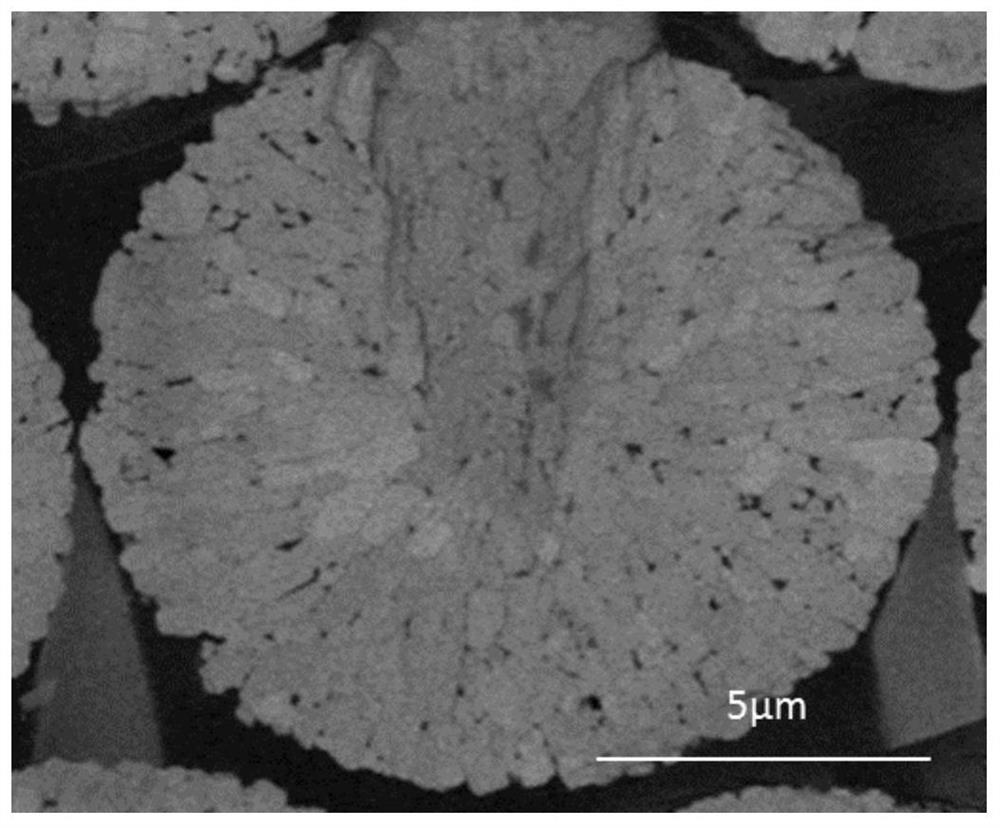

[0030] (1) In the preparation method of the positive electrode material provided by the present invention, through two synthesis, unsteady growth in the synthesis process of the precursor is made, and in the second synthesis and growth process, it is more favorable for the primary grains inside the precursor to be radially oriented growth, can prepare a precursor with an aspect ratio of the primary crystal grains inside the precursor ≥ 1.5, and the radial distribution ratio of the primary crystal grains inside the precursor ≥ 30%, so that when the precursor reacts with the lithium source, The high reactivity is conducive to the diffusion of lithium and the diffusion of additives during the sintering process; in addition, the addition of specific additives can facilitate the growth of primary grains along the (003) crystal plane, combined with specific precursor structures, the resulting positive electrode material has internal The primary crystal grains are distributed radially...

Embodiment 1

[0091] This example is to illustrate the positive electrode material with a divergent structure prepared by the preparation method of the present invention.

[0092] (1) Dissolve nickel sulfate, cobalt sulfate and manganese sulfate in pure water according to the metal molar ratio of 88:9:3 to obtain a mixed salt solution L of 2.0mol / L 1 , prepare the ammonia solution of 4mol / L as complexing agent, and the sodium hydroxide solution of 8mol / L as precipitating agent;

[0093] (2) Precursor crystal nucleus preparation: ammonia solution and sodium hydroxide solution are first added to the reactor with stirring in parallel, wherein, the pure water of 25% liquid level is placed in the reactor to obtain the first mixed solution, Wherein, based on the total volume of the reaction kettle, the amount of the first mixed solution is 20%, and the pH value of the first mixed solution is adjusted to 13.2;

[0094] Under the protection of nitrogen atmosphere, the mixed salt solution L 1 Add ...

Embodiment 2

[0106] This example is to illustrate the positive electrode material with a divergent structure prepared by the preparation method of the present invention.

[0107] (1) Dissolve nickel sulfate, cobalt sulfate and manganese sulfate in pure water according to the metal molar ratio of 83:11:6 to obtain a mixed salt solution L of 2.0mol / L 2 , prepare the ammonia solution of 4mol / L as complexing agent, and the sodium hydroxide solution of 8mol / L as precipitating agent;

[0108] (2) preparation of precursor crystal nucleus: ammonia aqueous solution and sodium hydroxide solution are first added to the reactor with stirring, wherein, the pure water of 25% liquid level is placed in the reactor to obtain the first mixed solution, Wherein, based on the total volume of the reaction kettle, the amount of the first mixed solution is 25%, and the pH value of the first mixed solution is adjusted to 11.6;

[0109] Under the protection of nitrogen atmosphere, the mixed salt solution L 2 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com