Preparation method of porous sheet-shaped sodium ion battery negative electrode material

A sodium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary battery manufacturing, electrolyte battery manufacturing, etc., can solve problems such as pore volume and pore diameter reduction, mesopore structure occupation, and poor air circulation, etc., to improve energy density and rate performance, increase the pore volume and pore size, and avoid the effect of stripping the pole piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

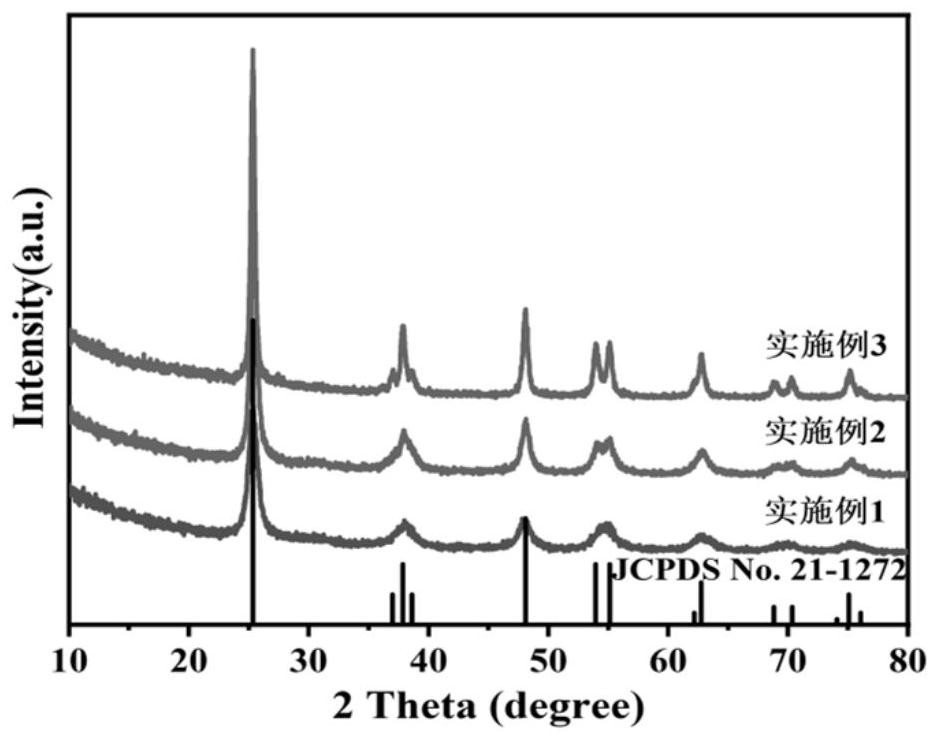

[0037] Example 1: Anatase titanium dioxide nanosheets with large pore volume and pore diameter were prepared according to the following method:

[0038] S1: 1 part by weight of graphene oxide is dispersed in 100 parts by weight of ethanol, and 1 part by weight of ammonia water is added to ensure that the pH of the solution is greater than 7;

[0039] S2: adding 2.5 parts by weight of titanium isopropoxide into S1, stirring and reacting at 60° C. for 18 hours, filtering and drying to obtain a composite material of titanium dioxide and graphene oxide, and pulverizing to obtain particles with a particle size of 1 to 5 mm, mixing titanium dioxide and graphite oxide The olefin composite material is pulverized into particles with a particle size of 1 to 5 mm;

[0040] S3: calcining the particles of the titanium dioxide and graphene oxide composite material at 400° C. for 2 hours through a particle calcining device to obtain mesoporous anatase titanium dioxide.

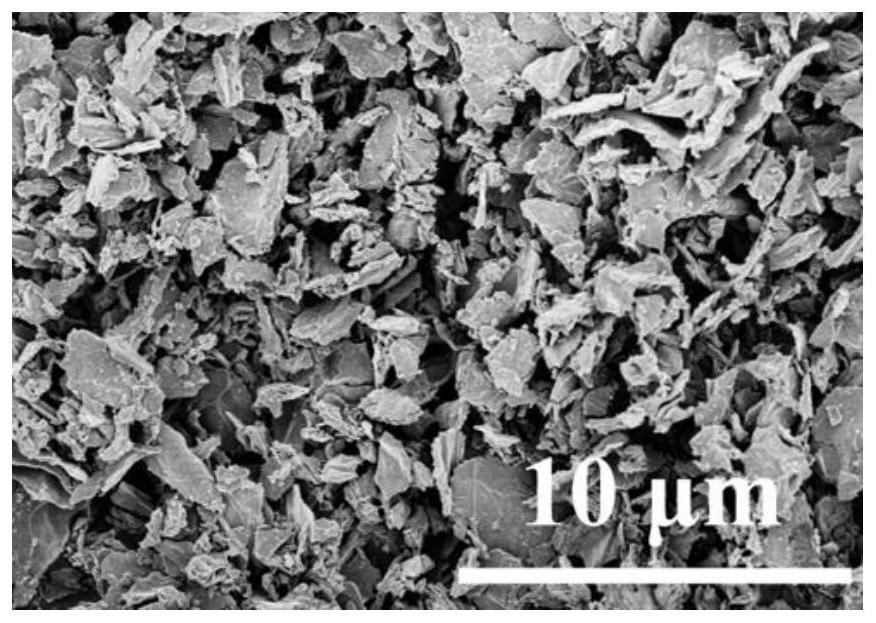

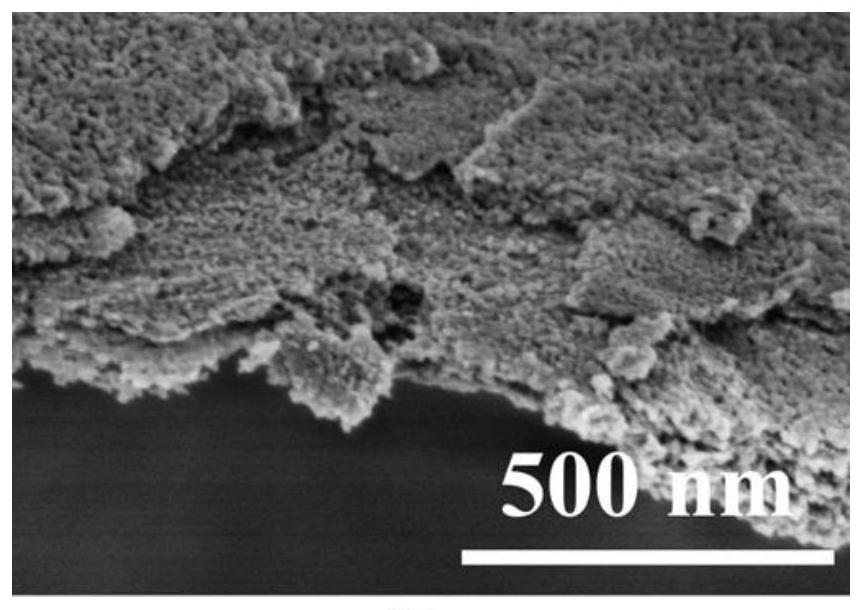

[0041] like Figur...

Embodiment 2

[0046] Embodiment 2: the rest are the same as embodiment 1, the difference is:

[0047] S1: 1 part by weight of graphene oxide is dispersed in 300 parts by weight of ethanol, and 1 part by weight of ammonia water is added to ensure that the pH of the solution is greater than 7;

[0048] S2: adding 2.5 parts by weight of titanium isopropoxide into S1, stirring and reacting at 60° C. for 24 hours, filtering and drying to obtain a composite material of titanium dioxide and graphene oxide, and pulverizing to obtain granules with a particle size of 1 to 5 mm;

[0049] S3: calcining the titanium dioxide and graphene oxide composite material in a particle calcining device at 500° C. for 2 hours to obtain mesoporous anatase titanium dioxide.

Embodiment 3

[0050] Embodiment 3: the rest are the same as embodiment 1, the difference is:

[0051] S1: 1 part by weight of graphene oxide is dispersed in 300 parts by weight of ethanol, and 1 part by weight of sodium hydroxide is added to ensure that the solution pH>7;

[0052] S2: adding 2.5 parts by weight of titanium n-propoxide into S1, stirring and reacting at 60° C. for 24 hours, filtering and drying to obtain a composite material of titanium dioxide and graphene oxide, and pulverizing to obtain granules with a particle size of 1 to 5 mm;

[0053] S3: calcining the titanium dioxide and graphene oxide composite material in a particle calcining device at 600° C. for 2 hours to obtain mesoporous anatase titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com