A kind of ferrous phosphate and preparation method thereof, lithium iron phosphate positive electrode active material and preparation method thereof

A technology of lithium iron phosphate and ferrous phosphate, which is applied in the field of lithium-ion batteries, can solve the problems of poor electrochemical performance and large particle size of lithium iron phosphate, and achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

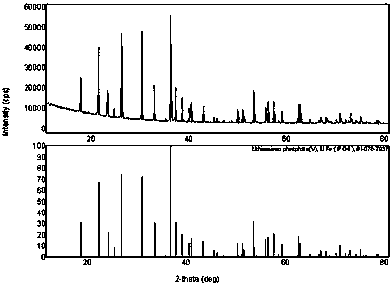

Image

Examples

preparation example Construction

[0034] According to the preparation method provided by the present invention, preferably, the mass concentration of the phosphoric acid is 10%-50%. The mass concentration of phosphoric acid will affect the amount of phosphoric acid molecules distributed around the unit metal iron. The amount of phosphoric acid molecules will accelerate the reaction between metal iron and phosphoric acid and shorten the reaction cycle. However, if the reaction is too fast, it will affect the morphology and shape of the synthesized ferrous phosphate. granularity. The invention controls the mass concentration of the phosphoric acid to be 10%-50%, and can obtain the ferrous phosphate with uniform particle size while ensuring the reaction speed.

[0035]According to the preparation method provided by the present invention, preferably, the metallic iron is at least one of iron powder, iron block and iron rod. Further preferably, the metallic iron is iron powder. The average particle size of the ir...

Embodiment 1

[0049] 1. Preparation of ferrous phosphate

[0050] Weigh 30.0mol metallic iron powder (purity 99.9wt%, average particle size 1um) and 35.3mol phosphoric acid (mass concentration 85%). Dilute phosphoric acid into a 30% phosphoric acid solution. Then metal Fe powder is added into the phosphoric acid solution and transferred to the autoclave together, nitrogen is introduced into the autoclave, and the change of the oxygen content in the autoclave is monitored at the same time, when the oxygen content is reduced to below 100ppm, the pressure is 1Mpa, airtight reactor. Raise the temperature to 50°C. After 5 hours, after the iron powder and phosphoric acid have completely reacted, lower the temperature in the kettle to room temperature 25°C to obtain ferrous phosphate A1 slurry with a pH of 3.5.

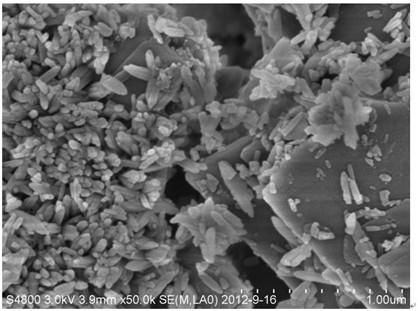

[0051] Dry the slurry of ferrous phosphate A1, and then use a scanning electron microscope to test its SEM image, the results are shown in figure 2 . The scanning electron microscope...

Embodiment 2

[0058] 1. Preparation of ferrous phosphate

[0059] Weigh 30.0mol metallic iron powder (purity 99.9wt%, average particle size 100um) and 35.3mol phosphoric acid (mass concentration 85%). Dilute phosphoric acid to a 50% phosphoric acid solution. Then metal Fe powder is added into the phosphoric acid solution and transferred to the autoclave together, nitrogen is introduced into the autoclave, and the change of the oxygen content in the autoclave is monitored at the same time, when the oxygen content is reduced to below 100ppm, the pressure is 2Mpa, airtight reactor. Raise the temperature to 40°C. After 5 hours, after the iron powder and phosphoric acid have completely reacted, lower the temperature in the kettle to room temperature 25°C to obtain ferrous phosphate A2 slurry with a pH of 3.2.

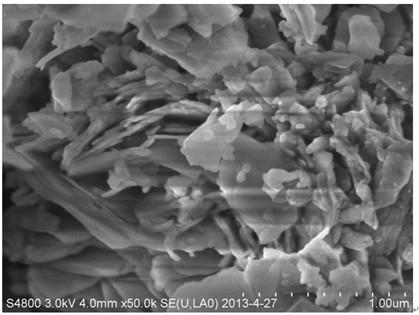

[0060] Dry the slurry of ferrous phosphate A2, and then test its SEM image with a scanning electron microscope, the results are shown in image 3 . The scanning electron microscope (S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com